Sol Gel Coatings: An Environmentally Acceptable Alternative to Cr

advertisement

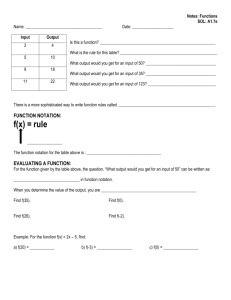

Sol Gel Coatings: An Environmentally Acceptable Alternative to Cr-Based Coatings/Pre-Treatments *R Akid & H Wang Materials & Engineering Research Institute Sheffield Hallam University Howard Street, Sheffield, S1 1WB. U.K. * Corresponding author (r.akid@shu.ac.uk) July 17-18th 2006 Outline • Challenges • Background – Conventional Cr-based pre-treatment – Aim of research – Sol gel chemistry, preparation and variant coating systems – Current trial applications – Alternative Cr-replacement study • Anti-corrosion performance studies • Summary Challenges End of Vehicle life (EVL) Directive • Around two million vehicles reach the end of their life in the UK each year. Currently, between 74-80% of the weight of a typical ELV is reused or recycled. • The EVL Directive (2000/53/EC) is concerned with cars, vans and certain three-wheeled vehicles. It's main requirements are that: – producers limit the use of certain hazardous substances in the manufacture of new vehicles and automotive components and promote the recyclability of their vehicles – ELVs are subject to de-pollution prior to dismantling, recycling or disposal – treatment facilities operate to higher environmental standards and have permits if they want to deal with undepolluted ELVs – producers pay ‘all or a significant part’ of the costs of treating negative or nil value ELVs at treatment facilities by 2007 Challenges Waste Electrical and Electronic Equipment (WEEE) Directive • The (WEEE) Directive aims to reduce the amount of WEEE being disposed of to landfill by promoting separate collection, treatment and recycling. • The Directive: – introduces requirements to mark EEE products with a ‘crossed out wheelie bin’ symbol – sets targets for the amount of WEEE to be collected separately from private households – requires the UK to establish and maintain a register of EEE producers – makes distributors and retailers responsible for making arrangements to take back WEEE free of charge in convenient way for customers – introduces recycling and recovery targets for various categories of WEEE. Challenges Restriction of Hazardous Substances (RoHS) in : • • • • large and small household appliances IT and telecommunication equipment TVs, videos, hi-fi lighting, electrical and electronic tools (except large stationary industrial tools) • toys, leisure and sports equipment • This Directive bans the placing on the EU market of new electrical and electronic equipment containing more than agreed levels of: – lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyl (PBB) and polybrominated diphenyl ether (PBDE) flame retardants Conventional Chromate Treatments on: Zn, Al, Mg.. conversion coating mixed Cr oxide passivation metal subsequent processing Organic top coat Component Primer (may or may not contain Cr(iV) metal Aim of research • To develop an environmentally acceptable (Cr-free) coating/pre-treatment for a selection of metals, including Al, Zn, Mg and mild steel to replace chromate and phosphate treatments. The Need! • • • • Corrosion costs approx 3.5% GDP Equivalent cost in USA is 1 Hurricane Katrina p.a. I tonne of metal every 90 seconds Approx £600 per person per year in the UK The need! Wong Tai Sin Temple – New Kokloon (July 2006) "Doaist god of healing" – secret for transforming Cinnabar (Hg2S) into an elixir for mortality! Sol gel Methodology Precursor 1 Organic and Inorganic components Mix and Age* Precursor 2 Functional Additives, e.g., corrosion inhibitors, bio-active molecules, etc. *Ageing time dependant upon formulation chemistry Apply to metal; Dip, Spray.. Use as functional/ barrier coating Cure at selected temperature Apply top coat directly to sol gel for anti-corrosion coating Sol gel processing • Conventional sol–gel synthesis involves, in the first step, the formation of a colloidal suspension (sol), usually obtained by controlled acid- or basecatalyzed hydrolysis and partial condensation of metal alkoxide precursors in alcoholic or other nonhydrolytic organic solvents. Further condensation leads to a viscous gel or dispersion of colloidal particles, depending on composition, pH and reaction conditions. • Cure temperature determines degree of crystallinity Sol gel chemistry Precursor Si (OC2H5)4 = Si-O-R', where R' = C2H5 CH3 Si-O-R' O R'-O-Si-O-R' + H OH Si-O-R' O R'-O-Si-O-R' O Si 0 H O Si- O-R' Metal substrate + R'OH Typical coating structure functional groups as appropriate l l l l l O-Si-O-Si-O-Si-O-Si-O-Si-O- ..........etc l l l l l O O O O O l l l l l Metal substrate Sol gel variants Cure regime Component Room Temperature + Organic component Inorganic component Properties Flexibility Hardness Oxidation resistance Functionality above 400oC high low low high high* low low high * (long chain or alkene) low high high limited ? Current sol gel variants being developed Anti-corrosion coatings - Biosensors - Microbial fuel cells Current trial applications •Mild steel – coil coated construction steel, •replacement of hot dipped zinc, domestic appliances Al – automotive, aerospace Mg – die cast products for automotive use •Cr-replacement- sports goods Stainless steel – domestic appliances, anti-bacterial coatings Summary of Non-Chrome alternatives* http://www.electronicssouth.com/ContentStore/Assets/7/17/phase_i_report%20from%20USA%20DOD.pdf * Environmental Security Technology Certification Programme – Naval Aviation systems Sol gel anti-corrosion performance trials • Substrates – Al alloys 2xxx, 5xxx, Mg, Mild steel, Hot dipped Zn, SS • Coatings – silane based, with and without inhibitors – silane based with and without bacteria • Environments – typically NaCl (3.5%) or artificial seawater • Test methods – Linear polarisation, Impedance Spectroscopy – Salt spray – Scanning electron microscopy, optical microscopy Processing 1. Clean substrate (acid/alkaline based soln) 2. Water rinse 3. Apply sol gel 4. Cure (R/T or R/T+) 5. Option – repeat steps 3 & 4 (multilayer systems) 6. Option – over-coat Multi-layer - Ecorr results Influence of surface roughness on Ecorr 0 1200 grit Polished Ecorr mV, (vs Ag/AgCl) -100 -200 -300 -400 -500 -600 0 1 2 3 Number of Coats 4 5 Morphology of coatings Al 2024-T3 Substrate Sol-gel Coating Bakelite Mounting SEM AFM 200 nm 1.00 μm ESEM Anti-corrosion performance trials • Al alloys (in 3.5% NaCl) -200 Potential, mV, vs. SCE -400 Bare Al2024 Sol gel coated Al 2024 2024alloy ChromateBare on Al 5xxx Chromate Sol gel Al 2024 2 3 1 -600 -800 -1000 -1200 10-11 ← Low 10-10 10-9 Corrosion rate 10-8 10-7 10-6 10-5 Current density (A/cm2) high→ 10-4 10-3 10-2 10-1 Anti-corrosion performance trials • Mg (in 3.5% NaCl) Commercial pre-treatment sol gel coating Anti-corrosion performance trials g HDZ g pg 2 1.00E+08 Bode Impedence (Ohms.cm ) 2 Bode Impedence (Ohms.cm ) Hot dipped Zn (galvanised mild steel) Immersed in 1.0% and pH=4 NaCl solution First day 1.00E+07 After 24 hrs 1.00E+06 After 48 hrs After 96 hrs 1.00E+05 1.00E+04 0.01 After 120 hrs 0.1 1 10 100 1000 10000 100000 2 Bode Impedence (Ohms.cm ) g g First day 1.00E+06 After 24 hrs After 48 hrs After 96 hrs After 120 hrs 1.00E+05 1.00E+04 0.01 0.1 1 10 100 1000 10000 100000 Frequency (Hz) 1.00E+08 Immersed in 3.5% NaCl solution 1.00E+07 First Day After 24 hrs 1.00E+06 HDZ + Chromate 1.00E+05 After 96 hrs 1.00E+04 1.00E+03 0.01 g Immersed in 1.0% and pH=4 NaCl solution Frequency (Hz) Note: different environments Galfan g 1.00E+07 0.1 1 10 100 Frequency (Hz) 1000 10000 100000 Anti-corrosion performance trials • Mild steel Anti-corrosion performance trials Mild steel (with and without encapsulated corrosion inhibitors) 15 hrs no inhibitor 3.5% NaCl 528 hrs with inhibitor Encapsulation to give functionality water l l l l l O-Si-O-Si-O-Si-O-Si-O-Si-Ol l l l REI l REI O O O REI O O REI l l l l l REI Metal substrate REI Rare Earth Inhibitor Treat encapsulated component to provide a 'bond' to the sol gel l l l l l O-Si-O-Si-O-Si-O-Si-O-Si-Ol l l l l REI REI REI REI O O O O O l l l l l REI Metal substrate Modified Rare Earth Inhibitor REI Adhesion performance (T-bend) T2.0 T0.5 Sol gel on HDZ (Galfan) Sol gel on Mild steel Functional anti-corrosion coatings Microbiologically Influenced Corrosion (MIC) (Bacteria & Biofilms) Microorganisms, especially bacteria, colonise surfaces to form Biofilms } Colonisation of Sulphate Reducing Bacteria (SRB) H2S formation Biofilm formation; up to 48hrs depending upon temperature Localised Corrosion (pitting) ‘Bacterial-active’ sol-gel coatings Anti-'microbial induced corrosion' (MIC) coating • Combination of anti-corrosion sol-gel coating and protective bacteria. • Uniform distribution of protective bacteria fixed on the surface Viable bacterial cells immobilised in coating 'Biocoat' Substrate Anti-corrosion performance trials Anti-MIC corrosion sol gel coating 2 LPR (Ohm.cm ) SS control 1e+5 Al control 1e+4 SSbact pfragi SS 1 pfragi AlAlbact 1 pfragi2 AlAlbact 2 AlAlbact 2 repeat polymyxa High ESEM image Low Corrosion rate 1e+6 1e+3 0 5 10 15 Time (days) Paper submitted to "Advanced Functional Materials" 20 25 30 35 Coating on SS containing bacteria Fluorescence Microscopy Coating at day 1 stained with EthBr. Spores not clearly visible Coating at day 30 (immersed in nutrient rich artificial seawater) is becoming colonised by bacteria Confirming Visual Examination D1 D2 D4 D8 D12 Al with bacteria 1 D16 D30 Bio-active coating field trials Sol gel treatments: Opportunities and challenges • Opportunities – – – – – – Totally Cr & PO4 free – RoHS compliant Non toxic Limited VOC emissions Reduction in process stages (reduced processing costs) Ease of recycling (reduced total life-cycle costs) Can be over-coated • Challenges – Scale up ? – Shelf life (currently months) – Optimisation of properties, e.g., Adhesion vs. Flexibility, Film thickness vs. corrosion protection, Repair and recoat, Hardness vs. cure temperature. Summary • Given an appropriate optimisation of the formulation chemistry and processing; sol gel based coating systems are a potential alternative candidate to Cr-based and PO4 systems, offering the following: – – – – – – – – easily prepared with simple formulation chemistry variable cure temperature options: from R/T upwards convenient methods of application to substrates totally Cr-free and RoHS compliant suitable for over-coating with paint systems good flexibility and adhesion excellent anti-corrosion properties may be functionalised to give variety of properties (anti-bacterial, hydrophobic..) Acknowledgments • • • • • Dr Tom Smith (microbiologist) Dr D Greenfield & Mr J Connell (corrosion testing) Prof J Earthman (bacteria selection) Sheffield Hallam University (funding/facilities) HKMFS & HKPC for the invitation to contribute to this conference