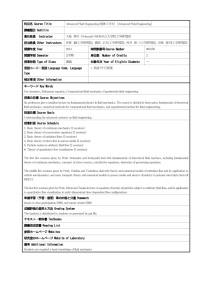

Chp1 - Faculty of Mechanical Engineering

advertisement

CHAPTER 1 INTRODUCTION By Ummikalsom Abidin C24-316 FKM, UTM SME 1313 Fluid Mechanics I Introduction Fluid Mechanics Fluid Statics - fluid at rest - deals with forces applied by fluids at rest Buoyant force applied by fluids on submerged or floating bodies e.g ships, submarines Fluid Dynamics - Hydrostatic forces on submerged bodies e.g dam, tanks storing fluid, automation actuators fluid in motion Hydrodynamics Gas dynamics e.g liquid flow in pipes and open channel (hydraulics), pumps,hydroturbine s, water cooling system e.g gas turbines, flow of air over a body (aerodynamics) – aircraft, rockets, automobiles SME 1313 Fluid Mechanics I Introduction Naturally occuring flows Meteorology Oceanography Hydrology SME 1313 Fluid Mechanics I What is fluid? Fluid is a substance that deforms continuously under the application of a shear (tangential) stress no matter how small the shear stress may be. F F t0 t1 t2 t2>t1>t0 (a) (b) Behavior of (a) solid and (b) fluid, under the action of a constant shear SME 1313 Fluid Mechanics I What is fluid? Fluids comprise the liquid and gas (or vapor) phases Distinction between solid,liquid and gas Atom Arrangement Solid Liquid Gas Intermolecular bonds Molecules are relatively fixed position Strongest Groups of molecules move about each other in the liquid phase Moderate Molecules move about at random in the gas phase Weakest SME 1313 Fluid Mechanics I What is fluid? Normal to surface Force acting on area Fn dA Tangent to surface dA Ft Normal stress: σ = Fn/dA Shear stress: ι = Ft/dA The normal stress and shear stress at the surface of a fluid element. For fluids at rest, the shear stress is zero and the pressure is the only normal stress SME 1313 Fluid Mechanics I No-slip Condition A fluid in direct contact with a solid “sticks” to the surface due to viscous effects, and there is no slip. The flow region adjacent to the wall in which the viscous effects (and thus the velocity gradients) are significant is called boundary layer. Uniform approach Relative velocities of fluid layers velocity, V Zero velocity at the surface Plate A fluid flowing over stationary surface comes to a complete stop at the surface because of the no-slip condition SME 1313 Fluid Mechanics I Classification of Fluid Flows Viscous vs. Inviscid Regions of Flow Viscous Flow Region – flows in which the frictional effect is significant Inviscid Flow Region – viscous forces are negligibly small compared to inertial or pressure forces Inviscid flow region Viscous flow region Inviscid flow region The flow of an originally uniform fluid stream over a flat plate, and the regions of viscous flow (next to the plate on both sides) and inviscid flow (away from the plate) SME 1313 Fluid Mechanics I Classification of Fluid Flows Internal vs. External Flow Internal flow – flows in which the fluid is completely bounded by solid surface e.g flow in a pipe or duct Dominated by the influence of viscosity throughout the flow field External flow – flows in which the fluid is unbounded over solid surfaces e.g flow over a plate, wire, sphere object Viscous effects are limited to boundary layers near solid surfaces and to wake regions downstream of bodies * Open-channel flow – the flow of liquids in a duct in which the liquid is partially filled and there is a free surface e.g rivers, irrigation channels SME 1313 Fluid Mechanics I Classification of Fluid Flows Compressible vs. Incompressible Flow Incompressible Flow – density of the fluid remains nearly constant throughout Compressible Flow – density changes of the fluid is significant liquids, gases at low speeds density changes of gas flows are under 5% or when Ma<0.3 gases at high speeds density changes of gas flows are above 5% or when Ma>0.3 Mach number, (Speed of sound=346 m/s) Ma = V = Speed of flow c Speed of sound Ma=1 (Sonic), Ma<1 (Subsonic), Ma>1(Supersonic), Ma>>1 (Hypersonic) SME 1313 Fluid Mechanics I Classification of Fluid Flows Laminar vs. Turbulent Flow In 1880s, Osborn Reynolds conducted an experiment to see flow patterns Tank arranged as above with a pipe taking water from the centre into which dye is injected through a needle SME 1313 Fluid Mechanics I Classification of Fluid Flows Filament of dye Laminar (viscous) Transitional SME 1313 Fluid Mechanics I Turbulent Classification of Fluid Flows Reynolds number, Re =ρud µ Laminar flow Transitional flow Turbulent flow Re<2000 2000<Re<4000 Re>4000 SME 1313 Fluid Mechanics I Classification of Fluid Flows Natural (or unforced) vs. Forced Flow Forced Flow – fluid is forced to flow over a surface or in a pipe by external means such as pump or a fan Natural Flow – any fluid motion is due to natural means such as buoyancy effect, where warmer (and thus lighter) fluid rises and cooler (and thus denser) fluid falls Schlieren image of a hot water (left) and ice water (right) in a glass SME 1313 Fluid Mechanics I Classification of Fluid Flows Steady vs. Unsteady Flow Steady Flow – no change of fluid properties (velocity, pressure) at a point with time Devices that are intended for continuous operation e.g turbines, pumps, boilers, condensers t1=5 s t2=10 s V1=10 m/s V2=10 m/s Unsteady Flow – fluid properties change at a point with time Transient – used for developing flows t1=5 s V1=10 m/s SME 1313 Fluid Mechanics I t2=10 s V2=11 m/s Classification of Fluid Flows Uniform vs. Non-uniform Flow Uniform Flow – no change of fluid properties with location over a specified region 1 2 V1=10 m/s V2=10 m/s or V=10 m/s Non-uniform Flow – if at a given instant, fluid properties change with location over a specified region V2=10 m/s 1 2 V1=10 m/s V2=11 m/s or SME 1313 Fluid Mechanics I V1=10 m/s Classification of Fluid Flows Steady uniform flow Steady non-uniform flow Conditions change from point to point in the stream but do not change with time e.g flow in tapering pipe with constant velocity at inlet, but velocity change along the length of the pipe toward the exit Unsteady uniform flow Conditions do not change with position and with time e.g flow of water in a pipe of constant diameter at constant velocity At a given instant of time, the conditions at every point are the same, but will change with time e.g pipe of constant diameter connected to a pump pumping at a constant rate which is then switched off Unsteady non-uniform flow Every condition of the flow may change from point to point and with time at every point e.g waves in channel SME 1313 Fluid Mechanics I Classification of Fluid Flows One-, Two-, and Three-Dimensional Flows 1-D Flow – flow parameters (such as velocity, pressure, depth) vary in one primary dimensions 2-D Flow - flow parameters vary in two primary dimensions 3-D Flow - flow parameters vary in three primary dimensions Developing velocity profile, V(r,z) Fully developed velocity profile, V(r) r z The development of the velocity profile in a circular pipe, V=V(r,z) and thus the flow is 2-D in the entrance region, and becomes 1-D downstream when the velocity profile fully develops and remain in theI flow direction, V=V(r) SME 1313 unchanged Fluid Mechanics Classification of Fluid Flows The dimensionality of the flow also depends on the choice of coordinate system and its orientation Rectangular coordinates, V(x,y,z) Cylindrical coordinates, V(r,θ,z) Higher dimensionality should be considered if only very high accuracy is required SME 1313 Fluid Mechanics I Application Areas of Fluid Mechanics Human body (Bio-fluid Mechanics) Cardiovascular system Pulmonary system Artificial heart Breathing machine Building Water supply system Sewerage system Heating and air-conditioning Aerodynamics forces and flow fields around structure SME 1313 Fluid Mechanics I Application Areas of Fluid Mechanics Automobiles Hydraulic brakes, power steering, automatic transmission Fuels line, fuel pump, fuel injectors Lubrication systems Cooling systems Air-conditioning Aerodynamics design Aircraft Aerofoil design Gas turbine SME 1313 Fluid Mechanics I Application Areas of Fluid Mechanics Ship, submarines, hovercraft Industry Cooling of electronics Automation system Recreational Hydrodynamics design Buoyancy and stability Badminton shuttle and golf ball aerodynamics Geophysical fluid dynamics Meteorology Oceanography SME 1313 Fluid Mechanics I System and Control Volumes System – quantity of matter or a region in space chosen for study Surroundings – mass or region outside the system Boundary – Real or imaginary surface that separates the system from its surroundings (fixed or movable) SURROUNDINGS SYSTEM BOUNDARY SME 1313 Fluid Mechanics I System and Control Volumes Closed System (Control Mass) Consists of a fixed amount of mass, and no work, can cross the boundary Energy in the form of heat and work can cross the boundary E.g piston-clinder device Open System (Control Volume) Both mass and energy can cross the boundary E.g compressor, turbine, nozzle, car radiator Imaginary boundary CV (a nozzle) Imaginary boundary CV Real boundary SME 1313 Fluid Mechanics I Imaginary boundary Dimensions and Units Any physical quantity can be characterized by dimensions Magnitude assigned to the dimensions are called units Primary or fundamental dimensions Dimension Unit Length meter (m) Mass kilogram (kg) Time second (s) Temperature kelvin (K) Electric of current ampere (A) Amount of light candela (cd) Amount of matter mole (mol) The seven fundamental (or primary) dimensions and their units in SI SME 1313 Fluid Mechanics I Dimensions and Units Derived or secondary dimensions are dimensions obtained from combination of primary dimensions SME 1313 Fluid Mechanics I Most used derived dimensions SI Units Metric SI (from Le Systeme International d’Unites) or International System SI system was produced by General Conference of Weights and Measures in 1960 SI is a simple and logical system and widely being used for scientific and engineering work in most of the industrialized nations SME 1313 Fluid Mechanics I SI Units Multiple Prefix 1012 tera, T 109 giga, G 106 mega, M 103 Kilo, k 102 hecto, h 101 deka, da 10-1 deci, d 10-2 centi, c 10-3 milli, m 10-6 micro, µ 10-9 nano, n 10-12 pico, p Standard in SI units SME 1313 prefixes Fluid Mechanics I Dimensional Homogeneity In engineering, all equations must be dimensionally homogeneous where every term in an equation must have the same unit SME 1313 Fluid Mechanics I Problem-Solving Technique Step 1:Problem Statement Step 2:Schematic State briefly and concisely (in your own words) the information given and the quantities to be found Draw a schematic of the system or control volume to be used in the analysis. Indicate any energy and mass interactions with the surroundings Listing the given information on sketch Step 3:Assumptions and Approximations State any assumptions and approximations made to simplify the problem to make it possible to obtain a solution SME 1313 Fluid Mechanics I Problem-Solving Technique Step 4:Physical Laws Step 5:Properties Apply all the relevant basic physical laws and principle and reduce them to their simplest form by utilizing the assumptions made Determine the unknown properties at known states necessary to solve the problem from property relations or tables Step 6:Calculations Substitute the known quantities into the simplified relations and perform the calculations to determine the unknown Pay attention to the units and unit cancellations Give appropriate number of significant digits SME 1313 Fluid Mechanics I Problem-Solving Technique Step 7:Reasoning, Verification, and Discussion Check to make sure that the results obtained are reasonable and intuitive and verify the validity of the questionable assumptions Repeat the calculations that resulted in unreasonable values SME 1313 Fluid Mechanics I