Aftercare - ENER-G

advertisement

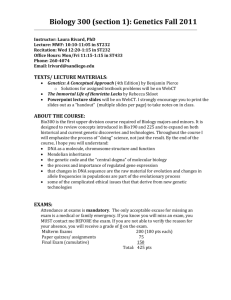

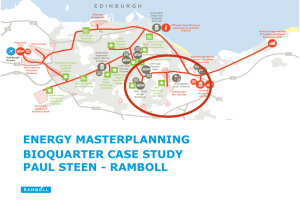

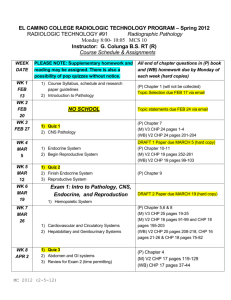

ENER-G Combined Power Aftercare ENER-G Combined Power Limited is committed to providing the highest standard of after sale service in the CHP market. About ENER-G Combined Power ENER-G has been an active player in the CHP industry for 25 years and currently maintain and operate over 50% of all operational CHP units in the United Kingdom and Ireland. ENER-G combines a myriad of knowledge and experience with a strong commitment to customer service to provide a market leading service to all clients. Remote monitoring An integral part of our CHP units is the on-board computer. The computer’s function is to provide optimised safe and efficient operation of the CHP unit. The computer also provides a two-way communication channel between your CHP unit and the ENER-G service centre, allowing live system operational monitoring and full historic data retrieval. In addition, in the event of system faults, ENER-G service centre can receive an SOS signal from the unit, run remote diagnosis, rectify problems and schedule an engineer if necessary. Cogeneration: A brief introduction Aftercare The first combined heat and power (CHP) system was designed and built by Thomas Edison in 1882 inside a New York City power plant. The heat generated by the power plant was redirected to the surrounding neighbourhood to provide free heating to residents. Remote monitoring reduces operational downtime and maintains client savings whilst generating monthly performance reports and offering customers the opportunity to log on and monitor operation and savings. Like Edison’s CHP your system produces electricity and heat energy in a single integrated system at up to 85% efficiency. Traditional power generation rejects the heat produced in this process however CHP systems harness this waste to provide free heat and discounted electricity delivering significant financial savings. ENER-G service centre To ensure optimum operation, benefits, and to maximise the life span of your CHP unit, our Service Department at the head office co-ordinates the deployment of our nationwide engineering team 7 days a week 365 days a year, offering immediate response to almost all incidents. All ENER-G engineers are Gas Safe registered, receive full electrical training in-house and are kept up-to-date with all legislative and technological advances. ENER-G Combined Power Limited Combined heat and power maintenance CHP systems require regular, periodic maintenance and inspection. Every unit requires a service after a predetermined amount of running hours. Units typically require between 6 to 10 services a year dependant upon operation. The service procedures vary throughout the year from replacing and recalibrating components to oil and filter changes. CHP units use gas as a fuel and are therefore subject to the Gas Safe Regulations. To ensure maximum savings and compliance with regulation, ENER-G offers two flexible maintenance packages: Premier Premier Service package includes: • • • • • • • • • • 24 hour remote monitoring Automated SOS alerts Communication with central servers Remote SOS alert via SMS Part identification Remote fault diagnosis and rectification Safe oil disposal Oil analysis programme Dedicated site engineer Routing scheduled servicing Maintenance procedure Discount energy purchase (DEP) customers receive the Premier Plus package free of charge as part of the contract agreement. Premier Plus Premier Plus service package includes all of the benefits associated with the premier package, but for the contract term, is also inclusive of all parts and labour required to rectify faults or repairs within the acoustic enclosure. The service is a fixed price paid annually for the term of the contract. To offer flexibility and the opportunity to take advantage of early savings, the price can also be profiled against the age of the system across the contract term (subject to contract). Premier Plus is the number one CHP maintenance package in the industry, covering both service and repairs, without the need to raise purchase orders and minimising operational downtime. Premier Plus is the best way to achieve the biggest savings. Inside the ENER-G CHP Unit The diagram below shows the internal aspect of a CHP unit and also the components covered by the Premier Plus package. • • • • • • • • • • • • • • Oil sampling Engine inspection Spark plug inspection and replacement Gas tightness testing Recalibrations Air filter replacement Oil filter replacement Ignition calibration Valve setting and measurement Cleaning of unit interior and exterior Replace rocker covers Drain and flush of water system Monitoring of system pressures Battery condition checks Premier Plus Case Study ENER-G Combined Power maintains and operates a CHP unit at a leisure centre in Sutton, Nottinghamshire. The centre currently pays 7.2p per kWh for their electricity and 1.5p per kWh for gas. Through the operation of an ENER-G 150 on a Premier Plus service contract, the centre has achieved savings over £45,000 within the last twelve months. Discount energy purchase (DEP) Case Study ENER-G Combined Power maintains and operates a CHP unit at a Hotel near Heathrow Airport. The Hotel currently pays 8.6p per kWh for their electricity and 2.3p per kWh for gas. By installing the 2 ENER-G 185 systems on a DEP scheme, the hotel has achieved savings over £35,000 within the last twelve months from no capital outlay. ENER-G PLC ENER-G House Daniel Adamson Road Salford Manchester M50 1DT T: +44 (0)161 745 7450 F: +44 (0)161 745 7457 E: info@energ.co.uk W: www.energ.co.uk