Outside Telephone Cable

advertisement

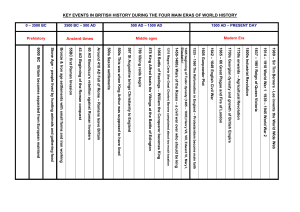

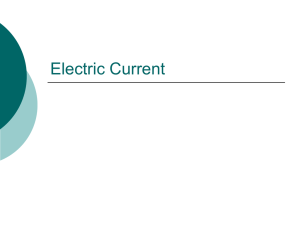

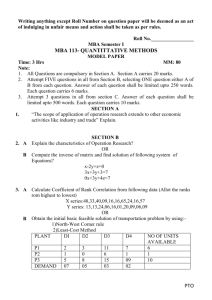

Outside Telephone Cable Filled Core. Moisture Barrier. Description Soft copper wires insulated with high density polyethylene, foam skin or solid. Filled core, conformed by groups of pairs or by unit of groups of pairs. Aluminum shield and external jacket in polyethylene type moisture barrier. Construction Conductor Soft copper wires Insulation Foam skin or solid high density polyethylene. Twisted Pairs Insulated conductors are twisted into pairs Core Assembly Up to 70 pairs, groups of 10 pairs, from 100 to 300 pairs groups of 25 pairs, from 400 pairs and more, units of 100 pairs (each unit is conformed by 4 groups of 25 pairs) Spare pairs One spare pair white-red colored at the interstices of each 100 pairs unit, to guarantee nominal numbers of pairs. Identification Pairs, groups and units that conform the core, are identified by color code (Attached) Core Wrap Non-hygroscopic dielectric tape. Offers dielectric strength between core and sheath Shield Corrugated Aluminum tape both sides covered with copolymer Jacket Black polyethylene, abrasion, weather, and penetration to water resistant 7 Moisture Barrier Filled Core with elastomeric compound, aluminum tape both sides covered with copolymer and polyethylene external jacket, firmly bonded to external side of aluminum tape Options Manufacturing according to REA and/or Bellcore specifications Shield in Flat Aluminum tape. Armor in corrugated and copolymer covered Steel tape for direct buried and for rodent protection. Galvanized steel wires armor for vertical installations. Other Core Assemblies are available upon request. Applications Trunk cable and distribution cable networks. Special for wet locations; the elastomeric compound filler prevents the entrance of moisture to the core. Installation in ducts or raceways; for buried direct in locations without heavy traffic. CENTELSA Outside Telephone Cable, are able for voice and data transmission up to 6.3 MHz, optimizing the bandwidth of copper cables. Standards and Specifications CENTELSA Outside Telephone Cable, are manufactured under the following standards: ANSI/ICEA S-84-608 Telecommunications cable filled, polyolefin insulated copper conductor. ANSI/ICEA S-85-625 Telecommunications cable aircore, polyolefin insulated copper conductor. NTC-2061 Telecommunications copper conductor multipair cables, polyolefin insulated and covered, filled and dry. Certifications CENTELSA Outside Telephone Cable, are certified by: ICONTEC (Colombia). Norma NTC 2061. Note: Other configurations, sizes, colors and length not specified herein are available upon request. 8 Outside Telephone Cable. Filled Core. Moisture Barrier. Foamed-Skin polyethylene insulation. Standards: ANSI/ICEA S-84-608 Telecommunications cable filled, polyolefin insulated copper conductor. NTC-2061 Telecommunications copper conductor multipair cables, polyolefin insulated and covered, filled and dry. NOMINAL PAIRS SPARE PAIRS CONDUCTOR DIAMETER (mm) INSULATION THICKNESS (mm) JACKET THICKNESS (mm) OVERALL DIAMETER (mm) APPROX. TOTAL WEIGTH (kg/km) STANDARD LENGTH BY REEL (m) 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 1 2 2 3 4 5 6 9 12 15 18 24 1 2 2 3 4 5 6 9 12 15 18 24 1 2 2 3 4 5 6 9 12 15 18 24 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.60 1.80 1.80 1.80 2.00 2.20 2.40 2.40 2.40 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.80 1.80 2.00 2.00 2.20 2.40 2.40 2.60 2.60 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.80 1.80 1.80 2.00 2.20 2.20 2.40 2.60 2.60 2.80 2.80 9.75 11.56 12.96 14.13 15.17 16.96 19.30 22.87 25.48 29.91 34.06 37.35 40.32 48.48 55.32 61.43 66.73 75.88 10.67 12.86 14.55 15.97 17.23 19.40 22.22 26.46 29.62 35.40 39.92 44.39 47.99 57.64 66.03 72.92 79.57 90.63 12.08 14.86 17.00 18.80 20.38 23.55 27.13 32.38 36.39 43.25 49.38 54.80 59.35 71.67 81.99 90.72 99.02 113.03 94 141 187 231 275 356 479 692 886 1270 1668 2044 2419 3565 4699 5837 6941 9126 120 188 252 316 378 498 682 996 1283 1876 2446 3037 3606 5312 7018 8684 10386 13682 158 257 350 442 531 724 994 1452 1880 2732 3605 4475 5309 7848 10374 12846 15371 20280 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 Note: 1. Data herein indicated are approximated and are subject to normal manuracturing tolerances. 9 Outside Telephone Cable. Filled Core. Moisture Barrier. Solid polyethylene insulation. Standards: ANSI/ICEA S-84-608 Telecommunications cable filled, polyolefin insulated copper conductor. NTC-2061 Telecommunications copper conductor multipair cables, polyolefin insulated and covered, filled and dry. NOMINAL PAIRS 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 Note: 10 SPARE PAIRS 1 2 2 3 4 5 6 9 12 15 18 24 1 2 2 3 4 5 6 9 12 15 18 24 1 2 2 3 4 5 6 9 12 15 18 24 CONDUCTOR DIAMETER (mm) 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 INSULATION THICKNESS (mm) 0.23 0.23 0.23 0.23 0.23 0.23 0.23 0.23 0.23 0.23 0.23 0.23 0.23 0.23 0.23 0.23 0.23 0.23 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 JACKET THICKNESS (mm) 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.80 1.80 2.00 2.00 2.20 2.40 2.40 2.60 2.60 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.80 1.80 1.80 2.00 2.20 2.20 2.40 2.60 2.60 2.80 2.80 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.80 1.80 2.00 2.20 2.40 2.40 2.60 2.60 2.80 2.80 3.00 1. Data herein indicated are approximated and are subject to normal manuracturing tolerances. OVERALL DIAMETER (mm) APPROX. TOTAL WEIGTH (kg/km) 10.34 12.40 13.98 15.32 16.49 18.53 21.18 25.18 28.15 33.59 37.83 42.05 45.43 54.51 62.26 68.88 75.13 85.52 11.83 14.51 16.57 18.30 19.83 22.90 26.34 31.42 35.27 41.88 47.81 53.04 57.42 69.31 79.26 87.67 95.68 109.18 13.13 16.35 18.82 20.90 22.74 26.33 30.47 36.49 41.11 49.45 56.44 62.83 68.10 82.11 93.57 104.08 113.20 129.82 106 160 211 262 311 405 548 792 1015 1476 1913 2377 2812 4128 5440 6714 8026 10547 142 224 306 384 459 620 850 1232 1590 2300 3033 3762 4454 6561 8663 10713 12813 16877 177 294 407 514 624 849 1168 1710 2215 3262 4292 5324 6320 9325 12270 15260 18183 24082 STANDARD LENGTH BY REEL (m) 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 Outside Telephone Cable Filled Core. Double Jacket. Moisture Barrier. Description Soft copper wires insulated with high density polyethylene, foam skin or solid. Core conformed by groups of pairs or by unit of groups of pairs. Filled core Aluminum shield and double Jacket (inner and outer) in polyethylene type moisture barrier. Construction Conductor Soft copper wires Insulation Foam skin or solid high density polyethylene. Twisted Pairs Insulated conductors are twisted into pairs Core Assembly Up to 70 pairs, groups of 10 pairs, from 100 to 300 pairs groups of 25 pairs, from 400 pairs and more, units of 100 pairs (each unit is conformed by 4 groups of 25 pairs) Spare pairs One spare pair white-red colored at the interstices of each 100 pairs unit, to guarantee nominal numbers of pairs. Identification Pairs, groups and units that conform the core, are identified by color code (Attached) Inner Jacket Black polyethylene, abrasion, weather, and penetration to water resistant 11 Core Wrap Non-hygroscopic dielectric tape. Offers dielectric strength between core and sheath Shield Corrugated Aluminum tape both sides covered with copolymer Outer Jacket Black polyethylene, abrasion, weather, and penetration to water resistant Moisture Barrier Filled Core with elastomeric compound, inner polyethylene jacket, aluminum tape both sides covered with copolymer and outer polyethylene external jacket, firmly bonded to external side of aluminum tape. Options Manufacturing according to REA and/or Bellcore specifications Shield in Flat Aluminum tape. Armor in corrugated and copolymer covered Steel tape for direct buried and for rodent protection. Galvanized steel wires armor for vertical installations. Other Core Assemblies are available upon request. Applications Trunk cable and distribution cable networks. Special for wet locations; the elastomeric compound filler prevents the entrance of moisture to the core. Trunk cable and distribution cable networks. Special for wet locations; the elastomeric compound filler prevents the entrance of moisture to the core. The inner jacket offers additional blocking to the entrance of humidity to the core, increases the dielectric strength pair-shield and improves cable resistance to penetration of sharp objects. CENTELSA Outside Telephone Cable, are able for voice and data transmission up to 6.3 MHz, optimizing the bandwidth of copper cables. 12 Standards and Specifications CENTELSA Outside Telephone Cable, are manufactured under the following standards: Standards: ANSI/ICEA S-84-608 Telecommunications cable filled, polyolefin insulated copper conductor. NTC-2061 Telecommunications copper conductor multipair cables, polyolefin insulated and covered, filled and dry. Certifications CENTELSA Outside Telephone Cable, are certified by: ICONTEC (Colombia). Standard NTC 2061. Note: Other configurations, sizes, colors and length not specified herein are available upon request. 13 Outside Telephone Cable. Filled Core. Moisture Barrier. Foamed-Skin polyethylene insulation. Standards: ANSI/ICEA S-84-608 Telecommunications cable filled, polyolefin insulated copper conductor. NTC-2061 Telecommunications copper conductor multipair cables, polyolefin insulated and covered, filled and dry. NOMINAL PAIRS SPARE PAIRS CONDUCTOR DIAMETER (mm) INSULATION THICKNESS (mm) JACKET THICKNESS (mm) OVERALL DIAMETER (mm) APPROX. TOTAL WEIGTH (kg/km) TOTAL WEIGTH (kg/km) 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 1 2 2 3 4 5 6 9 12 15 18 24 1 2 2 3 4 5 6 9 12 15 18 24 1 2 2 3 4 5 6 9 12 15 18 24 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.18 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.70 0.70 0.70 0.70 0.70 0.70 0.70 0.80 0.80 0.80 0.90 0.90 0.90 1.00 1.10 1.20 1.20 1.20 0.70 0.70 0.70 0.70 0.70 0.70 0.70 0.80 0.80 0.90 0.90 1.00 1.00 1.10 1.20 1.20 1.30 1.30 0.70 0.70 0.70 0.70 0.70 0.80 0.80 0.90 0.90 0.90 1.00 1.10 1.10 1.20 1.30 1.30 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.60 1.80 1.80 1.80 2.00 2.20 2.40 2.40 2.40 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.80 1.80 2.00 2.00 2.20 2.40 2.40 2.60 2.60 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.80 1.80 1.80 2.00 2.20 2.20 2.40 2.60 2.60 2.80 2.80 11.15 12.96 14.36 15.53 16.57 18.36 20.70 24.47 27.08 31.51 35.86 39.15 42.12 50.48 57.52 63.83 69.13 78.28 12.07 14.26 15.95 17.37 18.63 20.80 23.62 28.06 31.22 37.20 41.72 46.39 49.99 59.84 68.43 75.32 82.17 93.23 13.48 16.26 18.40 20.20 21.78 25.15 28.73 34.18 38.19 45.05 51.38 57.00 61.55 74.07 84.59 93.32 101.82 115.83 116 166 215 261 307 392 519 746 947 1341 1759 2144 2526 3712 4882 6057 7173 9390 143 216 283 350 415 539 729 1059 1354 1971 2552 3178 3751 5502 7254 8938 10686 14031 183 285 386 481 574 780 1059 1539 1977 2850 3754 4656 5504 8104 10690 13196 15775 20748 Note: 14 1. Data herein indicated are approximated and are subject to normal manuracturing tolerances. STANDARD LENGTH BY REEL (m) 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 Outside Telephone Cable Air Core. Moisture Barrier. Description Soft copper wires insulated with high density polyethylene, foam skin or solid. Air core, conformed by groups of pairs or by unit of groups of pairs. Aluminum shield and external jacket in polyethylene type moisture barrier. Construction Conductor Soft copper wires Insulation Foam skin or solid high density polyethylene. Twisted Pairs Insulated conductors are twisted into pairs Core Assembly Up to 70 pairs, groups of 10 pairs, from 100 to 300 pairs groups of 25 pairs, from 400 pairs and more, units of 100 pairs (each unit is conformed by 4 groups of 25 pairs) Spare pairs One spare pair white-red colored at the interstices of each 100 pairs unit, to guarantee nominal numbers of pairs. Identification Pairs, groups and units that conform the core, are identified by color code (Attached) Core Wrap Non-hygroscopic dielectric tape. Offers dielectric strength between core and sheath Shield Corrugated Aluminum tape both sides covered with copolymer Jacket Black polyethylene, abrasion, weather, and penetration to water resistant 15 Moisture Barrier Filled Core with elastomeric compound, aluminum tape both sides covered with copolymer and polyethylene external jacket, firmly bonded to external side of aluminum tape Options Manufacturing according to REA and/or Bellcore specifications Shield in Flat Aluminum tape. Armor in corrugated and copolymer covered Steel tape for direct buried and for rodent protection. Galvanized steel wires armor for vertical installations. Other Core Assemblies are available upon request. Applications Trunk cable and distribution cable networks. For use in pressurized networks. Installation in ducts or raceways CENTELSA Outside Telephone Cable, are able for voice and data transmission up to 6.3 MHz, optimizing the bandwidth of copper cables. Standards and Specifications CENTELSA Outside Telephone Cable, are manufactured under the following standards: ANSI/ICEA S-85-625 Telecommunications cable aircore, polyolefin insulated copper conductor. NTC-2061 Telecommunications copper conductor multipair cables, polyolefin insulated and covered, filled and dry. Certifications CENTELSA Outside Telephone Cable, are certified by: ICONTEC (Colombia). Standard NTC 2061. Note: Other configurations, sizes, colors and length not specified herein are available upon request. 16 Outside Telephone Cable. Air Core. Moisture Barrier. Foamed-Skin polyethylene insulation. Standards: ANSI/ICEA S-85-625 Telecommunications cable aircore, polyolefin insulated copper conductor. NTC-2061 Telecommunications copper conductor multipair cables, polyolefin insulated and covered, filled and dry. NOMINAL PAIRS 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 Note: SPARE PAIRS 1 2 2 3 4 5 6 9 12 15 18 24 1 2 2 3 4 5 6 9 12 15 18 24 1 2 2 3 4 5 6 9 12 15 18 24 CONDUCTOR DIAMETER (mm) 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 INSULATION THICKNESS (mm) 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.21 0.21 0.21 0.21 0.21 0.21 0.21 0.21 0.21 0.21 0.21 0.21 0.21 0.21 0.21 0.21 0.21 0.21 JACKET THICKNESS (mm) 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.60 1.60 1.80 1.80 2.00 2.00 2.20 2.20 2.60 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.80 1.80 2.00 2.00 2.20 2.20 2.40 2.40 2.60 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.60 1.60 1.80 1.80 2.00 2.00 2.20 2.40 2.60 2.60 2.80 OVERALL DIAMETER (mm) APPROX. TOTAL WEIGTH (kg/km) STANDARD LENGTH BY REEL (m) 9.41 11.09 12.38 13.46 14.42 16.08 18.24 21.57 23.98 28.08 31.53 34.98 37.73 45.31 51.28 56.92 61.68 71.10 10.26 12.28 13.84 15.15 16.30 18.31 20.91 24.86 27.77 33.13 37.30 41.39 44.78 53.71 60.93 67.85 73.60 84.22 11.47 14.00 15.94 17.58 19.02 21.94 25.19 29.59 33.23 39.82 45.09 50.09 54.23 65.44 74.86 83.21 90.39 103.54 86 125 163 200 232 300 404 579 734 1047 1353 1678 1977 2908 3800 4716 5595 7438 108 164 217 270 318 419 566 823 1054 1541 1998 2478 2941 4323 5662 7040 8372 11070 133 214 288 361 433 587 801 1147 1478 2165 2829 3515 4164 6139 8113 10087 12004 15884 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 1. Data herein indicated are approximated and are subject to normal manuracturing tolerances. 17 Outside Telephone Cable. Air Core. Moisture Barrier. Solid polyethylene insulation. Standards: ANSI/ICEA S-85-625 Telecommunications cable aircore, polyolefin insulated copper conductor. NTC-2061 Telecommunications copper conductor multipair cables, polyolefin insulated and covered, filled and dry. NOMINAL PAIRS 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2400 Note: 18 SPARE PAIRS 1 2 2 3 4 5 6 9 12 15 18 24 1 2 2 3 4 5 6 9 12 15 18 24 1 2 2 3 4 5 6 9 12 15 18 24 CONDUCTOR DIAMETER (mm) INSULATION THICKNESS (mm) 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 JACKET THICKNESS (mm) 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.60 1.80 1.80 1.80 2.00 2.20 2.40 2.40 2.60 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.80 1.80 2.00 2.00 2.20 2.40 2.40 2.60 2.60 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.80 1.80 1.80 2.00 2.20 2.20 2.40 2.60 2.60 2.80 2.80 1. Data herein indicated are approximated and are subject to normal manuracturing tolerances. OVERALL DIAMETER (mm) APPROX. TOTAL WEIGTH (kg/km) 11.15 13.55 15.39 16.94 18.30 20.67 23.75 28.34 31.79 37.63 43.05 47.39 51.32 62.01 70.92 78.85 85.65 98.13 12.66 15.68 17.99 19.95 21.67 24.66 28.54 34.21 38.56 46.42 52.63 58.51 63.61 76.74 87.91 97.39 106.37 121.58 14.21 17.87 20.68 23.05 25.14 29.18 33.89 40.68 46.02 54.96 63.06 70.07 76.07 91.95 105.41 116.91 127.71 146.16 107 160 208 254 298 385 515 738 938 1334 1752 2138 2520 3694 4858 6024 7142 9417 137 213 284 352 418 548 742 1075 1378 2009 2605 3228 3818 5602 7383 9106 10882 14297 172 276 374 468 560 758 1034 1501 1933 2787 3670 4545 5380 7914 10442 12895 15414 20283 STANDARD LENGTH BY REEL (m) 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 500 500 500 350 300 250 250 250 Outside Telephone Cable Self-supported Figure 8. Air Core. Moisture Barrier. Description Soft copper wires insulated with high density polyethylene, foam skin or solid. Air core, conformed by groups of pairs or by unit of groups of pairs. Aluminum shield, support messenger and external jacket in polyethylene type moisture barrier. Construction Conductor Soft copper wires Insulation Foam skin or solid high density polyethylene. Twisted Pairs Insulated conductors are twisted into pairs Core Assembly Up to 70 pairs, groups of 10 pairs, from 100 to 300 pairs groups of 25 pairs, from 400 pairs and more, units of 100 pairs (each unit is conformed by 4 groups of 25 pairs) Spare pairs One spare pair white-red colored at the interstices of each 100 pairs unit, to guarantee nominal numbers of pairs. Identification Pairs, groups and units that conform the core, are identified by color code (Attached) Core Wrap Non-hygroscopic dielectric tape. Offers dielectric strength between core and sheath Shield Corrugated Aluminum tape both sides covered with copolymer Support Messenger 7 Strand high strength galvanized steel wire. Jacket Black polyethylene, abrasion, weather, and penetration to water resistant 19 Moisture Barrier Air Core (for pressurerd systems) with elastomeric compound, aluminum flat tape both sides covered with copolymer and polyethylene external jacket, firmly bonded to external side of aluminum tape Options Manufacturing according to REA and/or Bellcore specifications Shield in corrugated Aluminum tape. Filled Core. Galvanized steel wires fully flooded for corrosion protection. Other Core Assemblies are available upon request. Applications For pressured systems overhead trunk cable and distribution cable networks. Aerial installation suspended from Messenger CENTELSA Outside Telephone Cable, are able for voice and data transmission up to 6.3 MHz, optimizing the bandwidth of copper cables. Standards and Specifications CENTELSA Outside Telephone Cable Figure 8, are manufactured under the following standards: ANSI/ICEA S-85-625 Telecommunications cable aircore, polyolefin insulated copper conductor. NTC-2061 Telecommunications copper conductor multipair cables, polyolefin insulated and covered, filled and dry. Certifications CENTELSA Outside Telephone Cable, are certified by: ICONTEC (Colombia). Standard NTC 2061. Note: Other configurations, sizes, colors and length not specified herein are available upon request. 20 Outside Telephone Cable. Figure 8. Air Core. Self Supported. Moisture Barrier. Foamed-Skin polyethylene insulation. Standards: ANSI/ICEA S-85-625 Telecommunications cable aircore, polyolefin insulated copper conductor. NTC-2061 Telecommunications copper conductor multipair cables, polyolefin insulated and covered, filled and dry. NOMINAL PAIRS 10 20 30 40 50 70 100 150 200 300 10 20 30 40 50 70 100 150 200 300 Note: SPARE PAIRS 1 2 2 3 1 2 2 3 CONDUCTOR DIAMETER (mm) INSULATION THICKNESS (mm) 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 JACKET THICKNESS (mm) 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.60 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.60 EXTERNAL DIMENSIONS (mm) 8.03 9.71 11.00 12.08 13.04 14.70 16.86 20.19 22.61 26.70 8.88 10.90 12.46 13.77 14.93 16.93 19.54 23.48 26.39 31.34 x 18.67 x 20.35 x 21.64 x 22.72 x 23.68 x 25.34 x 27.50 x 32.15 x 34.57 x 38.66 x 19.52 x 21.54 x 23.10 x 24.41 x 25.57 x 27.57 x 31.50 x 35.44 x 38.35 x 43.30 MESSENGER STRANDS DIAMETER No. (mm) 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 1.57 1.57 1.57 1.57 1.57 1.57 1.57 2.03 2.03 2.03 1.57 1.57 1.57 1.57 1.57 1.57 2.03 2.03 2.03 2.03 APPROX. TOTAL WEIGTH (kg/km) STANDARD LENGTH BY REEL (m) 221 261 298 334 368 435 536 789 946 1256 242 298 352 403 453 552 780 1033 1266 1728 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 1. Data herein indicated are approximated and are subject to normal manuracturing tolerances. 21 Outside Telephone Cable. Figure 8. Air Core. Self Supported. Moisture Barrier. Solid polyethylene insulation. Standards: ANSI/ICEA S-85-625 Telecommunications cable aircore, polyolefin insulated copper conductor. NTC-2061 Telecommunications copper conductor multipair cables, polyolefin insulated and covered, filled and dry. SPARE PAIRS NOMINAL PAIRS 1 2 2 3 1 2 2 3 10 20 30 40 50 70 100 150 200 300 10 20 30 40 50 70 100 150 200 300 Note: 22 CONDUCTOR DIAMETER (mm) INSULATION THICKNESS (mm) JACKET THICKNESS (mm) 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 0.19 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.60 1.40 1.40 1.40 1.40 1.40 1.40 1.40 1.60 1.60 1.60 EXTERNAL DIMENSIONS (mm) 8.03 9.71 11.00 12.08 13.04 14.70 16.86 20.19 22.61 26.70 9.10 11.22 12.85 14.22 15.43 17.52 20.25 24.35 27.40 32.57 x x x x x x x x x x x x x x x x x x x x 18.67 20.35 21.64 22.72 23.68 25.34 27.50 32.15 34.57 38.66 19.74 21.86 23.49 24.86 26.07 28.16 32.21 36.31 39.36 44.53 MESSENGER STRANDS DIAMETER No. (mm) 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 1. Data herein indicated are approximated and are subject to normal manuracturing tolerances. 1.57 1.57 1.57 1.57 1.57 1.57 1.57 2.03 2.03 2.03 1.57 1.57 1.57 1.57 1.57 1.57 2.03 2.03 2.03 2.03 APPROX. TOTAL WEIGTH (kg/km) STANDARD LENGTH BY REEL (m) 222 263 300 336 371 439 543 799 959 1277 246 305 361 414 467 570 805 1071 1315 1800 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 1500 1500 1500 1500 1500 1500 1000 1000 1000 750 Outside Telephone Wire DWP Drop Wire Paralell Description Drop Wire Paralleled. Hard copper conductors or steel copper covered, polyethylene or PVC insulated. Construction Conductor Hard copper or steel copper covered (CCS) Insulation Single layer Polyethylene for DWP-PE and insulation – jacket integral for DWP2PE, weather resistant. Polyethylene Insulation and PVC jacket for DWP PE-PVC. Flame retardant PVC for DWP-PVC. Paralleled conductors with polarization ridge and conductor separator membrane. Application Self supporting one pair parallel conductor Drop Wire intended for aerial service connection to the subscriber Standards CENTELSA telephone wires DWP are manufactured under the following standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. Certifications CENTELSA Outside Telephone Wire, are certified by: CIDET (Colombia). Standard NTC 1300. Package 100 or 200 meters spools in corrugated carton boxes Note: other configurations and sizes not specified in this catalogue are available upon request. 23 Outside Telephone Wire (International System Unit) Drop Wire Parallel Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. TYPE SIZE No. x AWG DWP PVC 2 x 18 2 x 20 DWP PVC CCS 2 x 18 DWP PE CCS DWP PE DWP 2PE DWP PE-PVC 2 x 18 2 x 18 2 x 20 2 x 18 2 x 18 2 x 20 CONDUCTOR STRAND CROSS INSULATIONMATERIAL INSULATION SEPARATOR JACKET EXTERNAL AISLAMIENTO DIAMETER SECTION MATERIAL THICKNESS (mm) THICKNESS DIMENSIONS (mm) (mm2) (mm) (mm) (mm) Hard Copper Hard Copper Copper Clad Steel Copper Clad Steel Hard Copper Hard Copper Hard Copper Hard Copper Hard Copper APPROX. DC INSULATION TOTAL RESISTANCE RESISTANCE WEIGTH AT 20° C1 (Mohm-km) (kg/km) (ohm/km) ONE CONDUCTOR TENSILE STRENGTH (Nominal) (MPa) 1.02 0.81 0.82 0.52 PVC PVC 0.800.80 0.800.80 1.00 1.00 - 2.62 x6.25 2.41 x 5.83 29 22 22.2 35.2 249 288 460 473 1.02 0.82 PVC 0.800.80 1.00 - 2.62 x 6.25 28 72.6 249 875 1.00 - 2.62 x 6.25 23 72.6 6229 875 1.00 1.00 - 0.80 0.80 2.62 x 6.25 2.41 x 5.83 4.22 x 7.17 4.02 x 8.05 3.81 x 7.63 24 18 36 49 40 22.2 35.2 22.2 22.2 35.2 6229 7202 7167 362 409 460 473 460 460 473 1.02 0.82 PE 1.02 0.81 1.02 1.02 0.81 0.82 0.52 0.82 0.82 0.52 PE PE PE PE PE 0.80 0.80 0.80 1.500.80 0.80 1.60 0.70 0.70 Notes: 1. DC resistance calculated based on a 10.785 ohm-cmil/ft resistivity for Hard cooper and 33.91 ohm-cmil/ft for steel copper covered. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. Outside Telephone Wire (International System Unit) Drop Wire Parallel Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. TYPE SIZE No. x AWG DWP PVC 2 x 18 2 x 20 DWP PVC CCS 2 x 18 DWP PE CCS 2 x 18 DWP PE DWP 2PE DWP PE-PVC 2 x 18 2 x 20 2 x 18 2 x 18 2 x 20 CONDUCTOR STRAND CROSS INSULATION INSULATION SEPARATOR JACKET EXTERNAL DIAMETER SECTION MATERIAL THICKNESS (mils) THICKNESS DIMENSIONS (mils) (kcmil) (mils) (mils) (mils) Hard Copper Hard Copper Copper Clad Steel Copper Clad Steel Hard Copper Hard Copper Hard Copper Hard Copper Hard Copper DC RESISTANCE AT 20° C1 (ohm/kft) INSULATION RESISTANCE (Mohm/kft) ONE CONDUCTOR TENSILE STRENGTH (Nominal) (ksi) 40 32 1.63 1.02 PVC PVC 31 31 39 39 - 103 x 246 95 x 229 20 15 6.77 10.7 817 944 67 69 40 1.63 PVC 31 39 - 103 x 246 19 22.1 817 127 40 1.63 PE 31 39 - 103 x 246 15 22.1 6229 875 40 32 40 40 32 1.63 1.02 1.63 1.63 1.02 PE PE PE PE PE 31 31 63 28 28 39 39 - 31 31 103 x 246 95 x 229 166 x 282 158 x 317 150 x 300 16 12 25 33 27 6.77 10.7 6.77 6.77 10.7 20437 23628 23514 1188 1342 Notas: 24 APPROX. TOTAL WEIGTH (pound/kft) 67 69 67 67 69 1. DC resistance calculated based on a 17.93 ohm-mm2/km resistivity for Hard cooper and 58.62 ohm-mm2/km for steel copper covered. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. Outside Telephone Wire DWT Drop Wire Twisted Description Drop Wire Twisted. Hard copper conductor, individually insulated with polyethylene or PVC. Construction Conductor Hard copper Insulation Black Polyethylene weather resistant or flame retardat PVC. Application Self supporting one pair twisted conductor Drop Wire intended for aerial service connection to the subscriber Standards CENTELSA telephone wires DWT are manufactured under the following standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. Certifications CENTELSA Outside Telephone Wire, are certified by: CIDET (Colombia). Standard NTC 1300. Package 100 or 200 meters spools in corrugated carton boxes Note: other configurations and sizes not specified in this catalogue are available upon request. 25 Outside Telephone Wire (International System Unit) Drop Wire Twisted Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. TYPE SIZE No. x AWG DWT PVC DWT PVC DWT PE DWT PE 2 x 18 2 x 20 2 x 18 2 x 20 STRAND DIAMETER (mm) 1.02 0.81 1.02 0.81 Notes: CROSS SECTION (mm2) INSULATION DIAMETER THICKNESS OVER (mm) INSULATION (mm) 0.82 0.52 0.82 0.52 0.80 0.80 0.80 0.80 EXTERNAL DIAMETER (mm) 2.62 2.41 2.62 2.41 APPROX. TOTAL WEIGTH (kg/km) DC RESISTANT AT 20°C1 (ohm/km) 28 21 23 17 5.25 4.83 5.25 4.83 22.7 35.9 22.7 35.9 INSULATION ONE CONDUCTOR RESISTANCE TENSILE STRENGTH (Mohm-km) (Nominal) (MPa) 249 288 6229 7202 460 473 460 473 1. DC resistance calculated based on a 17.93 ohm-mm2/km resistivity for Hard cooper. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. Outside Telephone Wire Drop Wire Twisted Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. TYPE SIZE No. x AWG DWT PVC DWT PVC DWT PE DWT PE 2 x 18 2 x 20 2 x 18 2 x 20 STRAND CROSS DIAMETER SECTION (mils) (kcmil) Notes: 26 40 32 40 32 1.63 1.02 1.63 1.02 INSULATION SEPARATOR EXTERNAL THICKNESS (mils) DIAMETER (mils) (mils) 31 31 31 31 103 95 103 95 207 190 207 190 APPROX. TOTAL WEIGTH (pound/kft) 19 14 16 11 DC RESISTANT AT 20°C1 (ohm/kft) 6.90 11.0 6.90 11.0 1. DC resistance calculated based on a 10.785 ohm-cmil/ft resistivity for Hard cooper. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. INSULATION ONE CONDUCTOR RESISTANCE TENSILE STRENGTH (Mohm-kft) (Nominal) (ksi) 817 944 20437 23628 67 69 67 69 Inside Telephone Cables Description Soft copper wires insulated with flame retardant PVC, paired, unshielded or shielded with aluminum foil and drain wire, external PVC jacket. Construction Conductor Soft copper Insulation Flame retardant PVC Pairs Two insulated conductor twisted together Core Up to 25 pairs one group of pairs, for 30 pairs and more, groups of 10 or 25 pairs. Spare pairs One pair color coded White-Red for 10 pairs or more. Identification Pairs, groups an units in the assembly core, are identified by color code (included in this catalogue) Core Wrap Non hygroscopic polyester tape Shield Unshielded or shielded with aluminum foil and tinned copper drain wire Jacket Flame retardant PVC, gray colored. Characteristics Mutual capacitance 120 nF/km. Capacitive Unbalance 400 pF (referred to 500 m). 27 DC Conductor Resistance 97.8 ohm/km. Maximum Operating Voltage 60 V. Insulation Resistance 500 Mohm-km. Dielectric Strength (60 seg) 1000 V AC, 1500 V DC. Applications For inside residential commercial and industrial applications. Appropriate for locations with electric interference produced by near power electric circuit. Installation in dry locations in ducts trays and race ways. Standards CENTELSA Inside Cables are manufactured under the following standards: NTC-983, IEC 189. Cables e hilos para bajas frecuencias con aislamiento y cubierta en PVC. Notes: 28 1. Optionally with tinned copper conductor 2. Other configurations and sizes not specified in this catalogue are available upon request. Inside Unshielded Telephone Cable Standards: Low Frecuency Cables and Wire with PVC Insulation and PVC Sheat. NOMINAL PAIRS SPARE PAIRS CONDUCTOR DIAMETER (mm) INSULATION THICKNESS (mm) 1 2 3 4 5 6 10 20 25 30 40 50 70 100 1 1 1 1 1 1 1 1 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 Note: JACKET THICKNESS (mm) 0.60 0.60 0.60 0.60 0.60 0.70 0.70 0.80 0.80 0.90 0.90 0.90 1.00 1.00 OVERALL DIAMETER (mm) 3.18 3.93 4.50 4.98 5.40 6.00 7.26 9.46 10.32 11.32 12.72 13.95 16.31 19.03 APPROX. TOTAL WEIGTH (kg/km) 15 22 28 34 40 49 79 139 168 200 255 310 424 584 STANDARD LENGTH BY REEL (m) 100 1000 1000 1000 1000 1000 2000 2000 2000 2000 1500 1000 1000 1000 Data herein indicated are approximate and are subject to normal manufacturing tolerances. Inside Unshielded Telephone Cable Standards: Low Frecuency Cables and Wire with PVC Insulation and PVC Sheat. NOMINAL PAIRS SPARE PAIRS CONDUCTOR DIAMETER (mm) INSULATION THICKNESS (mm) 1 2 3 4 5 6 10 20 25 30 40 50 70 100 1 1 1 1 1 1 1 1 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 Note: JACKET THICKNESS (mm) 0.60 0.60 0.60 0.60 0.60 0.70 0.70 0.80 0.80 0.90 0.90 0.90 1.00 1.00 OVERALL DIAMETER (mm) 3.36 4.11 4.68 5.16 5.58 6.18 7.44 9.64 10.50 11.50 12.90 14.13 16.49 19.21 APPROX. TOTAL WEIGTH (kg/km) 16 23 30 36 42 51 81 142 171 204 259 314 429 590 STANDARD LENGTH BY REEL (m) 100 1000 1000 1000 1000 1000 2000 2000 2000 2000 1500 1000 1000 1000 Data herein indicated are approximate and are subject to normal manufacturing tolerances. 29 Inside Telephone Wire JWT Jumper Wire Twisted Description Twisted pair for cross connections, for inside use. Soft tinned copper insulated with PVC or PVC and Nylon, assembly in pairs, triads or quads. Construction Conductor Soft tinned copper wire Insulation Flame retardant PVC for JWT. Flame retardant PVC insulation; abrasion oil and gasoline resistant Nylon jacket for JWT PVC-NY. Applications JWT: twisted telephone wire for inside use, cross connections, telephonic derivations and radio and TV equipment wiring. JWT PVC-NY: connection wire in distributors, mini-distributors and telephonic equipment. Nylon jacket provides abrasion resistance. JWT NY: connection wire in distributors, mini-distributors and telephonic equipment. Radio and TV equipment wiring, weld able without remove the insulation, Diameter reduced tightness and low friction advantages given by Nylon insulation. Installation in dry locations, ducts or open installation. Standards CENTELSA telephone wires JWT are manufactured under the following standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. 30 Certifications CENTELSA Outside Telephone Wire, are certified by: CIDET (Colombia). Standard NTC 1300. Package 100 or 200 meters spools in corrugated carton boxes Note: other configurations and sizes not specified in this catalogue are available upon request. Inside Telephone Wire JWT PVC (International System Units) Jumper Wire Twisted PVC Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. SIZE AWG or mm 2 x 22 3 x 22 4 x 22 2 x 24 3 x 24 4 x 24 2 x 0.6 3 x 0.6 4 x 0.6 2 x 0.5 3 x 0.5 4 x 0.5 Notes: STRAND DIAMETER (mm) 0.64 0.64 0.64 0.51 0.51 0.51 0.60 0.60 0.60 0.50 0.50 0.50 CROSS SECTION (mm²) 0.32 0.32 0.32 0.21 0.21 0.21 0.28 0.28 0.28 0.20 0.20 0.20 INSULATION THICKNESS (mm) 0.30 0.30 0.30 0.25 0.25 0.25 0.30 0.30 0.30 0.25 0.25 0.25 OVERALL DIAMETER (mm) 1.24 1.24 1.24 1.01 1.01 1.01 1.20 1.20 1.20 1.00 1.00 1.00 APPROX. EXTERNAL DIAMETER TOTAL WEIGTH (kg/km) (mm) 2.49 2.68 3.00 2.02 2.18 2.44 2.40 2.59 2.90 2.00 2.16 2.41 8.4 12.6 16.8 5.4 8.1 10.9 7.6 11.3 15.1 5.2 7.9 10.5 DC RESISTANCE AT 20° C¹ (ohm/km) 57.4 57.4 57.4 91.0 91.0 91.0 66.0 66.0 66.0 95.0 95.0 95.0 INSULATION RESISTANCE (Mohm/km) 174 174 174 180 180 180 183 183 183 183 183 183 1. DC resistance calculated based on a 17.93 ohm-mm2/km resistivity for Tinned cooper. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. 31 Inside Telephone Wire JWT PVC Jumper Wire Twisted PVC Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. SIZE AWG or mm 2 x 22 3 x 22 4 x 22 2 x 24 3 x 24 4 x 24 Notes: STRAND DIAMETER (mils) 25 25 25 20 20 20 CROSS SECTION (sq inches) INSULATION THICKNESS (mils) 0.64 0.64 0.64 0.40 0.40 0.40 11.8 11.8 11.8 9.8 9.8 9.8 OVERALL DIAMETER (mils) 48.9 48.9 48.9 39.8 39.8 39.8 APPROX. EXTERNAL DIAMETER TOTAL WEIGTH (pound/kft) (mils) 97.9 105.5 118.1 79.6 85.8 96.1 5.7 8.5 11.3 3.6 5.5 7.3 DC RESISTANCE AT 20° C¹ (ohm/kft) 17.5 17.5 17.5 27.7 27.7 27.7 INSULATION RESISTANCE (Mohm/kft) 572 572 572 592 592 592 1. DC resistance calculated based on a 17.93 ohm-mm2/km resistivity for Tinned cooper. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. Inside Telephone Wire JWT PVC-NY (International System Units) Jumper Wire Twisted PVC-Nylon Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. SIZE AWG or mm 2 x 26 2 x 24 2 x 22 2 x 0.4 2 x 0.5 2 x 0.6 STRAND DIAMETER (mm) 0.40 0.51 0.64 0.40 0.50 0.60 CROSS SECTION (mm2) NSULATION THICKNESS (mm) DIAMETER OVER INSULATION (mm) 0.13 0.21 0.32 0.13 0.20 0.28 0.17 0.17 0.17 0.17 0.17 0.17 0.74 0.85 0.98 0.74 0.84 0.94 Notes: JACKET DIAMETER EXTERNAL THICKNESS OVER JACKET DIAMETER (mm) (mm) (mm) 0.11 0.11 0.11 0.11 0.11 0.11 0.96 1.07 1.20 0.96 1.06 1.16 1.93 2.14 2.41 1.92 2.12 2.32 APPROX. TOTAL WEIGTH (kg/km) 3.8 5.5 7.9 3.8 5.3 7.1 DC RESISTANCE AT 20°C1 (ohm/km) 146 91.0 57.4 148 95.0 66.0 INSULATION RESISTANCE (Mohm-km) 39 33 28 39 33 29 1. DC resistance calculated based on a 17.93 ohm-mm2/km resistivity for Tinned cooper. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. Inside Telephone Wire JWT PVC-NY Jumper Wire Twisted PVC-Nylon Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. SIZE AWG or mm 2 x 26 2 x 24 2 x 22 STRAND DIAMETER (mils) 15.9 20.1 25.3 CROSS SECTION (sq inches) NSULATION THICKNESS (mils) DIAMETER OVER INSULATION (mils) 0.25 0.40 0.64 6.7 6.7 6.7 29.3 33.5 38.7 Notes: 32 JACKET DIAMETER EXTERNAL THICKNESS OVER JACKET DIAMETER (mils) (mils) (mils) 4.3 4.3 4.3 38.0 42.2 47.4 75.9 84.3 94.7 APPROX. TOTAL WEIGTH (kg/km) 2.6 3.7 5.3 1. DC resistance calculated based on a 10.785 ohm-cmil/ft resistivity for Tinned cooper. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. DC RESISTANCE AT 20°C1 (ohm/km) 44.4 27.7 17.5 INSULATION RESISTANCE (Mohm-km) 126 108 91 Inside Telephone Wire JWT NY (International System Units) Jumper Wire Twisted PVC-Nylon Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. SIZE AWG or mm 2 x 26 2 x 24 2 x 22 2 x 0.4 2 x 0.5 2 x 0.6 Notes: STRAND DIAMETER (mm) 0.40 0.51 0.64 0.40 0.50 0.60 CROSS SECTION (mm²) INSULATION THICKNESS (mm) 0.13 0.21 0.32 0.13 0.20 0.28 0.17 0.17 0.17 0.17 0.17 0.17 DIAMETER OVER INSULATION (mm) APPROX. EXTERNAL DIAMETER TOTAL WEIGTH (kg/km) (mm) 0.74 0.85 0.98 0.74 0.84 0.94 1.49 1.83 2.37 1.48 1.81 2.27 3.0 4.5 6.8 3.0 4.3 6.0 DC RESISTANCE AT 20° C¹ (ohm/km) 146 91.0 57.4 148 95.0 66.0 INSULATION RESISTANCE (Mohm/km) 10 10 10 10 10 10 1. DC resistance calculated based on a 17.93 ohm-mm2/km resistivity for Tinned cooper. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. Inside Telephone Wire JWT NY Jumper Wire Twisted PVC-Nylon Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. SIZE AWG or mm 2 x 26 2 x 24 2 x 22 Notes: STRAND DIAMETER (mils) 15.9 20.1 25.3 CROSS SECTION (sq inches) 0.25 0.40 0.64 INSULATION THICKNESS (mils) 6.7 6.7 6.7 DIAMETER OVER INSULATION (mils) 29.3 33.5 38.7 APPROX. EXTERNAL DIAMETER TOTAL WEIGTH (pound/kft) (mils) 58.6 72.2 93.4 2.0 3.0 4.6 DC RESISTANCE AT 20° C¹ (ohm/kft) 44.4 27.7 17.5 INSULATION RESISTANCE (Mohm/kft) 33 33 33 1. DC resistance calculated based on a 10.785 ohm-cmil/ft resistivity for Tinned cooper. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. 33 Inside Telephone Wire JWP Jumper Wire Parallel Description Inside drop wire paralleled. Soft copper insulated with PVC. Construction Conductor Soft copper wire Insulation Flame retardant white PVC, paralleled conductors with polarization ridge. Applications Paralleled telephone wire for inside use from the interior box to exterior box; telephonic derivations. Installation in dry locations, ducts or open installation. Standards CENTELSA telephone wires JWP are manufactured under the following standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. Certifications CENTELSA Outside Telephone Wire, are certified by: CIDET (Colombia). Standard NTC 1300. Package 100 or 200 meters spools in corrugated carton boxes Note: other configurations and sizes not specified in this catalogue are available upon request. 34 Inside Telephone Wire JWP (International System Units) Jumper Wire Parallel Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. SIZE AWG or mm STRAND DIAMETER (mm) 2 x 20 2 x 22 0.81 0.64 Notes: CROSS SECTION (mm²) 0.52 0.32 INSULATION THICKNESS (mm) 0.60 0.60 EXTERNAL DIAMETER (mm) 2.01 x 4.03 1.84 x 3.69 APPROX. TOTAL WEIGTH (kg/km) 18.1 13.5 DC RESISTANCE AT 20° C¹ (ohm/km) 33.9 54.2 INSULATION RESISTANCE (Mohm/km) 240 279 1. DC resistance calculated based on a 17.241 ohm-mm2/km resistivity for Soft cooper. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. Inside Telephone Wire JWP Jumper Wire Parallel Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. SIZE AWG or mm STRAND DIAMETER (mm) 2 x 20 2 x 22 32.0 25.3 Notes: CROSS SECTION (kcmil) 1.02 0.64 INSULATION THICKNESS (mils) 23.6 23.6 EXTERNAL DIAMETER (mils) 79.3 x 158.5 72.6 x 145.1 APPROX. TOTAL WEIGTH (pound/kft) 12.2 9.1 DC RESISTANCE AT 20° C¹ (ohm/kft) 10.3 16.5 INSULATION RESISTANCE (Mohm/kft) 787 914 1. DC resistance calculated based on a 10.371 ohm-cmil/ft resistivity for Soft cooper. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. 35 Inside Telephone Wire JWP Jumper Wire Parallel Description Inside drop wire paralleled. Soft copper insulated with PVC. Construction Conductor Soft copper wire Insulation Flame retardant white PVC, paralleled conductors with polarization ridge. Applications Paralleled telephone wire for inside use from the interior box to exterior box; telephonic derivations. Installation in dry locations, ducts or open installation. Standards CENTELSA telephone wires JWP are manufactured under the following standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. Certifications CENTELSA Outside Telephone Wire, are certified by: CIDET (Colombia). Standard NTC 1300. Package 100 or 200 meters spools in corrugated carton boxes Note: other configurations and sizes not specified in this catalogue are available upon request. 34 Inside Telephone Wire JWP (International System Units) Jumper Wire Parallel Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. SIZE AWG or mm STRAND DIAMETER (mm) 2 x 20 2 x 22 0.81 0.64 Notes: CROSS SECTION (mm²) 0.52 0.32 INSULATION THICKNESS (mm) 0.60 0.60 EXTERNAL DIAMETER (mm) 2.01 x 4.03 1.84 x 3.69 APPROX. TOTAL WEIGTH (kg/km) 18.1 13.5 DC RESISTANCE AT 20° C¹ (ohm/km) 33.9 54.2 INSULATION RESISTANCE (Mohm/km) 240 279 1. DC resistance calculated based on a 17.241 ohm-mm2/km resistivity for Soft cooper. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. Inside Telephone Wire JWP Jumper Wire Parallel Standards: NTC 1300 Service Drop telephone wire, inside installations and jumper. SIZE AWG or mm STRAND DIAMETER (mm) 2 x 20 2 x 22 32.0 25.3 Notes: CROSS SECTION (kcmil) 1.02 0.64 INSULATION THICKNESS (mils) 23.6 23.6 EXTERNAL DIAMETER (mils) 79.3 x 158.5 72.6 x 145.1 APPROX. TOTAL WEIGTH (pound/kft) 12.2 9.1 DC RESISTANCE AT 20° C¹ (ohm/kft) 10.3 16.5 INSULATION RESISTANCE (Mohm/kft) 787 914 1. DC resistance calculated based on a 10.371 ohm-cmil/ft resistivity for Soft cooper. 2. Data herein indicated are approximate and are subject to normal manufacturing tolerances. 35 Electrical Characteristics Outside Telephone Cables SIZE (mm) MUTUAL CAPACITANCE (nF/km) 0.4 52 55 64 0.5 52 55 64 CAPACITIVE UNBALANCE (pF refered to 500m) INDIVIDUAL VALUE 95% OF VALUES Pair to pair (pF refered to 500m) Pair to shield1 (pF/km) 250 2625 150 - Nominal1 Maximum average Maximum individual 0.6 52 55 64 CROSSTALK Power Sum dB/305m ELFEXT Average Frequency kHz 150 772 1600 3150 6300 0.4 mm 61 47 41 35 29 0.5 mm 63 49 42 37 31 ELNEXT Worst Pair 0.6 mm 63 49 43 37 31 0.4 144.0 150.0 Maximum average Maximum individual 0.5 92.1 95.9 0.6 63.9 66.6 SIZE (mm) RESISTIVE UNBALANCE1 (%) 0.4 2.0 5.0 Maximum average Maximum individual DIELECTRIC STRENGTH (Volts) Conductor A vs Conductor B Conductor vs Shield 0.5 1.5 5.0 SOLID POLYETHYLENE FOAM SKIN POLYETHYLENE 2000V, 3s 1000V, 60s 6000V, 3s 3000V, 60s 1000V, 3s 500V, 60s 2000V, 3s 1000V, 60s 0.6 1.5 4.0 INSULATION RESISTANCE (Mohm-km) Filled Core 1500 MAXIMUM AVERAGE ATENUATION1 (db/km) A 1000 Hz A 150 kHz A 772 kHz Notes: 36 Air Core 5000 SIZE (mm) 0.4 1.88 12.1 23.0 1. Test or value not indicated in Standard NTC 2061. 2. Data herein indicated are subject to normal tolerances. 0.5 1.51 8.90 18.4 Worst Pair 0.4, 0.5 and 0.6 mm 0.4, 0.5 and 0.6 mm 0.4, 0.5 and 0.6 mm 57 58 53 43 47 42 37 43 38 31 38 33 25 34 29 SIZE (mm) Conductor DC Resistance (ohm/km) Average 0.6 1.26 6.90 15.5 Pairs Codes in 25 Pairs Groups Inside¹ and Outside Telephone Cables PAIRS CODES IN 25 PAIRS GROUPS PAIR No. 10 PAIRS GROUP COLOR CODE INSULATION COLOR PAIR No. 1 2 3 4 5 6 7 8 9 10 CONDUCTOR A CONDUCTOR B WHITE WHITE WHITE WHITE WHITE RED RED RED RED RED BLUE ORANGE GREEN BROWN GREY BLUE NARANJA GREEN BROWN GREY 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 INSULATION COLOR CONDUCTOR A CONDUCTOR B WHITE WHITE WHITE WHITE WHITE RED RED RED RED RED BLACK BLACK BLACK BLACK BLACK YELLOW YELLOW YELLOW YELLOW YELLOW PURPLE PURPLE PURPLE PURPLE PURPLE BLUE ORANGE GREEN BROWN GREY BLUE ORANGE GREEN BROWN GREY BLUE ORANGE GREEN BROWN GREY BLUE ORANGE GREEN BROWN GREY BLUE ORANGE GREEN BROWN GREY GROUP IDENTIFICATION CONSTRUCTION 10 PAIR GROUPS 25 PAIR GROUPS Note: GROUP No. 1 2 3 4 5 6 7 1 2 3 4 5 6 7 8 9 10 11 12 PAIRS 1 to 10 11 to 20 21 to 30 31 to 40 41 to 50 51 to 60 61 to 70 1 to 25 26 to 50 51 to 75 76 to 100 101 to 125 126 to 150 151 to 175 176 to 200 201 to 225 226 to 250 251 to 275 276 to 300 BINDER COLOR WHITE - BLUE WHITE - ORANGE WHITE - GREEN WHITE - BROWN WHITE- GREY RED - BLUE RED - ORANGE WHITE - BLUE WHITE - ORANGE WHITE - GREEN WHITE - BROWN WHITE- GREY RED - BLUE RED - ORANGE RED - GREEN RED - BROWN RED - GREY BLACK - BLUE BLACK - ORANGE 1. Specifications for inside telephone cables up to 100 pairs. 37 Unit Color Code Identification Outside Telephone Cables IDENTIFICATION FOR 4 GROUPS IN 100 PAIRS UNITS CONSTRUCTION GROUP No. 25 PAIRS 1 2 3 4 BINDER COLOR WHITE - BLUE WHITE - ORANGE WHITE - GREEN WHITE - BROWN UNITS IDENTIFICATION CONSTRUCTION UNIT No. PAIRS 100 PAIRS UNIT (4 GROUPS OF 25 PAIRS EACH) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 1 to 100 101 to 200 201 to 300 301 to 400 401 to 500 501 to 600 601 to 700 701 to 800 801 to 900 901 to 1000 1001 to 1100 1101 to 1200 1201 to 1300 1301 to 1400 1401 to 1500 1501 to 1600 1601 to 1700 1701 to 1800 1801 to 1900 1901 to 2000 2001 to 2100 2101 to 2200 2201 to 2300 2301 to 2400 38 BINDER COLOR WHITE - BLUE WHITE - ORANGE WHITE - GREEN WHITE - BROWN WHITE - GREY RED - BLUE RED - ORANGE RED - GREEN RED - BROWN RED - GREY BLACK - BLUE BLACK - ORANGE BLACK - GREEN BLACK - BROWN BLACK - GREY YELLOW - BLUE YELLOW - ORANGE YELLOW - GREEN YELLOW - BROWN YELLOW - GREY PURPLE - BLUE PURPLE - ORANGE PURPLE - GREEN PURPLE - BROWN Unit Color Code Identification Outside Telephone Cables CORE ASSEMBLY IN GROUPS OR UNITS PAIRS 10 20 30 40 50 70 100 150 200 300 400 500 600 900 1200 1500 1800 2100 2400 ASSEMBLY (0+1) (0+2) (0+3) (0+4) (0+5) (1+6) (0+4) (1+5) (2+6) (3+9) (0+4) (0+5) (1+5) (2+7) (3+9) (1+5+9) (2+6+10) (2+8+11) (2+8+14) PAIRS BY GROUP GROUPS GROUPS GROUPS GROUPS GROUPS GROUPS GROUPS GROUPS GROUPS GROUPS UNITS UNITS UNITS UNITS UNITS UNITS UNITS UNITS UNITS 10 10 10 10 10 10 25 25 25 25 25 25 25 25 25 25 25 25 25 GROUPS BY UNIT 4 4 4 4 4 4 4 4 4 39 Assembly and Identification for Multipair Telephone Cable Core Inside¹ and Outside Telephone Cables 10 PAIRS GROUP CABLES 25 PAIRS GROUP CABLES 20 to 70 pairs 100 to 300 pairs Assembly (0+2) 20 Pairs White Orange Assembly (0+4) 100 Pairs White Blue Assembly (0+3) 30 Pairs White Brown White Blue White Green White Orange Assembly (1+5) 150 Pairs Red Blue White Green White Blue White Grey White Orange Assembly (0+4) 40 Pairs White White Orange Blue White Green White Brown Assembly (2+6) 200 Pairs Red Green White Brown White Blue White Green White Orange Red Orange Red Blue White Grey White Brown White Green White Blue Red Brown Red Green Assembly (1+6) Red Orange Red Blue White White Orange White Blue Blanco Grey Verde White Brown Note:: 40 Assembly (3+9) 300 Pairs Red Grey White Orange 70 Pairs White Brown White Grey Assembly (0+5) 50 Pairs White Green White White Orange Blue 1.Specifications for telephone cables up to 100 pairs. Black Black Blue Orange White White Green Blue White Grey White Orange Red Orange White Brown Red Blue Assembly and Identification for Multipair Telephone Cable Core Inside¹ and Outside Telephone Cables 100 PAIRS UNIT CABLES (EACH UNIT 4 GROUPS OF 25 PAIRS) 400 to 2400 pairs Assembly (0+4) 1500 Pairs 400 Pairs White Blue White Orange Black Green White Green White Brown Black White Orng Grey White Grey White Blue White Brown Red Blue Yellow Green Red Green 2100 Pairs Red Brown Yellow Orange White Green Red Brown White Brown Red Grey White Green 2400 Pairs Purple Blue Black Blue Black Orange White White Green Blue White Brown White Grey White Orange Red Orange Yellow Brown Red Blue White Grey Black Green Black Brown Purple Orange Assembly (2+8+14) Purple Green Purple Brown Red Red Brown Grey Yellow Grey White Green Red Green Yellow Red Green Orange Black Blue White Black Brown Orange Black Grey Assembly (3+9) Purple Blue White White Orange Blue Red Blue White Brown 1200 Pairs Assembly (2+8+11) Red Green Yellow Blue White Grey Black Blue Black Orange Yellow Yellow Grey Brown Red Red Brown Grey Red Orange White Green Red White White Orange Orange Blue White Grey Black Green Assembly (2+7) Red Green Assembly (2+6+10) Red Blue Black Brown Yellow Green 900 Pairs Red Brown Red Brown Black Red Grey Orange White Green White Brown Rojo Gris Red Orng Red White Green Green Yellow Orange Yellow Blue White Orange White Blue Red Blue White Brown 1800 Pairs Assembly (1+5) Red Green White Orange White White Orange Blue 600 Pairs White Grey White Blue Black Grey Red Grey White Orange White Green Red Blue Black Blue Assembly (0+5) 500 Pairs Assembly (1+5+9) Black Brown White White Orange Blue White Brown Red Blue Yellow Orange Yellow Blue White Grey Black Grey Black Blue Black Orange Orange Green Black Brown 41