BioBundle Systems

advertisement

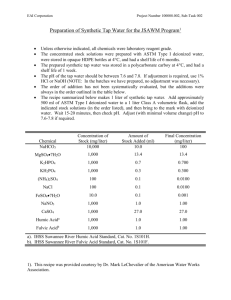

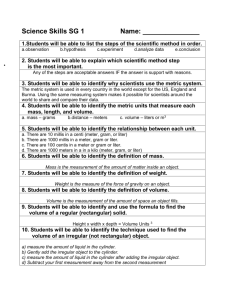

BioBundle Systems C O M P L E T E F E R M E N TAT I O N S Y S T E M S F O R M I C R O B I A L A N D C E L L C U LT U R E A P P L I C AT I O N S C O M PAL U E TT EO FCE LR A ME V NATB A TLI E O N SS YY S S TTE EM M S S F O R M I C R O B I A L A N D C E L L C U LT U R E A P P L I C AT I O N S Laboratory BioBundle Systems Introduction Applikon Biotechnology is a privately-owned Dutch company developing, manufacturing and supplying bioreactor systems for both research and production use. Starting in 1973 Applikon has grown from a small-sized company supplying laboratory instrumentation to a dynamic worldwide enterprise capable of supplying a broad and diverse line of bioreactor systems. Our autoclavable bioreactor systems are the worldwide industry standard. Applikon’s ISO 9001 certification and our ISO certified manufacturing partners ensure that only products made to the highest standards will be delivered to our customers. Applikon Biotechnology has expertise in: • Validation procedures • Fermentation technology • Cell culture technology • Mechanical and electronic engineering • Process engineering • Control system engineering • Sterile and hygienic processing • Software development and automation Our product range consists of 7 liter Bio Bench Pilot System 60 liters Laboratory Pilot Plant • Glass Autoclavable • Autoclavable Stainless Steel Bioreactor systems Bioreactor systems ranging ranging from 1 to 20 liter • Stainless Steel Steam 1500 liter Fermentor Projects • Customized Bioreactor systems up to 25,000 liter from 20 to 110 liter • Stainless Steel Steam In Place Bench top In Place Pilot Bioreactor systems Bioreactor systems ranging from 7 to 30 liter ranging from 20 to 140 liter Measurement, control and software • Applikon has been providing customers with software and control system solutions since the middle of the eighties. The products are developed by software and electronics specialists in close co-operation with bioreactor users. The software and the controllers are used from laboratory scale up to production scale and comply with major international pharmaceutical standards. Key features are ease of operation and high control accuracy. Laboratory Pilot Plant Applikon Biotechnology BioBundle Fermentation Systems are the fastest, easiest and most economical way to get your fermentation projects up and running. Complete and ready to assemble, pre-packaged BioBundle fermentation systems include everything you need for a wide range of applications. Your choice of sizes Uncompromising quality BioBundle bioreactors are available in 1-liter, and performance Every BioBundle system is made of the finest 3-liter, 7-liter or 15-liter sizes for microbial or cell materials available and built to GMP standards. culture, including bacteria, yeasts, fungi, mamma- All materials in contact with the medium are lian cells and plant cells. constructed of either 316L stainless steel, EPDM, silicone rubber, PTFE or borosilicate glass. Applikon Biotechnology ADI 1010 Bio Controller High precision motor pH, dissolved O2 and temperature sensors Applikon Biotechnology ADI 1025 Bio Console Easy access headplate Autoclavable glass bioreactor The BioBundle shown here is upgraded with extra pumps and rotameters Projects C O M PAL U E TT EO FCE LR A ME V NATB A TLI E O N SS YY S S TTE EM M S S F O R M I C R O B I A L A N D C E L L C U LT U R E A P P L I C AT I O N S Laboratory BioBundle Systems BioBundle Components Each BioBundle system component is thoroughly tested and evaluated based on many years of successful usage in a wide range of applications. Below is a partial listing of the components included in the BioBundle system. 3 liter dished 1 liter dished Components 1 liter 1 liter 3 liter 3 liter Cell Culture BioBundle Microbial BioBundle Cell Culture BioBundle Microbial BioBundle ❖ 6 ports ❖ Fermentor headplate 6 ports 18 ports 18 ports Vessel total volume 1.25 L 1.25 L 3.2 L 3.2 L Vessel working volume 0.9 L 0.9 L 2.7 L 2.7 L Vessel minimum working volume 0.35 L 0.35 L 0.47 L 0.47 L Lipseal stirrer ■ ■ ■ ■ Marine impeller ■ ■ 6-bladed turbine impeller 2 each 2 each Motor, speed controller, cable 100 W motor 100 W motor 100 W motor 100 W motor Liquid addition bottle 1 each, 0.5 L 3 each, 0.5 L 1 each, 0.5 L 3 each, 0.5 L Filters 3 each 2 each 3 each 2 each ■ Sparger pipe ■ Sparger pipe with porous nozzle ■ ■ Septum holder ■ ■ ■ ■ Stainless steel air outlet condenser ■ ■ ■ ■ Air overlay pipe ■ ■ ■ Sample pipe ■ ■ ■ Heat exchanger ■ ■ Thermometer pocket ■ ■ ■ Reagent inlet assy. w/ 3 pipes ■ ■ ■ Baffles 2 each 2 each ■ ■ ■ ■ 3 each Blind plug for 6 mm ports 3 each Blind plug for 10 mm ports 2 each 2 each Blind plug for 12 mm ports 2 each 2 each Blind plug for 18 mm ports 1 each Blind plug for 27 mm ports pH sensor, holder, cable ■ ■ ■ ■ Dissolved O2 sensor, holder, cable ■ ■ ■ ■ Temperature sensor ■ ■ ■ ■ ■ Level/foam sensor, cable ■ ADI 1010 Bio Controller ■ ■ ■ ■ Power unit for controller ■ ■ ■ ■ PC config software for controller ■ ■ ■ ■ ADI 1025 Bio Console ■ ■ ■ ■ Rotameter for air 100 mL/min 1 L/min 500 mL/min 5 L/min Rotameter for oxygen 100 mL/min 500 mL/min Rotameter for carbon dioxide 50 mL/min 100 mL/min Control valve for rotameter 1 each 1 each 1 each 1 each Fixed speed drive, pump head, tubing 1 each 3 each 1 each 3 each Heating blanket ■ ■ ■ ■ ■ Control valve for cooling water Startup kit ■ Silicone tubing for liquid additions 7.5 meter ■ ✼ ■ ■ ■ ✼ ■ ■ ✼ ■ ■ ✼ Laboratory Pilot Plant Applikon Biotechnology 7 liter dished 15 liter dished 7 liter 7 liter 15 liter 15 liter Cell Culture BioBundle Microbial BioBundle Cell Culture BioBundle Microbial BioBundle 18 ports 18 ports 18 ports 18 ports 7L 7L 15 L 15 L ❖ The fermentor headplate contains the following non-removable components: • Thermometer pocket 5.2 L 5.2 L 12 L 12 L • Inoculation pipe 2L 2L 2.5 L 2.5 L • Air overlay pipe ■ ■ ■ ■ • Sample pipe ■ ■ • Sparger pipe 2 each 100 W motor 140 W motor 2 each 100 W motor ▼ 1 each, 0.5 L 3 each, 0.5 L 1 each, 1 L 3 each, 1 L 3 each 2 each 3 each 2 each ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ assemblies • 2 o-rings for stirrer assembly ■ ■ The startup kit consists of the • 24 assorted o-rings for port ■ ■ ✼ following items: ■ ■ • Heat exchanger with two baffles 1000 W motor ■ ■ ■ • 5 rubber septa for septum holder ■ • 2 clamping rings for pH holder • 6 lipseals for stirrer assembly ■ ■ ■ ■ ■ ■ ■ ■ 3 each 3 each • Allen key, 1.5 mm • Reducer, male-male, 1/8”- 3/16” 6 each 1 each 6 each 1 each • 25 cable ties 2 each 2 each 2 each 2 each • 2 headplate o-rings 1 each 1 each 1 each 1 each • 3 reducers, male-male, 1.6 - 4.8 mm • T-connector, 4.8 x 4.8 x 4.8 mm ■ ■ ■ ■ ■ ■ ■ ■ ■ • T-connector, 3.2 x 3.2 x 3.2 mm • 6 tubing clamps ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ 10 L/min 5 L/min 50 L/min 1 L/min ■ • 5 meter norprene food grade 500 mL/min 100 mL/min tubing size 15 • 5 meter norprene food grade tubing size 16 5 L/min 1 each 1 each 1 each 1 each 3 each 1 each 3 each ■ ■ ■ ■ ■ ■ ✼ clamping ring 500 mL/min 1 each ■ • 1.5 meter silicone tubing for headplate ■ ■ ■ ■ ✼ ■ ■ reduction to provide higher torque capability. ■ ✼ ▼ P100 motor includes a 6:1 gear ✼ Projects C O M PAL U E TT EO FCE LR A ME V NATB A TLI E O N SS YY S S TTE EM M S S F O R M I C R O B I A L A N D C E L L C U LT U R E A P P L I C AT I O N S Laboratory BioBundle Systems Save time and money Affordable By prepackaging BioBundle systems, Applikon ters and adapts easily to both autoclavable or steam-in-place vessels. realizes significant cost savings, which are passed on to you. Easy The BioBundle Systems are packaged for fast, Complete BioBundle systems are shipped with everything trouble-free assembly. Setup requires no special skills or tools. you need to start, including an autoclavable glass bioreactor, sensors, controller, pumps, flow meters, Integrated filters, valves, tubing, clamps, accessories and com- Equipment required to operate the BioBundle plete instructions. All you have to add is media and system is housed in the ADI 1025 Bio Console that cells. organizes the work area for easy access and optimum performance. Powerful Each BioBundle system includes the versatile ADI 1010 Bio Controller, which provides programmable control and optimization of system parame- Ready BioBundle systems are available for immediate delivery. Call your nearest distributor for information. Laboratory Pilot Plant Applikon Biotechnology ADI 1010 Bio Controller included with every BioBundle system The ADI 1010 Bio Controller is the smallest and most intelligent controller in the Applikon product range. It is specially designed for process development in laboratory scale bioreactor systems and offers you an easy-to-use and powerful instrument that excels in accurate and dependable process control. The ADI 1010 controls pH, temperature, dissolved oxygen, foam/level and stirrer speed. ADI 1010 Bio Controller • Built to GAMP standards • Fully compatible with autoclavable Adaptive control What makes this controller smart is its capability to use adaptive control technology to automatically set the PID values. This results in shorter development times and reduced time to market for your new products. The Bio Controller is equipped with a serial and benchtop stainless steel vessels • Easy, intuitive operation • Adapts easily to changing needs and applications • Eight digital and five analog outputs for maximum versatility • Dependable - one ADI 1010 Bio Controller interface that allows the system to be connected per vessel reduces changes of error and to a computer for data logging and supervisory costly breakdowns control. Applikon offers a wide range of software • The ADI 1010 configuration can be modified products that seamlessly integrate with the con- using the software configuration tool included trollers to further enhance the capabilities. in the BioBundle Ask your local Applikon distributor for details on these add-on products. Projects Laboratory A P P LA I KUO TN OBCI OL TAE V CA H NBOLLEO GSY YBSI OT BEUMN S DLES Pilot Plant Projects Global Distributor Network C a n a d a Applikon Inc. North West Office 1459 Moore Place V3E 389 Coquitlam BC Phone (1) 604 552 6147 Telefax (1) 604 552 6148 E-mail info@applikonbio.com U S A Applikon Inc. Main US Office 1180 Chess Drive Foster City CA 94404 Phone (650) 578-1396 Fax (650) 578-8836 E-mail info@applikonbio.com Applikon Inc. East Coast Office Perryville Corporate Park III P.O. Box 4014 Clinton, NJ 08809-4014 Phone (908) 735-2708 Fax (908) 735-8124 E-mail info@applikonbio.com M e x i c o Equipos Tecnicos y Cientificos. S.A. de C.V. Poniente 126 #413 Col Nueva Vallejo 07750 Mexico D.F. Phone (52) 55-87-58-78 Telefax (52) 55-87-36-15 E-mail info@applikonbio.com Europe B e l g i u m AppliTek N.V. De Prijkels Venecoweg 19, B-9810 Nazareth Phone (32) 9 386 3402 Telefax (32) 9 386 7297 E-mail biotech@applitek.com D e n m a r k Claus Damm A/S Bakkegårdsvej 202 DK-3050 Humlebaek Phone (45) 49 163388 Telefax (45) 49 16-3330 E-mail mail@clausdamm.dk F r a n c e Applikon France 9, rue Levassor B.P. 2024 78132 Les Mureaux Phone (33) 1 3492 9999 Telefax (33) 1 30919390 E-mail applikon@applikon.fr G e r m a n y Applikon Biotek GmbH&CO Auf dem Berge 7 D-34593 Knüllwald, Remsfeld Phone (49) 5681812 Telefax (49) 56811516 E-mail UMa@applikon.com I t a l y Applikon Italia s.r.l. Via Montallegro 6 16145 Genova Phone (39) 010 318620 Telefax (39) 010 311172 E-mail info@stateoftheart.it N o r w a y Prosess-Styring AS Syretårnet 39 3048 Drammen Phone (47) 32820214 Telefax (47) 32826595 E-mail info@prsess-styring.no P o r t u g a l Hucoa Erlöss E.N.10, Urbanização Real Forte lote1-bloco2-loja6 2685-050 Sacavérn Phone (0351) 21 940 9940 Telefax (0351) 21 940 9949 S p a i n Hucoa Erloss C/Luis I, No. 9 Edificio Hucoa 28031 Madrid Phone (34) 913806710 Telefax (34) 913808502 E-mail atc@hucoa-erloss.com S w e d e n AB Ninolab Instrumentvägen 4 Box 137 SE-19422 Upplands Väsby Phone (46) 8 59086070 Telefax (46) 8 59083867 E-mail info@ninolab.se S w i t z e r l a n d Kuhner AG Dinkelbergstrasse 1 4127 Birsfelden (Basel) Phone (41) 61 3199393 Telefax (41) 61 3199394 E-mail office@kuhner.com U n i t e d K i n g d o m / I r e l a n d Applikon Biotechnology Ltd Station Drive, Bredon, Tewkesbury, Gloucestershire, GL20 7HH United Kingdom Phone 44 (0) 1684 774900 Telefax 44 (0) 1684 774901 E-mail info@applikon.co.uk Asia I n d i a BioGentek BG PVT. Ltd. 306, Shahpuri Tirath Singh Tower, C-58, C-Block, Community Center Janakpuri, New Delhi-110058 Phone (91) 11 25622255, 25513104 Telefax (91) 11 25513106 E-mail bgtek@ndf6.vsnl.net.in I n d o n e s i a Pt. Arico Sainsindo Nusantara Kedoya Elok Plaza Jl. Panjang Blok DB-32 Jakarta 11520 Phone (62) 21 5806342 Telefax (62) 21 5806788 E-mail arico@dnet.net.id Australia & New Zealand A u s t r a l i a Enztech Pty Ltd. P.O. Box 281 Woollahra NSW 2025 Phone (61) 2 9360 4971 Telefax (61) 2 9363 3105, 2 9979 3969 E-mail enztech@ozemail.com.au Applikon Bioreactor Systems - V3X0123011 - Subject to modifications - Printed by Applikon Dependable Instruments bv - The Netherlands May 2003 North America Applikon Dependable Instruments bv Biotechnology Division De Brauwweg 13 P.O. Box 149, 3100 AC Schiedam The Netherlands Phone +31 10 298 35 55 Fax +31 10 437 96 48 E-mail biotech@applikon.com Internet www.applikon.com