new collection system for food waste to biogas

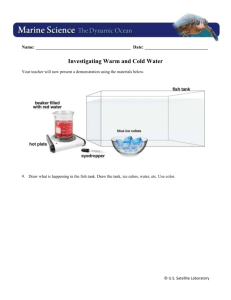

advertisement