JM POLYISOCYANURATE ROOFING PRODUCT LINE

advertisement

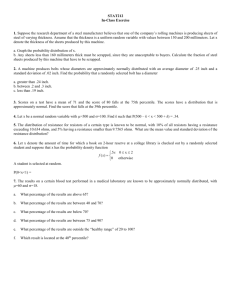

JM POLYISOCYANURATE ROOFING PRODUCT LINE Revised LTTR Values Effective January 1, 2014 ASTM C1289 Standard Change: All polyiso products follow ASTM C1289 (Standard Specification for Faced Rigid Polyisocyanurate Thermal Insulation Board). As part of that standard, the products must meet R-value requirements presented as Long-Term Thermal Resistance (LTTR). As foam ages over time, air and blowing agents diffuse in and out of the foam structure, resulting in reduced R-value. The LTTR test is a technically supported, more-descriptive measure (15-year weighted average) of the foam’s thermal resistance. In the past, PIMA (Polyisocyanurate Insulation Manufacturers Association) members were audited (under the PIMA Quality Mark™ program) for LTTR values according to CAN/ULC-S770-03: Standard Test Method for Determination of Long-Term Thermal Resistance of Closed-Cell Thermal Insulating Foams. With the 2011 version (11a) of ASTM C1289, the polyiso standard specification was changed to reflect improved test methods to better predict long-term thermal behavior of foams. The 2011 version of ASTM 1289 (and subsequent versions) calls out two optional methods of measuring LTTR: A) CAN/ULC-S770-09 – the 2009 version of the current test method B) ASTM C1303; Standard Test Method of Predicting Long Term Thermal Resistance of Closed Cell Foam Insulation Since the change in ASTM C1289, JM and other PIMA members have been working diligently to get polyiso products certified to the new LTTR test methods by a third-party laboratory. In some cases, thinner products can take up to a year of testing before they can be certified. Because of this lengthy certification period, PIMA has set the date of January 1, 2014, as the time when its members (including JM) will begin reporting LTTR numbers from the new test methods on their products, data sheets and marketing literature. Furthermore, to be PIMA Quality Mark certified, JM will be third-party audited to the new standard in 2014. JM has prepared this packet of information to help educate its customers and to ease the transition to the new test method and the change in LTTR values effective January 1, 2014. Polyiso still remains the highest R-value per inch of any available insulation. JM is proud to be a PIMA member and have its product third-party certified under the PIMA Quality Mark program. JM Revised LTTR Values: JM suggests that design professionals use 5.7 R/inch as a “design specification” for its foam products. Prior to this, 6.0 R/inch was the “design specification” for polyiso. Specifically, the new LTTR values are compared to the old as follows: LTTR Change Board Thickness OLD LTTR (CAN/ULC-S770-03) LTTR Value R/Inch NEW LTTR (CAN/ULC-S770-09) LTTR Value R/Inch 1" 6.0 6.0 5.7 5.7 2" 12.1 6.0 11.4 5.7 3" 18.5 6.2 17.4 5.8 4" 25.0 6.2 23.6 5.9 The LTTR (a 15-year, time-weighted, average R-value) is largely affected by thermal aging where air diffuses in and blowing agent diffuses out of the foam. The thicker the foam core, the slower the diffusion and thermal aging, which is why the R/inch increases with thicker board. JM Polyiso Product Has Not Changed: JM will not be changing its product on January 1, 2014. The current product that JM makes tests at 6.0 R/inch with CAN/ULC-S770-03 and at 5.7 R/inch with the new LTTR test method CAN/ ULC-S770-09. Only the LTTR values on the data sheets and product labels will change because of the test method change. JM Product LTTRs to Be Revised: On December 31, 2013, JM will upload its revised technical data sheets to reflect the new LTTR values and standard. JM polyiso products (flat and tapered) that will receive new LTTR values include: ENRGY 3®, ENRGY 3® CGF, ENRGY 3® FR, ENRGY 3® AGF, ENRGY 3® Plus, Fesco® Foam, DuraFoam®, ValuTherm™ and R-Panel. JM Sheathing R-Values Will Not Change: JM’s wall sheathing line, AP Foil and CI Max, are not governed by LTTR test methods and have different R-value measurement standards. JM Operational Plan: In Q4 2013, JM will modify its packaging to reflect LTTR values by both test methods. As an example, a 1" board label will include information from LTTR-S770-03: 6.0 and LTTR-S770-09: 5.7. We will minimize our inventories at year end, but there will be some inventory that will be shipped in 2014 and labeled to the old standard. For those old-inventory cases, we offer the attached transition letter for all stakeholders that explains the change. Design Professionals: JM is announcing its new LTTR numbers in Q3 2013 in order to give design professionals ample time to factor the conversion into their designs. For jobs that will pull a building permit in 2013, the design professional should specify insulation thickness based R-value on the “6.0 R/inch” design guideline associated with the old LTTR test method. Likewise, for jobs that will be permitted in 2014, the design professional should specify insulation thickness based on the “5.7 R/inch” design guideline associated with the new LTTR test method. JM suggests that the design professional specify polyiso insulation by its thickness and its full ASTM designation rather than R-value to avoid potential confusion during this transition time. Distribution: JM suggests that distribution prepare for the January 1, 2014, transition time by analyzing its mostpurchased sizes today, and prepare for a change in its size mix. As an example, a distributor today may sell significant quantities of 2.7" thick product with an old LTTR value of 16.6. To meet (or exceed) that R-value after January 1, 2014, it is reasonable to assume the distributor’s base would begin buying 2.9" product (with a new LTTR value of 16.8). Contractors: JM encourages contractors to talk to design professionals during this transition time to ensure their jobs are specified by thickness and not by R-value. Providing the design professional has compensated for the change in the R-value, the contractor only needs to order the thickness specified. We also encourage the contractor to consider the following scenarios: a) Job designed for 2014 and is permitted in 2014: No action is required. b) J ob designed for 2014 but is permitted in 2013: In this case, thicker polyiso based on 5.7 R/inch could have been designed by the professional and bid by the contractor. The job could be completed as was planned (exceeds the R-value requirement). However, verify with the design professional as to which standard applies. c) Job designed for 2013 and is permitted in 2013: No action is required. d) J ob designed for 2013 and is permitted in 2014: In this case, thinner polyiso based on 6.0 R/inch could have been designed by the professional and bid by the contractor. We suggest the contractor contact the design professional as to which standard applies. 2013 Building Permit 2014 Building Permit Designed for 2013 (6.0 R/in.) No Issues Below R-value Requirement (increase polyiso thickness) Verify with Design Professional Designed for 2014 (5.7 R/in.) Exceeds R-value Requirement (decrease polyiso thickness) Verify with Design Professional No issues Anticipated Thickness Requirements: The table below illustrates how two-layer constructions will change in thickness with the advent of the LTTR test method change in the ASTM C1289 specification. In general, the test method change results in an extra 0.1" of thickness per board, or 4% to 6% more material/thickness, depending upon desired R-value. Please consider this extra thickness requirement when designing blocking heights and specifying fastener lengths. ASHRAE Climate Zone IECC 2012 R-Value Requirements 1, 2, 3 4, 5 6 7, 8 R-20 R-25 R-30 R-35 Polyiso Thickness to Meet IECC OLD LTTR Method NEW LTTR Method 2 Layers 1.7" 2 Layers 2.1" 2 Layers 2.5" 2 Layers 2.9" 2 Layers 1.8" 2 Layers 2.2" 2 Layers 2.6" 2 Layers 3.1" JM suggests two layers of polyiso (with a cover board for protection) over a single thick polyiso layer to minimize thermal shorts in the system and improve system strength with staggered joints. Canadian Commentary: JM manufactures polyiso in both Canada and the U.S. and ships product both directions across the border. In Canada, provinces have jurisdiction on the construction industry and adopt the model National Building Code (NBC) as is, with slight modifications, or with substantial modifications. The 2010 Canadian NBC uses CAN/ULC-S770-03 (6.0 R/inch), but the first set of errata/revisions will be published mid-2013. JM anticipates that these revisions will reference the new CAN/ULC-S770-09 (5.7 R/inch). JM will continue to label both S770-03 and S770-09 values on its products until the new standard is finalized in the Canadian NBC. Detailed LTTR Value Comparison for Flat and Tapered ENRGY 3 Flat ENRGY3 Nominal LTTR Value Tapered ENRGY 3 Thickness (inches) OLD LTTR (CAN/ULC-S770-03) NEW LTTR (CAN/ULC-S770-09) Designation 0.5 0.75 1.0 1.1 1.2 1.25 1.3 1.4 1.5 1.6 1.7 1.75 1.8 1.9 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3.0 3.1 3.2 3.25 3.3 3.4 3.5 3.6 3.7 3.75 3.8 3.9 4.0 4.1 4.2 4.5 3.0 4.5 6.0 6.6 7.2 7.5 7.8 8.4 9.0 9.6 10.3 10.6 10.9 11.5 12.1 12.8 13.4 14.0 14.7 15.3 15.9 16.6 17.2 17.9 18.5 19.1 19.8 20.1 20.4 21.1 21.7 22.4 23.0 23.4 23.7 24.3 25.0 25.7 26.3 28.3 2.9 4.3 5.7 6.3 6.8 7.1 7.4 8.0 8.6 9.1 9.7 10.0 10.3 10.8 11.4 12.0 12.6 13.2 13.8 14.4 15.0 15.6 16.2 16.8 17.4 18 18.6 18.9 19.2 19.9 20.5 21.1 21.7 22.0 22.3 23.0 23.6 24.2 24.9 26.8 1A 1B 1 2 3 4 5 6 AA A B C D E F G H J K L M I X Y Z ZZ SS TT Q QQ R S T U V W XX KK JJ FF LL MM 717 17th St. Denver, CO 80202 (800) 922-5922 www.jm.com/roofing Slope 1/16 1/16 1/16 1/16 1/16 1/16 1/16 1/16 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/4 1/4 3/16 3/16 3/16 3/16 1/4 1/4 1/4 1/4 1/4 3/8 3/8 1/2 1/2 1/8 1/8 1/8 1/8 1/8 1/8 1/4 3/16 3/16 1/8 3/16 3/16 Nominal LTTR Value OLD LTTR (CAN/ULC-S770-03) NEW LTTR (CAN/ULC-S770-09) 3.8 5.3 6.8 8.3 9.8 11.4 13.0 14.5 4.5 7.5 10.6 13.7 16.9 20.1 23.4 9.0 15.3 8.3 13.0 17.7 22.5 21.7 6.0 12.1 18.5 25.0 7.5 16.9 9.0 21.7 6.0 9.0 12.1 15.3 18.5 21.7 12.1 9.8 5.3 26.6 14.5 19.3 3.6 5.0 6.4 7.8 9.3 10.7 12.1 13.6 4.3 7.1 10.0 12.9 15.9 18.9 22.1 8.6 14.4 7.8 12.1 16.6 21.2 20.5 5.7 11.4 17.4 23.6 7.1 15.9 8.6 20.5 5.7 8.6 11.4 14.4 17.4 20.5 11.4 9.3 5.0 25.2 13.6 18.2 RS-5131 8-13 (New)