Speciality Kraft Paper

advertisement

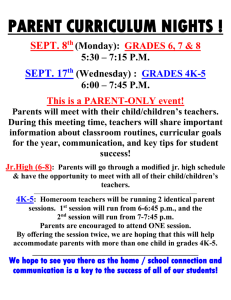

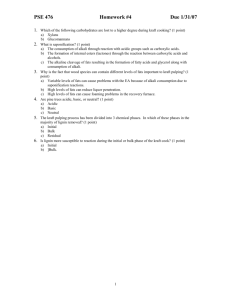

Speciality Kraft Paper IN TOUCH EVERY DAY www.mondigroup.com Welcome to the world of Mondi Speciality Kraft Paper – the one-stop shop for your paper-based packaging needs. Our products are used every day in a multitude of applications, ranging from heavy-duty industrial packaging to attractive and functional point-of-purchase food packaging on supermarket shelves. Our portfolio includes a broad range of paper grades designed for special needs and customised applications. We are experts in transforming our customers’ requirements into tailored packaging solutions, combining technical functionality with the material design and print solutions that deliver maximum performance and service at the lowest cost. OTHER SPECIALITIES BAGS & SHOPPERS COATING & LAMINATES RELEASE BASE, HYGIENE & ENVELOPE RELEASE LINERS, BAKERY 2 www.mondigroup.com MEDICAL Mondi speciality kraft paper. Every day. Speciality kraft paper production 3D animation Speciality kraft paper production video 3 www.mondigroup.com Integrated value chain Pulp Mondi speciality kraft paper mills Speciality kraft paper Market pulp Our integrated business model generates win-win solutions along the entire value chain. Mondi’s kraft paper is sourced from virgin fibre to ensure the strength properties and high hygiene standards necessary for demanding packaging applications. The additives used in our pulping process are non-toxic and recoverable, up to 100%. All the bleached pulp in our products is produced in ECF (elementary chlorinefree) processes. The energy required for pulp production is based entirely on renewable biofuel. Paper machine waste is repulped and transferred back into the process, and the additives used to optimise strength and stiffness are made of renewable resources. We can offer speciality kraft paper grades certified according to either the PEFC™ or the FSC™ international forestry certification scheme. Furthermore, Mondi confirms that it is positioned to fulfil all requirements to comply with the EUTR (European Union Timber Regulation) as all of our wood and fibre is sourced from legal and responsibly managed sources. Our high-quality papers are made of renewable resources and can be recycled up to seven times. Top quality also eases the task of meeting strict food safety requirements. 4 www.mondigroup.com Sustainable. Every day. Bags & shoppers Coating & laminates Release base, hygiene and envelope release liners, bakery Medical Other specialities Mondi Green Range Mondi sustainability 5 www.mondigroup.com Research & Development Our R&D activities focus on finding ways to develop products and optimise processes, constantly increasing consumer protection and product stewardship. To keep providing our customers with break­ through products, we invest in innovative research facilities and cutting-edge technology for our mills. Mondi’s R&D Innovation Centre and Bag Application Centre have the capability of mirroring the complete pulp and papermaking process – all the way from wood to the finished paper. The Mondi Food Safety Laboratory includes a facility for analysing organic compound traces using automatic sample preparation and gas chromatographic appliances. A brand-new Print Competence Centre has been established at the Štětí mill in the Czech Republic. To achieve the best possible print result for each packaging application, a team of highly skilled paper and printing experts can help you choose the most suitable paper grades, printing methods and inks for both white and brown paper. Mondi is always looking for new solutions that yield increased quality and efficiency. Close co-operation with paper converters worldwide is key to responding better and more swiftly to customer demands. R&D at Mondi Speciality Kraft Paper 6 www.mondigroup.com Innovative. Every day. 7 www.mondigroup.com Application areas Mondi offers a wide range of speciality kraft papers on the market. You will practically always find what you are looking for among our machine finished (MF), smooth finished (SF) and machine glazed (MG) grades. Constant feedback from our customers and intensive research and development yield innovative new paper products and packaging solutions. This means that every one of our grades delivers superior quality, including excellent runnability, optimised converting productivity and the right packaging characteristics for the end-user. Bags & shoppers Paper for bags & shoppers PM7 – the true next-generation paper machine Our Advantage speciality kraft paper portfolio offers a com­ pre­ hensive range of papers for bags and shoppers. It includes white and brown MG (machine glazed), white and brown MF (machine finished) as well as white SF (smooth finished) grades. Our MG grades are also available with a ribbed surface and our white MG grades in calendered versions. In 2014 Mondi started up the new PM 7, an additional machine at the Štětí mill in the Czech Republic, to meet the growing demand for bleached speciality kraft paper. www.paperforbags.com www.mondigroup.com/pm7 Coating & laminates Some of our MG grades feature the characteristics necessary for demanding coating and lamination applications. These papers offer high strength and excellent surface properties on the glazed side. Outstanding runnability is ensured by good dimensional stability and high stiffness. Balanced basis weights and moisture profiles guarantee good bonding of the laminates. 8 www.mondigroup.com Our products touch the lives of millions. Every day. Release base, hygiene and envelope release liners, bakery Mondi’s release base papers are typified by excellent formation and low porosity. We offer cost-efficient release liners used mainly by the feminine hygiene and light adult incontinence markets, for envelopes as well as baking paper. Our international manufacturing base ensures a secure and stable supply chain. We are specialised in printing tailored designs in order to provide product differentiation and branding. Mondi’s experienced technical teams offer skilled product knowledge to assist you in optimising your operational efficiency. Medical Mondi’s medical paper grades are especially developed for sterile medical packaging and recommended for direct sealing processes for pouches and reels, and FFS applications and coating bases for some converters. The product port­ folio meets the medical industry’s requirements for quality, barrier properties and safety, and complies with international standards and the main sterilisation processes. We also offer a range for rotary sealing equipment, for use as top and bottom webs. Other specialities Mondi offers a wide variety of solutions for flexible packaging converting. We thrive on challenges, finding creative solutions to demanding customer requirements. Our customised products include paper solutions for ream wrapping, gift and flower wrapping as well as dunnage bags. 9 www.mondigroup.com Buyer’s guide With dozens of paper grades to choose from and no limits on their potential uses, finding the paper to fit the package can be a challenge. Machine finished / Smooth finished grades WHITE BROWN Grammage range (g/m²) Advantage MF EcoComp 70, 75 Advantage MF Kraft 70 - 120 Advantage MF Lining 50 Advantage MF SpringPack Plus 110 - 160 Advantage MF Wrap 70 - 110 Advantage MF Z 50 Advantage MF Power 90, 100 Advantage MF White Kraft 70 - 90 Advantage MF White Pulp Wrapping 140 - 160 Advantage MF White Suprakraft 50 - 120 Advantage Smooth White 50 - 130 Advantage Smooth White Gloss 70 - 120 Advantage Smooth White Strong 50 - 120 Advantage Formable White 120 - 140 Aluminium lamination Bakery Carrier bags • • • • • Compostable bags • Consumer bags Extrusion coating and lamination • • • • • • • • • • • • • • • WHITE BROWN Machine glazed grades Advantage MG Coating 40 - 120 Advantage MG Cover 40 - 60 Advantage MG Gumming 40 - 100 Advantage MG Kraft 30 - 120 Advantage MG Mail 50 - 120 Advantage MG PE Coating 60 - 120 Advantage Bakery C2S 39 Advantage MG White 25 - 70 Advantage MG White C 25 - 70 Advantage MG White Cote 30 - 60 Advantage MG White Cote Opaque 30 - 60 Advantage MG White Cote Print 30 - 60 Advantage MG White Flex/Flex Plus 28 - 110 Advantage MG White Flex C 28 - 90 Advantage MG White Flex RB 35 - 70 Advantage MG White Gloss 30 - 70 Advantage MG White GR (LGR/MGR/HGR) 30 - 60 Advantage MG White High Gloss 28 - 80 Advantage MG White Opaque 30 - 60 Advantage MG White Opaque C 40 - 60 Advantage MG White RB 35 - 70 Advantage MG White Reflex 35 - 60 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Medical packaging paper range WHITE Grammage range (g/m²) Sterilisation process Advantage Medi Coating Base 60 ETO/irradiation Advantage Medi ETO/R 60 - 67 ETO/irradiation Advantage Medi Innerwrap 35, 40 ETO/irradiation Advantage Medi Soft Peel 63 - 70 ETO/irradiation Advantage Medi Steam 60, 68, 70 Advantage Medi Steam Bag 60 Steam/ETO/formaldehyde Steam/ETO Release liner grades WHITE Grammage range (g/m²) M-Liner (precoated MG) 35 - 70 Machine width 15 - 2310 10 www.mondigroup.com Form, fill & seal Rotary seal Direct seal pouches • • • • • • • • • Coating base Medical wrap • • • • • The buyer’s guide below is intended to help you pinpoint the relevant grades for your application. Please do not hesitate to contact us for further information. Flower & gift wrap Food packaging Form, fill & seal • • • • • • • • Lidding Ream wrap Reel wrap • • • • • • • • • • • • • • • • • • • • Interleaving • • • • • • • • • • • Release base Others • • • • • • • • • • • • • • • • • • Sealing side treated • • •• • 11 www.mondigroup.com • • • • • • • • • • • • • © Mondi Paper Sales GmbH, March 2015, printed on NAUTILUS® SuperWhite 250 g/m2 Mondi Paper Sales GmbH Marxergasse 4A 1030 Vienna, Austria Tel: +43 1 79013 0 Fax: +43 1 79013 951 Email: kraft.paper@mondigroup.com www.mondigroup.com