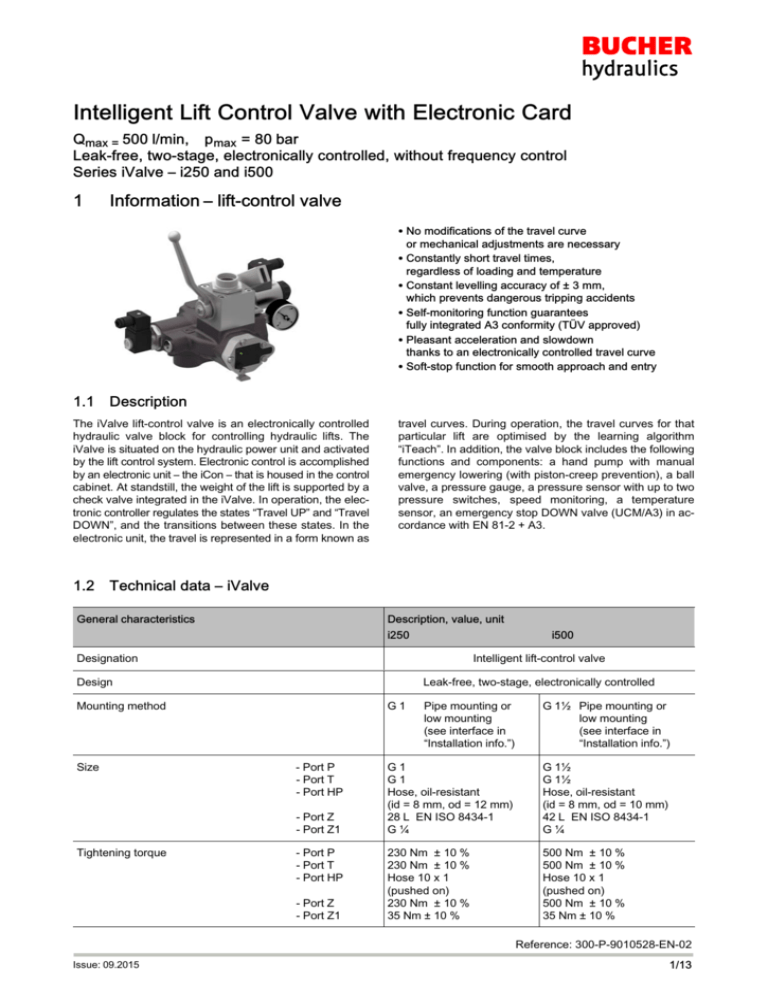

Intelligent Lift Control Valve with Electronic Card

Qmax = 500l/min,pmax = 80bar

Leak-free, two-stage, electronically controlled, without frequency control

Series iValve – i250 and i500

1

Information – lift-control valve

S No modifications of the travel curve

or mechanical adjustments are necessary

S Constantly short travel times,

regardless of loading and temperature

S Constant levelling accuracy of ± 3 mm,

which prevents dangerous tripping accidents

S Self-monitoring function guarantees

fully integrated A3 conformity (TÜV approved)

S Pleasant acceleration and slowdown

thanks to an electronically controlled travel curve

S Soft-stop function for smooth approach and entry

1.1 Description

The iValve lift-control valve is an electronically controlled

hydraulic valve block for controlling hydraulic lifts. The

iValve is situated on the hydraulic power unit and activated

by the lift control system. Electronic control is accomplished

by an electronic unit – the iCon – that is housed in the control

cabinet. At standstill, the weight of the lift is supported by a

check valve integrated in the iValve. In operation, the elec­

tronic controller regulates the states “Travel UP” and “Travel

DOWN”, and the transitions between these states. In the

electronic unit, the travel is represented in a form known as

travel curves. During operation, the travel curves for that

particular lift are optimised by the learning algorithm

“iTeach”. In addition, the valve block includes the following

functions and components: a hand pump with manual

emergency lowering (with piston-creep prevention), a ball

valve, a pressure gauge, a pressure sensor with up to two

pressure switches, speed monitoring, a temperature

sensor, an emergency stop DOWN valve (UCM/A3) in ac­

cordance with EN 81-2 + A3.

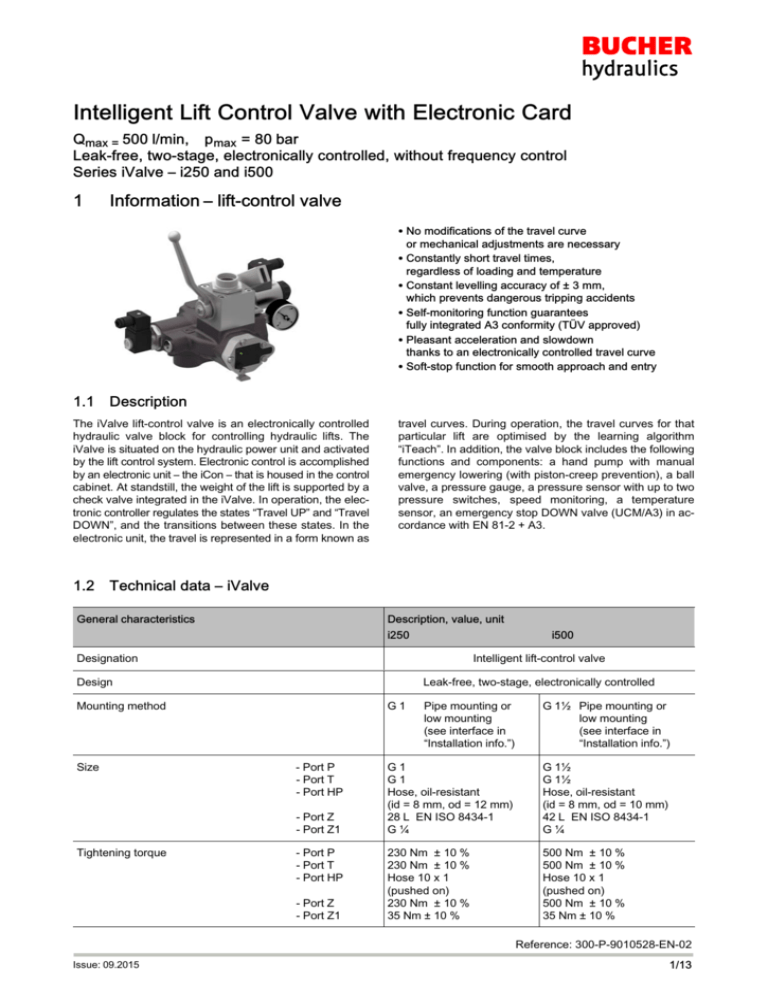

1.2 Technical data – iValve

General characteristics

Description, value, unit

i250

Designation

Intelligent lift-control valve

Design

Leak-free, two-stage, electronically controlled

Mounting method

Size

G1

- Port P

- Port T

- Port HP

- Port Z

- Port Z1

Tightening torque

i500

- Port P

- Port T

- Port HP

- Port Z

- Port Z1

Pipe mounting or

low mounting

(see interface in

“Installation info.”)

G1½ Pipe mounting or

low mounting

(see interface in

“Installation info.”)

G1

G1

Hose, oil-resistant

(id = 8 mm, od = 12 mm)

28L EN ISO 8434-1

G¼

G1½

G1½

Hose, oil-resistant

(id = 8 mm, od = 10 mm)

42L EN ISO 8434-1

G¼

230 Nm ± 10%

230 Nm ± 10%

Hose 10 x 1

(pushed on)

230 Nm ± 10%

35Nm±10%

500 Nm ± 10%

500 Nm ± 10%

Hose 10 x 1

(pushed on)

500 Nm ± 10%

35Nm±10%

Reference: 300-P-9010528-EN-02

Issue: 09.2015

1/13

General characteristics

Weight

Description, value, unit

i250

10.4 kg

Mounting attitude

22.5 kg

As illustrated – see section “Dimensions”

Ambient temperature range

Hydraulic characteristics

i500

+2°C … +40°C

Description, value, unit

i250

i500

Nominal pressure

80bar

80bar

Maximum flow rate

250l/min

500l/min

Nominal flow rate Down (Z > T)

see section “Performance graphs”

Flow direction

P → T (bypass)

P → Z (UP)

Z → T (DOWN)

Hydraulic fluid

HL and HLP mineral oil to DIN 51 524;

for other fluids, please contact BUCHER

Hydraulic fluid temperature range

Viscosity range

Minimum fluid cleanliness

Cleanliness class to ISO 4406:1999

Electrical characteristics

+0°C … +60°C

20 ... 500mm2/s (cSt)

Class 21/19/16

Description, value, unit

i250

i500

Supply voltage

24VDC

Supply voltage tolerance

±10%

2/13

300-P-9010528-EN-02/09.2015

Series iValve

1.3 Schematic – iValve

Z

3

Z1

C

9

6

P

U

Q

U

T

U

8

A

D

7

4

5

1

300−P−10024709

2

HP

P

T

Item

Description

1

Main spool

2

Pressure relief valve

C

iBox

3

Ball valve

P

Pump

4

Pilot operated check valve

T

Tank

5

Emergency stop DOWN valve (UCM / A3)

6

Piston-creep prevention

Z

Cylinder

7

Hand pump

Z1

Test port

8

Pressure relief valve in the hand pump

9

Pressure gauge

300-P-9010528-EN-02/09.2015

Series iValve

Item

Description

iCon (included in the delivery)

HP

Hand pump

3/13

1.4 Performance graphs

–––

Legend

500 mm2/s (cSt) Motorex Corex HLP 46 at approx. 2°C

_____ 75 mm2/s (cSt) Motorex Corex HLP 46 at approx. 30°C

iValve 250

1.4.1

Δp = f (Q) Pressure drop - Flow rate characteristic [i250/160]

(min. dynamic pressure/flow rate)

Δp = f (Q) Pressure drop - Flow rate characteristic [i250/250]

(min. dynamic pressure/flow rate)

Δ p [bar]

Δ p [bar]

12.5 iValve-250_P01.ai

12.5 iValve-250_P02.ai

10.0

10

Down (Z-T)

Down (Z-T)

7.5

7.5

Up (P-Z)

5.0

5.0

Up (P-Z)

2.5

2.5

0

20

1.4.2

40

80

120

140

160 Q [l/min]

0

160

175

190

205

220

235

250 Q [l/min]

iValve 500

Δp = f (Q) Pressure drop - Flow rate characteristic

(min. dynamic pressure/flow rate)

Δ p [bar]

9

iValve-500_P01.ai

8

7

Down (Z-T)

6

5

4

Up (P-Z)

3

2

1

0

150

4/13

250

350

500 Q [l/min]

300-P-9010528-EN-02/09.2015

Series iValve

1.5 Dimensions, interface iValve – i250

159.3

313

512

312.25

(G1“)

(G1/4“)

72.4

T

HP

(G1“)

67.6

101.6

134.3

B-B

300-4-10022900

P

Z1

95

25

42

3

A-A

52

153.5

187.5

507

Low-mounting connection – see Figure A-A

60

A-A

Pipe-mounting connection – see Figure B-B

60

52

B-B

34

ø44

ø42

T

300-P-9010528-EN-02/09.2015

Series iValve

43

43

HP

34

(17)

109

7

P

71

52

16.5

5/13

1.6 Dimensions, interface iValve – i500

142

(490)

(466)

49

Z

HP

172

(M52x2)

4

A-A

T (G1½)

300-P-10024847-03-B1

75

(G1½) P

B-B

148.75

71

197

Low-mounting connection – see Figure A-A

Pipe-mounting connection – see Figure B-B

93.7

71

71

B-B

100

100

T

HP

HP

300-P-10024847-03-B2

P

74

37

70

A-A

44.5

6/13

300-P-9010528-EN-02/09.2015

Series iValve

1.7 Application examples

S The lift-control valve is an electronically controlled hy­

draulic valve block for controlling hydraulic-powered pas­

senger and goods lifts.

S The lift-control valve is situated on a hydraulic power unit

and activated by a lift control system.

1.8 Model code – iValve

IVALVE

-

250

/

160

Rx.x

IVALVE = Intelligent lift-control valve

500

250

500

250

160

=

=

=

=

=

R1.0

= Release / Design stage

2

Nominal size 500

Nominal size 250

Flow rate 500l/min (nominal size 500)

Flow rate 250l/min (nominal size 250)

Flow rate 160l/min (nominal size 250)

Electronic card for lift-control valve – iCon

S Potential-free switching output for faults

S Two configurable switching outputs

(pressure switch, train speed supervision)

S Functions can be expanded via options board

2.1 Description iCon

The iValve lift-control valve is an electronically controlled

hydraulic valve block for controlling hydraulic lifts. The elec­

tronic control is accomplished by an electronic unit – the

iCon – that is housed in the control cabinet. In operation, the

electronic controller regulates the states “Travel UP” and

“Travel DOWN”, and the transitions between these states.

In the electronic unit, this travel is represented in a form

known as travel curves. During operation, the travel curves

for that particular lift are optimised by the learning algorithm

"iTeach".

300-P-9010528-EN-02/09.2015

Series iValve

The ParamCard is a memory card on which the system-spe­

cific parameters and data are stored. The ParamCard plugs

into the iCon. Without the ParamCard being plugged in, no

lift travel can be carried out.

7/13

2.2 Technical data

General characteristics

Description, value, unit

Designation

iCon

Design

Printed circuit board with 4 layers

Electrical connection

- solenoids

- electronics

3-pin square plug to ISO 4400 / DIN 43650

PCB connector 3.5 / 5 mm (screw terminals)

Plug connector kit available - see the chapter Accessories

Mounting method iCon

15/35 mm cap rail

acc. to EN50035 (G32) or EN 50022 (TS15, TS35)

Mounting method

Option boards

4 spacer studs M4x16 (included in delivery)

Weight

0.20kg

Ambient temperature range

+2°C … +40°C

Relative air humidity

0…90% (without condensation)

Dimensions (overall sizes W x H x D)

112x122x63mm (without options board)

Supply voltage

24VDC

Supply voltage tolerance

±10%

Max. ripple

250 mV pp max. (ripple and noise)

Power consumption at max. control current

50W (i250) – 75 W (i500)

Command inputs

GNDactive/+24Vactive (configurable)

Switching outputs

Potential-free relay contacts

Relative duty cycle

100%

Max. Nominal power consumption at standstill

3W

Relay contact rating:

Min. control current

Max. voltage

Max. power

10 mA / max. 3A

250 VAC

750 VA (AC) / 90W (DC)

Electromagnetic compatibility: interference immunity

EN 12016

Electromagnetic compatibility: interference emission

EN 12015

Protection class to ISO20653 / EN60529

IP 00

8/13

300-P-9010528-EN-02/09.2015

Series iValve

2.3 Block diagram

iCon

Lift control system

(customer`s)

X1

+

24V

DC

1

+24V DC

2

GND

3

PE

ParamCard

X7

K1

6

1

K2

5

2

K3

4

3

K4

3

4

K5

2

5

1

GND

X6

K6

4

6

K7

3

7

K8

2

8

1

GND

+24V

*

**

X8

+24V

2k15

+24V DC

0,7A

17W

+24V

X10

Monitoring

SMA

2

1

i500

i250

+24V DC +24V DC

2.0 A

1.2 A

30W

+SMA (24V DC)

(0.2A)

GND

X5

NR

FR

4

m0-

3

m0+

2

m1-

1

m1+

X2

1

2

3

NR'

FR'

4

5

6

ge

gn

br

ws

7

8

iValve

9

nc

error

no

Switching output

Relay - fault /

SIU

nc

s1

no

Switching output

Relay s1

nc

s2

no

Switching output

Relay s2

iBox

X4

Solenoid

Solenoid

UCM / A3 UP-/DOWN travel

(black plug)

(grey plug)

X3

RS232

Handterminal / PC

*

Configurable via software, GND-active/ +24V-active

(applies to all inputs K1 ... K8)

300-P-9010528-EN-02/09.2015

Series iValve

*

300-P-10024761-02

com/meas

Configurable via software, GND-active/ +24V-active

(applies to all inputs K1 ... K8)

9/13

2.4 Dimensions

2.4.1

Electronic card iCon – basic board

112

min.60

100

~44

122

100

105

~47

11

6

G32 EN 50035

300−P−10024940−00

TS35 EN 50022

106

2.4.2

Electronic card iCon – with options board (2 additional switching outputs)

56.8

70

10

33.8

72

59

8

50

G32 EN 50035

300-P-10024940-00

TS35 EN 50022

10/13

300-P-9010528-EN-02/09.2015

Series iValve

2.5 Pin assignments

iCon electronic card – basic board

X7

X10

X5

X10

X7

X6

1

1

1

X4

X5

X4

1

X8

1

2

3

4

5

6

7

8

GND

GND

1

+SMA

pwr

run

up

down

misc.

X6

GND

X8

−

−

+

m0(9)

+

m1(10)

com/meas

X3

1

X9

X3

card

RS232

2

X9

X1

PE

GND

+24V DC

select

1

errror

error

s1

s2

X2

s1

s2

1

X1

300−P−10024940−00

C011

ok

X2

Item

Description

Item

1

ParamCard

X5

Connector block solenoids

2

Top-hat rail TS15, TS35 (EN50022) or

G-type rail G32 (EN50035)

X6

Connector block command signals K6…K8

X7

Connector block command signals K1…K5

X8

Socket for ParamCard

X9

Socket for options boards

X10

Connector block, SMA

X1

Connector block power supply

X2

Connector block switching outputs

X3

Connection Handterminal / PC

X4

Connection iBox

IMPORTANT!:

Two independent switching outputs are available

on the iCon. For each switching output, a relay (s1

and s2) is available, each with a break/make con­

tact.

300-P-9010528-EN-02/09.2015

Series iValve

Description

IMPORTANT!:

K coding and binary coding are possible.

For other information, please contact BUCHER!

11/13

2.5.1

Options board, switching output

Options board for version with pressure switch

X150

X150

X20

1

X20

S3

X21

300-P-10024940-01

S4

Item

Description

X-20

Connector block, switching outputs

X-21

Not used

12/13

Item

Description

X-150 Socket for options board

300-P-9010528-EN-02/09.2015

Series iValve

2.6 Dummy iCon – optional

2.6.1

Description

The "Dummy iCon" can be pre-installed in the control cabin­

et as a "placeholder" instead of the real iCon (control elec­

tronics for the iValve). It has all the plug connectors that the

iCon has, so that the wiring can also be done in advance

(cable lengths and cable positions).

2.6.2

How customers contact the test system

The central "X11" plug offers an additional benefit. All sig­

nals that are wired from outside to the iCon are available on

this plug. Consequently, the wiring can be checked with an

automatic test system.

2.7 Accessories

PartNo.

Description

3007019906

Dummy iCon

3007010231+

Handterminal including connecting cable

3007020027+

PC software "iWin", including connecting cable

3007020442+

Power supply module i250

3007020476+

Power supply module i500

3007020030+

Plug connector kit

3007010472+

3000008998+

3000009002+

Solenoid connection cable: 1.5 metre

, 6.0 metre

, 12 metre

(for Halogen-free versions, contact Bucher)

3007019644+

3007020460+

3007020461+

iBox connection cable:

3

1.5 metre

6.0 metre

12 metre

Related documents

Reference

Description

300-D-9010542

Planning information iValve

300-I-9010544

Commissioning and maintenance iValve

300-I-9010543

Parametrization and maintenance iValve

300-S-9010437

Spare parts iValve / iCon – i250

300-S-9010548

Spare parts iValve / iCon – i500

info.ch@bucherhydraulics.com

www.bucherhydraulics.com

E 2015 by Bucher Hydraulics AG, CH-6345 Neuheim

All rights reserved.

Data is provided for the purpose of product description only, and must not be construed as warranted characteristics in the legal sense. The

information does not relieve users from the duty of conducting their own evaluations and tests. Because the products are subject to continual

improvement, we reserve the right to amend the product specifications contained in this catalogue.

Classification: 430.330.500..

300-P-9010528-EN-02/09.2015

Series iValve

13/13