the winners of the Emerson STAR Safety Award

advertisement

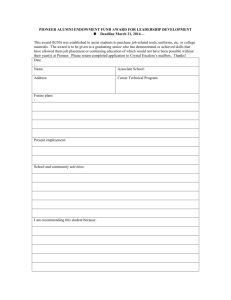

S afety through T eamwork A ccelerates R esults Award E M E R S O N S TAR S AF E T Y AWAR D P R O G R AM 2 0 1 4 The Emerson STAR Safety Award Program recognizes those locations that have achieved working one to five years, according to their man-hour category requirements, with no more than one lost time/restricted case with a total of no more than three total recordables. All locations meeting the award criteria for the first time will receive the Perpetual Safety Award with a faceplate indicating the year of the achievement. For each subsequent year that a location meets the award criteria, a faceplate with the year is awarded. In addition, a qualifying location is eligible for the Emerson STAR Award. ONE STAR AWARD will be given for each man-hour category. The award will be presented to the location by the Emerson Safety & Health Department along with the Business Unit. To qualify for a Perpetual Award a location must meet the following criteria in its respective man-hour category 1100,000 EMERSON INDUSTRIAL A U T O M AT I O N C L E V E L A N D O H I O Qualify the first year with zero recordables Accumulate no more than one lost-time/restricted case with a total of no more than three recordables for the first year plus the next four years for a total of five years 100,001 – 300,000 A P P L E T O N G R O U P – AT X AM IENS FRANCE Qualify the first year with zero lost-time/restricted case and one recordable accident Accumulate no more than one lost time/restricted case with a total of no more than three recordables for the first year plus the next two years for a total of three years 300,001 – 1,000,000 R E G U L AT O R T E C H N O L O G I E S ELK RIVER Accumulate no more than one lost-time/restricted case with a total of no more than three recordables for the current year 1,000,000 EMERSON PROCESS M A N A G E M E N T C H E N N A I LT D F I S H E R V A LV E S Accumulate no more than one lost-time/restricted case with a total of no more than three recordables for the current year EMERSON INDUSTRIAL AUTOMATION CLEVELAND OHIO S afety through T eamwork A ccelerates R esults Award E M E R S O N S TAR S AF E T Y AWAR D P R O G R AM 2 0 1 4 Emerson Industrial Automation, Cleveland Ohio Automation Center was commissioned in 1996, building integrated AC and DC Drive Systems for the industrial market. In 2010, the Cleveland Automation Center expanded its operations to include larger, more complex automation systems and moved to its existing location in Valley View, Ohio. The move to the new facility opened a new chapter in the implementation of a comprehensive safety program. As the new building was planned, safety systems and policies were improved and/or implemented to ensure a safe working environment and to foster a safety culture. Under the direction of our business unit Health and Safety Director, all aspects of the manufacturing process were reviewed and modified based on job assessments. The assessments review each role and the requirements to perform the job safely. This drove the implementation of proper Personal Protective Equipment procedures and equipment throughout the facility. For example, metal working and drilling practices were modified and PPE requirements were reviewed. An Arc Flash incident energy study was conducted and the proper gear was implemented for testing and verification of product. Test floor employees were given new power-on procedures to ensure the safety of the test technician and other Manhour Category: 1-100,000 employees. In addition, emergency response drills and a first responder team were implemented. Evacuation paths, emergency lighting and communications to local emergency services were improved. A safety committee was created and safety audits began, encouraging employee involvement in the safety process and culture. Local programs for safety shoes and safety glasses were implemented. All new warehouse racking was installed to ensure proper rack interlocking and guarding. Continuous employee safety training is also a part of the automation centers culture. The Automation Center has implemented weekly Toolbox safety meetings, quarterly departmental safety training, and ongoing online training specific to the employee’s role. Emerson Industrial Automation, Cleveland Ohio Automation Center continues to foster a safety culture and improve workplace safety with the overall goal of providing a safe work environment for all employees. APPLETON GROUP - ATX AMIENS FRANCE S afety through T eamwork A ccelerates R esults Award E M E R S O N S TAR S AF E T Y AWAR D P R O G R AM 2 0 1 4 Appleton Group is a global manufacturer of industrial electrical products for explosion proof, hazardous and ordinary location environments with some of the most well known brands in the industry, including Appleton, ATX, EasyHeat, Nelson, O-Z/Gedney, SOLA/Hevi-Duty. Over 100 years of combined market leadership with more than 24,000 products and Industry-leading enclosures, controls, receptacles and other equipment for hazardous locations. Safety is important to Appleton Group as we believe that our people are our greatest resource. Accidents cause human suffering, property damage, reduced efficiency, and morale problems. Accidents decrease Company profits directly through increased medical, compensation and insurance costs, and indirectly through lost productivity and absenteeism. Management has to provide equipment that meet appropriate safety standards. Our goals are to have every employee actively support our safety efforts, comply with all established rules and procedures, participate in safety-related activities and programs. Since July 2008, the facility has implemented more than 500 actions in Manhour Category: 100,001-300,000 order to prevent accidents and lost time. The HSE Committee has mandatory quarterly meetings with management. Supervisors have daily round tour factory trip and communication with employees on Safety. Site regularly implements Safety & Health assessment. Last October 2014, employees celebrated six years safety at Samara, a Mecca of Prehistory in France. It was created by the General Council of the Somme, around prehistoric remains unearthed during excavations in the heart of the Valley of the Somme known to have played a key role in the birth of prehistory as an object of scientific study. The park offers all visitors a place to discover gestures and techniques of our prehistoric ancestors, such as Appleton Group – ATX offers its customers techniques by using safety gestures. REGULATOR TECHNOLOGIES ELK RIVER S afety through T eamwork A ccelerates R esults Award E M E R S O N S TAR S AF E T Y AWAR D P R O G R AM 2 0 1 4 At Tescom we specialize in high pressure gas regulators and are part of the Regulator Technologies Division within Emerson Process Management. We’ve been in business since 1916 and were acquired by Emerson in 2005. Our design and manufacturing facility in Elk River, MN specializes in engineered solutions for standard and custom pressure regulators, valves, manifolds, and systems for a wide array of industrial markets in addition to semiconductor industries. We currently utilize many manufacturing processes, including CNC machining, Metal Finishing, Assembly/Test, Laser Marking, and much more. our Central Health and Safety Committee which consists of eight safety sub committees: 1) Audits and Inspection, 2) Housekeeping, 3) Rules & Procedures, 4) Training, 5) Ergonomics, 6) Fire & Emergency, 7) Incident Investigation, 8) Pressurized Systems. Each team is a combination of production, lab, office, and management employees. The teams are lead by a member of the site leadership. These teams work together and execute all of our safety & health goals and objectives. A special note of appreciation goes out to all the Team members for their commitment to work in a safe manner for themselves and for their co workers. Safety is a core business value and we’re committed to providing a safe work environment. Providing a safe work environment protects our most valuable asset, the employee, from injury and illness. We believe industrial injuries and illnesses and property loss through incidents are needless, costly and most importantly…preventable. All business activities are conducted in a manner that protects the health and safety of our employees. Susan Hughes, VP & General Manager states: “We believe that fostering a safe environment stems from the proactive involvement of all of our employees. We have a number of different safety teams that focus on different aspects of safety from ergonomics to incident investigation. These teams are just one aspect of how we pursue improvement opportunities. There is nothing more important than providing a safe environment. Our employees and their families count on it.” In the past 3 years, we have had only three OSHA recordable incidents. During that time, we went nearly 900 days without a loss time injury. We have dedicated significant amount of resources to providing safe working conditions for all employees. Many of our resources take an active role with We continue to strive for an injury free workplace with the active involvement of all employees at the site and constantly pursue continuous improvement towards our Safety Journey. At the end of the day, we want everyone to go home to their families the same way they came to work. Manhour Category: 300,001-1,000,000 EMERSON PROCESS MANAGEMENT CHENNAI LIMITED FISHER VALVES S afety through T eamwork A ccelerates R esults Award E M E R S O N S TAR S AF E T Y AWAR D P R O G R AM 2 0 1 4 Fisher commenced manufacturing in India in 1995 as part of a joint venture with the Sanmar group and became fully owned by Emerson in 2011. The organization since then has evolved to become an important location for the global Fisher manufacturing. It witnessed a sales of $35M in 2014 representing a CAGR of 11% from 2011. A brief on the plant’s safety history is as follows: In the first year, the site was audited by FM global and rated “C”. The site worked meticulously to implement the recommendations and upgraded the rating to “B+”. In the second year during the Environmental audit, the site scored a good score, subsequently followed by successful instances of corporate safety audit in July 2014 and OPEX audit in October 2014. It is notable that the site scored outstanding ratings in both the audits. In the 2012-2014 periods, TRR reduced from 2.63 to .38 primarily owing to total employee involvement and continued commitment from the top management. The facility continues to implement plant wide improvements, focusing upon safety and productivity. Manhour Category: 1,000,000 We take this opportunity to thank the evaluating team for recognizing and motivating us through this award. The recognition will boost the site’s morale and will propel the site to work even harder to inject this even deeper into its culture and work habits.