BK 80 deutsch (Page 2)

advertisement

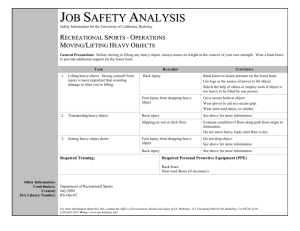

Chain Slings – Grade 80 – INTER LINE S SYSTEM Edition 06 The passion of chain manufacturing! The round steel chain link production in Unterkochen has been running for about 130 years. Producing chains for lifting, lashing, conveying, tire protection as well as snow and off-road chains. Our headquarters and manufacturing plant is one of the most modern chain producing companies world wide. Developed from a small chain forging company by the river Kocher, the RUD group has stood to the test of time to become a global player with approximately 800 motivated employees, subsidiaries and sales representatives around the world. Innovation and quality take first priority at RUD. We are always leading in decisive developments. Examples in the lifting and lashing chains field: LIFTING MEANS 50 80 1967: 1. Approval of quality class 5, H1-5 by the Berufsgenossenschaft (*employers liability insurance association). 1972: First chain factory to gain approval for the quality class 8, H1-8 by the BG* Technical Committee ”Steel and Metal“. The first idea of a mecano system from RUD – foolproof connection of the correct chains and components, as well as suspension links. This idea became the standard at Ruhrkohle RAG (coal board mining). 1981: The first series of lifting points type RBS and RBG with a design factor 4:1 in any direction. 1992: First chain factory to obtain certification for their quality assurance system acc. to DIN/ISO 9001. 1994: First chain factory to obtain approval of the BG for their VIP-special quality with up to 50% higher WLL than Grade 8. 2002: The first universal lifting point – called PPS. 2 Almost 500 national and international protective clauses are the evidence for our progress. The well established brand name RUD stands for quality, technical innovation and know how. Continuous research and development has enabled us not only to produce products meeting the highest expectations but also with consistent quality standards. Experience, diligence, ambition and passion are the virtues we manifest in order to remain favourite for our customers. With the above virtues in mind, RUD has successfuly entered a new century with the trust and satisfaction of our customers as our prime objective for the future. What are tomorrow`s concepts? This is one of the The quality assurance sysquestions which RUD is trytem, certified at RUD in December 1992 by the TÜV- ing to address while facing the challenge of consistently South West, according to DIN/ISO 9001, was an impor- providing the best solutions tant contribution in order to to our customers. meet these requirements and extends once more the quality requirements with regard to the quality assurance system used by the 8 10 company RUD during the past 10 years according to Tested by the BG (Employers‘ Liability AQAP 4. Insurance Association) Iron and Metal Technical Commitee Norddeutsche Eisen- und Stahl-Berufsgenossenschaft (North German Iron and Steel Employers‘ Liability Insurance Association) Tested by the BG: BG vehicle keeping Hamburg TÜV (Technical Monitoring Association) tested. TÜV Rhineland. Clevis System LIFTING MEANS RUD load pins of quality class10 can be mounted in RUD grade 80 components with a stepped borehole. The dimensional coordination of the RUD clevis system ensures non-interchangeable, inevitable assignment of the correct RUD chain gauge. Q The BG specifies: Universal system 1.) Chain suspensions of quality class 10 must not be used with chains and components from other manufacturers of quality class 10. 2.) Suspensions of quality class 8 must not be combined with components that identifiably belong to quality class 10. In brief: It is forbidden to mix quality classes 8 and 10. ET round steel chain corresponds to EN 818-2, quality class 8 During assembly and repair, particular attention must be paid to ensuring that chains and components are of the correct matching dimensions. Identification and loading capacity tags must be attached separately. Surface: magic black. Use VIP chains quality class 10 for higher working loading capacities. Nominal thickness d x t (mm) 6 x 18 7 x 21 8 x 24 10 x 30 13 x 39 16 x 48 Load-bearing capacity t 1,12 1,5 2,0 3,15 5,3 8,0 Weight kg/m Order no.: 0,8 1,1 1,4 2,2 3,7 5,7 0062495 0062496 0062497 0062498 0062499 0062500 Breaking elongation, magic black, at least 20%. Ratio of load stress to production test stress to breaking stress = 1 : 2.5 : 4 (200 : 500 : 800 N/mm2). = mark on fully assembled chain suspensions. = mark confirms that the technical requirements of the European EU Directives have been fulfilled. Please comply with the following regulations without fail: EN 818/EN 1677/ BGR 500,2.8 – BetrSichV (Operational Safety Regulations). We accept no liability for damage arising from disregard of the standards and regulations stated in the above instructions. 3 1 strand LIFTING MEANS 2 strand  3 and 4 strand  Loading capacity table in kg For single and multistrand sling chains at various angles of inclination and symmetrical loading of the strands according to EN 818-4. n Now i s s a l yc qualit 10-VIP 16 20 22 Inclination- Load factor 4 Chain diam. (quality class 10-VIP only) 6 7 8 10 13 16 18 22 26 0° 0–45° 45–60° 0–45° 45–60° 1 (630) 1120 1500 2000 3150 5300 8000 10000 16000 20000 1,4 (880) 1600 2100 2800 4250 7500 11200 14000 22400 28000 1 (630) 1120 1500 2000 3150 5300 8000 10000 16000 20000 2,1 (1320) 2360 3150 4250 6700 11200 17000 21200 33600 42000 1,5 (950) 1700 2250 3000 4750 8000 11800 15000 25600 30000 Ask for a VIP brochure or look under www.rud.com! Warning! With an asymmetrical load, the loading capacity is only 50% of the stated value. Endless chain (basket) Choke hitch   n Now i s s y cla qualit 10-VIP 16 20 22 Inclination- Load factor 4 Chain diam. (quality class 10-VIP only) 6 7 8 10 13 16 18 22 26 0–45° 1,1 (550) 1230 1650 2200 3600 5700 9000 11200 17600 22000 45–60° 0,8 (400) 900 1200 1600 2600 4000 6400 8000 12800 16000 0–45° 1,7 (850) 1900 2550 3400 5400 8500 13600 17000 27200 34000 45–60° 1,2 (600) 1350 1800 2400 3800 6000 9500 12000 19200 24000 0° 0,8 (400) 900 1200 1600 2600 4000 6400 8000 12800 16000 0–45° 1,1 (550) 1230 1650 2200 3600 5700 9000 11200 17600 22000 45–60° 0,8 (400) 900 1200 1600 2600 4000 6400 8000 12800 16000 Warning! With an asymmetrical load, the loading capacity is only 50% of the stated value. Temperature °C 4 The authorized loading capacity must be reduced if sling chains are used at temperatures above 200°. Loading capacity in % at chain temperatures of –40 to + 200° C over 200 to 300 °C over 300 to 400 °C 100 % 90 % 75 % BK1 suspension head with welded in, all-round moveable ring fork – RG –, giving constrained connection for chain diameter and number of strands. Complete identification tag with loading capacity information. Connection bolt and locking pin are pre-assembled. Also available as last link (B 1–) (without identification tag). C T For hoist hooks Name BK 1 – 6 (B1-6) BK 1 – 8 (B1-8) BK 1 – 10 (B1-10) BK 1 – 13 (B1-13) BK 1 – 16 (B1-16) A 13 16 18 22 26 B 25 34 40 50 65 Suspension head 1 strand BK 1 C 54 70 85 115 140 T 82 107 131 174 211 kg/item. 0,5 0,7 1,1 2,0 3,3 Order. no. 50 552 (50 608) 50 556 (50 609) 50 560 (50 610) 50 564 (50 611) 50 568 (50 612) Suspension head 1 strand AK 1 Suspension head AK 1 can be used up to crane hook no. DIN 15401. 6– no. 2,5 10– no. 5 16– no. 8 Size 8– no. 2,5 Size 13– no. 6 C Size Size Size A B for standard crane hooks T AK1 suspension head with welded in, all-round moveable ring fork – RG –, giving constrained connection for chain diameter and number of strands. Complete identification tag with loading capacity information. Connection bolt and locking pin are pre-assembled. B LIFTING MEANS Dimensions correspond to link form B according to DIN 5688. Adequate for hooking into small load hooks on lifting equipment. Chain Load. capacity t 6 1,12 8 2,0 10 3,15 13 5,3 16 8,0 A Also available as last link (A 1–) (without identification tag). Dimensions correspond to suspension link form A according to DIN 5688. Chain Load. capacity t 6 1,12 8 2,0 10 3,15 13 5,3 16 8,0 Name AK 1 – 6 (A1-6) AK 1 – 8 (A1-8) AK 1 – 10 (A1-10) AK 1 – 13 (A1-13) AK 1 – 16 (A1-16) A 13 16 18 22 26 B 60 60 75 90 100 C 110 110 135 160 180 T 138 147 181 218 250 kg/item. 0,6 0,9 1,4 2,4 3,7 Order. no. 50 469 (50 617) 50 473 (50 618) 50 477 (50 619) 50 481 (50 620) 50 485 (50 612) SAK 1 – 140/190/250 SAK 2 – 140/190/250 SAK 3/4 – 140/190/250 Special suspension heads SAK T For dimensions, see VIP catalog edition 16. C On request. 5 B T C A BK 2 suspension head with 2 welded in, all-round moveable ring forks – RG –, giving constrained connection for chain diameter and number of strands. Complete identification tag with loading capacity information. Connection bolt and locking pin are pre-assembled. LIFTING MEANS Suspension head 2 strand BK 2 Adequate for small hoist hooks. Dimensions correspond to link form B according to DIN 5688. Chain 6 8 10 13 16 A Name BK 2 – 6 BK 2 – 8 BK 2 – 10 BK 2 – 13 BK 2 – 16 A 13 16 18 22 26 B 25 34 40 50 65 C 54 70 85 115 140 AK 2 suspension head with 2 welded in, all-round moveable ring forks – RG –, giving constrained connection for chain diameter and number of strands. Complete identification tag with loading capacity information. Connection bolt and locking pin are pre-assembled. B T C Suspension head 2 strand AK 2 Load. capacity t 1,6/1,12 2,8/2,0 4,25/3,15 7,5/3,5 11,2/8,0 for standard crane hooks T 82 107 131 174 211 kg/item. 0,5 0,9 1,4 2,7 4,4 Order. no. 50 553 50 557 50 561 50 565 50 569 Can be used up to crane hook no. DIN 15401. Size Size Size Size Size 6– 8– 10– 13– 16– no. 2,5 no. 5 no. 6 no. 8 no. 10 Dimensions correspond to suspension link form A according to DIN 5688. Chain 6 8 10 13 16 Load. capacity t 1,6/ 1,15 2,8/ 2,0 4,25/3,15 7,5/ 5,3 11,2/ 8,0 Suspension head 4 strand AK 4 Name AK 2 – 6 AK 2 – 8 AK 2 – 10 AK 2 – 13 AK 2 – 16 A 13 18 22 26 32 B 60 75 90 100 110 C 110 135 160 180 200 A B kg/item.. 0,74 1,4 2,3 3,9 6,6 Order. no. 50 470 50 474 50 478 50 482 50 486 Can be used up to crane hook no. according to DIN 15401. Size Size Size Size Size T C AK 4 strand suspension head – technical description as for AK 2, but with 4 ring forks. T 138 172 206 238 270 6– 8– 10– 13– 16– no. 5 no. 6 no. 8 no.10 no. 16 nsion suspeAK 3, d n a r 3 st s AK 3-S as 4 head rder no. n io o a s me nd suspensate stra No separ d. . n heads for 3 stra e storag Chain 6 8 10 13 16 6 Load. capacity t 2,63/1,7 4,2/3,0 6,7/4,75 11,2/8,0 17,0/11,8 Name AK 4 – 6 AK 4 – 8 AK 4 – 10 AK 4 – 13 AK 4 – 16 A 18 22 26 32 36 B 75 90 100 110 140 C 135 160 180 200 260 T 217 268 311 373 470 kg/item. 1,6 3,0 4,9 8,9 14,8 Order. no. 50 472 50 476 50 480 50 484 50 488 For ET sling chains, design corresponds to EN 1677-4, quality class 8. For connection lock (VS) assembly, without identification tag – order separately. Chain mm 6 7 8 10 13 16 Bezeichnung ET-AKO ET-AKO ET-AKO ET-AKO ET-AKO ET-AKO 1–6 1–7 1–8 1–10 1–13 1–16 Load. capacity t 1,12 1,5 2,0 3,15 5,3 8,0 d 13 13 16 18 22 26 Dimensions mm b 60 60 60 75 90 100 LIFTING MEANS t 110 110 110 135 160 180 Weight kg/item 0,36 0,36 0,55 0,82 1,52 2,32 Order. no. 7985066 7985066 7985067 7985068 7985069 7985070 ET suspension link 2 strand For ET sling chains, design corresponds to EN 1677-4, quality class 8. For connection lock (VS) assembly, without identification tag – order separately. Chain mm 6 7 8 10 13 16 Name ET-AKO ET-AKO ET-AKO ET-AKO ET-AKO ET-AKO 2–6 2–7 2–8 2–10 2–13 2–16 Load. capacity t b = 0–45° b = 45–60° 1,6 1,12 2,1 1,5 2,8 2,0 4,25 3,15 7,5 5,3 11,2 8,0 d 13 16 18 22 26 32 Dimensions mm b 60 60 75 90 100 110 Weight t kg/item. 110 0,36 110 0,55 135 0,82 160 1,52 180 2,32 200 3,92 Order. no. 7985066 7985067 7985068 7985069 7985070 7985071 ET suspension link 3/4 strand For ET sling chains, design corresponding to EN 1677-4 quality class 8. For connection lock (VS) assembly, without identification tag, order separately. Chain mm 6 7 8 10 13 16 Name Load. capacity t b = 0–45° b = 45–60° ET-AKO 3/4–6 2,36 1,70 ET-AKO 3/4–7 3,15 2,25 ET-AKO 3/4–8 4,25 3,0 ET-AKO 3/4–10 6,7 4,75 ET-AKO 3/4–13 11,2 8,0 ET-AKO 3/4–16 17,0 11,8 d 18 18 22 26 32 36 Dimensions mm b 75 75 90 100 110 140 ET suspension link 1 strand Weight t kg/item. 190 1,2 190 1,2 230 2,26 265 3,42 315 60,4 400 10,02 Order. no. 7985072 7985072 7985073 7985074 7985075 7985076 7 For ET sling chains, design corresponds to EN 1677-4, quality class 8. A For connection lock (VS) assembly, without identification tag, order separately. 190 LIFTING MEANS ET special suspension link 1/2 strand …with 190 mm internal width ET special suspension link 3/4 strand B Chain mm 6 7 8 10 13 16 Name Load. capacity t b = 0–45° b = 45–60° ET-SAKO 1/2–6 1,6 1,12 ET-SAKO 1/2–7 2,1 1,5 ET-SAKO 1/2–8 2,8 2,0 ET-SAKO 1/2–10 4,25 3,15 ET-SAKO 1/2–13 7,5 5,3 ET-SAKO 1/2–16 11,2 8,0 Dimensions mm A B 22x300x190 13x54x25 22x300x190 13x54x25 26x300x190 16x70x34 32x300x190 18x85x40 32x300x190 22x115x50 36x300x190 26x140x65 Weight kg/item. 3,0 3,0 4,5 6,8 7,8 11,0 Order. no. Weight kg/item. 3,0 3,0 4,5 6,8 11,0 Order. no. 7984154 7984154 7984155 7984156 7984152 7984153 For ET sling chains, design corresponds to EN 1677-4, quality class 8. A For connection lock (VS) assembly, without identification tag, order separately. 190 …with 190 mm internal width B Chain mm 6 7 8 10 13 ET identification tag – Universal – Name Load. capacity t b = 0–45° b = 45–60° ET-SAKO 3/4–6 2,36 1,7 ET-SAKO 3/4–7 3,15 2,25 ET-SAKO 3/4–8 4,25 3,0 ET-SAKO 3/4–10 6,7 4,75 ET-SAKO 3/4–13 11,2 8,0 Dimensions mm A B 22x300x190 13x54x25 22x300x190 13x54x25 26x300x190 16x70x34 32x300x190 18x85x40 36x300x190 26x140x65 7984154 7984154 7984155 7984156 7984153 With single and multistrand symbols, without diameter and loading capacity information, complete with wire rope connection and alu grommet, colored red. Stamps according to loading capacity information, page 4. Symbol layout, see top of page 13. Name ET-KZA 8 Weight kg/item. 0,02 Order. no. 0060587 Replacement pin with securing elementment D ET connection lock T The universal chain connection lock. During assembly, attention must be paid to ensuring that chains and components are of the correct matching dimensions. LIFTING MEANS Universal System (not non-interchangeable) A Chain mm Name Load. capacity t 6 8 10 13 16 ÖH 5/6 ÖH 7/8 ÖH 10 ÖH 13 ÖH 16 Chain mm 6 8 10 13 16 Name AÖH 6 AÖH 8 AÖH 10 AÖH 13 AÖH 16 1,12 2,0 3,15 5,3 8,0 Dimensions mm A B P 87 24 34 102 26 40 122 35 41 154 40 52 185 50 60 Load. capacity t 1,12 2,0 3,1 5,3 8,0 A 114 134 170 210 260 Dimensions mm B C D 15 25 24 21 29 30 28 34 40 32 43 50 40 57 60 ET-VS ET-VS ET-VS ET-VS ET-VS ET-VS ET-VS ET-VS 5/6 8 10 13 16 18 22 26 1,12 2,0 3,15 5,30 8,0 10,0 15,0 21,2 Weight kg/item. Order. no. 0,26 0,54 0,97 1,75 2,8 7982773 7982775 7982777 7982779 7982781 P 33 43 47 61 78 Dimensions mm A D T 14 7 40 18 8 56 24 11 68 29 14 88 35 17 104 42 21 122 48 24 146 66 32 180 Weight kg/item. 0,06 0,18 0,3 0,6 1,3 2,2 3,3 5 Order. no. 0,53 0,95 1,90 3,30 7,30 7984536 7984537 7984538 7984539 7984540 0060172 0060173 0060183 0060184 0061256 0061257 0061258 0061766 ÖH eye hooks B Weight kg/item. Order. no. A 7101780 7101782 7101783 7101784 7101785 7101786 7101787 7101820 Load. capacity t W P AÖH automatic eye hooks D A 5/6 8 10 13 16 18 22 26 Name WP C VS-BLZ VS-BLZ VS-BLZ VS-BLZ VS-BLZ VS-BLZ VS-BLZ VS-BLZ Chain mm 6 8 10 13 16 18 22 26 W Order. no. W Name B 9 ....... . . . . . . . . ...... originasl! Theen a mil.li.o.n.t.i.m.e... .. prov ......... Extremely robust design has proven itself a million times. A Forged safety latch slots into tip of hook, protecting it against bending sideways. Triple coiled double leg spring, stainless. T Granit-Super hook GSH Ergonomic design, fingerprotecting actuating hollows. B F LIFTING MEANS Wearing edges on both sides – high bending resistance. D Double composite locking sleeve, easy exchangeable. Completely pre-assembled with load pin and adapter sleeve. C G Safety set order no. 53 133 53 134 53 135 53 136 53 137 AGH automatic fork head hook (with grooved load pin) Chain Load.cap. t 6 1,12 8 2,0 10 3,15 13 5,3 16 8,0 Name GSH – 6 GSH – 8 GSH – 10 GSH – 13 GSH – 16 A 27 38 46 58 67 B 22 28 36 46 56 Chain mm 6 8 10 13 16 B A C 16 20 26 30 36 D 20 28 35 37 49 Load. capacity t 1,12 2,0 3,15 5,3 8,0 F 25 30 35 40 48 Name AGH 6 AGH 8 AGH 10 AGH 13 AGH 16 G 74 98 122 139 164 T 75 97 108 126 152 kg/item. 0,3 0,8 1,4 2,5 4,1 Dimensions mm A B C D P 95 15 25 31 33 117 21 29 41 43 142 28 34 53 47 169 32 43 64 61 219 40 57 78 78 Weight kg/item. 0,53 0,97 2,00 3,40 7,60 Order. no. 53 068 53 069 53 070 53 071 53 072 Order. no. 7984530 7984531 7984532 7984533 7984534 P C Widemouthed hook/foundry hook WH Also known as a foundry or container hook. With a considerably wider mouth than the GSH, but without a securing element. D T E Only use where unintentional unhooking is impossible. Does not comply with EU Machinery Directive 98/37 EEC I/4.4.1. Not suitable for transport above people. B A F Robust cross-section (dimension C/B) to withstand higher bending forces. Wearing edges on both sides protect the mounted chain link. Completely pre-assembled with load pin and adapter sleeve. C Chain Load. cap. t 6 1,12 8 2,0 10 3,15 13 5,3 16 8,0 10 Name WH – 6 WH – 8 WH – 10 WH – 13 WH – 16 A 30 40 46 51 64 B 22 29 37 45 56 C 18 26 30 37 40 D 30 40 50 64 75 E 22 29 36 46 56 F 50 64 76 90 102 T 88 115 130 168 190 kg/item. 0,45 0,90 1,70 3,00 5,70 Order. no. 7101891 7101892 7101818 7101893 7101621 n e! sh o rte Notic ndard for ation: in g sta epar A newnts is in pr ts e e le m 1 6 7 7 - 7 . in g e le m e n n N e E t l r r l p D sh o w it h a A ll R U y c o m p ly d a a lr e e m e n t s . r e q u ir Chain mm 8 10 13 16 Load. capacity t 2,0 3,15 5,3 8,0 Name VH 7/8 VH 10 VH 13 VH 16 P Dimensions mm T P 59 10 74 12 100 15 137 18 Weight kg/item. 0,35 0,80 1,70 4,00 T Order. no. LIFTING MEANS 7982847 7982849 7982851 7982853 VH shortening hook (with grooved load pin) Possibilities for using shortening elements ET-AKO ET-AKO AK1 VS VS BSEK 3 links b O max. 60° VH VH SH GSH O Optimal combination of max. mouth width with the smallest shackle pin. O The turned fork head universal joint makes it very resistant to bending. Chain Load. cap. t 6 1,12 8 2,0 10 3,15 13 5,3 16 8,0 Name V-GSCH 6 V-GSCH 8 V-GSCH 10 V-GSCH 13 V-GSCH 16 A 17 21 27 33 38 H D E T High-tensile, patented design with integrated safety thread in the shackle yoke. The bolt brakket in the shackle is smooth on both sides. The bolt can be turned. There is no bending stress in the thread, it only has a safety function. Pre-assembled with locking sleeve. Secured for long periods by driving-in a locking sleeve. Non-interchangeable fork shackle VGSCH B C A G B 8 10 13 17 22 C 22 26 34 42 49 D 10 12 16 20 24 E 21 32 35 41 49 G 40 48 62 81 95 H 28 39 45 59 69 T 36 48 61 78 96 kg/item. 0,15 0,26 0,65 1,35 2,5 Order. no. 7983526 7983527 7983528 7983529 7983531 11 Shortening claw – V – with flexible self-locking. Rubber safety device can be retrofitted. Chain-protecting recessed seating. No reduction of loading capacity. The shape and the flexible rubber locking device provide a double safeguard against the hooked chain disengaging itself. LIFTING MEANS Handling the shortening claw ! load not Do Shortening claw V (with G-pin) e! Noticstandard Load side Hook in Chain 6 8 10 13 16 Shortening claw BSEK – a better – quicker – simpler – claw When shortening elements are used for transporting loads, in most cases the load is not symmetrical. (This is caused by a non-centred centre of gravity and/or points of attachment at different levels). In such cases, the highest stress occurs in the single strand with the smallest angle of inclination. The loading capacity therefore has to be reduced by 50 %. 12 Name V–6 V–8 V – 10 V – 13 V – 16 B2 A 35 45 57 75 92 B 35 46 59 73 93 Direction of load. Hook out C 25 34 42 55 65 T 39 52 65 85 107 kg/item. 0,2 0,5 1,0 2,0 2,7 Order. no. 50 648 50 650 50 651 50 652 50 653 A further development of the RUD shortening claw V which has proven its worth for decades. Captivefitted in the continuous chain strand. No additional chain or coupling parts needed. Can be fitted on any part of the chain strand. The chain is ideally supported by the link-shaped recessed seating – so there is no reduction of the loading capacity. Conforms to prEN 1677-7. T G The robust, spring mounted securing bolt prevents the hooked chain from disengaging, whether loaded or unloaded. If the BSEK is not permanently fitted, please follow the instruction below. New! Warning! Load. caoacity t 1,12 2 3,15 5,3 8 B1 A Chain Load. capacity t 6 8 10 13 16 1,12 2 3,15 5,3 8,0 1) 2) Name A B1 BSEK – 6 BSEK – 8 BSEK – 10 BSEK – 13 BSEK – 16 38 46 58 74 91 34 41 50 64 79 B2 40 52 64 86 105 T G kg/item. Order. no. 66 88 110 143 176 38 48 60 76 98 0,3 0,55 1,1 2,4 4,4 79 84073 71 02686 71 02687 71 02688 71 01419 Fitting: 1) Pull a loose chain strand through the intersecting slots. Hook the chain into the locking slot at the intended position. The chain strand is now securely fixated in the BSEK claw. Preferably fit the third chain link from the suspension link into the shortening slot. 3) B * Load le A newortening eah p s e r r fo is in p m e n t s: l n r a t io 1 6 7 7 - 7 . A l g N E n i r n p h o rte y R U D s n t s a lr e a d e e le m ly w it h a ll co m p e m e n ts. r e q u ir Handling: 2) With the chain slack, fit the desired link into the recessed seating, pull the chain down while pressing the securing bolt. Release by performing these steps in the reverse order. Warning! 3) When using the BSEK without a retaining pin lokking sleeve, ensure that the chain is always completely hooked into the locking slot (B). When pulling or lifting the shortened chain ensure that the chain is always completely hooked into the locking slot (B). *Do not load a slack, shortened chain. Identification tags, single and multistrand complying with EN 818, including open, bendable link 7 x 21. LIFTING MEANS KZA for single and multistrand chains KZA model without symbols for internal labeling Identification tag KZA Order. no. 60 442 Order. no. 59 384 Test data tag PDA for marking the annual check under BGR 500-2.8. The back is blank for sequential chain number and/or internal labeling. Including open, bendable link 7 x 21. Test data tag PDA PDA test data tag Order. no. 60 228 Edge protection RSK RUD-RSK System Secutex made of hardwearing, robustedged polyurethane. Flexible in all directions, can be slid along the chain by hand. L B ma x A Diagonal cross-chain distributes the load evenly. Max. 2 m available. Chain Name A 6 RSK – 6 27 8 RSK – 8 33 10 RSK – 10 38 13 RSK – 13 50 16 RSK – 16 63 Supplied in 1 and 2 m lengths only. B 27 33 38 50 63 Lmax 2000 2000 2000 2000 2000 Order. no. 56 033 56 037 55 810 56 038 on request RUD testing service Testing = maintaining value! D 30 Chains VISUAL INSPECTION SICHTPRÜFEN S YEAR vi ce RU RECORDING ERFASSEN te sting ser CERTIFICATION BESCHEINIGEN MAINTENANCE INSTANDHALTEN MEASUREMENT MESSEN CRACK TEST RISSPRÜFEN BG R s chain 0,000 cause 0 3 r e Ov d in the teste f safety! o Testing of sling equipment with test certificate under Operational Safety Regulations BGR 500 - EN 818-EN 1677 13 KK – for chains, suspension links, eye link. The loading capacity of the round loop is not reduced. Lightweight design with the lowest height. Simple, practical mounting and dismounting. Tested and stamped: complies with EN 1677. LIFTING MEANS CombiCoupler KK Patent: 3726738 Load. cap. Name T in t 1,12 KK 6–8* 25 2,0 KK 8–8* 39 3,15 KK 10–8 44 5,3 KK 13–8 55 * With convex round sling seating. CombiCoupler adapter KKA A B C D E F 35 40 54 60 25 28 30 37 9 13 15 21 20 24 28 34 60 71 90 107 5,5 8 10 13 A B C D E F Weight in kg 0,15 0,25 0,40 0,80 Part no. 62029 61575 61607 61780 Weight in kg 0,15 0,25 0,45 0,90 Part no. 62030 61576 61608 61781 KKA – for fork head link Non-interchangeable connection of all RUD clevis connectors in combination with chains. A shortening element can be used to change the length of the round loop. Patent: 3726738 Load. cap. in t 1,12 2,0 3,15 5,3 Special hook - special load lifting tackle - special components Name T KKA 6–8 KKA 8–8 KKA 10–8 KKA 13–8 29 38 44 54 35 40 54 60 25 28 30 37 7,2 9,7 12,2 15,7 6 8 10 13 RUD load lifting tackle is manufactured according to the rules of the technology, DIN 5428 and BGR 500. The welding is performed by qualified welders. Weld joints are crack-tested. Supplied with test certificate and load lifting tackle index card for regular testing and user information. Let us know your task specification or briefly state your technical data (e.g. loading capacity, relevant dimensions and function). 14 60 71 90 107 쮿 Chain suspensions must be tested by an expert at least once every year. Tests may be necessary at shorter intervals, depending on the operational conditions. Chains must be subjected to a special test to ensure that they are crack-free at least every three years. Chains must also be tested for cracks if incidents occur which could affect their loading capacity. 쮿 Visual inspection Finding external faults such as bent chain links , twisted or dented links. Examining the condition of the parts and checking that they have been put together correctly, and checking the completeness and effectiveness of the safety devices. 쮿 Checking for wear and elongation. 1. Checking the wear on the diameter dm. 2. 2. Checking that the permanent elongation caused by overloading is not more than 5% of the division of 3 d. 3. 3. Checking the pitch extension by the wear on the nominal thickness. LIFTING MEANS Regular maintenance and checks d + d2 dm = 1 0,9 d 2 쮿 Accessories: Load hooks must be rejected when the mouth width has opened by more than 10 %, or the bottom of the hook has worn by more than 5% or has deep indentations. The same applies to load hooks that have been bent sideways. The maximum permissible wear on the diameter of the G bolt is 10%. When exchanging accessories, always use new connection bolts and securing elements (locking sleeves). 쮿 Documentation in a chain card index: The entries in the chain card index provide information about the user's regular monitoring activities while using hitching chains. It is essential that the user has this verification for the factory inspectorate /Employers' Liability Insurance Association to prove compliance with the industrial safety / accident prevention measures(EU Directives 89/655). 쮿 Only use original RUD spare parts. Only the manufacturer may make a surface treatment. Be aware of the effects of temperature (see table on page 4). Please comply with the following regulations without fail: – Operational Safety Regulations – BGR 500/2.8, EN 818, EN 1677, RUD user information. We accept no liability for damage arising from disregard of these standards, regulations or the above instructions. 15 Lifting points - for bolting Maximum transport weight "G" in "tonnes" with different lifting methods Thread size PP-S (Vario) PowerPoint-Star M 6M150 PP-B (Vario) PowerPoint-B PP-VIP (Vario) PowerPoint-VIP WBG-V Load ring (Vario) VLBG Load ring (Vario) 6,7 10 0,3 0,6 1 1,5 2,5 4 4 8 10 15 20 1 2 0,6 0,9 1,2 2,6 4 7 10 12 2 0° 1,2 3 5 8 13,4 20 0,6 1,2 2 8 10 14 16 20 30 40 2 4 1,2 1,8 2,4 5,2 8 14 20 2 1 90° 0,6 1,5 2,5 4 5 8 0,3 0,6 1 1,5 2,5 4 4 2 3 5 8 5 5 7 7 8 10 15 20 1 0,3 0,45 0,6 1,3 2 3,5 5 (0,4) (0,6) (0,7) (1,5) (2,5) (4) 8 8 10 14 16 20 30 40 2 4 0,6 0,9 1,2 2,6 4 7 10 (8) (12) 3 5 8 10 16 045° 0,8 2,1 3,5 5,6 7,1 11,2 2 4560° 0,6 1,5 2,5 4 5 8 0,3 0,6 1 1,5 2,5 4 4 5 7 8 10 15 20 1 2 0,3 0,4 0,6 1,3 2 3,5 5 asymmetrical 5 (0,8) (1,2) (1,5) (3) 1,2 0,6 1,5 2,5 4 5 8 0,3 0,6 1 1,5 2,5 4 4 5 7 8 10 15 20 1 2 0,3 0,4 0,6 1,3 2 3,5 5 03+4 45° 1,3 3,2 5,3 8,4 10,5 16,8 453+4 60° 0,9 2,2 3,8 6 7,5 12 0,6 1,5 2,5 4 5 8 0,3 0,6 1 1,5 2,5 4 2 0,3 0,4 0,6 1,3 2 3,5 5 M 12 M 16 M 20 M 24 M 30 M 36 M M M M M M M M M M M M M M M 8 10 12 16 20 24 27 30 36 36 42 42 48 16 20 M M M M M M M 8 10 12 16 20 24 30 0,4 0,8 1,4 2,1 3,5 5,6 5,6 7 9,8 11,2 14 21 28 1,4 2,8 (5) 0,4 0,6 0,8 1,8 2,8 4,9 7 M 3 6 (7 1 (1 8 (10 0,6 1,3 2,1 3,1 5,2 8,4 8,4 10,514,716,8 21 31,5 42 2,1 4,2 0,6 0,9 1,2 2,7 4,2 7,3 10,5 0,4 0,9 1,5 2,2 3,7 6 0,4 0,6 0,9 1,9 3 5,2 7,5 6 7,5 10,4 12 15 22,5 30 1,5 3 6 (7 6 (7 12 (15 9 (11 Thread 3+4 3 (6) 2 90° 2 0,6 1,2 2 WBG-V 5 t 4 WBG-V 2 t 2,5 VLBG 20 t 1,5 VLBG 15 t 0,6 VLBG 10 t 1 0° VLBG 8 t M M M M M M M 8 10 12 16 20 24 30 2 4 5 7 8 10 15 20 1 RUD Lifting Points O All parts are either 100% crack detected or proof loaded accord. to EN 1677. O All original bolts from RUD are 100% crack detected. O RUD patented features such as clamping spring (VLBS) for noise reduction and distance lugs for a perfect root pass weld increase the ease of use. O Design factor 4:1 in any direction. O RUD CD-ROM and slide chart “RUD-MULTI-MASTER” facilitate the correct selection of lifting points. O Types VRS, VRM and VLBG have to be adjusted to the load direction. O Low installation height, high dynamic and static strength. 16 WBG-V 3,5 t WBG-V 1,3 t WBG-V 0,6 t WBG-V 0,45 t WBG-V 0,3 t LBG(3) M20 RS 2t LBG(3) M16 RS 1t VLBG 7 t spec. VLBG 0,3 t M M M M M M M M M M M M M M M 8 10 12 16 20 24 27 30 36 36 42 42 48 16 20 VLBG 5 t PP-S 8 t M 36 VLBG 4 t PP-S 5 t M 30 VLBG 4 t PP-S 4 t M 24 VLBG 2,5 t PP-S 2,5 t M 20 VLBG 1,5 t PP-S 1,5 t M 16 VLBG 1 t PP-S 0,63 t VLBG 0,63 t Type M 12 asymmetrical G Thread Number of strands Direction of load inch thread (UNC,...) and special lengths on request 6 (7 M 3 Lifting points - for bolting Maximum transport weight "G" in "tonnes" with different lifting methods Starpoint VRS (Vario) eyebolt M M M M M M M M M M M M M M 8 10 12,512,512,5 16 16 16 25 25 25 35 35 35 35 1 25 25 25 32 32 32 50 50 50 70 70 70 70 33 6 36 8 39 42 48 42-52 56 64 56-85 72-76 80-85 90 90-150 8 10 10 10 15 15 15 25 30 35 35 M M M M M M M M M M M M M M M M M M M M M M M M RBG 3 t VRBG 10 t VRBG 16 t VRBG 30 t VRBG 50 t VRBG 80 t RS M48 RS M42 RS M36 RS M30 RS M24 RS M20 RS M16 RS M14 RS M12 RS M10 RS M8 RS M6 VRS M42 N ew ! VRS M36 VRM M10 VRS M12 VRM M12 VRS M16 VRM M16 VRS M20 VRM M20 VRS M24 VRM M24 VRS M30 VRM M30 VRS M10 VRM M8 VRS M8 WBG 35-spec. WBG 35 t WBG 30 t WBG 25 t WBG 15-spec. WBG 15 t WBG 15 t WBG 10-spec. WBG 10 t WBG 10 t WBG 8- spec. WBG 8 t WBG 6-spec. Starpoint VRM lifting eye nut RBG/VRBG Load ring RS & RM high-tensile eyebolt/lifting eye nut INOXSTAR VRS M48 INOX M12 INOX M16 INOX M20 INOX M24 INOX M30 WBG Load ring 2x 4x 4x 4x 6x 8x 12 M 16 M 20 24 30 14 16 20 24 1 2 4 6 8 12 16 24 32 1,2 2,4 3,6 5,2 - 0,4 0,8 1 1,6 3 4 6 8 12 16 24 32 3 10 16 30 50 80 2 2 4 8 12 16 24 32 48 64 2,4 4,8 7,2 10,4 - 0,8 1,6 2 3,2 6 8 12 16 24 32 48 64 6 20 32 60 100 160 0,4 0,4 0,7 1,5 2,3 3,2 4,5 7 9 12 0,6 1,2 1,8 2,6 - 3 10 16 30 50 80 0,8 0,8 1,5 6 20 32 60 100 160 36 42 48 12 16 20 24 30 6 8 10 12 30 36 42 48 M M M M M M 16 20 30 36 50 (7,5) (10) (10) (12,5)(12,5)(12,5) (18) (18) (18) (30) (35) (40) (40) 12 16 16 20 20 20 30 30 30 50 60 70 70 (15) (20) (20) (25) (25) (25) (36) (36) (36) (60) (70) (80) (80) 8,4 11,211,2 14 14 14 21 21 21 35 42 49 49 0,56 0,56 1 3 4,6 6,4 9 14 18 24 1,2 2,4 3,6 5,2 - 2,1 3,2 4,5 6,3 9,8 12,616,8 0,8 1,7 2,5 3,6 - (10,5) (14) (14) (17,5)(17,5)(17,5)(25,2)(25,2)(25,2) (42) (49) (56) (56) 4,2 14 22,4 42 70 112 6 8 8 10 10 10 15 15 15 25 30 35 35 0,4 0,4 0,7 1,5 6 8 8 10 10 10 15 15 15 25 30 35 35 0,4 0,4 0,7 1,5 2,3 3,2 4,5 7 9 12 0,6 1,2 1,8 2,6 - 12,6 16,8 16,8 21 21 21 31,5 31,5 31,5 52,5 63 73,5 73,5 0,8 0,8 1,5 3,1 4,8 6,7 9,4 14,7 18,9 25 1,3 2,5 3,8 5,5 - 0,6 0,6 1,1 2,2 3,4 4,8 6,7 10,5 13,5 18 0,9 1,8 2,7 3,9 - 10,5 0,4 0,4 0,7 1,5 2,3 3,2 4,5 7 M M M M M M M M M M M M M M M M M M M M M M M M M M M (7,5) (10) (10) (12,5)(12,5)(12,5) (18) (18) (18) (30) (35) (40) (40) (7,5) (10) (10) (12,5)(12,5)(12,5) (18) (18) (18) (30) (35) (40) (40) 2,3 3,2 4,5 7 9 12 0,6 1,2 1,8 2,6 - type For this ion, ns of suspe o use either mend t we recom RS-Starpoint«, the »V n be set which ca ection in the dir werPoint 3 or Po of force, ball bearing! ble with dou 25 3 3 10 16 30 50 80 8 3 10 16 30 50 80 6,3 21 33,6 63 105 168 (15,7) (21) (21) (26,2)(26,2)(26,2) (38) (38) (38) (63) (73,5) (84) (84) 9 12 12 15 15 15 22,5 22,5 22,5 37,5 45 52,5 52,5 4,5 15 24 45 75 120 (11,2) (15) (15) (18,8)(18,8)(18,8) (27) (27) (27) (45) (52,5) (60) (60) 6 8 8 10 10 10 15 15 15 25 30 35 35 9 12 0,6 1,2 1,8 2,6 - 7 3 3 10 16 30 50 80 2x 4x (7,5) (10) (10) (12,5)(12,5)(12,5) (18) (18) (18) (30) (35) (40) (40) M M M M M M M M M M M M M 33 36 39 42 48 42-52 56 64 56-85 72-76 80-85 90 90-150 8 10 12 16 20 24 30 36 42 48 12 16 20 24 30 6 8 10 12 14 16 20 24 30 36 42 48 4x 4x 6x 8x M M M M M M 16 20 30 36 50 CD-ROM for the calculation and selection of the correct lifting point. We provide you with the geometric datas for your design. New: 3D CAD datas. www.rud.com 17 Weld seam G Direction of load Number of strands WPP 8 t WPP 5 t WPP 2,5 t WPP 1,5 t WPP 0,63 t 0,6 1,5 2,5 4 3+4 3,5 4,5 5 8 HV HV HV HV 3+5 3+6 3+8 3+10 8 0,6 1,5 2,5 4 HV HV HV HV 4,5 3+4,5 3+5 3+8 3+10 3,5 5 2,25 0,9 2,2 3,8 6 7,5 12 0,9 2,2 3,8 6 7,5 12 4560° HV 5+3 1,5 HV 8+3 4 6 10 16 24 16 HV HV HV 12+4 16+4 25+6 6,7 10,1 15 10 16 3+4 6,7 10 3,15 8,4 14,1 21 33,6 4 6,7 1,3 3,2 5,3 8,4 10,5 16,8 1,3 3,2 5,3 8,4 10,5 16,8 1,5 4 045° 8 1,5 3+4 5 8 0,6 1,5 2,5 4 8 5 5 8 0,6 1,5 2,5 4 0,6 1,5 2,5 4 32 2 13,4 20 5 8 16 2,1 5,6 9,38 14 22,4 3 10 0,6 1,5 2,5 4 10 16 6,7 32 4560° 8 4 13,4 20 16 2 5 1,5 8 10 0,8 2,1 3,5 5,6 7,1 11,2 0,8 2,1 3,5 5,6 7,1 11,2 10 16 1,2 3 8 3 6,7 VLBS 6,7 t 045° 8 5 8 13,4 20 8 0,6 1,5 2,5 4 5 VLBS 4 t 4 VLBS 10 t 2 5 1,2 3 2 90° 5 8 13,4 20 1,2 3 0,6 1,5 2,5 4 5 1 90° Type 1,2 3 1,5 WPPH 0,63 t 0,6 1,5 2,5 4 6,7 10 0,6 1,5 2,5 4 6,7 10 WPP 4 t 2 0° 1 0° WPPH 1,5 t all variants WPPH 2,5 t all variants WPPH 4 t New! LBS(1) RS 0,5 t LBS(3) RS 1 t 2 1 2 1 4 2 4 2 LBS(5) RS 2 t 1 1 2 2 HV 5+3 0,5 HV 8+3 1 0,75 1,5 HV 12+4 2 3 1,05 2,1 4,2 0,5 0,5 0,7 1,4 2,8 1 0,5 1 0,5 VRBS 4 t VRBS 6,7 t 10 VRBS 10 t 10 13,4 20 6,7 13,4 20 6,7 VRBS 16 t 32 16 32 16 6,7 6,7 10 10 16 16 50 30 30 50 50 70 60 100 30 HV 4+3 4 6 10 16 24 30 45 50 75 HV HV HV HV HV 5,5+3 8,5+4 8,5+4 15+4 25+8 6,7 10,1 15 8,4 14,1 21 33,6 63 105 4 4 50 VRBS 50 t 60 100 30 VRBS 30 t 5,6 9,38 14 22,4 42 8 4 8 4 New! New! 16 32 20 10 13,4 6,7 13,4 20 10 10 6,7 6,7 10 HV 5,5+3 HV 6+4 HV 8,5+4 HV 4+3 4 16 10 6,7 HV 5+3 6,7 HV 8+3 10 10,1 15 6 24 10 10 10,1 15 6,7 6,7 14 13,4 20 6,7 8,4 14,1 21 4 4 10 13,4 20 6,7 5,6 9,38 8 4 8 4 New! 14,1 21 33,6 16 16 14 22,4 9,38 32 16 10 6,7 VRBK 4 t VRBK VRBK Load for ringedges eye block for edges VRBK 6,7t VRBSS Loadblock ring eye with adjustment lock VRBSS 6,7 t VRBS VRBS Loadweldable ring eye block weldable VRBSS 16 t VRBSS 10 t VLBS VLBS load Load blockring weldable weldable VLBS 16 t asymmetrical VRBK 10t WPP series PowerPoint fixed rigid WPPH 5 t WPPH 8 t Ⱔ Ⱔ asymmetrical Weld seam G Number of strands 3+4 3+4 3+4 2 2 2 4560° 045° 2 90° 1 90° 2 0° 1 0° Direction of load 4560° 045° asymmetrical VLBS 1,5 t Ⱔ Ⱔ 18 asymmetrical WPP series PowerPoint swivelling Lifting points - for welding - Maximum transport weight "G" in "tonnes" with different lifting methods A nut r RUD-An fü ung nleit en fü r sich an ere H dhab ung u ermei nd V dung vo äh n Gef gen. 8 sse tekla ...Gü 10 sse tekla ...Gü ke8tt – hlag se teklas Ansc – Gü rrm d Zu - un 10 – hlag– Güteklasse Ansc n rdun en ittel Tragfähi »t« gkeit in Loading capacity poster t 1 1,5 6,0 4,0 10 15 30 tr an g 2-S ® 4 6 1,5 8 2,5 9,5 14 13 6,7 16 10 16 3-4 Ne un sym 22 20 -Str igu n VIP quality class 10 and quality class 8. 20 28 ° tu ng :B ei 420 x 625 mm. 10 4,0 22,4 tra ng 45 .2006 3/2.11 Ø t 0,6 42 Ach lisch – eng 100966 Gü-M-7 log – 3,5 5,6 21 33 ,6 45 ° 2,1 5,3 8,4 14 -S ¨ 0,9 3,2 6,7 10 16 3-4 60 ° t 1,3 2,5 20 RUD order no. 7991453 ms yste ng –S i h s 0 a 1 nd L l Grade ng a – Specia Lifti 24 du en nw iA Be AU GEBR BAU TEN ett nzk Kra 3,8 n 06 Editio , 7 EG , L 98/3chtlinie 77. ri EG-R 16 tlinie tzungs818, EN EN enrich Benu N n 16 ATIO chin tsmittel R 500, Editio MENT BG ei d Mas l / DOKU rb en ge NG Re ALTUR EG-A rech ANDH Ensp echend haftliche INSTREPARATU sc pr TION/ Ents nossen SPEK UNG IN fsge PRÜF Beru CH KAS ls ra e Ketten od g Prüfen von eilen an rg und Bauthend nü entsprec Sch EN 818 im BGR 500 ng 2,3 Güteklas 10 ata t/RUD-K diaScrip 19 Me TS 443 n! re zie du re n zu hlagkette % en Ansc 20 rsträngig winkeln nge und meh ungs um von ein-chiedenen Neig stung der Strä it ke bei vers metrischer Bela hig bei sym fä ag t Tr RUDdie mittel t hlag 0,6 Ansc t se 10 e is R INTEE LIN EMS SYST AHL/ AUSW EM SYST ! o tic e n g n stru ci n r Wa e in o r w th f Follomanual sling t io n e le v a n t th e r s! c h a in ...in preparation! 90 x 120 mm. The chain thickness is select according to the weight of the load, taking into account the measured inclination angle, quality class 10-VIP and quality class 8. an g gs- met risc  he r Be Kette mm 45° lastu ¨ 0° ng = Trag te schlagpunkßbar RUD-An bar/schwei schraub 2-Stra ng 1Strang fähi gkeit nur 5 0% des angegebenen 0° Wertes! Ø RUD order no. 7101019 com www.rud. Quality class 10-VIP modular system – the best in the long run. Ne 3D Cw! A D a ta D LIFTING MEANS ® EANS NG M LIFTI .06/MS /BA/09 100966 Gü-M/7 Subject hnical to tec tions. alterna RUD order no. 7104459. Edit ion 16 Please ask for the special VIP sling chains brochure. Mit freundlicher Genehmigung der MAN TURBO AG. ® Quality class 10-VIP lashing chains have 30% more lashing strength LC than quality class 8 LIFTING MEANS – you won't find a better one – 90° 90° 80° 80° 80° 70° 90° ␣ ␣ 90° 60° 50°45° ° 40 80° 30° 20° 10° 0°  30° 60° 50° 45° 40° Zur ▲ g , ittlun lel elerm Wink ser paralZur elmes te Lade Winkßenkan w. bz hrerzur Au e (Fa fläch erseite) hr Beifa ! en anleg 70° 20° Zur 60° g , ittlun rallel de elerm r pa Winkelmessenkante La bzw. e) eit Wink r Auße e (Fahreren! zu fläch Beifahrers anleg  0° dies 70° 60° 50° 45° 40° 30° 20° 10° 10° g ␣, 70° ▲ Be atio rm o n f e t t n e zeri schlagk Protractor e Kan 10° te an 20° ittlun Kette nstr an 45° 40° 30° le g an gen! « STER RMA R U Z LTI »MU Win rm kele 50° n uge hrze enfa traß uf S 195-1 ng a N 12 te)! heru , prE -Ket VIP( gssic 700/02 ® ® ZU RR MI TT EL t „t“ ewich ngsg Ladu ert beiw Reib With lashing multimaster and calculation CD. 19 Tradition in Leadership RUD Ketten Rieger & Dietz GmbH u. Co. KG Friedensinsel 73432 Aalen/Germany Telefon: +49 7361 504-1371-1314-1527 Telefax: +49 7361 504-1460 info@rud.com www.rud.com German engineering from the heart of Europe! 7 93 9 3 70 70 5 3 73 93 9 81 6 6 6 3 7 81 9 93 8 8 7 81 9 94 Further RUD products for diverse applications: Materials handling systems Load lifting tackle Hoisting chains