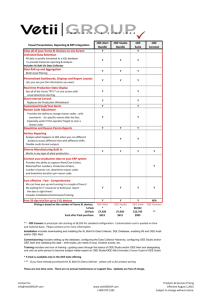

OEE Connect

advertisement

Integrated Solutions Leveraging All Systems. All Working Together. All Delivering Results. OEE Connect provides the connection between your data, your systems and your reports wherever the data may be. With today’s emphasis on real-time data from the plant floor, we can help you collect data from all of your production assets and connect that data with your enterprise system. Opportunities & Solutions Do you have any idea how your business is doing except at the end of the month? Would you like to know how to: • get your data faster? • reduce data entry overhead? • realize results in real-time? The goal is to provide managers with greater visibility into production helping them to see whether they are losing or making money and why. Today’s Challenge Do your operators manually fill out paperwork at end of shift? Next day, do your supervisors enter that paperwork into the ERP system data entry screen? Here’s how we can help: To get data to your ERP system, you will need the XL Bolt-On Data Collector (MS SQL Server) and the OEEConnect software we have developed that collects the specific data and puts it in the format of your choosing. Before - Daily tracking included manual paper entry generating a multitude of paperwork required to track line and operator production. XL Bolt-On Data Collector MS SQL Database ERP System We provide the ability to capture Work/Cost Center, Material/Part numbers, Production Orders, number of pieces run, downtime reason codes and downtime duration per reason code. After - OEE CONNECT automatically captures production data and make it available for your ERP system. This information is captured on a (configurable) basis or at the end of each shift and is made available to your ERP system. We stage the data in the SQL Server where the Vorne data is collected and make it available for your use. “I just want to let you know the good things I am seeing coming from the Vorne boards. I am seeing the operators staying more attentive to their jobs and addressing any issues they have quicker. They are staying at their machines and keeping them running. The Vorne boards have also helped us correct a lot of the standards that we have on the system. They are giving us data rather than assumptions. It’s a lot easier than trying to track OEE manually.” B . G . O p s. Mg r. L ea d i n g S u p p l i er o f C o n t ro l s f o r O i l a n d G as Pr odu cer s Results The information is already in the database used to collect the data from all of the Vorne units. We make this data available to your ERP system. Working with you and the ERP development team, we can customize OEE Connect to fit your needs. The key is to: • identify what data you want; (flat-file, query, table) • when you want it and • how often you want your ERP system updated. From downtime to production results, our collaborative approach with your IT team helps to seamlessly automate the manual processes of getting your real-time production data into the ERP system, accurately and timely. ERP Integration OEE Connect works with all ERP systems, including: Vetii | GROUP Products & Services Real-Time Tactical Strategic XL Bolt-On Data Link OEEAlert XL Bolt-On Data Collector XL Bolt-On OPC Server OEEConnect OEEAudit XL Bolt-On Display Viewer Reporting Development ERP Systems Integration Vorne Authorized Reporting Consultants Trademarks of Vorne Industries and Vetii | GROUP Email: info@vetiigroup.com www.vetiiGroup.com Debbie Olk - 815.988.5534 Jim Sulzer - 262.617.7788