usda/ncda&cs facility guidelines for meat processing plants

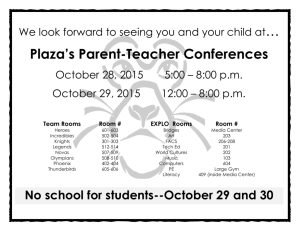

advertisement