Experiment 7 Sluice Gate

advertisement

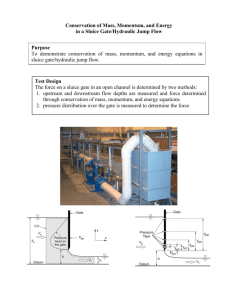

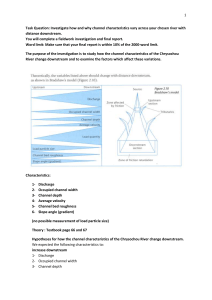

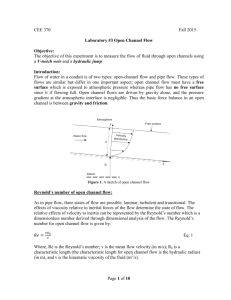

CE403 Hydraulics Laboratory Experiment 7 Flow under Sluice Gate A. Introduction The sluice gate provides a convenient means of flow regulation, especially in irrigation and drainage schemes where flow has to be distributed in networks of interconnected channels. The gate is provided with a lifting mechanism so that the aperture beneath it may be set to any desired position. When closed, the aperture is sealed so that no flow can pass through the gate. In this experiment we measure the discharge under the gate and establish the effective coefficient of discharge. The sheet of water which emerges from the aperture is supercritical so that a standing wave can be formed downstream of the gate, and the experiment may be extended to study this standing wave and the variation of specific energy through it. B. Equipment Sluice gate, two depth gauges, restriction block for controlling the downstream flow, stopwatch. C. Procedure 1. Set the channel slopes to 1/1500. The channel is first set to a mild slope of about 1/1500 as indicated by the linear and circular scales. Check the slope by using the depth gauge to establish the change of depth over a length of channel (say 4 m length) with static water retained in the channel. 2. Fix the Sluice gate carefully at a station approximately 2 m from upstream of the channel. 3. Set the height of the Sluice gate opening to 20 mm using internal callipers. 4. Set the restriction block at a station approximately 30 cm from downstream of the channel. 5. Before starting the experiment observe the general characteristics of the water surface profile, which may be produced in the flume by changing discharge. Make sure there is a hydraulic jump downstream of the sluice gate during each measurement. 6. Measure and record the discharge by using gravimetric tank. 7. Measure and record the flow depth y at 30 cm upstream of the sluice gate. 8. Measure and record the flow depth y1 at the upstream of the hydraulic jump. 9. Measure and record the flow depth y2 at the downstream of the hydraulic jump. 10. Change the discharge and repeat the steps 6-­‐10 for seven more times for different discharges. By Dr. İsmail HALTAŞ April 7, 15 CE403 Hydraulics Laboratory D. Theory Flow under a sluice gate with a hydraulic jump at the downstream is shown in Figure 1. The water depth upstream of the sluice gage is h, and the jet emerging from the aperture of height a has a thickness CCa where CC is the contraction coefficient. The static head across the aperture varies from (h-­‐a) at he upper edge to h at the bottom, so the average static head is (h-­‐a/2). Figure 1: Flow under a sluice gate with a hydraulic jump at the downstream Specific energy E is calculated as E = h+ V2 2g Equation 1 Where V is the velocity of approach, the average total head on the aperture is (E-­‐ a/2). The average velocity in the contracted section, across which the pressure is hydrostatic, is therefore Vc = Cv 2g ( E − a 2 ) Equation 2 Where CV is the velocity coefficient, which allows for the slight loss in total head up to the section. The discharge Q may now be written as the produce of flow area and velocity: By Dr. İsmail HALTAŞ April 7, 15 CE403 Hydraulics Laboratory Q = Cc aBCv 2g ( E − a 2 ) Equation 3 Q = CcCv aB 2g ( E − a 2 ) Equation 4 or Replacing the product CCCV by the discharge coefficient C, we obtain. Q = CaB 2g ( E − a 2 ) Equation 5 The value of C is deduced from this equation using measured values of Q and E. Coming now to the standing wave, where the depths of flow upstream and downstream are y1 and y2, we note that there is an irreversible loss of specific energy through the wave, the energy being dissipated by turbulence in the flow. The relationship between the upstream and downstream depths at hydraulic jump is obtained using momentum and energy equations as: y2 1 " = # 1+ 8Fr12 −1$% y1 2 Equation 6 Note that in 5 meter flume the channel width is B = 75 mm and the opening of the sluice gate a = 20 mm. E. Results Calculate the discharge coefficient C for each discharge tested. Tabulate your results as in the following Example Table. Table 1: Flow variables and discharge coefficient C for the tested discharges Discharge,+ Head,+h+ Upstream+ Specific+Energy,+ Total+Head,+H+ C Q+(lt/s) (mm) Velocity,+V+(m/s) E+(mm) (mm) 1.350 118 0.167 119.4 109.4 0.614 1.300 109 0.175 110.6 100.6 0.617 1.240 101 0.182 102.7 92.7 0.613 1.190 92 0.193 93.9 83.9 0.618 1.140 89 0.192 90.9 80.9 0.603 1.090 80 0.208 82.2 72.2 0.611 (E@a/2) 0.5 10.46 10.03 9.63 9.16 8.99 8.50 Plot a graph of Discharge Q (lt/s) vs. (E-­‐a/2)0.5 (mm0.5) as in the Example Figure 2. Fit a linear line to the measurement points and find the equation of the line. By Dr. İsmail HALTAŞ April 7, 15 CE403 Hydraulics Laboratory (E#a/2)0.5+(mm0.5)+ 15" y"="7.7632x" 10" 5" 1.0" 1.1" 1.2" 1.3" 1.4" Discharge+Q+(lt/s)+ Figure 2: Discharge Q vs. (E-­‐a/2)0.5 Calculate the Froude Number Fr1 at upstream of the hydraulic jump as well as the depth ratio using Equation 6 and tabulate your results as in the following Example Table. Table 2: Hydraulic jump variables for the tested discharges Upstream+ Discharge,+ Q+(lt/s) Depth,+y 1 +(mm) 1.350 26.06 1.300 25.41 1.240 24.63 1.190 23.96 1.140 23.28 1.090 22.60 Downstream+ Depth,+y 2 +(mm) 85 82 81 78 75 71 Upstream+ Velocity,+V 1 +(m/s) 0.691 0.682 0.671 0.662 0.653 0.643 Fr1 y2 /y 1 2.70 2.74 2.78 2.82 2.86 2.90 3.262 3.227 3.289 3.256 3.221 3.142 y2 /y 1 +(from+RHS+ of+Eq.+6) 3.353 3.401 3.462 3.516 3.573 3.633 Plot a graph of measured flow depth ratio y2/y1 vs. flow depth ratio y2/y1 calculated by Equation 6 as in the Example Figure 3. By Dr. İsmail HALTAŞ April 7, 15 CE403 Hydraulics Laboratory y2/y1%(Eq.%6)% 4.0$ 3.5$ 3.0$ 3.0$ 3.5$ 4.0$ y2/y1% Figure 3: Measured Critical Depth yc (mm) vs. Specific Energy E (mm) F. Discussion How would the approach velocity V change with larger sluice gate opening (i.e. 30mm)? Why? Based on the measured flow depth ratio y2/y1 what kind of hydraulic jump (check the hydraulic jump types from the reference books) you observed in the experiment. What is the percent error in the calculated average discharge coefficient C if there is 1 mm error in the opening of the gate, a. Discuss about the reason of the difference between the measured and calculated flow depth ratio based on Figure 3. By Dr. İsmail HALTAŞ April 7, 15