Onesteel Know Your Steel Online Mass Book

advertisement

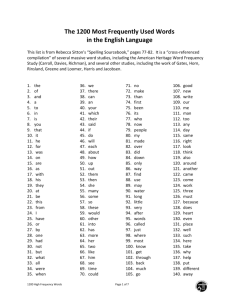

A FT KNOW YOUR STEEL D R STEEL MASS BOOK January 2007 www.metaland.com.au D A R FT Foreword This publication has been prepared by OneSteel Manufacturing Pty Limited ABN 42 004 651 325 (“OneSteel”) which is part of an operating business group known as OneSteel Market Mills. The aim of this booklet is to provide customers with useful Australian steel information. Every effort has been made to ensure that the information contained in this publication is accurate. FT It should be noted that the company cannot accept responsibility for errors or omissions, or for changes which have taken place since the printing of this edition. Unless required by law, the company cannot accept any responsibility for any loss, damage or consequence resulting from the use of this publication. A The preferred range of sizes only has been covered. Additional information concerning nonpreferred sizes, range of specifications available, or related data not included in this booklet is available on request through OneSteel Direct. Contact details are available on the back cover of this booklet. Note: Mass Calculations have been based on a mass for carbon steel of 7,850 kg/m3 rounded off, and invoicing practice includes 2.5% rolling tolerance where applicable. Sources R HRWSS Pricing Guide September 2006 EzySteel Pricing Guide May 2006 Structural - Aus Price Book September 2006 OSMB Price Book July 2005 • Aus Profiles Price Book September 2006 • Aus BTM Price Book September 2006 • Midalia Steel Price List September 2005 Trademarks D • • • • Registered trademarks of OneSteel Trading Pty Ltd. DuraGal®, Galtube Plus®, Tubecolor®, DuraGal Building System® Registered trademarks of OneSteel Manufacturing Pty Ltd. 300PLUS® Trademarks of OneSteel Trading Pty Ltd. Galvatube™ Registered trademarks of MBS Pty Ltd. MARBRITE® Registered trademarks of BlueScope Steel Ltd. BLACKFORM®, BRIGHTFORM®, GALVABOND®, GALVASKIN®, ZINCANNEAL®, ZINCALUME®, COLORBOND® Registered trademarks of Eltrak International & Staff Pty Ltd. ELTRAK® & ELGATE® Registered trademark of Hunt Engineering & Staff Pty Ltd. Hopleys® Table of Contents Mild STEEL sections Flat Bar - Square Edge Page 4-5 Page 24 DuraGal Silo Section ® Flat Bar - Round Edge 5 DuraGal Yardrail Flats - DuraGal 6 RHS - Squares: Black, Painted & DuraGal 25 Round Bar 6 RHS - Squares: Black & Painted only Square Bar 7 RHS - Rectangles: Black, Painted & DuraGal 27 7 RHS - Rectangles: Black & Painted only 27 Angles - 300PLUS® Equal 7 RHS - Squares: Galtube Plus® 28 Angles - DuraGal® 8 RHS - Rectangles: Galtube Plus® 28 Angles - 300PLUS Unequal 8 Tubecolor 28 Channels - DuraGal 9 Channels - 300PLUS Parallel Flange 9 SHEET & COIL Rails 9 Sheet - BLACKFORM® 29 Deformed Bar ® 24 ® ® ® 26 ® A FT ® ® ® Beams - 300PLUS Universal 10 Sheet - BRIGHTFORM 29 Beams - 300PLUS Welded 10 Sheet - Hot Rolled Pickled HA3-P 29 Beams - 300PLUS® Taper Flange 11 Sheet - Cold Rolled CA2S-E 30 Columns - 300PLUS® Universal 11 Sheet - Cold Rolled CA3SN-G 30 Columns - 300PLUS Welded 11 Sheet - GALVABOND G2 Z275 30 Plate - Coil 12 Sheet - GALVASKIN G2 Z200 31 ® R ® ® ® ® ® 13-14 Sheet - ZINCANNEAL G2S ZF100 31 Plate - Grades Boiler, Bisalloy 13-14 Sheet - ZINCALUME G300 AZ150 31 Sheet - COLORBOND CG300AZ150 32 D Plate - Grades 250, 300, 350 Plate - Floor ® ® 15 ® PIPE & TUBE STAINLESS STEEL ERW Steel Tube - Circular 16-17 ERW Steel Tube - Square 18 ERW Steel Tube - Rectangular ERW Steel Tube - Oval Pipe - Black Pipe - Galvanised Sheet & Coil - Austenitic 33 Sheet & Coil - Ferritic 33 Flat Bar: Grades 304, 316 33 Angle: Grades 304, 316 34 20-21 Round Bar: Grades 304, 316 & 431 34 22-23 Tubes - Round: Grades 304, 316, 431 34 18-19 19 Pipe - Galtube Plus 23 Tubes - Square: Grades 304, 316 35 Pipe - DuraGal® Extra Light 24 Tubes - Rectangular: Grades 304, 316 35 ® Table of Contents BRIGHT BAR Page MESH 36-37 Rounds, MARBRITE ® Page Mesh - Expanded Metal 53 Hexagons, MARBRITE 37 Handyman Mesh 53 Flat, Square Edge 38 General Purpose Mesh 54 Squares 39 Reinforcing Mesh 54 Trench Mesh 55 BUILDING PRODUCTS Reinforcing Accessories 55 Roof & Wall Cladding A FT ® 40 ELGATE® FENCE & GATE FITTINGS Cold Formed Angles 40 Tees - 3 Way 56 Cold Formed Plain Channels 41 Crosses - 4 Way 56 Lipped Channels 41 Fixed Corners - 4 Way 56 Purlins - C Sections 42 Adjustable Corners - 4 Way 56 Purlins - Z Sections 42 Post Caps - Round Pipe 56 Post Caps - Square Tube 57 Gate Hinges - Two Part 57 Gate Hinge Straps 57 43 Gate Hinge - Interlocking 57 Fasteners 44 Gate Tower Bolts & Lugs 57 Light Weight Sections - Topspan 45 Post Flanges - Round Pipe 57 Gate Gudgeons - Round Pipe 58 Gate Drop Bolts 58 - ZINCALUME® & COLORBOND® Gutter & Accessories - ZINCALUME® & COLORBOND® 43 R Downpipes & Accessories - ZINCALUME & COLORBOND ® ® D Light Weight Sections - Steel Building Frame Components DuraGal Flooring System ® 45 46-47 DuraGal® Carports 48 Hopleys® Trusses & Joists 49 Hopleys® Portal Rafter 49 Hopleys® Standard Fittings 49 ELTRAK - Sliding Door Hardware ® Telescoping Pipe & RHS Tables General Information: Pipe & RHS 50-51 52 Lintels DuraGal Plus Lintels ® 53 59-60 61 Flat Bar - Square Edge Size mm x mm Mass kg/m Metres per Tonne 2123 1274 1062 637 x x x x 3 5 6 10 0.471 0.785 0.942 1.57 25 x x x x x x 3 5 6 8 10 12 0.589 0.981 1.18 1.57 1.96 2.36 32 x x x x x x 3 5 6 8 10 12 0.754 1.26 1.51 2.01 2.51 3.01 40 x x x x x x x x 3 5 6 8 10 12 16 20 0.942 1.57 1.88 2.51 3.14 3.77 5.02 6.28 1062 637 532 398 318 265 199 159 50 x x x x x x x x x 3 5 6 8 10 12 16 20 25 1.18 1.96 2.36 3.14 3.93 4.71 6.28 7.85 9.81 849 510 424 318 254 212 159 127 102 1699 1019 847 637 510 424 D R A 1327 794 662 498 398 332 Mass kg/m Metres per Tonne 65 x x x x x x x x x 3 5 6 8 10 12 16 20 25 1.53 2.55 3.06 4.08 5.10 6.12 8.16 10.2 12.8 653 392 327 245 196 163 123 98 78 75 x x x x x x x x x 5 6 8 10 12 16 20 25 40 2.94 3.53 4.71 5.89 7.07 9.42 11.8 14.7 23.6 340 283 212 170 141 106 85 68 42 90 x 5 3.53 283 FT 20 Size mm x mm 6m 90 x x x x 6 8 10 12 4.24 5.65 7.07 8.48 236 177 141 118 100 x x x x x x x x x 5 6 8 10 12 16 20 25 50 3.93 4.71 6.28 7.85 9.42 12.6 15.7 19.6 39.3 254 212 159 127 106 79 64 51 25 Flat Bar - Square Edge Size mm x mm Mass kg/m Metres per Tonne 232 193 145 116 96 x x x x x 5 6 8 10 12 4.32 5.18 6.91 8.64 10.4 30 1 x x x x x x x x 5 6 8 10 12 16 20 25 5.10 6.12 8.16 10.2 12.2 16.3 20.4 25.5 50 1 x x x x x x x x x 5 6 8 10 12 16 20 25 50 80 1 x x x x 5 6 8 10 x x x x 12 16 20 25 7.07 8.48 11.3 14.1 142 118 88 71 R 170 141 106 85 71 53 42 34 17 6m Mass kg/m Metres per Tonne 17.0 22.6 28.3 35.3 59 44 35 28 00 2 x x x x x x x 6 8 10 12 16 20 25 9.42 12.6 15.7 18.8 25.1 31.4 39.3 106 79 64 53 40 32 25 50 2 x x x x x x x 6 8 10 12 16 20 25 11.8 15.7 19.6 23.6 31.4 39.3 49.1 85 64 51 42 32 25 20 00 3 x x x x x x x 6 8 10 12 16 20 25 14.1 18.8 23.6 28.3 37.7 47.1 58.9 71 53 42 35 27 21 17 Flat Bar - Round Edge4m Size mm x mm 10 13 196 163 123 98 82 61 49 39 5.89 7.07 9.42 11.8 14.1 18.8 23.6 29.4 58.9 D 80 1 A 10 1 Size mm x mm FT x x x x 3 3 5 6 Mass kg/m Metres per Tonne 0.25 0.31 0.53 0.56 4000 3226 1887 1786 Size mm x mm 16 x x x 3 5 8 Mass kg/m Metres per Tonne 0.36 0.60 1.03 2778 1667 971 DuraGal® Flats Mass kg/m Metres per Tonne Size mm 150 Mass kg/m Metres per Tonne 5 6 8 5.53 7.07 9.42 181 142 106 50 4 5 1.49 1.84 670 542 65 4 5 1.94 2.40 516 417 2.24 2.77 447 361 2.98 3.69 4.71 335 271 212 4.80 208 75 4 5 100 4 5 6 130 5 Nominal Thickness mm A FT Nominal Thickness mm Size mm 6m 200 5 6 8 7.38 9.42 12.6 136 106 79.6 250 5 8 9.22 15.7 108 63.7 300 5 8 11.1 18.8 90.3 53.1 Round Bar 6m Mass kg/m Metres per Tonne Diameter mm Mass kg/m 6 8 10 12 14 16 18 20 22 24 27 30 33 36 39 42 0.22 0.39 0.62 0.88 1.21 1.58 1.99 2.46 2.98 3.55 4.49 5.55 6.71 7.99 9.38 10.9 4505 2534 1621 1126 826 633 503 407 336 282 223 180 149 125 107 92 50 56 60 65 75 80 90 100 110 120 130 140 150 160 170 180 15.4 19.3 22.2 26.0 34.7 39.5 49.9 61.7 74.6 88.8 104 121 139 158 178 200 65 52 45 38 29 25 20 16 13 11 9.6 8.3 7.2 6.3 5.6 5 12.5 14.2 80 70 190 200 223 247 4.5 4 D R Diameter mm 45 48 Metres per Tonne Square Bar 10 12 16 20 25 32 40 x x x x x x x 10 12 16 20 25 32 40 Deformed Bar Mass kg/m Metres per Tonne Diameter mm Mass kg/m Metres per Tonne 0.81 1.13 2.01 3.14 4.91 8.24 12.5 1235 885 498 318 204 121 80 12 16 20 24 28 32 36 0.89 1.58 2.47 3.55 4.83 6.31 8.00 1126 633 406 282 207 158 125 A FT Size mm x mm 6m 300PLUS® Equal Angles Size mm x mm Mass kg/m Metres per Tonne Size mm x mm Mass kg/m Metres per Tonne 0.92 1087 1.12 1.65 2.08 893 606 481 75 x 75 x 5 x6 x8 x 10 5.27 6.81 8.73 10.5 190 147 115 95 1.35 2.01 2.56 741 498 391 90 x 90 x 6 x8 x 10 8.22 10.6 12.7 122 94 79 40 x 40 x 3 x5 x6 1.83 2.73 3.50 546 366 286 00 x 100x 6 1 x8 x 10 x 12 9.16 11.8 14.2 17.7 109 85 70 57 45 x 45 x 3 x5 x6 2.06 3.10 3.97 485 323 252 50 x 50 x 3 x5 x6 x8 2.31 3.48 4.46 5.68 433 287 224 176 25 x 125x 8 1 x 10 x 12 x 16 14.9 18.0 22.5 29.1 67 56 44 34 55 x 55 x 5 x6 3.84 4.93 260 203 50 x 150 x 1 x x x 10 12 16 19 21.9 27.3 35.4 42.1 46 37 28 24 65 x 65 x 5 x6 x8 x 10 4.56 5.87 7.51 9.02 219 170 133 111 00 x 200 x 2 x x x x 13 16 18 20 26 40.0 48.7 54.4 60.1 76.8 25 21 18 17 13 20 x 20 x 3 25 x 25 x 3 x5 x6 D R 30 x 30 x 3 x5 x6 DuraGal® Angles Nominal Thickness mm Mass kg/m Metres per Tonne 30 x 30 2.5 1.06 948 40 x 40 2.5 4.0 1.43 2.20 698 455 45 x 45 2.5 4.0 1.62 2.50 617 401 50 x 50 2.5 4.0 5.0 6.0 1.81 2.79 3.42 4.21 553 358 298 238 3.69 4.62 5.62 271 221 178 4.29 5.26 233 190 4.0 5.0 6.0 75 x 75 4.0 5.0 R 65 x 65 Size mm Nominal Thickness mm Mass kg/m Metres per Tonne 6.0 7.0 8.0 6.56 7.59 8.59 152 132 116 90 x 90 5.0 8.0 6.37 10.5 157 95.4 100 x 100 6.0 7.0 8.0 8.92 10.3 11.7 112 96.8 85.2 125 x 125 4.0 5.0 7.0 8.0 4.27 8.95 13.1 14.9 138 112 76.4 67.2 150 x 150 5.0 8.0 10.8 18.0 92.6 55.5 75 x 75 A FT Size mm D 300PLUS® Unequal Angles Size mm x mm Mass kg/m Metres per Tonne Size mm x mm Mass kg/m Metres per Tonne 65 x 50 x 5 x6 x8 4.02 5.16 6.59 249 194 152 125 x 75 x 6 x8 x 10 x 12 9.16 11.8 14.2 17.7 109 85 70 56 75 x 50 x 5 x6 x8 4.40 5.66 7.23 227 177 138 100 x 75 x 6 x8 x 10 7.98 10.3 12.4 125 97 81 150 x 90 x 8 x 10 x 12 x 16 14.3 17.3 21.6 27.9 70 58 46 36 50 x 100x 10 1 x 12 18.0 22.5 56 44 10 DuraGal® Channels Nominal Thickness mm Mass kg/m Metres per Tonne Size mm 75 x 40 4.0 4.25 236 200 x 75 00 1 125 150 180 x 50 4.0 5.29 179 x 65 4.0 x 75 5.0 230 x 75 250 x 90 300 x 90 x 75 5.0 Nominal Thickness mm Mass kg/m Metres per Tonne 5.0 6.0 12.4 15.5 80.9 64.6 6.0 16.9 59.2 6.0 19.2 52.0 6.0 7.0 8.0 21.6 25.1 28.5 46.3 39.9 35.1 A FT Size mm 7.23 138 10.5 95.1 11.6 86.0 300PLUS® Parallel Flange Channels Size mm x mm 3.83 5.92 8.33 11.9 17.7 20.9 Metres per Tonne R 25* 40 50 65 75 75 D 50 x 75 x 100 x 125 x 150 x 180 x Mass kg/m Size mm x mm 200 x 230 x 250 x 300 x 380 x 261 169 120 84.0 56.5 47.6 75 75 90 90 100 Mass kg/m Metres per Tonne 22.9 25.1 35.5 40.1 55.2 43.7 39.8 28.2 24.9 18.1 Section Mass kg/m Metres per Tonne 53 60 68 73 86 53.00 60.60 67.50 73.63 85.50 18.87 16.50 14.81 13.58 11.70 *Taper Flange Channel Rails Section Mass kg/m Metres per Tonne 10 15 22 30 41 50 10.10 15.20 22.30 30.10 40.80 50.60 99.00 65.79 44.84 33.22 24.51 19.76 11 300PLUS® Universal Beams Metric Designation Size mm x mm Mass kg/m Metres per Tonne Metric Designation Size mm x mm Mass kg/m Metres per Tonne 360 UB 52x171 3 356x171 359x172 44.7 50.7 56.7 22 20 18 150 x 75 155 x 75 14.0 18.0 71 56 180 UB 173 x 90 175 x 90 179 x 90 16.1 18.1 22.2 62 55 45 200 UB 198 x 99 202 x133 203 x133 207 x134 18.2 22.3 25.4 29.8 55 45 39 34 250 UB 248 x124 252 x146 256 x146 25.7 31.4 37.3 39 32 27 298 x149 304 x165 307 x166 32.0 40.4 46.2 31 25 22 A FT 150 UB R 310 UB 410 UB 03x178 4 406x178 53.7 59.7 19 17 460 UB 54x190 4 457x190 460x191 67.1 74.6 82.1 15 13 12 530 UB 28x209 5 533x209 82.0 92.4 12 11 610 UB 02x228 6 607x228 612x229 101 113 125 10 9 8 Mass kg/m Metres per Tonne 300PLUS® Welded Beams Size mm x mm D Metric Designation Mass kg/m Metres per Tonne Metric Designation Size mm x mm 700 WB 92 x 250 6 700 x 250 710 x 250 716 x 275 115 130 150 173 8.70 7.69 6.67 5.78 1000 WB 000x300 1 1010x350 1016x400 1024x400 215 258 296 322 4.65 3.88 3.38 3.11 800 WB 92 x 250 7 800 x 275 810 x 275 816 x 300 122 146 168 192 8.20 6.85 5.95 5.21 1200 WB 900 WB 00 x 300 9 910 x 350 916 x 400 924 x 400 175 218 257 282 5.71 4.59 3.89 3.55 170x275 1 1170x350 1176x400 1184x400 1184x500 1192x500 1200x500 249 278 317 342 392 423 455 4.02 3.60 3.15 2.92 2.55 2.36 2.20 12 300PLUS® Taper Flange Beams Size mm x mm Mass kg/m 100 x 45 Metres per Tonne 7.20 Size mm x mm Mass kg/m 125 x 65 139 Metres per Tonne 13.1 76.0 Metric Designation A FT 300PLUS® Universal Columns Size mm x mm Mass kg/m Metres per Tonne Metric Designation Size mm x mm Mass kg/m Metres per Tonne 100 UC 97 x 99 14.8 68 250 UC 54 x 254 2 260 x 256 72.9 89.5 14 11 150 UC 52 x 152 1 158 x 153 162 x 154 23.4 30.0 37.2 43 33 27 310 UC 03 x 203 2 206 x 204 210 x 205 46.2 52.2 59.5 22 19 17 08 x 305 3 315 x 307 321 x 309 327 x 311 96.8 118 137 158 10 8 7 6 200 UC R 300PLUS® Welded Columns Size mm x mm Mass kg/m Metres per Tonne Metric Designation Size mm x mm Mass kg/m Metres per Tonne 350 WC 31x350 3 339x350 347x350 355x350 197 230 258 280 5.08 4.35 3.88 3.57 500 WC 82x400 3 390x400 400x400 414x400 422x400 430x400 430x400 144 181 212 270 303 328 361 6.94 5.52 4.72 3.7 3.3 3.05 2.77 90x500 4 500x500 506x500 514x500 472x500 480x500 480x500 228 267 290 340 383 414 440 4.39 3.75 3.45 2.94 2.61 2.42 2.27 D Metric Designation 400 WC 13 Plate - Coil Plate- Grades 250, 300 350, Boiler, Bisalloy Mass kg/m2 kg/lineal metre of plate width 3 x 1200* x 1500* x 1800* x 2400* x 3000* 23.55 28.3 35.3 42.4 56.5 70.7 4 x 1200* x 1500* x 1800* x 2400* x 3000* 31.4 37.7 47.1 56.5 75.4 94.2 Size mm x mm A FT Size mm x mm 39.25 6 x 1200 x 1500 x 1800 x 2400 x 3000 x 3200 47.1 D R 5 x 1200 x 1500 x 1800 x 2400 x 3000 47.1 58.9 70.7 94.2 118 56.5 70.7 84.8 113 141 151 8 x 1200 x 1500 x 1800 x 2400 x 3000 x 3200 Mass kg/m2 62.8 kg/lineal metre of plate width 75.4 94.2 113 151 188 198 10 x x x x x x 1200 1500 1800 2400 3000 3200 78.5 94.0 118 141 188 236 251 12 x x x x x x 1200 1500 1800 2400 3000 3200 94.2 113 141 170 226 283 301 * Not available in Boiler or Bisalloy 14 Plate Size mm x mm Grades 250, 300 350, Boiler, Bisalloy Mass kg/m2 kg/lineal metre of Size mm x mm Mass kg/m2 plate width x x x x x x 1200 1500 1800 2400 3000 3200 125.6 20 x x x x x x 1200 1500 1800 2400 3000 3200 22 x x x x x 1200 1500 1800 2400 3000 25 x x x x x x 1200 1500 1800 2400 3000 3200 196.25 28 x x x x x 1200 1500 1800 2400 3000 219.8 32 x x x x x 1200 1500 1800 2400 3000 plate width 151 188 226 301 377 402 36 x x x x x 1200 1500 1800 2400 3000 282.6 339 424 509 678 848 40 x x x x x 1200 1500 1800 2400 3000 314 377 471 565 754 942 45 x x x x x 1200 1500 1800 2400 3000 353.25 424 530 636 848 1060 50 x x x x x 1200 1500 1800 2400 3000 392.5 471 589 707 942 1178 55 x x x x x 1200 1500 1800 2400 3000 431.75 518 648 777 1036 1295 60 x x x x x 1200 1500 1800 2400 3000 471 565 707 848 1130 1413 A FT 16 157 D R 172.7 251.2 kg/lineal metre of 188 236 283 377 471 502 207 259 311 415 518 236 294 353 471 589 628 264 330 396 528 659 301 377 452 603 754 15 Plate - Mass kg/m2 kg/lineal metre of plate width 612 765 918 1224 1530 20 1 659 824 989 1319 1649 x x x x x 1200 1500 1800 2400 3000 510 70 x x x x x 1200 1500 1800 2400 3000 550 75 x x x x x 1200 1500 1800 2400 3000 589 80 x x x x x 1200 1500 1800 2400 3000 90 x x x x x 1200 1500 1800 2400 3000 707 00 1 x x x x x 1200 1500 1800 2400 3000 785 110 x x x x x 1200 1500 1800 2400 3000 864 707 883 1060 1413 1884 A 65 R 628 D Size mm x mm Mass kg/m2 kg/lineal metre of plate width 1200 1500 1800 2400 3000 942 1130 1413 1696 2261 2826 30 x 1200 1 x 1500 x 1800 1021 1225 1532 1837 40 x 1200 1 x 1500 x 1800 1099 1319 1649 1978 50 x 1200 1 x 1500 x 1800 1177 1412 1766 2120 60 x 1200 1 x 1500 x 1800 1256 1507 1884 2261 80 x 1200 1 x 1500 x 1800 1413 1696 2120 2543 00 x 1200 2 x 1500 x 1800 1570 1884 2355 2826 25 x 1200 2 x 1500 x 1800 1766 2119 2649 3179 50 x 1200 2 x 1500 x 1800 1963 2355 2945 3533 x x x x x FT Size mm x mm Grades 250, 300 350, Boiler, Bisalloy 754 942 1130 1507 1766 848 1060 1272 1696 2120 942 1178 1413 1884 2355 1036 1295 1554 2072 2591 16 Floor Plate Size mm x mm Mass kg/m2 kg/lineal metre of plate width 18.5 22.2 3 x 1200 x 1500 25.6 30.7 38.3 4 x 1200 x 1500 33.4 5 x 1200 x 1500 41.3 6 x 1200 x 1500 x 1800 49.1 40.1 50.1 49.5 61.9 A 58.9 73.7 88.4 64.8 77.8 97.2 117 D R 8 x 1200 x 1500 x 1800 10 x 1200 x 1500 x 1800 17 Mass kg/m2 kg/lineal metre of plate width 80.5 96.6 121 145 12 x 1200 x 1500 x 1800 96.2 116 144 173 16 x 1200 x 1500 x 1800 128 153 191 230 20 x 1200 x 1500 x 1800 159 191 239 286 FT 2.1x 1200 Size mm x mm ERW Steel Tube - Circular Thickness mm Mass kg/m 12.7 0.9 1.2 1.4 1.6 0.262 0.340 0.390 0.438 16.0 0.9 1.2 1.4 1.6 2.0 2980 2280 1980 1760 1450 0.402 0.527 0.608 0.687 0.838 2490 1900 1650 1460 1190 0.473 0.621 0.718 0.813 1.00 1.26 2120 1610 1390 1230 1000 796 0.9 1.2 1.4 1.6 2.0 2.6 3.2 0.544 0.716 0.829 0.939 1.15 1.46 1.75 1840 1400 1210 1060 866 684 571 0.9 1.2 1.4 1.6 2.0 2.6 0.615 0.811 0.939 1.07 1.31 1.67 1630 1230 1060 936 762 600 22.2 0.9 1.2 1.4 1.6 2.0 2.6 D R 0.9 1.2 1.4 1.6 2.0 28.6 Size (OD) mm Thickness mm Mass kg/m Metres per Tonne 31.8 0.9 1.2 1.4 1.6 2.0 2.6 3.2 0.686 0.906 1.05 1.19 1.47 1.87 2.26 11460 1100 953 839 680 534 443 35.0 0.9 1.2 1.4 1.6 2.0 2.6 3.2 0.757 1.00 1.16 1.32 1.63 2.08 2.51 1320 1000 862 759 614 481 398 38.0 0.9 1.2 1.4 1.6 2.0 2.6 3.2 0.823 1.09 1.26 1.44 1.78 2.27 2.75 1210 918 791 696 563 441 364 40.0 1.6 1.52 660 41.3 0.9 1.2 1.4 1.6 2.0 2.6 3.2 0.897 1.19 1.38 1.57 1.94 2.48 3.01 1120 843 726 638 516 403 333 3820 2940 2560 2280 0.335 0.438 0.504 0.568 0.691 19.0 25.4 Metres per Tonne A FT Size (OD) mm Finishes: Hot rolled, commercial, Aluminised, Galvatube™ 18 ERW Steel Tube - Circular Thickness mm Mass kg/m 44.5 0.9 1.2 1.4 1.6 2.0 2.6 3.2 0.968 1.28 1.49 1.69 2.10 2.69 3.26 1030 780 672 591 477 372 307 47.6 0.9 1.2 1.6 2.0 2.6 3.2 1.04 1.37 1.82 2.25 2.89 3.50 965 728 551 445 347 285 1.91 524 1.47 1.71 1.95 2.42 3.10 3.77 679 584 513 414 322 265 1.56 1.82 2.07 2.56 3.30 4.01 640 551 484 390 303 249 50.0 1.6 51.0 54.0 R 1.2 1.4 1.6 2.0 2.6 3.2 D 1.2 1.4 1.6 2.0 2.6 3.2 Metres per Tonne Size (OD) mm Thickness mm 57.2 1.2 1.4 1.6 2.0 2.6 3.2 1.66 1.93 2.19 2.72 3.50 4.26 603 519 456 367 286 235 63.5 1.2 1.4 1.6 2.0 2.6 3.2 1.84 2.14 2.44 3.03 3.90 4.76 542 466 409 330 256 210 76.2 1.2 1.4 1.6 2.0 2.6 3.2 2.22 2.58 2.94 3.66 4.72 5.76 451 387 340 273 212 174 88.9 1.6 2.0 2.6 3.2 3.44 4.29 5.53 6.76 290 233 181 148 101.6 1.6 2.0 2.6 3.2 3.95 4.91 6.35 7.77 253 204 158 129 A FT Size (OD) mm Finishes: Hot rolled, commercial, Aluminised, Galvatube™ 19 Mass kg/m Metres per Tonne ERW Steel Tube - Square Mass kg/m Metres per Tonne 0.419 0.482 0.543 2390 2080 1840 Thickness mm 12.7 x 12.7 1.2 1.4 1.6 16.0 x 16.0 1.2 1.4 1.6 0.527 0.608 0.687 1900 1650 1460 19.0 x 19.0 0.9 1.2 1.4 1.6 2.0 0.487 0.640 0.740 0.838 1.03 2050 1560 1350 1190 974 22.2 x 22.2 0.9 1.2 1.4 1.6 2.0 0.583 0.769 0.890 1.01 1.24 1710 1300 1120 991 805 R 1.2 1.4 1.6 2.0 D 25.4 x 25.4 Dimensions mm x mm Thickness mm Mass kg/m Metres per Tonne 30.0 x 30.0 1.2 1.6 1.05 1.38 956 725 31.8 x 31.8 1.2 1.4 1.6 2.0 1.13 1.31 1.49 1.85 885 762 671 542 38.0 x 38.0 1.2 1.4 1.6 2.0 1.37 1.59 1.81 2.25 729 627 551 445 50.0 x 50.0 1.6 2.0 2.39 2.97 418 336 60.0 x 60.0 1.6 2.0 2.89 3.59 346 279 65.0 x 65.0 1.6 2.5 3.13 4.83 320 207 Mass kg/m Metres per Tonne A FT Dimensions mm x mm 0.881 1.02 1.16 1.43 1130 979 863 700 ERW Steel Tube - Rectangular Mass kg/m Metres per Tonne 0.9 1.2 1.4 1.6 0.488 0.642 0.742 0.842 2050 1560 1350 1190 1.2 1.4 1.6 0.762 0.882 1.00 1310 1130 999 Dimensions mm x mm Thickness mm 25.4 x 12.7 31.8 x 12.7 Dimensions mm x mm Thickness mm 31.8 x 22.2 1.2 1.4 1.6 0.933 1.08 1.23 1060 916 807 35.0 x 19.0 1.2 1.4 1.6 2.0 0.949 1.10 1.25 1.54 1050 908 800 648 Finishes: Hot rolled, commercial, Aluminised, Galvatube™ 20 ERW Steel Tube - Rectangular Thickness mm Mass kg/m Metres per Tonne 38.1 x 25.4 1.2 1.4 1.6 2.0 1.13 1.32 1.50 1.85 881 759 668 540 50.0 x 10.0 0.9 0.848 1240 50.0 x 25.0 1.2 1.4 1.6 2.0 1.32 1.53 1.75 2.16 757 652 573 463 1.2 1.4 1.6 2.0 1.48 1.71 1.95 2.42 679 584 513 413 50.8 x 31.8 Thickness mm Mass kg/m Metres per Tonne x 35.0 1.6 2.0 2.19 2.72 456 367 70.0 x 34.0 1.6 2.0 2.44 3.03 410 330 70.0 x 50.0 1.6 2.0 2.90 3.60 345 278 80.0 x 40.0 1.6 2.0 2.89 3.59 346 279 Dimensions mm x mm 57.0 A FT Dimensions mm x mm ERW Steel Tube - Oval Thickness mm Mass kg/m Metres per Tonne 0.826 1.09 1.44 1210 915 694 R Dimensions mm x mm 0.9 1.2 1.6 D 50.8 x 15.9 Dimensions mm x mm Thickness mm Mass kg/m Metres per Tonne 75.0 x 16.5* 0.9 1.2 1.17 1.55 853 643 *Flat sided oval Finishes: Hot rolled, commercial, Aluminised, Galvatube™ 21 Pipe - Black Nominal Size (DN) Section Outside Diameter mm 6.5m Wall Thickness mm Mass kg/m Metres per Tonne Medium Heavy 13.5 2.3 2.9 0.641 0.765 1560 1310 10 Medium Heavy 17.2 2.3 2.9 0.839 1.02 1190 985 15 Light Medium Heavy Extra Heavy 21.3 2.0 2.6 3.2 3.6 0.952 1.21 1.44 1.57 1050 830 696 636 20 Extra Light Light Medium Heavy Extra Heavy 26.9 2.0 2.3 2.6 3.2 4.0 1.23 1.40 1.56 1.87 2.26 814 717 642 535 443 25 Extra Light Light Medium Heavy Extra Heavy 33.7 2.0 2.6 3.2 4.0 4.5 1.56 1.99 2.41 2.94 3.24 640 502 414 340 309 Extra Light Light Medium Heavy Extra Heavy 42.4 2.0 2.6 3.2 4.0 4.5 1.99 2.55 3.10 3.80 4.53 502 392 322 263 221 R D 32 A FT 8 40 Extra Light Light Medium Heavy Extra Heavy 48.3 2.3 2.9 3.2 4.0 5.4 2.61 3.25 3.57 4.38 5.71 383 308 280 228 175 50 Extra Light Light Medium Heavy Extra Heavy 60.3 2.3 2.9 3.6 4.5 5.4 3.29 4.11 5.03 6.19 7.31 304 244 199 161 137 65 Extra Light Light Medium Heavy Extra Heavy 76.1 2.3 3.2 3.6 4.5 5.9 4.19 5.75 6.43 7.93 10.2 239 174 156 126 97.9 22 Pipe - Black 80 90 100 125 Outside Diameter mm Wall Thickness mm Mass kg/m 2.6 3.2 4.0 5.0 5.9 5.53 6.76 8.37 10.3 12.1 181 148 120 96.8 82.8 Metres per Tonne Extra Light Light Medium Heavy Extra Heavy 88.9 Extra Light Light Medium Heavy 101.6 2.6 3.2 4.0 5.0 6.35 7.77 9.63 11.9 158 129 104 84.0 Extra Light Light Medium Heavy 114.3 3.2 3.6 4.5 5.4 8.77 9.83 12.2 14.5 114 102 82.2 69.1 Extra Light Light Medium Heavy 139.7 3.0 3.5 5.0 5.4 10.1 11.8 16.6 17.9 98.9 85.1 60.2 55.9 Light Medium Heavy 165.1 3.5 5.0 5.4 13.9 19.7 21.3 71.7 50.7 47.0 R 150 Section A FT Nominal Size (DN) 6.5m D End Conditions: Ends can be plain, shouldered, roll grooved, screwed BSP or swaged 23 Pipe - Galvanised Nominal Size (DN) Section Outside Diameter mm 6.5m Wall Thickness mm Mass kg/m Metres per Tonne Medium Heavy 13.5 2.3 2.9 0.670 0.792 1490 1260 10 Medium Heavy 17.2 2.3 2.9 0.877 1.05 1140 951 Light Medium Heavy 21.3 2.0 2.6 3.2 1.01 1.25 1.48 994 798 674 20 Extra Light Light Medium Heavy 26.9 2.0 2.3 2.6 3.2 1.29 1.46 1.62 1.93 774 686 617 518 25 Extra Light Light Medium Heavy 33.7 2.0 2.6 3.2 4.0 1.64 2.07 2.49 3.02 608 482 401 332 32 Extra Light Light Medium Heavy 42.4 2.0 2.6 3.2 4.0 2.10 2.65 3.20 3.90 477 377 312 257 Extra Light Light Medium Heavy 48.3 2.3 2.9 3.2 4.0 2.73 3.36 3.68 4.49 367 297 272 223 50 Extra Light Light Medium Heavy 60.3 2.3 2.9 3.6 4.5 3.44 4.25 5.18 6.33 291 235 193 158 65 Extra Light Light Medium Heavy 76.1 2.3 3.2 3.6 4.5 4.37 5.94 6.61 8.12 229 168 151 123 80 Extra Light Light Medium Heavy 88.9 2.6 3.2 4.0 5.0 5.75 6.98 8.58 10.5 174 143 117 94.8 D 40 R 15 A FT 8 24 Pipe - Galvanised 90 100 125 150 Outside Diameter mm Section Wall Thickness mm Mass kg/m 2.6 3.2 4.0 5.0 6.60 8.02 9.88 12.2 152 125 101 82.3 Metres per Tonne Extra Light Light Medium Heavy 101.6 Extra Light Light Medium Heavy 114.3 3.2 3.6 4.5 5.4 9.05 10.1 12.4 14.8 110 98.9 80.4 67.8 Extra Light Light Medium Heavy 139.7 3.0 3.5 5.0 5.4 10.5 12.1 16.9 18.2 95.6 82.6 59.0 54.9 Light Medium Heavy 165.1 3.5 5.0 5.4 14.4 20.1 21.7 70.0 49.6 46.1 A FT Nominal Size (NB) 6.5m R End Conditions: Ends can be plain, shouldered, roll grooved, screwed BSP or swaged Galtube Plus® Pipe Outside Diameter mm Wall Thickness mm 20 25 32 40 50 65 26.9 33.7 42.4 48.3 60.3 76.1 2.0 2.0 2.0 2.3 2.3 2.6 D Nominal Size (DN) 25 Mass kg/m 1.23 1.56 1.99 2.61 3.29 4.71 Metres per Tonne 814 640 501 383 304 212 DuraGal® Extra Light Pipe Nominal Size (DN) Outside Diameter mm Wall Thickness mm 20 25 32 40 50 65 26.9 33.7 42.4 48.3 60.3 76.1 2.0 2.0 2.0 2.3 2.3 2.3 A FT 2.3 3.0 4.0 Mass kg/m Metres per Tonne 4.33 5.56 7.20 227 175 133 814 640 502 383 304 212 DuraGal® Yardrail Size mm Thickness mm Mass kg/m Metres per Tonne 115 x 42 2.0 2.5 4.27 5.30 234 189 120 x 48 2.0 4.53 221 125 x 40 2.0 4.54 220 D R 75 x 64 Thickness mm Metres per Tonne 1.23 1.56 1.99 2.61 3.29 4.19 DuraGal® Silo Section Size mm Mass kg/m 6m 26 RHS - Squares: Black, Painted & DuraGal® Size mm x mm x mm Mass kg/m Metres per Tonne 20 x 20 x 1.6 0.873 1150 30 x 30 x 1.6 x 2.0 35 x 35 x 1.6 x 2.0 x 2.5 x 3.0 890 733 610 529 1.38 1.68 727 596 1.63 1.99 2.42 2.83 615 502 412 353 1.88 2.31 2.82 3.30 4.09 533 434 303 244 R 40 x 40 x 1.6 x 2.0 x 2.5 x 3.0 x 4.0 1.12 1.36 1.64 1.89 2.38 2.93 3.60 4.25 5.35 6.39 D 50 x 50 x 1.6 x 2.0 x 2.5 x 3.0 x 4.0 x 5.0 Mass kg/m Metres per Tonne 2.0 2.5 3.0 4.0 5.0 6.0 3.13 3.88 4.78 5.66 7.23 8.75 10.1 319 258 209 177 138 114 98.6 75 x 75 x 2.0 x 2.5 x 3.0 x 3.5 x 4.0 x 5.0 x 6.0 4.50 5.56 6.60 7.53 8.49 10.3 12.0 222 180 152 133 118 96.9 83.1 89 x 89 x 3.5 x 5.0 x 6.0 9.06 12.5 14.6 110 80.0 68.3 90* x 90 x 2.0 x 2.5 5.45 6.74 184 148 00 x 100x 2.0 1 x 3.0 x 4.0 x 5.0 x 6.0 6.07 8.96 11.6 14.2 16.7 165 112 86.0 70.2 59.7 65 x 65 x 1.6 x x x x x x A FT 25 x 25 x 1.6 x 2.0 x 2.5 x 3.0 Size mm x mm x mm 420 300 278 236 187 156 * DuraGal® only 27 RHS - Squares: Black, Painted ONLY Size mm Mass kg/m Metres per Tonne 0.568 1760 15 x 15 x 1.8 0.681 1470 30 x 30 x 3.0 2.36 423 23.5 42.5 14.8 18.2 21.4 30.6 67.7 55.0 46.6 32.7 22.1 26.2 37.7 45.3 38.2 26.6 100 x 100x 9.0 25 x 125x 4.0 1 x 5.0 x 6.0 x 9.0 D R 50 x 150x 5.0 1 x 6.0 x 9.0 28 Mass kg/m Metres per Tonne 00 x 200x 5.0 2 x 6.0 x 9.0 29.9 35.6 51.8 33.4 28.1 19.3 50 x 250x 6.0 2 x 9.0 45.0 65.9 22.2 15.2 00 x 300x 6.0 3 x 9.0 x 12.0 54.4 80.1 105 18.4 12.5 9.56 50 x 350x 9.0 3 x 12.0 94.2 123 10.6 8.0 00 x 400x 9.0 4 x 12.0 108 142 9.23 7.03 A FT 13 x 13 x 1.8 Size mm RHS - Rectangles: Black, Painted & DuraGal® Mass kg/m Metres per Tonne 50 x 20x 1.6 x 2.0 x 2.5 x 3.0 1.63 1.99 2.42 2.83 615 502 412 353 50 x 25x 1.6 x 2.0 x 2.5 x 3.0 1.75 2.15 2.62 3.07 571 465 382 326 2.93 3.60 4.25 5.35 341 278 236 187 2.38 2.93 3.60 420 341 278 3.01 3.72 4.58 5.42 6.92 8.35 9.67 332 269 218 184 145 120 103 65 x 35x 2.0 x 2.5 x 3.0 x 4.0 75 x 25x 1.6 x 2.0 x 2.5 R 75 x 50x 1.6 x 2.0 x 2.5 x 3.0 x 4.0 x 5.0 x 6.0 Size mm x mm x mm Mass kg/m Metres per Tonne 100 x 50x 1.6 x 2.0 x 2.5 x 3.0 x 3.5 x 4.0 x 5.0 x 6.0 3.64 4.50 5.56 6.60 7.53 8.49 10.3 12.0 275 222 180 152 133 118 96.9 83.1 125 x 75 x 2.0 x 2.5 x 3.0 x 4.0 x 5.0 x 6.0 6.07 7.53 8.96 11.6 14.2 16.7 165 133 112 86.0 70.2 59.7 150 x 50 x 2.0 x 2.5 x 3.0 x 4.0 x 5.0 x 6.0 6.07 7.53 8.96 11.6 14.2 16.7 165 133 112 86.0 70.2 59.7 A FT Size mm x mm x mm D RHS - Rectangles: Black & Painted ONLY Size mm x mm x mm Mass kg/m Metres per Tonne 150 x 100x 4.0 x 5.0 x 6.0 x 9.0 14.8 18.2 21.4 30.6 67.7 55.0 46.6 32.7 200 x 100x 3.0 x 4.0 x 5.0 x 6.0 x 9.0 13.7 17.9 22.1 26.2 37.7 73.2 55.8 45.3 38.2 26.6 Size mm x mm x mm 29 Mass kg/m Metres per Tonne 50 x 150x 5.0 2 x 6.0 x 9.0 29.9 35.6 51.8 33.4 28.1 19.3 00 x 200x 6.0 3 x 9.0 x 12.0 45.0 65.9 86.8 22.2 15.2 11.7 00 x 200x 9.0 4 x 12.0 80.1 105 12.5 9.56 RHS - Squares: Galtube Plus® Thickness mm Mass kg/m Metres per Tonne Size mm x mm Thickness mm 20 x 20 1.6 0.873 1150 40 x 40 1.6 2.5 1.88 2.82 533 321 25 x 25 1.6 1.12 890 50 x 50 30 x 30 1.6 1.6 2.5 2.38 3.60 420 278 35 x 35 1.6 2.5 A FT Size mm x mm 1.38 727 1.63 2.42 615 412 Mass kg/m Metres per Tonne RHS - Rectangles: Galtube Plus® Size mm x mm Thickness mm 50 x 20 1.6 2.5 R 1.63 2.42 1.6 2.5 1.75 2.62 D 50 x 25 Mass kg/m Size mm x mm 64 76 x 38 x 38 90 x 38 Metres per Tonne 615 412 Size mm x mm Thickness mm 75 x 25 1.6 2.5 Mass kg/m 2.38 3.60 Metres per Tonne 420 278 571 382 Tubecolor® Thickness mm Mass kg/m 1.60 1.20 1.60 2.00 2.44 2.75 3.39 3.90 Size mm x mm 00 1 100 150 90 Note: Tubecolor® is only readily available in WA 30 x x x x 50 50 50 90 Thickness mm 1.60 2.00 2.00 2.00 Mass kg/m 3.64 4.50 6.07 5.45 BLACKFORM® steel Width mm Base Metal Thickness mm Width mm 1.50 1.50 1.60 1.60 1.60 1.60 1.95 1.95 1.95 1200 1210 910 1195 1200 1210 900 1195 1200 1.95 2.40 2.50 2.50 2.50 2.50 2.90 2.90 2.95 1210 1200 1195 1210 1495 1510 1210 1500 1200 Base Metal Thickness mm Width mm 2.95 2.95 3.00 3.00 3.00 3.00 3.00 3.00 1500 1800 895 1195 1210 1495 1510 1800 A FT Base Metal Thickness mm BRIGHTFORM® steel Base Metal Thickness mm 910 1210 1510 910 R 1.60 1.60 1.60 2.00 Width mm Base Metal Thickness mm Width mm Base Metal Thickness mm Width mm 2.00 2.00 2.50 1210 1510 1210 2.95 3.00 3.00 1210 910 1210 D Hot Rolled Pickled HA3-P steel Base Metal Thickness mm Width mm Base Metal Thickness mm Width mm 1.60 2.00 2.00 1210 910 1210 2.50 3.00 4.00 1210 1210 1210 31 Base Metal Thickness mm Width mm 5.00 6.00 1210 1210 COLD ROLLED CA2S-E steel Width mm Base Metal Thickness mm Width mm 0.75 0.75 0.80 0.90 915 1220 1220 1220 0.95 1.15 1.15 1.55 1220 915 1220 1220 Base Metal Thickness mm Width mm 1.95 2.45 3.00 1220 1220 1220 A FT Base Metal Thickness mm COLD ROLLED CA3sn-g steel Base Metal Thickness mm Width mm Base Metal Thickness mm Width mm Base Metal Thickness mm Width mm 0.60 0.80 1.00 1220 1220 1220 1.20 1.50 1.60 1220 1220 1220 2.00 2.50 3.00 1220 1220 1220 R GALVABOND® G2 Z275 steel Width mm Base Metal Thickness mm Width mm Base Metal Thickness mm Width mm 0.40 0.40 0.45 0.50 0.55 0.55 0.55 0.55 0.60 0.70 0.75 0.75 0.75 0.75 915 1220 915 1220 915 1200 1220 1500 1525 1220 915 1200 1220 1500 0.80 0.90 0.90 0.95 0.95 0.95 1.00 1.00 1.10 1.10 1.15 1.15 1.15 1.15 1525 915 1220 1200 1220 1500 1220 1525 915 1220 915 1200 1220 1500 1.20 1.50 1.50 1.50 1.55 1.55 1.55 1.60 1.90 1.95 1.95 2.40 2.45 2.90 1525 915 1220 1500 1200 1220 1500 1525 1220 1200 1220 1220 1200 1220 D Base Metal Thickness mm 32 GALVASKIN® G2 Z200 steel Width mm 0.40 0.40 0.45 0.50 0.55 0.55 0.55 0.55 915 1220 915 1220 915 1200 1220 1500 Base Metal Thickness mm Width mm Base Metal Thickness mm Width mm 0.60 0.70 0.75 0.75 0.75 0.75 0.80 1525 1220 915 1200 1220 1500 1525 0.90 0.90 0.95 0.95 0.95 1.00 1.00 915 1220 1200 1220 1500 1220 1525 A FT Base Metal Thickness mm ZINCANNEAL® G2S ZF100 steel Base Metal Thickness mm Base Metal Thickness mm Width mm Base Metal Thickness mm Width mm 1220 1220 1220 1220 1200 915 1220 1200 0.95 1.00 1.10 1.10 1.10 1.15 1.15 1.20 1220 1200 1050 1200 1220 1200 1220 1200 1.40 1.50 1.50 1.50 1.55 1.60 1.90 1.95 1220 915 1200 1220 1200 1200 1220 1200 D R 0.50 0.55 0.70 0.75 0.80 0.90 0.90 0.95 Width mm ZINCALUME® G300 AZ150 steel Base Metal Thickness mm Width mm Base Metal Thickness mm Width mm 0.40 0.55 0.55 1200 1200 900 0.75 1.00 1.00 1200 900 1200 33 Base Metal Thickness mm Width mm 1.20 1.20 900 1200 COLORBOND® Sheet Grade : CG300AZ150 Size mm x mm x mm Colours Mass sheets/tonne Headland® Manor Red™ Jasper™ Sandbank™ Classic Cream™ Surfmist® Paperbark ™ Dune® Shale Grey™ Windspray® Woodland Grey™ Bushland™ Pale Eucalypt™ Wilderness® Cottage Green™ Blue Ridge™ Deep Ocean® Ironstone™ Night Sky™ 77 1200 x 2400 x 0.55 x 3050 x 0.55 x 3660 x 0.55 Surfmist® 77 61 52 1200 x 1800 x 0.55 x 2400 x 0.55 Sign White 103 77 1200 x 2440 x 0.55 Appliance 76 1200 x 2400 x 0.80 x 2440 x 0.80 Sign White 54 53 D R A FT 1200 x 2400 x 0.55 34 Stainless Steel - Austenitic Sheet & Coil Thickness Range mm Width mm 316 0.55 to 6.00 914, 1219, 1500, 1525 304 0.55 to 6.00 914, 1219, 1500, 1525 A FT Grade Stainless Steel - Ferritic Sheet & Coil Grade Thickness Range mm Width mm 430 0.55 to 0.9 914, 1219 Range of Stainless Steel includes: Grades: 304, 316, 430 Finishes: 2B, No. 4 Polished, bright annealed Coil cut to custom length R Stainless Steel - Flat Bar Size mm x mm 3 6 0.29 0.58 3 5 6 0.49 0.81 0.98 x x x x x 3 5 6 10 12 0.61 1.02 1.21 2.04 2.45 32 x 3 0.77 D 12 x x Mass kg/m 20 x x x 25 Mass kg/m Size mm x mm 32 x x x 5 6 10 1.30 1.57 2.62 40 x x x x x 3 5 6 10 12 0.98 1.61 1.96 3.27 3.92 50 x x x x 3 5 6 10 1.21 2.04 2.45 4.08 Range of Stainless Steel includes: Grades: 304, 304L, 316, 316L Nitro Plasma Cutting available for all products 35 (Grades 304, 316) Size mm x mm Mass kg/m 50 x 12 4.90 65 x x 5 6 2.61 3.18 65 x 10 5.31 75 x x x x 5 6 10 12 3.06 3.68 6.04 7.25 00 x 1 x 6 10 4.91 8.18 Stainless Steel - Angle Mass kg/m mm 25 x 25 x 3 x5 x6 30 x 30 x 3 x5 x6 1.16 1.72 2.13 Mass kg/m Size mm 40 x 40 x 3 x5 x6 1.90 2.84 3.64 1.40 2.09 2.66 50 x 50 x 3 x5 x6 2.40 3.62 4.63 Stainless Steel - Round Bar Diameter mm 4.8 9.5 12.7 15.8 15.8 19.0 19.0 22.2 x x x x x x x x 0.5 0.7 0.7 1.2 1.6 1.2 1.6 1.2 75 x 75 x 5 x6 5.40 7.09 00 x 100x 6 1 x 10 9.42 15.0 Mass kg/m Diameter mm mm Mass kg/m 0.06 0.14 0.25 0.40 0.58 0.64 20.0 22.2 24.0 25.4 30.0 31.8 2.46 3.16 3.69 4.14 5.78 6.48 50.8 55.5 57.2 63.5 66.0 69.9 16.3 19.4 20.6 25.5 28.5 30.8 0.92 1.02 1.59 1.62 2.33 33.0 36.0 38.1 40.0 44.5 6.99 8.33 9.32 10.28 12.68 76.2 82.6 88.9 102 36.7 43.1 49.9 65.2 Mass kg/m O.D 4.67 6.12 (Grades 304, 316 & 431) Stainless Steel Tube - Round Size 65 x 65 x 5 x6 Diameter D 12.0 12.7 15.9 16.0 19.1 mm Mass kg/m R 3.18 4.76 6.35 7.94 9.63 10.0 Mass kg/m Size A FT Size (Grades 304, 316) 0.05 0.15 0.21 0.43 0.56 0.53 0.69 0.62 Mass kg/m Size O.D 22.2 25.4 25.4 31.8 31.8 38.1 38.1 x x x x x x x (Grades 304, 316) 1.6 1.2 1.6 1.2 1.6 1.2 1.6 0.81 0.72 0.94 0.91 1.19 1.09 1.44 36 Mass kg/m Size O.D 44.4 44.4 50.8 50.8 63.5 76.2 101.6 x x x x x x x 1.2 1.6 1.2 1.6 1.6 1.6 1.6 1.30 1.69 1.47 1.94 2.44 2.95 4.02 Stainless Steel Tube - Square (Grades 304, 316) Mass kg/m Size mm Mass kg/m Size mm x mm 9.0 x 19.0x 1.2 1 x 1.6 0.70 0.91 1.8 x 31.8x 1.2 3 x 1.6 1.20 1.58 0.8 x 50.8x 1.2 5 x 1.6 5.4 x 25.4x 1.2 2 x 1.6 0.95 1.27 8.1 x 38.1x 1.2 3 x 1.6 1.45 1.91 mm A FT Size Mass kg/m 1.92 2.58 Stainless Steel Tube - Rectangular (Grades 304, 316) mm x mm x mm Mass kg/m mm x mm x mm Mass kg/m 8.1 x 25.4x 1.2 3 x 1.6 1.20 1.58 0.8 x 25.4x 1.2 5 x 1.6 1.45 1.91 Size Annealed Unannealed Polished Finish Plastic Sleeving Specification Tube (e.g. Heat Exchanger Applications) D R Range includes: Size 37 MARBRITE® Bright Bar - Rounds Metric Size Imp. Equiv mm “ 9/32 5/16 3/8 7/16 1/2 9/16 Metric Size Imp. Equiv mm “ 0.222 0.249 0.302 0.314 0.389 0.395 0.499 0.559 0.617 0.746 0.761 0.888 0.994 1.04 1.21 1.26 1.39 1.55 1.58 1.78 1.88 2.00 2.23 2.24 2.47 2.63 2.72 2.98 3.04 3.26 3.50 3.55 3.85 3.98 4.17 4.49 4506 4016 3310 3182 2573 2534 2003 1790 1622 1341 1314 1126 1006 960 828 794 721 644 634 561 532 501 449 447 406 381 368 335 329 307 286 282 260 251 240 223 27.0 28.0 28.57 30.0 31.75 32.0 33.0 33.34 34.92 35.0 36.0 38.1 39.0 40.0 41.27 42.0 44.45 45.0 47.62 48.0 50.0 R 5/8 Metres per Tonne 11/16 3/4 13/16 7/8 15/16 1 1-1/16 1-1/8 A FT 1/4 D 6.00 6.35 7.00 7.14 7.94 8.00 9.00 9.52 10.0 11.0 11.11 12.0 12.7 13.0 14.0 14.29 15.0 15.87 16.0 17.0 17.46 18.0 19.0 19.05 20.0 20.64 21.0 22.0 22.22 23.0 23.81 24.0 25.0 25.4 26.0 26.99 Mass kg/m 50.8 52.0 55.0 56.0 57.15 60.0 60.32 63.5 65.0 66.67 69.85 70.0 75.0 76.20 80.0 38 1-1/4 1-5/16 1-3/8 1-1/2 1-5/8 1-3/4 1-7/8 2 2-1/4 2-3/8 2-1/2 2-5/8 2-3/4 3 Mass kg/m per Tonne 4.49 4.83 5.03 5.55 6.22 6.31 6.71 6.85 7.52 7.55 7.99 8.95 9.38 9.86 10.5 10.9 12.2 12.9 14.0 14.2 15.4 223 207 199 180 161 158 149 146 133 132 125 112 107 101 95 92 82 80 72 70 65 15.9 16.7 18.7 19.3 20.1 22.2 22.4 24.9 26.0 27.4 30.1 30.2 34.7 35.8 39.5 63 60 54 52 50 45 45 40 38 36 33 33 29 28 25 Metres MARBRITE® Bright Bar - Rounds Metric Size Imp. Equiv mm “ 85.0 88.9 90.0 95.0 95.3 100 102 110 3-3/4 4 44.5 48.7 49.9 55.6 55.9 61.7 63.6 74.6 Metres Metric Size Imp. Equiv per Tonne mm “ 22 21 20 18 18 16 16 13 114.3 120 127 130 139.7 140 150 152.4 4-1/2 5 A FT 3-1/2 Mass kg/m 5-1/2 6 Mass kg/m per Tonne 80.5 88.8 99.4 104 120 121 139 143 12 11 10 10 8 8 7 7 Metres MARBRITE® Bright Bar - Hexagons Metric Size Imp. Equiv mm “ 0.84 1.10 1.15 1.33 1.39 1.53 1.58 1.74 1.97 2.07 2.45 2.47 2.90 2.95 3.00 3.29 3.36 3.71 3.85 3.92 4.25 4.39 R 7/16 1/2 9/16 0.600 11/16 D 11.11 12.7 13.0 14.0 14.29 15.0 15.24 16.0 17.0 17.46 19.0 19.05 20.64 20.83 21.0 22.0 22.22 23.37 23.81 24.0 25.0 25.4 Mass kg/m 3/4 13/16 0.820 7/8 15/16 1 Metres Metric Size Imp. Equiv per Tonne mm “ 1192 912 870 751 720 654 633 575 509 483 407 405 345 339 334 304 298 269 259 255 235 228 25.65 26.99 27.0 28.57 30.0 30.48 31.75 32.0 33.02 33.34 34.92 36.0 36.51 37.59 38.0 38.1 42.42 46.0 47.24 52.07 55.0 61.21 39 1.010 1-1/16 1-1/8 1.200 1-1/4 1.300 1-5/16 1-3/8 1-7/16 1.480 1-1/2 1.670 1.860 2.050 2.410 Mass kg/m per Tonne 4.47 4.95 4.96 5.55 6.12 6.32 6.85 6.96 7.41 7.56 8.29 8.81 9.06 9.61 9.82 9.87 12.2 14.4 15.2 18.4 20.6 25.5 224 202 202 180 163 158 146 144 135 132 121 114 110 104 102 101 82 70 66 54 49 39 Metres Bright Bar - Flat, Square Edge Size mm x mm Mass kg/m Metres per Tonne Dimensions mm x mm Mass kg/m Metres per Tonne x 3 0.283 3539 40 x 4 1.256 796 x x x x x 4 5 6 7 8 0.377 0.471 0.565 0.659 0.754 2654 2123 1769 1517 1327 x x x x x x 5 7 10 15 20 25 1.57 2.198 3.14 4.71 6.28 7.85 637 455 318 212 159 127 16 x x x x x 3 4 5 6 7 0.377 0.502 0.628 0.754 0.879 2654 1990 1592 1327 1137 20 x x x x x 3 4 5 7 10 0.471 0.628 0.785 1.10 1.57 2123 1592 1274 910 637 50 x x x x x x x 4 5 7 10 15 20 25 1.57 1.96 2.75 3.93 5.89 7.85 9.81 637 510 364 255 170 127 102 25 x x x x x x 3 4 5 7 10 15 0.589 0.785 0.981 1.37 1.96 2.94 1699 1274 1019 728 510 340 75 x x x x x x x 4 5 7 10 15 20 25 2.36 2.94 4.12 5.89 8.83 11.8 14.7 425 340 243 170 113 85 68 00 1 x x x x x x x 4 5 7 10 15 20 25 3.14 3.93 5.50 7.85 11.8 15.7 19.6 318 255 182 127 85 64 51 D R A FT 12 32 x x x x x x x 4 5 7 10 15 20 25 1.01 1.26 1.76 2.51 3.77 5.02 6.28 995 796 569 398 265 199 159 40 Bright Bar - Square Metric Size Imp. Equiv mm “ 5/16 1/2 5/8 3/4 Metric Size Imp. Equiv mm “ 0.495 0.502 0.711 0.785 1.13 1.27 1.33 1.54 1.98 2.01 2.54 2.85 2021 1990 1406 1274 885 790 754 650 506 498 393 351 20.0 22.22 25.0 25.4 28.0 28.57 31.75 32.0 34.92 35.0 38.1 7/8 1” A FT 3/8 Metres per Tonne D R 7.94 8.00 9.52 10.0 12.0 12.7 13.0 14.0 15.87 16.0 18.0 19.05 Mass kg/m 41 1-1/8 1-1/4 1-3/8 1-1/2 Mass kg/m per Tonne 3.14 318 3.88 4.91 5.07 6.15 6.41 7.91 8.04 9.57 9.62 11.40 258 204 197 162 156 126 124 104 104 88 Metres Roof & Wall Cladding - ZINCALUME® & COLORBOND® Profile Base Metal Thickness mm Coated Thickness mm Width of Coverage mm 0.42 0.48 0.47 0.53 762 762 A FT Custom Orb / Corrugated Trimdek Hi-Ten Monoclad 0.42 0.48 0.47 0.53 762 762 Spandek Hi-Ten Longspan 0.42 0.48 0.47 0.53 700 700 0.42 0.48 0.60 0.47 0.53 0.65 406 406 406 Klip-Lok Hi-Ten Available COLORBOND® Colours R Headland®, Manor Red™, Jasper™, Sandbank™, Classic Cream™, Surfmist®, Paperbark ™, Dune®, Shale Grey™, Windspray®, Woodland Grey™, Bushland™, Pale Eucalypt™, Wilderness®, Cottage Green™, Blue Ridge™, Deep Ocean®, Ironstone™, Night Sky™ Cold Formed Angles Size mm x mm x mm Mass kg/m LA2725 LA3225 LA4030 27 x 27 x 2.5 32 x 22 x 2.5 40 x 40 x 3.0 1.00 1.00 1.79 D Cat. No. 42 Cat. No. Size mm x mm x mm Mass kg/m LA4630 LA5130 46 x 35 x 3.0 51 x 30 x 3.0 1.79 1.79 Cold Formed Plain Channels Cat. No. Size mm x mm x mm LCO1916 LCO2516 LCO3816 LCO5116 LCO5130 LCO5725 LCO6425 LCO7630 x x x x x x x x 12 13 16 15 25 26 22 37 x x x x x x x x 1.6 1.6 1.6 1.6 3.0 2.5 2.5 3.0 0.49 0.58 0.84 0.97 2.15 2.00 2.00 3.34 Cat. No. Size mm x mm x mm LCO8330 LCO8930 LCO9530 LC10330 LC10230 LC12730 LC15230 83 89 95 103 102 127 152 A FT 19 25 38 51 51 57 64 76 Mass kg/m x x x x x x x 34 31 35 31 55 49 50 x x x x x x x 3.0 3.0 3.0 3.0 3.0 3.0 3.0 Mass kg/m 3.34 3.34 3.70 3.70 5.78 5.26 6.86 Lipped Channels LL05116 LL06425 LL07610 LL07625 LL10225 LL10232 Size mm x mm 51 x 64 x 76 x 76 x 102 x 102 x 35 38 44 44 51 51 Bass Metal Thickness mm 1.6 2.5 1.0 2.5 2.5 3.0 R Cat. No. Mass kg/m Cat. No. 1.68 2.91 1.43 3.33 4.39 5.25 LL12725 LL12730 LL15230 LL20330 LL25430 D Note: Cold formed angles are also available in zinc-coated steel 43 Size mm x mm 27 1 127 152 203 254 x x x x x 51 51 64 76 89 Bass Metal Thickness mm 2.5 3.0 3.0 3.0 3.0 Mass kg/m 4.89 5.85 7.18 9.07 11.20 Purlins - C Sections C 10010 C 10012 C 10015 C 10019 C 15012 C 15015 C 15019 C 15024 Size mm x mm x mm 102 102 102 102 152 152 152 152 x x x x x x x x 53 53 53 53 65 65 65 66 x x x x x x x x 1.0 1.2 1.5 1.9 1.2 1.5 1.9 2.4 Mass kg/m Designation 1.74 2.07 2.58 3.25 2.84 3.54 4.46 5.62 C 20015 C 20019 C 20024 C 25019 C 25024 C 30024 C 30030 C 35030 Size mm x mm x mm 203 x 79 x 203 x 79 x 203 x 79 x 254 x 79 x 254 x 79 x 300 x 100x 300 x 100x 350 x 129x FT Designation 1.5 1.9 2.4 1.9 2.4 2.4 3.0 3.0 Mass kg/m 4.44 5.68 7.15 6.43 8.10 10.0 12.6 15.1 Purlins - Z Sections 102 102 102 102 152 152 152 152 x x x x x x x x 51 51 51 51 64 64 64 64 x x x x x x x x 1.0 1.2 1.5 1.9 1.2 1.5 1.9 2.4 Mass kg/m Designation 1.74 2.07 2.58 3.25 2.84 3.54 4.46 5.62 Z 20015 Z 20019 Z 20024 Z 25019 Z 25024 Z 30024 Z 30030 Z 35030 D R Z 10010 Z 10012 Z 10015 Z 10019 Z 15012 Z 15015 Z 15019 Z 15024 Size mm x mm x mm A Designation Size mm x mm x mm 03 2 203 203 254 254 300 300 350 x x x x x x x x 76 x 76 x 76 x 76 x 76 x 96 x 96 x 125x 1.5 1.9 2.4 1.9 2.4 2.4 3.0 3.0 Notes: Purlins are made from high tensile steel to be fastened rather than welded. More sizes available on application - please enquire. 44 Mass kg/m 4.44 5.68 7.15 6.43 8.10 10.0 12.6 15.1 Gutter & Accessories - ® ® ZINCALUME & COLORBOND ProductCustom cut lengths Sheerline Gutter Sheerline Gutter Clips General purpose Universal 3.6m to 8.0m 6m Sheerline Gutter - Stop End - - - - - - Colonial Gutter - 6m Gutter Straps Timber fix Metal fix - - - Corners - - - - R Stop Ends Downpipe & Accessories - ZINCALUME ® Profile D Stock lengths FT A Profile ® & COLORBOND Product Stock lengths 1800mm and 2400mm Rectangular Downpipes 75mm x 50mm 95mm x 45mm 100mmx 50mm Round Downpipes 75mm diameter Elbows (80 ) Saddle Straps 75mm Pops 75mm 45 Stock lengths Stock lengths Stock lengths Fasteners Profile Self Drilling with Hex Head and Neoprene Washer RUSPRO - CLASS 3 to AS 3566 A FT For fixing to Timber A B 12 x 25mm 12 x 50mm 12 x 65mm For fixing to Steel A B 10 x 16mm 12 x 20mm 12 x 35mm 12 x 45mm 12 x 65mm Aluminium Rivets - Steel Stem 4-2 3.2 x 6mm 4-3 3.2 x 8mm 4-4 3.2 x 10mm 4-6 3.2 x 15mm R D Note: A wide range of fasteners are available from your Metaland store. 46 Light Weight Sections - Topspan Height mm Base Metal Thickness mm Stock Lengths Topspan Tile Batten 20 0.48 6.1 Topspan Ceiling Batten 25 0.42 6.1 Topspan 40 Roof Batten 40 0.55 0.75 6.1 6.1 Topspan Roof batten 50 0.75 6.1 Topspan 61 61 0.75 1.00 6.1 6.1, 7.6 Topspan 120 120 0.70 0.90 4.5, 6.1, 7.0 6.1, 7.5, 8.65 Product R A FT Profile Light Weight Sections - Steel Building Frame Components Size mm x mm Base Metal Thickness mm Standard Stud 75 x32 Nogging Plate Product D Profile Stock Lengths Lengths per Bundle 1.2 7.4 10.0 50 72 x34 1.2 7.4 50 78 x31 1.2 7.4 50 47 DuraGal Flooring System® Fully Engineered System The DuraGal Flooring System® is a fully engineered steel flooring system* developed to provide a termite resistant, economical and easy-to-install alternative to conventional timber bearers & joists. A FT Easy to Install The DuraGal Flooring System® uses high strength C450L0 grade galvanized DuraGal® Hollow Sections. The sections are strong and lightweight making them easy to handle on site. DuraGal® is easy to cut and drill, and best of all the system has been designed so that it simply screws together on site using a screw gun fitted with a hex head bit. The DuraGal Flooring System® features a range of specialty galvanized fittings designed to allow you to get on with the job easily and quickly. Fast and accurate levelling of the floor using the adjustable piers during and after construction is a great feature. R Sheet flooring can still be attached in the traditional way using building adhesive and gunnailing. Most reputable nail tool suppliers have hardened tipped nails to suit common nail guns to suit fixing sheet flooring to steel joists up to and including 2mm thick. Bearer end support Blocking D Floor joist to bearer DuraGal® Pier. Pier to bearer connection Pier to footing Internal joiners End cap to bearer or joist *The DuraGal Flooring System® requires independent engineering certification to determine compliance of site specific conditions with statutory requirements. Top bracing Bottom bracing 48 DuraGal Flooring System® DURAGAL® PIER Pier adjustable top connection fits 90x90x2.0 DuraGal® SHS – 100mm in adjustment, maximum recommended <70mm – Suits 50mm wide bearers – Maximum height 4.5m BEARER END SUPPORT Double joists under load bearing walls DuraGal® pier 90x90x2.0mm Moment base plate (for use where additional bracing is required) A FT Pier bottom connection to suit 90x90x2.0mm DuraGal® pier INTERNAL JOINERS Internal joiner (bearer and joist) PIER TO BEARER CONNECTION Adjustable top fitting Pier bottom connection FLOOR JOIST TO BEARER CONNECTIONS mm min PIER TO FOOTING DETAIL (BASE PLATE) Masonry anchors Also available in 45 and 90 degrees for standard sizes R PIER TO FOOTING DETAIL (CAST IN) Footing to engineer’s specification. Finished 50mm above ground level and trowelled level. Not included in quotation. PRYDA® UNITE 50mm min Masonry anchors Note: Which type used will be dependent on the tie down requirements Depth to engineer’s specifications D 100mm min (may be precast) Width or diameter to engineer’s specifications PRYDA® TRIPLE GRIPS PRYDA® PERGOLA ANGLES Spans Joists are typically 100x50x1.6mm with continuous spans of 2800 mm and bearers are typically 150x50x2.0mm with continuous spans of 3000mm. Other sizes may be specified with differing spans subject to the floor layout and site conditions. Your DuraGal Flooring System® distributor will be able to nominate the most economical sizes and layout upon receipt of the house plans. Typical sections of Internally Painted DuraGal® Piers: 90 x 90 x 2.0mm Bearers: 150 x 50 x 2.0mm Joists: 100 x 50 x 1.6mm SPLIT LEVEL ARRANGEMENT DuraGal® joist DuraGal® bearer (upper level) Verandah Sleeve DuraGal® pier 49 Pier adjustable top connection DuraGal® joist DuraGal® bearer (lower level) DuraGal® Carports Size Range FT The DuraGal® Building Systems Carport brings to the market a system that offers: • A lightweight, efficient structure constructed from high strength DuraGal® RHS. • A cost-effective coating system. The inline hot dip galvanized external coating applied to DuraGal® RHS provides a product ready for use. • Proprietary fittings allow fast and efficient assembly. • A selection of sizes includes cyclone ratings to suit all markets. DuraGal® IP sizes Standard Height 2.150m Rafters: 150x50x2.0/3.0 • 5.4 x 3.0 & 5.4 (m) • 6.0 x 3.0, 3.6 & 6.0 (m) Purlins: 150x50x2.0/3.0 • 7.0 x 3.6 & 6.0 (m) 100x50x1.6/2.0 100x50x1.6/2.0 A Posts: 90x90x2.0 D R The DuraGal® Carport uses high strength C450L0 grade galvanised DuraGal® Hollow Sections. The sections are strong and lightweight making them easy and safe to handle on site. The DuraGal® Carport is designed using a range of specialty fittings to allow safe and easy construction. Advantages of the DuraGal® Building Systems Carport • Material pre-cut and delivered direct to • Simple Purlin fixing. site as a flat pack, read to install. • Self-drilling screws allow speedier • Reduced edges minimise the chance of assembly. vermin perching and nesting. • Easily cleaned. • No protruding fasteners. • No welding and no time-consuming • Easy & quick to erect. bolted connections. • Visually pleasing clean lines. 50 Hopleys® Trusses and Joists Height mm Length m 150 200 250 300 6.10 6.10 6.10 7.62 FT Profile Hopleys® Portal Rafter A Profile Height mm Length m 300 9.00 Hopleys® Standard Fittings R Profile D (a) (a) Shoes for fitting joists to uprights, columns, walls for making “T” connections in joists. (b) (b) Load Clips for bracing where concentrated loads fall between nodes. (c) Nail Clips for fastening joists to top plates, etc. (c) (d)Splicing Channels for joining two separate joists together. Can be welded or tek screwed. Note: when splicing webs, keep them continuous and straight and weld webs together. (e) (d) Product (e) Knee Channels for full strength angle connections. A simple bolted joint to provide full movement capacity of the joists. 51 ELTRAK® - Sliding Door Hardware Profile Guide Pin (Plated) Carriage (4 Wheel Steel) Medium Heavy For doors to Weight: 120kg Height: 2400mm For doors to Weight: 200kg Height: 3000mm For doors to Weight: 450kg Height: 4500mm For doors to Weight: 650kg Height: 6000mm ED2 45 x 35mm 1.20mm Stock Length 6.0m & 7.2m EM1 61 x 50mm 1.50mm Stock Length 6.0m & 7.2m EH1 61 x 50mm 1.60mm Stock Length 6.0m, 7.2m & 7.6m EG2 34 x 30mm 1.00mm Stock Length 6.0m ED5 120 per pack EG12 100 per pack R Trackmaster Carriage Light A FT Track (Galvanised) Extra Light D Weld on Bracket Bolt on Bracket EH5 80 per pack ED12 80 per pack EH EH12ST 30 per pack - EH15ST 30 per pack EG18 1150 per pack ED19 140 per pack EH19 50 per pack EG19 150 per pack ED19 140 per pack EH19 50 per pack - ED19BS 140 per pack EH19BS 200 per pack Bolt Set 52 ELTRAK® - Sliding Door Hardware Profile Extra Light Light Medium Heavy For doors to Weight: 120kg Height: 2400mm For doors to Weight: 200kg Height: 3000mm For doors to Weight: 450kg Height: 4500mm For doors to Weight: 650kg Height: 6000mm Side Fix Bracket EG20 100 per pack ED120 80 per pack EH120 40 per pack EG23 150 per pack ED23 80 per pack EH23 50 per pack EG22 60 per pack ED25 50 per pack EH24 30 per pack - ED27 60 per pack EH27B 30 per pack - ED30 200 per pack EH30 200 per pack - ED37 100 per pack A FT on ED & EH use in conjunction with ED19 & EH19 Single Overhead Support Bracket Double Overhead Support Bracket R Overhead Support Weld on Bracket D End Plate Top Plate and Adjusting Nut EM37 100 per pack Track Stop EC40 200 per pack - 53 EH37 100 per pack Lintels Flat 85 x 8 Multi Rib up to 600mm 600 - 700 700 - 800 800 - 900 900 - 1000 1000 - 1100 1100 - 1200 1200 - 1500 1500 - 1800 1800 - 2100 2100 - 2400 2400 - 2700 2700 - 3000 3000 - 3300 3300 - 3600 4000 - 4200 4200 - 4500 4800 - 5100 5400 - 5700 800 900 1000 1100 1200 Max Clear 150 x 100 x 6 100 x 75 x 10 150 x 90 x 10 150 x 100 x 10 Multi Rib Multi Rib Traditional Traditional Traditional 1800 2100 2400 2700 3000 3300 3600 4000 4500 5000 5500 6000 2100 2400 2700 3000 3300 3600 4000 4500 5000 5500 6000 900 1200 1200 1200 1500 1500 1800 2100 2400 2700 Rendabar 1200 1200 1500 1500 1800 2100 2400 2700 3000 1800 2100 2400 2700 3000 3300 3600 4000 100 x 100 x 8 150 x 100 x 8 200 x 200 x 7 200 x 200 x 9 200 x 200 x 10 250/10x200/10 250/12x200/10 Rendabar 900 900 1200 1200 1200 1500 1500 1800 2100 2400 D up to 600mm 600 - 700 700 - 800 800 - 900 900 - 1000 1000 - 1100 1100 - 1200 1200 - 1500 1500 - 1800 1800 - 2100 2100 - 2400 2400 - 2700 2700 - 3000 3000 - 3300 3300 - 3600 3600 - 4000 4000 - 4200 4200 - 4500 4500 - 4800 4800 - 5100 5100 - 5400 5400 - 5700 5700 - 6000 900 T-Bar R Opening (mm) 100 x 100 x 6 A Opening (mm) Angle FT Max Clear Rendabar Multi Rib 1800 2100 2400 2700 3000 3300 3600 4000 900 1200 1200 1200 1500 1500 1800 2100 2400 2700 3000 3300 3600 3900 Multi Rib 3600 3900 4200 4500 4800 5100 5400 5700 6000 6300 54 Traditional Traditional 2700 3000 3300 2800 5200 5400 5600 6000 6300 Traditional 5200 5400 6000 DuraGal® Plus Lintels Size mm x mm Nominal Thickness mm Mass kg/m 6.0 8.0 8.92 11.7 100 x 100 Size mm x mm Nominal Thickness mm Mass kg/m 6.0 8.0 11.3 14.9 150 x 100 Reference Number Sheet Size mm x mm D GM50105/ (WK3008) Reference Number M25252524 M50252524 M50253124 M505031524 M50504024 M50754024 mm x mm mm Mass kg/m2 Strand Width 000 x 3 x x x 1200 900 750 600 42 x x x x 135 135 135 135 8.0 8.0 8.0 8.0 14.6 14.6 14.6 14.6 300 x 2 x x x 1200 900 750 600 42 x x x x 135 135 135 135 11.0 11.0 11.0 11.0 19.5 19.5 19.5 19.5 R GM50075/ (WK3022) Nominal Opening Size A GR50080/ (WK4514) GR50110/ (WK4519) FT Mesh - Expanded Metal 000 x 3 x x x 1200 900 750 600 25 x x x x 75 75 75 75 7.5 7.5 7.5 7.5 22.0 22.0 22.0 22.0 300 x 2 x x x 1200 900 750 600 30 x x x x 75 75 75 75 10.5 10.5 10.5 10.5 28.1 28.1 28.1 28.1 Handyman Mesh Sheet Size mxm Wire Spacing Wire Diameter mm x mm mm Approx Mass kg/sheet 2.4 x 1.2 25 x 25 2.50 9 1.2 1.2 1.2 1.2 1.2 50 x x x x x 25 25 50 50 75 2.50 3.15 3.15 4.00 4.00 7 11 8 12 10 x x x x x 55 General Purpose Mesh Reference Number Wire Diameter mm x mm mm Approx Mass kg/sheet 3 x x x x x x x x x 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 25 50 100 x x x x x x x x x 25 25 25 50 50 75 75 100 150 2.50 3.15 3.15 4.00 5.00 4.00 5.00 5.60 5.60 23 36 27 29 45 24 39 29 25 30 x x x x x x 0.9 1.2 1.8 0.9 1.2 1.8 50 100 x x x x x x 75 75 75 100 100 100 2.50 2.50 2.50 2.50 2.50 2.50 36 47 71 21 28 43 R Galv. Rolls G232A9 G232A12 G232A18 G442A9 G442A12 G442A18 Wire Spacing A FT Galv. Sheets G112A G113 G213 G224 G225 G234 G235 G445A G465A Sheet Size mxm Reinforcing Mesh Sheet Size mxm D Reference Number SL 81 F 41 SL 102 SL 92 SL 82 SL 72 SL 62 SL 52 SL 63* SL 53* 6 x x x x x x x x x x 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.3 Wire Spacing mm x mm 00 1 200 300 x x x x x x x x x x 100 100 200 200 200 200 200 200 300 300 *Only available in WA 56 mm Approx Mass kg/sheet 8.00 4.00 10.0 9.00 8.00 7.10 6.30 5.00 6.30 5.00 116 29 89 72 58 45 36 23 24 15 Wire Diameter Trench Mesh L8TM2 L8TM3 L8TM4 L8TM5 Width (metre) 0.2 0.3 0.4 0.5 Wire Spacing mm x mm 00 1 x x x x Diameter Long/Cross mm/mm Approx Mass kg/sheet 8/4 8/4 8/4 8/4 8 10 13 15 300 300 300 300 A FT Reference Number Reinforcing Accessories Reference Number PLASTIC COMBINATION BAR CHAIRS PLASTIC COMBINATION BAR CHAIRS PLASTIC COMBINATION BAR CHAIRS PLASTIC COMBINATION BAR CHAIRS BLACK POLYTHENE BUILDING FILM D R COM2540 COM50650 COM7590 COM85100 PB24 Product Description 57 Product Specifications 25/40mm 50/65mm 75/90mm 85/100mm 4m x 50m per 100 per 100 per 100 per 100 each ELGATE®: Pipe & Gate Fittings Tees - 3 Way QTY= kg 15 20 20 20 25 25 25 25 32 32 32 32 40 40 40 40 50 50 50 50 65 80 80 80 80 100 140 100 100 80 80 80 60 50 60 50 40 40 40 40 30 25 40 30 25 25 15 30 25 25 15 25 15 15 20 25 20 25 32 40 25 32 40 50 25 32 40 50 25 32 40 50 50 25 32 40 50 32 R T1515 T2015 T2020 T2025 T2520 T2525 T2532 T2540 T3225 T3232 T3240 T3250 T4025 T4032 T4040 T4050 T5025 T5032 T5040 T5050 T6550 T8025 T8032 T8040 T8050 T1003 Thru Butt Code 18 14 17 14 12 17 22 25 21 22 21 24 17 19 16 16 19 17 16 18 19 19 25 28 21 25 C1515 C2020 C2025 D X1515 X2020 X2025 X2525 X2532 X2540 X2550 X3232 X3240 X3250 X4040 X4050 X5050 X5065 Thru Butt QTY= kg 15 20 20 25 25 25 25 32 32 32 40 40 50 50 120 80 60 50 30 30 25 30 30 20 20 20 15 10 15 20 25 25 32 40 50 32 40 50 40 50 50 65 15 20 20 15 20 25 QTY= kg 80 48 48 18 19 20 Adjustable Corners - 4 Way Code AC2525 AC2532 AC2540 AC2550 AC3232 AC3240 AC3250 AC4040 AC4050 AC5050 Thru Butt QTY= kg 25 25 25 25 32 32 32 40 40 50 30 30 30 20 20 16 16 16 16 12 25 32 40 50 32 40 50 40 50 50 17 19 21 16 17 14 14 15 15 15 Post Caps - Round Pipe Code K20 K25 K32 K40 K50 K65 K80 K90 K100 Crosses - 4 Way Code Thru Butt A FT Code Fixed Corners - 4 Way 17 21 18 30 15 14 18 19 22 16 15 17 17 18 PC20 PC25 PC32 PC40 PC50 PC65 PC80 PC90 PC100 PC125 PC150 58 Finish Tube QTY= kg Galv 20 25 32 40 50 65 80 90 100 400 400 200 200 120 80 50 40 40 7 15 12 13 12 11 9 9 11 G/bond 20 25 32 40 50 65 80 90 100 125 150 400 400 200 200 120 80 50 40 40 20 15 7 15 12 15 12 11 9 9 10 8 8 ELGATE®: Pipe & Gate Fittings Post Caps - Square Tube Code QTY= kg G/bond 300 200 150 100 60 50 40 35 35 35 35 35 35 35 Code 10 9 9 9 7 8 8 GH2020 GH2520 GH2525 GH3220 GH3225 GH4020 GH5020 Gate Hinges - Two Part Code Post Gate QTY= kg A FT SPC35 SPC40 SPC50 SPC65 SPC75 SPC90 SPC100 Finish Tube Gate Hinge - Interlocking 25 32 25 32 25 32 25 32 40 25 32 40 R 40 40 50 50 65 65 80 80 80 100 100 100 32 32 32 32 24 24 24 24 24 24 24 24 Code 18 14 17 14 12 17 22 25 21 22 21 24 D 120 80 60 50 30 30 25 17 21 18 18 15 14 18 NB QTY= kg HSLF20 HSLF25LD HSLF25HD HSLF32 HSLF40 20 25 25 32 40 200 120 70 60 60 18 19 21 21 21 HSTF20 HSTF25 HSTF32 HSTF40 HSTF50 20 25 32 40 50 200 70 60 60 60 19 19 18 19 21 Diam. Size QTY= kg TB1 TB2 TB3 TB600 12 16 16 16 255 355 825 600 60 40 5 5 19 29 7 6 DBL12 DBL16 14 18 (pair) (pair) 300 300 18 18 Post Flanges - Round Pipe Code Gate Hinge Straps Code 15 20 25 25 32 40 50 Gate Tower Bolts & Lugs Post Gate QTY= kg TH4025 TH4032 TH5025 TH5032 TH6525 TH6532 SH8025 SH8032 SH8040 SH10025 SH10032 SH10040 15 20 20 25 25 25 25 OPF20 OPF25 OPF32 OPF40 OPF50 RPF32 RPF40 RPF50 RF25 RF32 RF40 RF50 PF32 PF40 PF50 59 Finish Tube QTY= kg Galv 20 25 32 40 50 32 40 50 G/bond 25 32 40 50 32 40 50 100 100 60 60 60 40 40 40 80 40 40 40 40 40 40 13 16 20 22 21 21 21 20 14 22 22 20 13 13 22 Gate Drop Bolts Gate Gudgeons - Round Pipe PinNB QTY= kg AG20 AG25 AG27 AG33 20 25 27 33 20 25 25 32 100 80 80 40 BG20 BG25 BG27 BG33 20 25 27 33 20 25 25 32 LBG20 LBG25 LBG27 LBP 20 25 27 - 20 25 25 - Code SDB1200 SDB1400 DB900 DB1050 DB1200 DB75012 DB250A DB350A DB450A DB800A FT 23 21 24 23 80 80 80 40 820 22 24 24 60 60 60 100 20 22 24 24 D R A Code 60 Diam. Size QTY= kg 16 16 16 16 16 12 12 16 16 16 5 5 5 5 5 10 50 30 30 5 1200 1400 900 1050 1200 750 250 350 450 800 10 13 8 9 10 8 16 22 27 7 Telescoping RHS Female(outer) Nominal Clearance Male(inner) d b t top side d b mm mm mm mm mm mm mm Square Hollow Sections Female(outer) Nominal Clearance Male(inner) d b t top side d b mm mm mm mm mm mm mm 89 75 89 89 89 89 89 3.5 5.0 6.0 7.0 4.0 2.0 7.0 4.0 2.0 75 75 75 75 75 75 90 90 90 90 2.0 2.5 11.0 10.0 11.0 10.0 75 75 75 75 100 100 100 100 100 100 100 100 100 100 100 100 100 100 2.0 2.5 3.0 4.0 5.0 6.0 9.0 6.0 5.0 4.0 2.0 0.0 13.0 7.0 6.0 5.0 4.0 2.0 0.0 13.0 7.0 90 90 90 90 90 75 75 90 90 90 90 90 75 75 125 125 125 125 125 125 125 125 4.0 5.0 6.0 9.0 17.0 15.0 13.0 7.0 17.0 15.0 13.0 7.0 100 100 100 100 100 100 100 100 150 150 150 150 150 150 5.0 6.0 9.0 15.0 13.0 7.0 15.0 13.0 7.0 125 125 125 125 125 125 200 200 200 200 200 200 5.0 6.0 9.0 40.0 38.0 32.0 40.0 38.0 32.0 150 150 150 150 150 150 250 250 250 250 6.0 9.0 38.0 38.0 32.0 32.0 200 200 200 200 1.8 1.8 No Section Available 20 20 1.6 1.8 1.8 15 15 25 25 25 25 25 25 1.6 2.0 2.5 1.8 1.0 0.0 1.8 1.0 0.0 20 20 20 20 20 20 30 30 30 30 1.6 2.0 1.8 1.0 1.8 1.0 25 25 25 25 35 35 35 35 35 35 35 35 1.6 2.0 2.5 3.0 1.8 1.0 0.0 4.0 1.8 1.0 0.0 4.0 30 30 30 25 30 30 30 25 40 40 40 40 40 40 40 40 40 40 1.6 2.0 2.5 3.0 4.0 1.8 1.0 0.0 4.0 2.0 1.8 1.0 0.0 4.0 2.0 35 35 35 30 30 35 35 35 30 30 50 50 50 50 50 50 50 50 50 50 50 50 1.6 2.0 2.5 3.0 4.0 5.0 6.8 6.0 5.0 4.0 2.0 0.0 6.8 6.0 5.0 4.0 2.0 0.0 40 40 40 40 40 40 40 40 40 40 40 40 65 65 65 65 65 65 65 65 65 65 65 65 65 65 1.6 2.0 2.5 3.0 4.0 5.0 6.0 11.8 11.0 10.0 9.0 7.0 5.0 3.0 11.8 11.0 10.0 9.0 7.0 5.0 3.0 50 50 50 50 50 50 50 50 50 50 50 50 50 50 75 75 75 75 75 75 75 75 75 75 75 75 75 75 2.0 2.5 3.0 3.5 4.0 5.0 6.0 6.0 5.0 4.0 3.0 2.0 0.0 13.0 6.0 5.0 4.0 3.0 2.0 0.0 13.0 65 65 65 65 65 65 50 65 65 65 65 65 65 50 A 13 15 75 75 75 75 75 75 50 50 50 50 50 50 50 1.6 2.0 2.5 3.0 4.0 5.0 6.0 6.8 6.0 5.0 4.0 2.0 0.0 13.0 11.8 11.0 10.0 9.0 7.0 5.0 13.0 65 65 65 65 65 65 50 35 35 35 35 35 35 25 100 100 100 100 100 100 100 100 50 50 50 50 50 50 50 50 1.6 2.0 2.5 3.0 3.5 4.0 5.0 6.0 21.8 21.0 20.0 19.0 18.0 17.0 15.0 13.0 21.8 21.0 20.0 19.0 18.0 17.0 15.0 13.0 75 75 75 75 75 75 75 75 25 25 25 25 25 25 25 25 100 100 100 100 100 100 100 100 50 50 50 50 50 50 50 50 1.6 2.0 2.5 3.0 3.5 4.0 5.0 6.0 31.8 31.0 30.0 29.0 28.0 27.0 25.0 23.0 11.8 11.0 10.0 9.0 8.0 7.0 5.0 3.0 65 65 65 65 65 65 65 65 35 35 35 35 35 35 35 35 125 125 125 125 125 125 75 75 75 75 75 75 2.0 2.5 3.0 4.0 5.0 6.0 21.0 20.0 19.0 17.0 15.0 13.0 21.0 20.0 19.0 17.0 15.0 13.0 100 100 100 100 100 100 50 50 50 50 50 50 150 150 150 150 100 100 100 100 4.0 5.0 6.0 9.0 17.0 15.0 13.0 7.0 17.0 15.0 13.0 7.0 125 125 125 125 75 75 75 75 200 200 200 200 100 100 100 100 4.0 5.0 6.0 9.0 42.0 40.0 38.0 32.0 42.0 40.0 38.0 32.0 150 150 150 150 50 50 50 50 250 250 250 150 150 150 5.0 6.0 9.0 40.0 40.0 38.0 38.0 32.0 32.0 200 200 200 100 100 100 FT ‑ 15 Rectangular Hollow Sections 50 50 50 50 20 20 20 20 1.6 2.0 No Section 2.5 Available 3.0 50 50 50 50 25 25 25 25 1.6 2.0 No Section 2.5 Available 3.0 65 65 65 65 35 35 35 35 2.0 2.5 3.0 4.0 11.0 10.0 9.0 7.0 6.0 5.0 4.0 2.0 50 50 50 50 25 25 25 25 75 75 75 25 25 25 1.6 2.0 2.5 21.8 21.0 20.0 1.8 1.0 0.0 50 50 50 20 20 20 R D 13 Female(outer) Nominal Clearance Male(inner) d b t top side d b mm mm mm mm mm mm mm TOP CLEARANCE FEMALE CLEARANCE TOP CLEARNACE FEMALE NOTE RHS is not a precision tube and all dimensions shown in the chart, although in accordance with the specifications, may vary marginally within the tolerance bands permitted. Sizes shown in bold print are sizes that provide a clearance of less than 2.0mm. The internal weld bead and variation in corner radii between sections will need to be considered when closer fits are indicated. Where telescoping over some length is desired, additional allowance may be needed for straightness. For tight fits it is recommended that some form of testing be carried out prior to committing material. How To use this chart 1. Select the appropriate table for the type of hollow section required. Select the size of female (or outside) member closest to your requirements for the left hand column. 2. Depending on the application select the clearance required between the two members. Members may need to slide freely MALE inside each other, or be BORE locked with a pin, spot welded or FEMALE fixed with wedges. This means, in some cases, a ‘sloppy’ fit do may be suitable, while for others the tightest fit possible may be more appropriate. MALE SIDE CLEARANCE MALE SIDE CLEARANCE 3. Having selected the most suitable clearance for your application, take the appropriate size of the male (inner) section from the right hand column, eg: 5. RHS has the obvious advantage that its shape prevents rotation of the sections. When pipe is used it may need to be fixed against twisting by welding or bolting. Female Section (outer) 75 x 75 x 3.0 6. Press Fit. For short pieces with no need for separation or sliding an interference fit can be achieved using the available ductility of the steel. Clearance mm 4.0x4.0 Male Section (inner) 65 x 65 Note that clearance is total available difference between member dimensions, not the gap on both sides. 4. Where two telescoping sections are being used, thickness should be similar and will be determined by normal structural requirements. If a third section is to be used, consideration of both clearance and thickness within the size list available may be required. 61 Note: Sizes where clearance is shown as 0.0 will generally require press fit. Telescoping CHS Female(outer) Size DN Quality do t 15 Light 21.3 x 2.0 Medium 2.6 Heavy 3.2 Extra Light 26.9 x 2.0 - - - - - - - - - 15 21.3 0.4 Female(outer) Size DN 65 Quality do t Extra Light 76.1 x 2.3 2.6 Galtube® Plus Light 3.2 Medium 3.6 Heavy 4.5 Extra Heavy 5.9 A FT 20 DN Male(inner) Size Minimum Clearance do mm DN Male(inner) Size Minimum Clearance do mm 50 50 50 50 50 50 60.3 60.3 60.3 60.3 60.3 60.3 9.8 9.2 8.0 7.2 5.4 2.6 Extra Light 33.7 x 2.0 Light 2.6 Medium 3.2 Heavy 4.0 20 20 15 15 26.9 26.9 21.3 21.3 1.6 0.4 4.8 3.2 80 Light 88.9 x 3.2 Medium 4.0 Heavy 5.0 Extra Heavy 5.9 65 65 65 50 76.1 76.1 76.1 60.3 4.8 3.2 1.2 15.3 32 Extra Light 42.4 x 2.0 Light 2.6 Medium 3.2 Heavy 4.0 25 25 25 20 33.7 33.7 33.7 26.9 3.5 2.3 1.1 6.3 90 Extra Light 101.6x 2.6 Light 3.2 Medium 4.0 Heavy 5.0 80 80 80 80 88.9 88.9 88.9 88.9 5.6 4.4 2.8 0.8 40 Extra Light 48.3 x 2.3 Light 2.9 Medium 3.2 Heavy 4.0 Extra Heavy 5.4 32 25 25 25 25 42.4 33.7 33.7 33.7 33.7 0.1 7.6 7.0 5.4 2.6 100 Extra Light 114.3x 3.2 Light 3.6 Medium 4.5 Heavy 5.4 90 90 90 80 101.6 101.6 101.6 88.9 4.1 3.3 1.5 12.6 50 Extra Light 60.3 x 2.3 Light 2.9 Medium 3.6 Heavy 4.5 Extra Heavy 5.4 40 40 40 40 40 48.3 48.3 48.3 48.3 48.3 6.4 5.2 3.8 2.0 0.2 125 Extra Light 139.7x 3.0 Light 3.5 Medium 5.0 Heavy 5.4 100 100 100 100 114.3 114.3 114.3 114.3 16.9 15.9 12.9 12.1 150 Light 165.1x 3.5 Medium 5.0 Heavy 5.4 125 125 125 139.7 139.7 139.7 15.4 12.4 11.6 NOTE R 25 Clearance = (AS1163 Min do - 2t) - (AS1163 Max do) CHS is not a precision tube and all dimensions shown in the chart, although in accordance with the specifications, may vary marginally within the tolerance bands permitted. D Sizes shown in bold print are sizes that provide a clearance of less than 2.0mm. The internal weld bead will need to be considered when closer fits are indicated. Where telescoping over some length is desired, additional allowance may be needed for straightness. For tight fits it is recommended that some form of testing be carried out prior to committing material. How To use this chart 1. Select the size of female (or outer) member closest to your requirements from the left hand column. 2. Depending on the application select the clearance required between the two members. Members may need to slide freely 3. Having selected the most suitable clearance for your application, take the appropriate size of the male (inner) section from the centre column, eg: TO CLEARANCE inside each other, or be locked with a pin, spot welded or fixed with wedges. This means, in some cases, a ‘sloppy’ fit may be suitable, while for others the tightest fit possible may be more appropriate. (See Note 6 Press Fit). Female Section (outer) 76.1x5.9 Male Section (inner) 60.3 Clearance mm 2.6 Note that clearance is total available difference between member dimensions, not the gap on both sides. 4. Where two telescoping sections are being used, thickness should be similar and will be determined by normal structural requirements. If a third sections is the be used, consideration of both clearance and thickness within the size list available may be required. 62 BORE MALE FEMALE do MA 5. Pipe may need to be fixed against twisting by welding or bolting. 6. Press Fit. For short pieces with no need for separation or sliding an interference fit can be achieved using the available ductility of the steel. GENERAL INFORMATION ON PIPE & RHS CONVERSION FACTORS IMPERIAL Gauge 0.50 26 0.60 24 0.80 22 1.00 20 1.20 18 1.40 17 1.60 16 1.80 15 2.00 14 2.30 13 2.50 12 Decimal COLOUR inch A FT mm COLOUR CODE: RHS 0.032 1/32 0.048 3/64 0.056 0.063 1/16 0.072 Wall Thickness mm inch Purple 1.6 0.063 Chocolate Brown 1.8 0.072 Yellow 2.0 0.080 Silver 2.3 0.091 Pink 2.5 0.098 Gold 2.8 0.110 Dark blue 3.0 0.118 5/64 Grey 3.5 0.138 0.092 3/32 Green 4.0 0.160 0.098 Orange 5.0 0.197 11 0.110 White 6.0 0.236 10 1.128 9 0.138 Pink 8.0 0.315 8 0.160 5/32 Purple 9.0 0.354 5.00 6 0.197 3/16 6.00 4 0.263 6.30 3 0.250 1/4 8.00 2 0.315 5/16 9.00 1 0.354 10.00 0 0.394 3/8 12.70 0.500 1/2 16.00 0.625 5/8 19.00 0.750 3/4 22.00 0.875 7/8 25.40 1.000 1 2.80 3.00 3.50 D 4.00 R 0.080 1/8 COLOUR CODE: PIPE Colour 63 Guage Green end Extra light Yellow end Light Blue band Medium Red band Heavy White band Extra heavy ONESTEEL DIRECT Freecall 1800 178 335 Website www.onesteel.com Email onesteeldirect@onesteel.com D R A Postal address Locked Bag 8825 Wollongong DC NSW 2500 Australia FT Freefax 1800 101 141 For details on our great range of products and services, visit www.metaland.com.au or contact your local Metaland. DISTRIBUTED BY 64