Assessing the Impact of Trade Liberalization on Import

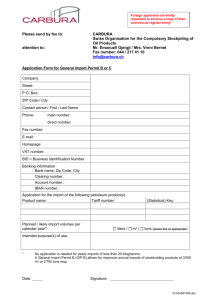

advertisement