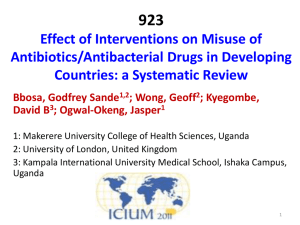

effects of chloride ion and the types of oxides on the antibacterial

advertisement