Amorphous Materials - Department of Materials Science and

advertisement

IA

Natural Sciences Tripos Part IA

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

PRACTICAL BOOKLET

Name............................. College..........................

Michaelmas Term 2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

2014-15

Course A Practical Booklet

Before attending each session, you will be required to do a short pre-lab exercise

which will involve answering a series of questions online based on reading through

the relevant script in advance of attending the class. Apart from the introductory

practical, AP0, these exercises will be assessed and count for a small amount towards

your IA Materials final grade. If you do not complete the exercise in advance of the

class and attend the class in person, you will not receive any credit.

This booklet contains scripts for all practicals for Course A (Atomic Structure of

Materials) of the Part IA Materials Science course – it is important that you bring this

booklet with you to every session.

Practical Page

Title

AP0

2

Amorphous Materials: Elastomers – Glasses or Rubbers?

AP1

7

Crystalline Materials & Close-Packing of Spheres

AP2

15

Lattice Planes, Miller Indices and X-ray Diffractometry

AP3

28

Phase Identification and Quantification for Cubic Crystal

AP4

37

Introduction to Optical Diffraction

Practicals are held in the Teaching Labs at the Department of Materials Science &

Metallurgy on the West Cambridge site. These are most easily accessed from the

Coton cycle path, entering the building from the south entrance, and turning right

when in the reception area. You will need your University Card to access the labs –

please bring this with you to every session.

http://map.cam.ac.uk/Department+of+Materials+Science+and+Metallurgy

Please make every effort to attend your allotted session. If, in extenuating

circumstances, this is not possible you should attend an alternative session of the same

practical and report to the Head of Class of the session that you attend. Practicals

begin at 2pm sharp and end at 5pm.

The first practical, AP0, will commence from Thursday 9th October 2014, and will

include an induction tour and safety briefing, followed by the practical. Note that the

online exercise for AP0 is not assessed, but should still be completed in advance of

practical to enable you to benefit fully from the session. You will be notified by email about when and how to complete the online exercise.

1

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP0

AmorphousMaterials:Elastomers–GlassesorRubbers?

Aims and Objectives of this Practical

To introduce you to amorphous materials by using properties of elastomers as

an example. In the next practical, you’ll look at crystalline materials;

Understand how the elastic properties of elastomers change with temperature;

Carry out an experiment to study the glass transition and determine Tg.

Materials science is fundamentally concerned with understanding how microscopic

structure relates to macroscopic behaviour in a material. In this first practical, you will

investigate the change in the properties of a squash ball with temperature and the

microstructural explanation for this behavioural change.

Squash balls are made from mainly natural rubber (polyisoprene) and can display

either rubbery (bouncy) or glassy (hard/brittle) behaviour in response to an impact,

depending on the temperature and chemical structure. You may have been used to

thinking about the terms ‘glass’ and ‘rubber’ as referring to particular types of

material, but actually they relate to the microscopic structure of the system and its

physical state. In particular, at a certain temperature known as the glass transition

temperature, Tg – see Background section below, an abrupt change in the behaviour of

the squash ball is observed. In this practical, you will study this by measuring the

bounce height of a squash ball as it warms through the glass transition point from the

temperature of liquid nitrogen.

IMPORTANT HEALTH AND SAFETY INFORMATION

During this practical, you will be handling objects that have been cooled in liquid

nitrogen to 77 K (–196 ºC). Although the low thermal conductivity of polymer

samples will protect you to a certain extent from chill burns, you must observe all

safety precautions involving the use of liquid nitrogen, and be careful not to touch

objects below ice freezing temperature (0 ºC) with exposed skin. Use gloves and

goggles provided when handling liquid nitrogen. Report spillages to the Head of

Class.

1

Background - measuring bounce height of squash ball warming through Tg

Each group is provided with a squash ball. The main component of these is

polyisoprene (–[CH2-CH=C(CH3)]n–), originally extracted from the Para rubber tree,

Hevea brasiliensis, although this is heavily treated with a range of additives to give it

the right strength, consistency, colour and elasticity.

2

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP0

Most importantly, the rubber is partially ‘cross-linked’ by addition of sulphur in a

process known as vulcanisation. Strong covalent linkages are formed between some

isoprene units on adjacent chains, shown schematically below.

Not all the isoprene monomer units are cross-linked, as then the ball would be very

brittle, like a thermosetting polymer (e.g. Bakelite). The degree of cross-linking is a

very important factor in determining elastic properties of the squash ball and also its

glass transition temperature, Tg (see below). A small amount of cross-linking will be

sufficient to prevent viscous flow of the polyisoprene, but further cross-linking will

limit its ability to deform and recover through bond rotations.

Most polymers are can exist in either a glassy or rubbery state, depending on the

chemical structure and temperature. In a cross-linked rubber, viscous flow is not

possible, but shape-change via local bond rotations gives rise to rubbery behaviour.

The time necessary for the polymer to change in shape is called the relaxation time,

and is temperature-dependent. For high temperatures, the relaxation time is very short,

and so shape changes can readily occur and rubbery behaviour is observed. For low

temperatures, there is not enough time for shape changes to occur by bond rotation,

with only bond deformation (i.e. flexing) possible, and the material behaves as a

glass. At the glass transition temperature, bond rotations can occur, but only slowly.

Away from Tg, the response to an applied stress is rapid, but around Tg the response is

slower, with much of the energy lost as heat rather than stored as elastic potential

energy.

Since it is obvious that the behaviour of a squash ball is rubbery at room temperature,

it is clear that Tg for polyisoprene must lie some way below this. In fact, Tg for pure

uncrosslinked polyisoprene is around 200 K (–73 ºC), rising to around 300 K (27 ºC)

when 15% of the isoprene monomers have been cross-linked. Note that Tg increases

with increasing cross-link density as shape changes by bond rotation become more

difficult to achieve. In this practical, therefore, we will consider that Tg is only

affected by the degree of cross-linking. To those who play squash, the change in

elastic behaviour of the squash ball with temperature, as the ball warms up during

play, will be well known. This heating effect comes from the dissipation of energy by

repeated uncoiling and coiling of polymer chains as the squash ball is deformed

during play.

In the vicinity of the glass transition, as stated above, the effect of the dissipation is so

great that any kinetic energy of the ball is quickly transformed. Far below the glass

transition, as no bond rotations are allowed, the energy dissipation will be low. Hence,

it is expected that a minimum in the bounce height should be observed in the vicinity

of Tg.

3

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP0

In the following experiment, we will try to identify this minimum, and therefore

estimate Tg for the squash balls provided.

2

Measurement of bounce height at room temperature

You are given a squash ball, a metal plate (to control the rebound), and a large

diameter plastic tube (to confine the ball) to which a measuring scale has been

affixed. Arrange the plastic tube on the bench so that the bounce height of a ball

inside the tube can be clearly read off the scale, using the top of the ball as the

reference point.

You may find it helpful to get a rough idea about how high the ball bounces on the

first bounce, and then use subsequent bounces to refine your estimate. Use the stickybacked plastic strip to fix a position on the measuring scale, and then adjust after each

bounce. Try to estimate the error in your readings (for example: 0.3 cm). This is the

precision of the measurement, as opposed to the accuracy of the result, and should

reflect your confidence in having achieved the stated precision.

Can you devise any procedures to minimize the error in your measurements?

You may also find it helpful to work in threes, with one person dropping the ball, and

the other two observing and recording the bounce height.

3

Measurement of bounce height at ice water temperature

Iced water will be available for communal use on each bench. Place the squash ball

into the iced water and leave for 5 minutes to fully cool.

Remove the ball from iced water, dry its surface quickly using a paper towel, and

measure the bounce height as soon as possible using the same methodology as earlier.

In this case you should aim to make your measurement using only as few bounces as

possible.

Why is this? What happens to the bounce height as the ball warms up?

4

Measurement of bounce height at liquid N2 temperatures

Liquid nitrogen will be dispensed into small polystyrene cups on the bench tops.

The quantities provided are not sufficient to be dangerous when handled properly,

but if a spillage occurs, move quickly away from the area and inform the Head of

Class. Do NOT put anything other than squash balls into liquid N2 or attempt to

take the liquid N2 out of the containers.

Place the squash ball carefully into the cup, using the tongs provided, being careful

not to splash liquid N2. Wear goggles to protect your eyes. Do not use the tongs to

keep the ball under the liquid N2 surface.

4

JAE M2014

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

2014-15

AP0

Once the ball has fully cooled and nitrogen has stopped boiling off, remove the ball

carefully with tongs, and, using protective gloves, swiftly transfer the ball to a heatresistant tile. Start a stopwatch as soon as the ball is removed from the liquid N2. Be

sure to only grip the squash ball lightly with the tongs, as if the ball is held too

tightly it is likely to shatter.

Being careful to avoid direct contact between exposed skin and squash ball, measure

the bounce height about four minutes after removal from N2 using the same

methodology as earlier. Bouncing the ball too soon after removal from N2 may result

in it shattering! Again, ensure the squash ball is only lightly gripped.

Make repeated measurements of the bounce height at 1-minute intervals for a period

of 20 minutes after the squash ball is removed from the liquid N2. Use no more than 2

or 3 bounces (taking 10 to 15 seconds) to determine each bounce height. You may

need to periodically clean the frozen condensation from the squash ball carefully

using a piece of paper towel. Be careful not to burn yourself during this process, and

wear gloves.

The temperature of an identical squash ball has been measured as a function of time

during the heating process, and is shown below. Since direct temperature

measurement tends to interfere with the measurement of bounce height, use the

calibration curve to transform your data of average bounce height versus time into

average bounce height versus temperature. In order to help you do this, a cubic

polynomial fit has been added to the calibration curve to help you transform from

time, t, (in minutes) to temperature, T (in degrees Celsius). This is not based on any

physical law, but is intended to allow easy conversion of time into temperature. The

fitted equation for transforming between these two quantities is:

T = 0.0447 t3 – 1.9697 t2 + 32.102 t – 199.69

0

-20

0

2

4

6

8

10

12

14

16

18

20

-40

-60

]

C

º[ -80

T

,

-100

re

tu

-120

ra

e

p

-140

m

e

T

-160

Heating curve

Poly. (Heating curve)

T = 0.0447 t3 - 1.9697 t2 + 32.102 t - 199.69

-180

-200

Time, t [min]

5

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP0

Carry out the transformation for your data, and plot bounce height against

temperature.

Check your curve using reference points taken at ambient and ice water

temperatures. Do they agree with the data points from your continuous curve? Is

the form of the curve as you would expect?

What do you notice about the behaviour of the bounce height with temperature?

Use this to estimate the glass transition temperature of the squash ball.

Assuming that the increase in Tg relative to pure uncrosslinked polyisoprene is

linearly proportional to the degree of cross-linking, estimate the degree of crosslinking in the squash ball, and state clearly any complicating factors.

5

Measurement of bounce height at elevated temperatures

Measure the bounce height at room temperature.

Heated water is provided in the form of a water bath set to 65 °C. Measure the actual

temperature of the water using a thermocouple provided.

Place the squash ball into the heated water and leave for 5 minutes to fully heat.

Remove from the heated water and measure the bounce height as soon as possible.

Once the heated ball has cooled again to room temperature, measure its bounce height

one more time.

Is the bounce height the same? What are the implications does this have for the

glass transition in polymers: i.e., would you say it was a chemical or a physical

type of phase transition?

Conclusions and take-home points

Polyisoprene is an example of an amorphous material, with no long-range order.

Amorphous materials can display different properties dependent on the temperature.

The glass transition is an example of a physical, reversible change whereas crosslinking represents a permanent, chemical change. You have determined the glass

transition temperature, Tg, for polyisoprene by a simple experiment, and quantified

(hopefully minimized!) any errors intrinsic to the experimental setup. In the next

practical, you will look at crystalline structures, which do possess long-range order

and can be described by a crystal lattice.

Please remember to fill in the feedback form with any comments on this practical

6

JAE M2014

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

2014-15

AP1

CrystallineMaterials&Close‐PackingofSpheres

Aims and Objectives of this Practical

To help you visualize crystal structures by building physical models.

To make you familiar with using the software package CrystalMaker to view

3-dimensional crystal structures.

Understand how to describe crystalline structures using the concepts of

coordination numbers, coordination polyhedra and unit cells.

Understand what is meant by “close-packing”.

Be able to differentiate between cubic and hexagonal close-packed structures.

and know how they have different stacking sequences of close-packed planes.

Understand the description of the structures in terms of close-packed planes

and how this relates to the conventional unit cell for both ccp and hcp

This practical has multiple parts. The first part (Section 1) is an exercise in building a

physical model of close-packed crystals, which are used later in the practical

(Sections 3-5), and the second part (Section 2) uses a computer to represent crystalline

structures. Your Head of Class will tell you whether to begin at Section 1 or Section

2, and tell you when to switch to the other sections.

1

Model building

You are supplied with a number of plastic balls with which to construct planes of

close-packed “atoms” possessing long-range order. Additionally, both the size and

shape of the spaces between atoms in close-packed structures are important (formally,

these are called interstices) so you will also build small ball models to illustrate two

kinds of interstice which occur in close-packing.

The balls need to be placed on the hexagonal template provided in a specified

arrangement so that each ball is touching its neighbours. You should stick them

together as follows:

Dip the small spatula into the solvent (butan-2-one) to collect a small amount. Put it

just above the point of contact of two balls as in figure (a). The solvent should flow

down the balls and be held by surface tension between the two balls; a disc of solvent

about 2 mm in diameter should be sufficient to stick the spheres together, figure (b).

Only a small quantity of solvent is needed – too much will dissolve the balls.

7

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP1

Extensive inhalation of the solvent would be harmful, so replace the lids on the

jars after use. If you splash solvent on your hands, wash it off.

When all the balls in a particular arrangement have been stuck together, the tray

containing the models should be placed in an oven for 10 minutes to evaporate the

solvent, and then quenched in water to solidify the bonds. The models may then be

gently lifted off the template on to a sheet of card.

You will use a single metal tray to make your models: this has a number engraved on

the top so that you can retrieve the correct one from the oven after drying. The

suggested arrangement for balls within the tray is illustrated below.

At either end of the hexagonal template, stick together a set of six white spheres in the

pattern shown in figure (c). Then position a blue sphere so that it rests in the recess at

the centre of the model as shown in (d) and glue it in place. These models will be

referred to as X models.

Now, on the same hexagonal template, place six black spheres and twelve blue

spheres in the arrangement shown in (e), and stick them together.

8

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP1

Next place six white balls into the recesses indicated by R in (e) and stick them in

position to make the model shown in (f). Make sure that X and Y models are not

glued to each other.

In between the two X models, glue together a group of three black balls in a triangle

as (h) below.

(h)

Make another set of three white balls in a triangle, as (h) above.

Finally, make another triangular group from white balls. However, this time position a

single white ball so that it rests on the recess at the centre of one of the triangles,

making a tetrahedron (i.e. each ball has its centre at one of the four corners of a

tetrahedron). Glue it in place.

Once your tray has come out of the oven and your models have been quenched, take

the two triangular groups that you have made and carefully position one set on top of

the other as shown in (i) below. Glue them together, making an octahedron and leave

the model to harden.

(i)

The X + Y models that you have made represent parts of two adjacent close-packed

layers, as found in the crystal structures of many metals. Once your models have set,

you should be able to invert each X model and insert it gently into a Y model as

shown in (g).

9

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP1

(g)

You will use the models in section 3, and you can then take them home: they should

be useful throughout the course.

2

Representation of crystal structures

A crystal is characterised by having translational symmetry, which implies long-range

positional order of the atoms, and can be described by a repeating array of points

called a lattice. Each of these points (a lattice point) is in an identical environment,

i.e. the lattice points are equivalent, even in non-primitive lattices (see below). The

constraint of translational symmetry places a severe restriction on the number of

lattices that can exist. In fact, there are only 14 possible Bravais lattices in 3D, each

composed of a crystal system and lattice type (defined below).

A repeating unit of the lattice, from which the entire crystal can be built, is called a

unit cell. This is often, but not always, the smallest repeating unit. The shape of cell

(more precisely, the rotational symmetry elements it contains) defines the crystal

system (e.g. cubic, hexagonal, orthorhombic). The unit cell can either be primitive,

with lattice points only at the corners and one lattice point per unit cell, or nonprimitive, with lattice points at the corners and other locations in the unit cell and

more than one lattice point per unit cell. For a cubic lattice, there are 3 possible lattice

types: primitive (P), face-centred cubic (F) and body-centred cubic (I). The unit cell

can be represented in 3D as a parallelepiped described by 3 vectors a, b and c. In a

cubic unit cell, these vectors are orthogonal to each other and equal in length.

The structure of a crystal is fully described by a combination of the lattice (i.e. crystal

system and lattice type) and the motif. The motif is a list of the atoms associated with

each lattice point, with each atom’s coordinates expressed as a fraction of the unit cell

length with the lattice point at the origin. Since each lattice point is equivalent, the

arrangement of atoms about each one must be the same.

Another way of thinking about crystal structures is to use the coordination number,

which is the number of nearest-neighbour atoms around a given atom. In a crystal,

these nearest-neighbour atoms often form a regular polyhedron. For example, 4 atoms

surrounding another atom may define the corners of a tetrahedron, or 6 atoms may

define an octahedron, with the reference atom at the centre. An example is the

octahedral coordination of Na+ by Cl, or of Cl by Na+, in NaCl (see below). Hence,

in addition the description of structures by space-filling models (hard spheres) and by

10

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP1

interatomic bonds (“a ball-and-spoke model”), they can also be described in terms of

coordination polyhedra linked at their corners or edges.

In this part of the practical, you will be using CrystalMaker, a graphics programme

helpful for viewing and manipulating models of crystals on the computer, to help you

visualise these structures in 3D. You may also find it helpful to look at the physical

“ball-and-stick” crystal models on display. If you are stuck, the CrystalMaker Users’

Guide can be found under the Help menu.

There is a large library of crystal structures available to view in CrystalMaker;

however, you should start by working through the following sequence.

-Fe

In the folder labelled “Crystal Structures Library” on the desktop, find the file “Iron –

gamma (fcc)” under the directory Minerals\Non-Silicates\Native Elements.

Open this and a window showing atoms in one unit cell of the structure should appear.

What is the shape of the unit cell, outlined in red (you can rotate the image

using the mouse)? How many lattice points are there in one unit cell?

From the “Transform” menu, select “Set Range”. Put 4 in each of the “maximum”

boxes for the x, y and z-axes and click “Apply”. This will show what the 64 unit cells

look like.

Do all the Fe atoms have the same coordination? What is the coordination

number?

NaCl (Halite)

Open this file (under the directory Minerals\Non-Silicates\Halides) and a single unit

cell of NaCl will be displayed (green = Cl, yellow = Na+). From the “Model” menu,

select “Space filling”. The unit cell will now be displayed with Na+ and Cl ions with

their correct relative sizes.

Alternate between the “Ball and Stick” and “Space Filling” models (in the “Model”

menu.

Describe the coordination of Na+ by Cl and Cl by Na+.

Which lattice does NaCl adopt? (give both crystal system and lattice type)

From the “Transform” menu, choose “Set Range” and put 2 into each of the

“maximum” boxes for the x, y and z axes. Convert the model to “Polyhedral” from the

“Model” menu.

What is the basic polyhedral unit of the NaCl structure? How are these

polyhedra connected to each other?

Hexagonal Close Packing

Open the file “Hexagonal Close Packing - Layers” found under Basic Structure

Stypes\A.

11

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP1

What lattice does this structure have? (give both crystal system and lattice type)

What is the motif?

Describe the coordination. How many lattice points are in the unit cell?

3

Hexagonal close-packing

Collect the models that you made earlier in Section 1, which should now have dried.

They should still have the smaller X models inserted into the larger Y models. Each

combined model now represents a pair of close-packed planes (assume all coloured

balls represent the same type of atom).

Identify the unit cell of a single two-dimensional close-packed layer and draw a 2-D

plan of four unit cells with a common corner. Draw touching circles to represent the

touching balls.

Mark on your plan the positions of holes into which the balls of the next layer could

fit.

Are the two holes within each unit cell exactly equivalent?

Could two balls be fitted in simultaneously?

Are the two holes related by a lattice vector?

Hold one combined model up to the light; some of the gaps between spheres in the top

layer are above gaps in the lower layer, while others are above spheres in the lower

layer. Thus, in any one layer the gaps between the spheres are of two types. On your

drawing label the circles A, and the two types of recess B and C.

Place one combined model on the bench with the layer of white balls uppermost.

Superimpose the other combined model, in the same orientation, so that the blue

spheres of the top model lie directly over the blue spheres of the bottom model. The

sequence of layers is now ABAB and the model represents hexagonal close-packing.

Place your model on a light box and note that gaps run right through the stack. Thus

one set of sites (the C sites) is always unoccupied in hexagonal close-packing (hcp).

Compare your model with a ball-and-spoke model of hcp. Describe or sketch the

three-dimensional arrangement of nearest neighbours (ignoring the colours of the

balls) around a sphere in a white layer and around one in a blue-and-black layer.

Are the arrangements different?

Are all the atoms exactly equivalent, i.e. do they have exactly the same

environment?

How many atoms are associated with each lattice point, i.e. how many atoms are

in the motif?

Find the three-dimensional unit cell of hcp and draw a large, accurate projection of

this structure on the close-packed plane showing four unit cells as above. Label the

axes in the close packed plane +x and +y, taking , the angle between them, as 120

Taking care to note that the axes are not orthogonal, write down the fractional

coordinates of the atoms in the unit cell. Mark on your plan the 3 close-packed

directions in the close packed plane, i.e. the lattice vectors joining the centres of

adjacent atoms in the close packed plane.

12

JAE M2014

2014-15

4

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP1

Cubic close-packing

Remove the top two layers of the model used earlier. Take the X model from this

double sheet and place it on top of the two close-packed layers of the lower double

unit so that the six white spheres sit on the recesses above the gaps which run right

through the two lower layers. This pyramidal model has the stacking sequence

ABCA.

Invert the spare Y model and carefully add it to the combined model to show more of

the two upper close-packed layers. The two blue-and-black layers should now be

directly above and below each other. This model represents cubic close-packing (ccp).

Hold your model up to the light. Note there are no gaps running through the structure.

Describe or sketch the distribution of nearest neighbours about a sphere in each of the

layers of type A, B, and C. Again, ignore the colour of the spheres – they represent

chemically identical atoms. (A ball-and-spoke model is available for comparison.)

Are the distributions different?

Are all the spheres exactly equivalent?

How many spheres are associated with each lattice point, i.e. how many spheres

are in the motif?

Identify the unit cell that has x and y in the blue-and-black close-packed layer and z

normal to the layers, and is thus similar to the one drawn in above. Draw a plan of

four of these unit cells projected onto the x-y plane.

How many lattice points are there in the cell? Is this cell primitive?

The stacking sequence ABCA has, in fact, cubic symmetry. There are three other sets

of close-packed planes related by this symmetry. Locate these on your model. This is

most easily done by removing the top Y model added earlier, leaving the inverted X

model on top of the X + Y model.

In ccp the symmetry makes it possible to choose a unit cell geometrically simpler than

that used above. This conventional unit cell is a cube with atoms at the corners and at

the centres of the faces. It may be extracted from your model by removing the top Y

model and then lifting out the two X models together, keeping the same relative

orientation.

Place this cube with one of its faces in the smaller of the two square templates. The

edges of the face will lie at 45˚ to the edges of the template.

Choose the origin of the cubic unit cell on the blue sphere of the lower face of the

cube. Take the cubic reference axes x and y in the plane of the template and the z axis

vertical. Draw a plan of this cell projected onto the x-y plane, showing all the atoms.

Remove the top X model by lifting its blue ball to expose a close-packed plane. Make

a sketch of the arrangement of atoms in this close-packed plane and mark in the three

close-packed directions.

Replace the upper half of the cube. Locate the three other close-packed planes.

13

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP1

5 Interstices in close-packed structures

Interstices in close-packed structures are sites where low concentrations of small

atoms such as H, C and N can be incorporated into crystal structures with minimal

distortion to the crystal structure. For example, cubic close-packed iron can take up to

1.7 wt% carbon into solid solution quite happily at 1130 ˚C. It is therefore important

to be able to appreciate what interstices are and their sizes relative to the atoms.

Examine the two models built in Section 1. They show the distribution of atoms

around so-called ‘octahedral’ and ‘tetrahedral’ interstices. These names are used since

the atoms around the two types of interstice are located at the corners of a regular

octahedron and tetrahedron.

Locate some of these interstices in your models of hexagonal and cubic closepacking. On the plan drawn earlier locate one interstice of each type, and give its

fractional coordinates.

Conclusions and take-home points

Physical models and computer software are useful tools for viewing and better

understanding crystal structures. We can describe crystalline structures in terms of the

coordination of one type of atom around another (coordination number) and the shape that

this coordination shell creates (coordination polyhedron). We can also visualise crystalline

structures in terms of repeating structures (unit cells) described by a lattice type, crystal

system and motif. The following facts about close-packed spheres are of great importance,

and will come up in the course time and again:

Stacking planes of close-packed layers ABAB… gives hcp, whereas the stacking

sequence ABCABC… gives ccp.

In both types, each atom has 12 neighbours, but the arrangements are different.

In ccp all atoms have identical environments, but this is not true in hcp where there

are two atoms in the motif.

For ccp a hexagonal unit cell of three atoms can be used, but the conventional unit

cell is a face-centred cube, with four atoms.

Both structures have tetrahedral and octahedral interstices. These are particularly

relevant for describing related structure types.

Please remember to fill in the feedback form with any comments on this practical

14

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP2

LatticePlanes,MillerIndicesandX‐rayDiffractometry

** BEFORE ATTENDING THIS PRACTICAL **

To assist you with the assessed exercises, first work through the DoITPoMS TLP

entitled “Lattice Planes and Miller Indices”.

http://www.doitpoms.ac.uk/tlplib/index.php

Aims and Objectives of this Practical

Know what “Miller Indices” are and how they are used

Be confident in “indexing” sets of lattice planes in 2-D and 3-D

Be able to draw a set of lattice planes when given the Miller Indices

Be able to use CrystalMaker to construct lattice planes and directions

Use a mini X-ray diffractometer to observe diffraction from a LiF crystal

See Bragg’s law in action, observing that both incoming and outgoing X-ray

beams must be aligned correctly with respect to the crystal to observe a peak

Learn that X-rays are not simply reflected from the surface of a crystal but

can be diffracted from planes inside the crystal inclined to the surface

This practical consists of two halves. The first part (Sections 1-4) is a paper, pen and

computer-based exercise on Miller Indices, and the second part (Sections 5-9) is an

introduction to X-ray diffractometry. Your Head of Class will tell you whether to

begin at Section 1 or Section 5, and tell you when to switch to the other part.

1

Lattice planes in 2-dimensions

The indices are defined as (hkl) if the first plane away from the origin makes

intercepts on the +x, +y, and +z axes of a/h, b/k and c/l, respectively.

Rutile (TiO2) is tetragonal with a = b = 4.59 Å and c = 2.96 Å. A projection on (100),

i.e. looking down the x-axis onto the y–z plane, of the lattice is shown in Figure 1. The

intersections (traces) of portions of seven sets of lattice planes normal to the paper

have been drawn on this plan. What is the h index for all these planes? For each set of

planes, determine the indices k and l.

How are (hkl) and ( hkl ) related?

A projection on (001) is shown in Figure 2. Use it to make a drawing similar to Figure

1 showing the traces of sets of lattice planes (110), (010), (210), ( 210 ) and ( 230 ).

A projection of a hexagonal crystal lattice (a = b, γ = 120°, the angle between x and y

axes) onto (001), i.e. looking down the z axis onto x-y plane is shown in Figure 3.

15

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP2

Index the directions shown on the plan, and then draw the lattice vector [310]

from the origin to the edge of the plan. Add the trace of one of the (310) planes

passing the unit cell closest to the origin.

What do you notice about the direction [310] relative to the trace of (310)

planes? Remember that the direction [hkl] is not necessarily perpendicular to the

(hkl) planes (this is only true in a cubic crystal).

2

Lattice planes in 3-dimensions

Figure 4 shows a view of a crystal lattice. Using the axes shown as your reference

axes, index the sets of lattice planes I to IV. Remember that in each case you may

choose any convenient lattice point as your origin.

Near the numeral IV, add to the diagram the traces of a few planes of the set ( 112 ).

Open the DoITPoMS TLP entitled “Lattice Planes & Miller Indices” on one of the

computers. Go to the page “Draw your own lattice planes” and satisfy yourself that it

provides the same answers for the 3-D planes you have drawn and indexed. Complete

the TLP questions (including the drag & drop game) if you haven’t already done so.

3

Lattice planes and directions

Assign some axes to the conventional unit cell of the

cubic close-packed structure (right).

What are the Miller Indices of the shaded

planes?

What are the lattice directions along which the

atoms in that plane touch? Use the Weiss Zone

Law to confirm that the directions you have

written down do indeed lie in that plane.

For nickel, cubic close-packed a = 3.52 Å, calculate the separation of the shaded

planes using trigonometry. Check your answer by using the formula for

interplanar spacing for crystals with orthogonal axes from the Data Book. Now,

calculate the interplanar spacing of the (312) planes, and note that this answer

would be difficult to obtain purely by trigonometry.

16

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP2

17

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP2

18

JAE M2014

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

2014-15

AP2

y

x

Figure 3

Figure 4

19

JAE M2014

2014-15

4

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP2

CrystalMaker exercises

Open the file Iron - gamma (fcc).cmdf (Found in Crystal Structures Library\

Minerals\Non-Silicates\Native Elements). Open the Set Range window from the

Transform menu and set the range from 0 to 2 for x, y and z. It may be helpful to

display the axes (ModelShow Axes). You should now have 8 unit cells displayed.

Miller indices

Bring up the Lattice Plane menu (TransformLattice PlaneEdit) and display the

(111) plane. Using the Lattice Plane tool from the Tools palette, adjust the position of

the plane so it is not bisecting the atoms and then slice the model to show the closepacked plane (TransformSlice Model). The red (111) plane can be hidden

(TransformLattice PlaneHide). Change the model type to Space Filling and

compare it to the physical models you have made in AP1.

By resetting the model (from the Plot Range window) or by opening another Iron gamma (fcc).cmdf file, try cleaving along higher indexed planes, e.g. (431).

What differences do you notice between the close-packed (111) and the higher

index planes (HINT: Think about how rough / smooth the planes are)?

Lattice vectors

In a close-packed structure, there are 12 close-packed directions (or six anti-parallel

pairs). The 6 in-plane directions are shown below:

Index the 12 close-packed directions for the cubic fcc/ccp unit cell and the 6

directions in a single close-packed plane for the hexagonal hcp unit cell. You may

find a 3D sketch helps to index the directions in the fcc cell (remember, close-packed

planes are of type {111} in fcc)

Which rule could confirm that the directions you have found lie in a closepacked plane? How would you represent the 12 symmetry equivalent directions

using crystallographic notation?

Plot one of the directions you have indexed as a lattice vector in CrystalMaker. Select

one of the atoms in the close packed plane from the previous section using the Arrow

tool and define the direction from SelectionVectorAdd.

Does it agree with your prediction?

20

JAE M2014

2014-15

5

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP2

Introduction to X-ray Diffractometry

In this part of the practical you will learn how to use a small, low-power X-ray

counter diffractometer to collect diffraction data from a LiF crystal. It will be

necessary to work in small groups of 2 to 3 students.

IMPORTANT HEALTH AND SAFETY INFORMATION

X-rays are potentially dangerous. In addition to a lead glass domed shield around the

X-ray tube, there is an interlocked plastic anti-scatter enclosure. Thus, the shutter can

only be opened allowing X-rays to exit the tube when the enclosure is correctly

positioned. You should be aware when the shutter is open and when it is closed, but

the interlocks are a backup to prevent any possible accident.

The LiF crystal may react with moisture, e.g. on your skin. Please wear gloves when

handling the crystals.

The portable diffractometer you will be using consists of a small solid-state high

voltage generator driving a copper anode X-ray tube that can be seen inside the lead

glass dome at the rear of the unit. X-rays generated at the anode emerge through a

thin glass port blown in the tube and then through a hole in the lead glass dome. After

passing through an interchangeable collimating slit, the beam passes over the central

turn-table on which a crystal can be mounted. X-rays diffracted by the crystal in a

particular direction pass through a receiving slit and are detected by a Geiger-Müller

(G.M.) tube positioned in a carriage moving concentrically with the crystal and

driven by the vernier wheel outside the transparent radiation protection cover.

The motion of the detector and crystal are coupled so that the angular velocity of the

former is twice that of the latter (known as a 2or 2 drive). The angular

setting (2) of the detector can be read off the scale around the perimeter of the top

plate of the unit while the setting () of the crystal is indicated on the scale

immediately around the central turntable.

Access to the working space is achieved by first checking the state of the X-rays. If

they are ON (red light, HT ON), turn (power) OFF, then carefully displace the

transparent cover sideways in the direction of the detector carriage and raise it. To

make a measurement, close the lid, then centre it (to engage the interlock) and turn on

the X-rays (Power ON and then X-rays ON).

Lights are top back and switches bottom front of instrument, see Figure 5.

Safety interlocks ensure that the high voltage generator can only be switched on when

the lid is both closed and centred. The high voltage generator is automatically

switched off if the lid is displaced from this position. However, this is a safety backup

only, and you always close the shutter manually before opening the lid.

The X-ray tube emits a relatively low level “white” radiation together with the strong

characteristic radiation Kand Kfrom the copper target; K is the stronger and has

the longer wavelength. You will use a filter to block out all but the Cu Kwavelength

X-rays.

21

JAE M2014

2014-15

6

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP2

Operating Instructions

Figure 5: Schematic of the portable X-ray diffractometer.

Defining the outgoing beam. Carefully remove the G.M. tube from the carriage and

insert the 1 mm receiving slit vertically in the detector carriage in sprung slot 14, and

the 3 mm slit similarly in the rearmost slot 30.

Defining the direction of the incoming X-ray beam. Align the detector carriage

pointer with the 2 = 0° graduation. With no crystal in position check that the

collimator slit on the lead glass dome is vertical. You should be able to see the anode

clearly through all three aligned slits; this line of sight will define the direction of the

primary X-ray beam, 2 = 0°.

Zeroing both drives. When the detector is at 2 = 0° the crystal-holder (central

spindle) scale should read = 0° also, with the "reflecting" surface facing right, as

shown in Figure 5.

If the scale does not read 0°, it is necessary to adjust it independently of the

detector carriage: loosen the knurled ring around the base of the crystal holder,

whereupon the setting can be adjusted as required. Tighten the knurled ring fingertight (without straining) so that the two-to-one linkage is re-engaged.

You might find it easier to stand over the set and look down to check that both the

crystal and detector are aligned at zero.

Orienting the crystal. Lithium fluoride is cubic. The lithium fluoride crystal supplied

is bounded by {100} cleavage planes. Insert the crystal into the holder at the centre of

the turntable with a large face against the vertical reference surface, and the longest

22

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP2

side vertical. If one of these large faces has a dull appearance due to slight abrasion,

mount the crystal so that this duller face is against the reference surface.

On looking through the collimating slits you should now see that the primary beam

direction lies in the surface of the crystal, as does the axis of rotation.

Note that, at this stage, when the detector carriage is moved, the normal to the crystal

face always bisects the angle between the primary beam direction and the centre-line

of the carriage, i.e. the crystal face is always symmetrically arranged with respect to

the incident and detected beam directions, i.e. = .

Installing the G.M. tube. Remove the 3 mm slit and replace the detector in sprung slot

24, with the cable emerging vertically upwards. The centre-line of the G.M. tube

should then be parallel to, but displaced from, that of the carriage. Place the antiscatter slit in slot 13. Place the Ni filter in slot 15. (Ensure that the cable is free of the

diffractometer cover. If you have any difficulty call a demonstrator.)

Setting the voltage. Check that the red switch on the top of the turntable is in the 30

kV position and that the time switch (front centre) is not at zero (suggest set for

~50mins) .

Checking the crystal holder. Move the detector around to the right (anti-clockwise)

through at least 15° of 2. Check that the crystal holder is arranged so that the X-rays

will be incident on the face of the crystal in contact with the vertical reference

surface. (If it appears that your unit has been set up so that the X-rays will be incident

on the other vertical surface of the crystal, consult a demonstrator at once.)

Powering up. Close and centre the radiation cover. Check that it cannot be re-opened,

simply by raising gently.

Switch on the mains supply: “POWER ON” switch. The white indicator lamp should

light up.

Turn on the high voltage generator to the X-ray tube by depressing the red

“X-RAYS ON” button on the front left of the unit. The red indicator lamp at the right

rear should light up. If it does not, check that the lid is correctly centred. Notice also

that the cathode of the X-ray tube is glowing.

7

Estimating the position of the 200 diffraction peak

LiF has the cubic NaCl structure; ball-and-spoke models of the NaCl structure are

available for inspection. The arrangement of the ions on a (001) plane is illustrated in

Figure 6 below.

Estimate the cell parameter a of LiF from the ionic radii: Li+Å

FÅ.

Note this approach provides a rough estimate. (Such information can often also be

obtained from databases.) In this practical you will obtain accurate values for the cell

parameters of the crystal that you have been given.

23

JAE M2014

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

2014-15

AP2

Using this estimated value of a and the Bragg equation (see Data Book),

estimate 2200 and 2400 for CuKradiation ( = 1.54 Å).the cell parameter a

of LiF from the ionic radii: Li+ÅFÅ.

Li

F

Figure 6: Arrangement of ions on (001) plane for LiF.

8

Recording the 200 diffraction peak

With the diffractometer set according to the operating procedure outlined in the previous

section, the counter arm should be populated as follows:

slot 13: anti-scatter slide

slot 14: 1 mm slit

slot 15: Ni filter

slot 24: counter

By turning the counter though the appropriate angle (2 and hence the crystal by ,

locate the 200 reflection close to the 2 value estimated in section 3 above.

Record the value of both 2and count rate (intensity) for this peak.

The crystal must now be oriented precisely. It has been assumed up to this point that a

zero reading on the crystal setting scale corresponds to the incident X-ray beam being

parallel to the (100) planes (i.e. the cleavage plane) of the LiF crystal. That assumption

is not necessarily precise: there may be a small zero-error in the crystal setting scale,

which can easily be eliminated by the following procedure:

Turn off the power and open the radiation cover. Note the reading for the crystal

setting ( 1/2 2loosen the knurled ring at the base of the crystal holder to

disconnect the 2:1 gearing; tighten the knurled ring finger tight without straining, and

then loosen it by half a turn so that the 2:1 gearing is loosely engaged.

Lay the setting bar flat on the diffractometer table so that its two studs engage with

two holes in the centre plate. (It is often easiest to put the setting bar on the same side

as the detector – when they are on opposite sides, it is difficult to close the cover

properly.) Replace the radiation cover and switch on the X-rays.

Hold the counter arm at the 200 peak maximum determined above and adjust the

angle of the crystal by moving the setting bar slightly each way to achieve maximum

counts. Do this very slowly in order to allow the recorder time to respond. Move the

counter arm slightly either way to locate maximum response.

24

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP2

Repeat the cycle until adjustment of the crystal setting for maximum counts leads to

no change in the setting of the counter arm. The normal to (200) planes of the LiF

crystal will now bisect the angle between the incident and diffracted X-ray beams.

Record this position of the inner ring in case you accidentally disturb it.

Compare the intensity measured here with what you measured earlier, before

precise orientation. Is there any improvement?

Turn off the X-rays. Open the radiation cover, remove the setting bar and gently retighten the knurled ring. Close and centre the radiation cover.

Plot count rate (allowing the detector some 5 seconds to respond before each reading)

against 2every 0.5° of 2, from 1.5° below to 1.5° above the peak position found in

0, and so determine a value for 2200.

Hence evaluate the cell parameter a for your LiF crystal.

Repeat the whole procedure in this section using the 400 reflection and the value of

2400 estimated in section 3, as this will lead to a more accurate measurement of the

cell parameter. If you want to see why this should be so, refer to the Appendix.

9

Recording the 420 diffraction peak

It is important to realize that Bragg “reflection” is not a surface reflection, and

therefore incident and diffracted beams are not necessarily symmetrical to the (100)

cleavage planes. To investigate this you are asked to find the diffracted beam arising

from the (420) planes.

Note the (420) interplanar spacing has components both perpendicular and parallel

to the large surface face of the crystal, whereas the (400) interplanar spacing is

perpendicular to this surface. By combining these 2 measurements one can calculate

the cell parameter in both directions.

Why might these values differ?

For a cubic crystal d(hkl) = a/(h2+k2+l2). Use this expression and the Bragg equation to

estimate 2420.

Evaluate the offset angle (100):(420) in order to calculate the angle through which the

crystal must be rotated (see Figure 7).

25

JAE M2014

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

2014-15

(a) For planes parallel to the sample

surface (1) Offset = 0

(a)

AP2

(b) & (c) For general planes (2)

Offset 0

(b)

2

( c)

2 0

n1 is the normal to planes parallel to the sample surface (1);

n2 is the normal to general planes (2)

Figure 7: Schematic demonstrating location of planes and angles between them.

Reset both the angles 2andto zero.

Loosen the knurled nut and use the setting bar to turn the crystal through the

(100):(420) offset angle calculated in above so that the (420) lattice plane is parallel

to the incident X-ray beam, as shown in Figure 7(b). After retightening the knurled

nut, moving the detector to 2will result in moving to [1/2(2offset angle], see

Figure 7(c).

Replace the radiation cover and switch on the X-rays. Locate the 420 reflection.

Repeat the crystal alignment procedure in section 4. Then, by plotting counts against

2, obtain an accurate value of 2.

Calculate the value of a using this measured plane spacing.

How does this result for cell parameter, calculated from 420 peak, compare with

those which you obtained in section 4 from the 200 and 400 peaks?

26

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP2

Conclusions and take-home points

Planes are described using Miller Indices, a description based on how far away from the

origin the first plane intercepts each coordinate axis. The direction [321] is not

necessarily normal to the plane (321) – though it is for cubic crystals! The Weiss Zone

Law is the way to work out whether a direction [UVW] is contained within a plane (hkl) –

it works for any crystal system.

In order to measure diffraction peaks from a single crystal both the detector position,

2and the crystal position, must be carefully aligned. Measurements made at higher

2angles give more accurate cell parameters, due to the slower variation of sinat

higher diffraction angles. y tilting, or offsetting, the sample cell parameters can be

measured in different directions of the sample, e.g. both perpendicular to and parallel to

the surface of a thin film.

Please remember to fill in the feedback form with any comments on this practical

Appendix : Accurate determination of lattice parameter

d

d

tan

Differentiate Bragg's law, 2dsin

For an error in , of

d

d

tan

For the highest sensitivity in angle:

tan.

d

0, as 90

d

d

d

best as 90 ;

i.e. 2 180

1.0

sin

0.8

0.6

use the highest angle line to give

highest accuracy.

0.4

0.2

0.0

0

20

40

60

27

JAE M2014

80

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP3

PhaseIdentificationandQuantificationforCubicCrystal

Aims and Objectives of this Practical

To show the relationship between “single crystal” and “powder” X-ray data

To learn how cell parameters and/or relative intensities can be used to

identify crystalline phases of a material and measure the amount of each

crystalline phase (or material) in a mixture (quantitative phase analysis)

To understand how the crystalline structure affects intensities by doing

structure factor calculations

To ‘index’ a cubic powder pattern, obtaining the lattice type and cell

parameter

Given possible trial structures with given lattice type, to determine which one

is best by comparing calculated intensities with the experimental values

Phase identification and quantification are important in materials science and have

many applications e.g. forensic work, drugs industry, corrosion, gas, oil & mining

exploration, catalysts, cement works and development of new materials & new

devices.

Both peak positions (which are related to cell parameters) and relative intensities

(related to the type of atom and their positions in the unit cell) are important

measurements to identify different crystalline phases. In a mixture, the relative

intensities are used to quantify each phase.

This practical is in several parts, and consists of a practical exercise involving the Xray diffractometers you used in AP2 plus a paper-and-pen exercise. It is important that

you attempt the whole practical – your Head of Class will tell you which section to

begin with, and when it is time to move on. You can return to any section if you have

time at the end.

IMPORTANT HEALTH AND SAFETY INFORMATION

X-rays are potentially dangerous. In addition to a lead glass domed shield around the

X-ray tube, there is an interlocked plastic anti-scatter enclosure. Thus, the shutter can

only be opened allowing X-rays to exit the tube when the enclosure is correctly

positioned. You should be aware when the shutter is open and when it is closed, but

the interlocks are a backup to prevent any possible accident.

The LiF crystal may react with moisture, e.g. on your skin. Please wear gloves when

handling the crystals.

28

JAE M2014

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

2014-15

1

AP3

Cell parameters

You are provided with these 4 crystals: LiF, NaCl, KCl and RbCl.

From Bragg’s Law, calculate the angle at which you would expect to find the

strongest peak, 200 or 002, for the crystals with CuKα radiation (λ = 1.54 Å):

(For a cubic structure the position and intensity of the 200 and 002 reflections

are identical and they are named by various different conventions)

LiF a = 4.03 Å

NaCl a = 5.64 Å

KCl a = 6.28 Å

RbCl a = 6.58 Å

Why do you think that these cell parameters are different?

You are provided with the same mini X-ray sets (TELTRONS) as in AP2. Take 1

crystal from the choice of those marked: Red, Green and Yellow. They could be: LiF,

NaCl, KCl, or RbCl. Mount the crystal and, using the same methodology as described

in the previous practical, find and measure the 200 reflection to determine the unit

cell (use the 3 mm slit rather than the 1 mm).

From your measurement of the unit cell, work out which crystal you have.

Do you think that you can measure the difference between KCl and RbCl?

If you have time, you may like to measure another crystal. Please replace crystals in

the correct tubes after use, as some will absorb water.

2

Intensities and cell parameters – calculation

The powder diffraction data for the 4 crystals you have been investigating are given

both graphically and in a table. Sample A is a mixture of 2 crystalline phases (i.e. LiF,

NaCl, KCl or RbCl). In this practical you will use the peak positions and intensities to

a) identify and quantify the crystalline phases present in the experimental powder

diffraction data of Sample A and b) gain some understanding of why the relative

intensities vary for cubic structures.

Counts Intensity (counts)

20 LiF

10

0

400

NaCl

200

0

KCl

500

0

2000

RbCl

1000

0

3000

2000

1000

0

Sample A

29

JAE M2014

10

20

30

40

50

60

2θº

CuKα

Position [°2Theta] (Copper (Cu))

70

80

90

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

2014-15

LiF

Height /cts

18

24

12

3

3

d /Å

2.33

2.02

1.42

1.22

1.16

NaCl

2

38.67

44.95

65.45

78.68

82.93

KCl

(hkl) Height /cts d /Å 2

111

002

022

113

222

41

455

279

10

89

39

5

104

78

3.26

2.82

1.99

1.70

1.63

1.41

1.29

1.26

1.15

AP3

27.37

31.70

45.45

53.87

56.47

66.23

73.07

75.29

83.99

RbCl

(hkl) Height /cts d /Å 2

(hkl) Height /cts d /Å 2 (hkl)

111

002

022

113

222

004

133

024

224

111

002

022

113

222

004

133

024

224

115

333

044

7

1040

656

4

214

93

1

246

181

1

1

59

3.63

3.14

2.22

1.89

1.81

1.57

1.44

1.40

1.28

1.21

1.21

1.11

24.54

28.41

40.61

48.02

50.30

58.78

64.65

66.55

73.88

79.20

79.20

87.89

799

2797

1930

394

645

290

158

782

582

116

116

185

119

402

402

3.80

3.29

2.33

1.98

1.90

1.64

1.51

1.47

1.34

1.27

1.27

1.16

1.11

1.10

1.10

Identify which two materials are in Sample A. Use the graphs and/or tables.

Using the strongest peak, roughly estimate the ratio (weight fraction) of these

two materials.

Looking at the intensity scales on the graphs or intensities in the tables above

(they are the same) can you obtain a calibration coefficient for the strongest

peaks of these two materials?

Now we will calculate the relative intensities (I) of the strongest peak (002)

I hkl Fhkl Fhkl

where Fhkl is the structure factor:

The atomic scattering factors (also known as form factors, fn) are given below:

2 /o

0

39

45

27

32

25

28

23

27

Li

3

1.8

1.7

-

Na

11

8.8

8.5

-

Atomic Scattering Factors, fn

K

Rb

F

19

37

9

6.5

5.8

15.2

14.6

32

31.2

-

Cl

17

13.3

12.3

13.7

13

14.1

13.2

(note: fn increase with increasing atomic number and decrease with increasing angle)

30

JAE M2014

23.40

27.09

38.68

45.70

47.86

55.85

61.38

63.15

70.00

74.95

74.95

82.96

87.69

89.26

89.26

111

002

022

113

222

004

133

024

224

115

333

044

135

006

244

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP3

All the crystals have the same cubic structure (NaCl). The atomic positions (x, y, z) in

fractional co-ordinates (i.e. as a proportion of the unit cell dimensions) are:

Metal cation (M)

Anion (A)

0,0,0

1/2,1/2,0 1/2,0,1/2 0,1/2,1/2

1/2,1/2,1/2 0,0,1/2

0,1/2,0

1/2,0,0

Using your intensities calculated for the structure factor and the relative peak

heights of the strong 002 peak, now see what value you get for the weight

fractions in sample A.

Looking back at the graphs and tables of the data for all 4 cubic structures, note how

both the peak positions and intensities vary. In particular, compare say KCl to LiF or

RbCl and note that the relative intensities vary, e.g. (111) and (002): h+k+l is even as

compared with h+k+l is odd.

For two of these materials, calculate the structure factors of (111) and (002).

You may have already done (002) in section 2 above.

What factors contribute to the variation in the relative peak intensities?

3

Intensities and cell parameters - computational

In this section you will use the same mixture data as in section 2 (Sample A) and the

commercial software X’pert Highscore Plus, with a small reference database, to

identify the compounds in the mixtures and obtain a semi-quantitative measure of

their relative amounts. The current commercial ICCD database contains over one

hundred thousand unique crystalline phases. Here, for simplicity, this database only

contains data on the 4 cubic phases you are studying. The procedure for using the

software is described below:

i. Open the program X’pert Highscore Plus (HS+).

ii. (The database should be set to Mary mini cubic database. If a problem check

CustomiseProgram SettingsReference PatternsMary mini cubic

database.)

iii. Open the mixture data from the FileOpen menu. Start with Sample A, which

is printed in this document and considered in section 2

iv. Now, to account for the background scattering, open the TreatmentDetermine

Background window. Check the background fitted looks okay and click Accept.

v. To automatically find the peaks present, go to TreatmentSearch Peaks and

search for the peaks. Check the assignment looks okay and then click OK.

vi. Now that the peaks have been found, the phases present can be analysed. Go to

AnalysisSearch and MatchExecute Search and Match and ensuring the

Restriction Set is at None, click Search.

vii. Set the additional graphics pane to enable easy peak comparisons at Set

ViewAdditional GraphicsSeparate Patterns.

31

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP3

viii. In the lists pane, you should now have the pattern list at the top and the list of

possible candidates at the bottom.

ix. Select the patterns in the bottom pane to check the match with the data on the

graph. Drag those that fit up to the Pattern list pane.

x. You may find it easier to see if you change the colours of the lines, using the tab

in the Pattern list pane.

xi. Remove candidates that don’t fit from the bottom pane.

xii. Once the peaks are assigned, scroll to the right-hand side in the Pattern list

pane. The last box should give the SemiQuant(%) value. This is the semiquantitative estimate of the relative amounts of each phase present.

xiii. (It is worth noting that once all the peaks are assigned then there will be no

more arrows on the lines denoting the peaks above the main pattern.)

How well do the results of this analysis agree with your work in section 2?

The semi-quantitative analysis is calculated using the I/Ic values for each phase. I/Ic

(RIR- reference intensity ratio) is the intensity of the strongest peak compared with

the strongest peak in corundum Al2O3. This ‘calibration’ accounts for differences in

the structure factors, multiplicity, absorption and other factors allowing relative

intensities to be converted to weight fractions. In this analysis, the intensity is

calculated from a single peak height rather than using the areas of all the peaks which

gives more reliable results. Thus this quick RIR method gives a ‘semi-quantitative

result’.

(xiv In pattern list, if you double click on the reference data, all the crystallographic

information for that phase should appear as in the data base)

Now, if you have time, try the same approach on some of the other data files –

Sample B, C &/or D (just using the HS+ software not manual calculations)

4

Interpretation of a cubic diffraction pattern

X-ray diffraction is the main technique for determining the structure of materials, i.e.

the crystal system, unit cell, space group and positions of the atoms in the unit cell.

Usually a full set of single crystal data are required (~1000 spots measured) but some

simple cubic structures can be determined from powder data with relatively few peaks.

Here we follow this method for the compound gallium phosphide (GaP).

For any powder diffraction pattern the interplanar spacing d of each powder line can

be calculated from the measured Bragg angle . For cubic powder patterns, in this

case from gallium phosphide, GaP, it is easy to go further and assign Miller indices to

each powder line and then determine the lattice type and unit cell parameter. Because

GaP is cubic and has a simple unit cell it is possible to do even better, and determine

the crystal structure by comparing the observed relative intensities of different powder

lines with those predicted on the basis of candidate crystal structures.

The sample used to obtain the powder pattern was sulphur-doped GaP provided by the

ESPRC III-V Semiconductor Facility in the University of Sheffield. This material is

used as the conducting substrate on which a thin film of gallium-aluminium-arsenic32

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP3

phosphide is deposited for use in opto-electronic devices. A level of sulphur doping of

< 0.1 at.% is used to tailor the electronic properties of the GaP substrate.

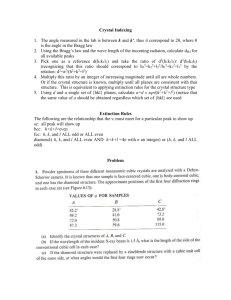

4.1 Determination of unit cell parameter and lattice type

You are provided with a powder diffractometer trace, obtained using CuK1

radiation. Values of 2 for the centre of each peak, obtained from the diffractometer

output, are also given.

Label each powder line in the pattern from n = 1 to n = 9 with increasing

diffraction angle . Set up a table of values of n and 2.

In view of the fact that the crystal is cubic, and thus:

1

h2 k2 l2

2

d hkl

a2 a2 a2

and, using the Bragg equation:

2 =4d 2 sin 2 and N hkl

a2

2

d hkl

Nhkl is thus proportional to sin2.

Add columns to your table for, sin2, (sin2n)/(sin21), N and hkl, where 1 is the

Bragg angle of the line with lowest 2, and n is the Bragg angle of the nth line.

Find the simplest set of integers, N, consistent with the values of (sin2n)/(sin21).

Using the values of N obtained above, index the diffraction pattern, i.e. assign hkl

values to all the powder lines.

Use the pattern of the indices of the observed reflections to determine the lattice type.

Use your value of the diffraction angle for the line with largest 2 to determine the

value of a. (Use the value of (CuK1) given in the Data Book.)

Estimate the accuracy of your result for a, if the uncertainty in measuring 2 for each

powder line is ~ ± 0.02°.

5

The structure of gallium phosphide

The structure of this relatively simple cubic substance can be determined by

considering the alternative atomic arrangements possible for the atoms contained

within the unit cell. We may then distinguish between the alternatives by calculating

the ratios of the intensities of certain reflections for each possible structure and

comparing these with the ratios that are observed experimentally.

33

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP3

5.1 Identifying the candidate crystal structures

From the evidence of section 4 it is clear that GaP is face centred cubic. From

measurements of density, it is found that there are 4 formula units of GaP per unit

cell. How many GaP units are there per lattice point?

Deduce the multiplicities of the 420 and 331 powder lines, e.g. by writing down all

the equivalent {420} and {331} planes.

GaP may exist as either the sodium chloride (NaCl) structure type or the sphalerite

(ZnS) structure type. For each structure type, write down the coordinates of the atoms

associated with the lattice point at the origin, i.e. the motif.

Figure 1: NaCl (top) and ZnS (zinc blende) (bottom) structure types for GaP.

34

JAE M2014

2014-15

5.2

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP3

Calculating the relative diffraction intensities for the candidate structures

Write down expressions for the intensities of the permitted hkl reflections for each of

the candidate structures, using the coordinates of atoms associated with the lattice

point at the origin only.

Hence obtain expressions for the intensities of the 420 and 331 reflections and for the

ratio of intensities I(420) / I(331) for each of the two structures.

Work out the ratio of intensities for the NaCl and ZnS (zinc blende) type structures,

using the following values for the atomic scattering factors:

fGa = 18.0, fP = 7.5 for the 420 reflection.

fGa = 18.3, fP = 7.6 for the 331 reflection.

Why are the values for a given atom not the same for both reflections?

Compare your qualitative observation of I(420) / I(331) for GaP with your calculated

estimates of the ratio for the two structures and hence determine the crystal structure

of sulphur-doped gallium phosphide as used for a substrate in opto-electronic devices.

Conclusions and take-home points

The size of the unit cell and the lattice type can be determined from the peak positions

in the diffraction pattern. The positions of atoms within the unit cell can be determined

from the relative peak intensities in the diffraction pattern.

X-ray diffraction is a powerful technique used to measure both the position and

intensity of diffraction peaks. The peak positions are related to the size of the unit cell

by Bragg’s law. The peak intensities are related to both the type and the positions of

atoms in unit cell. Thus by comparison with reference data, crystalline phases can be

identified and, with a suitable calibration factor, the amounts can be quantified.

Please remember to fill in the feedback form with any comments on this practical

35

JAE M2014

2014-15

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

AP3

36

JAE M2014

MATERIALS SCIENCE

Course A: Atomic Structure of Materials

2014-15

AP4

IntroductiontoOpticalDiffraction

** BEFORE ATTENDING THIS PRACTICAL **

Work through the DoITPoMS TLP entitled “Diffraction and imaging”.

http://www.doitpoms.ac.uk/tlplib/index.php

Aims and Objectives of this Practical

To understand the basic principles behind optical diffraction.

To understand how a lens can be used to form an image from a diffraction

pattern

To understand the difference between bright field and dark field imaging

To estimate the data density of a CD and DVD.

1

Introduction to diffraction

Diffraction concerns the spreading of light as it passes through a narrow slit or past

the edge of a small object. Laser light provides a narrow, coherent beam of light