NMC Phase Plan ID Sheets - Natividad Medical Center

advertisement

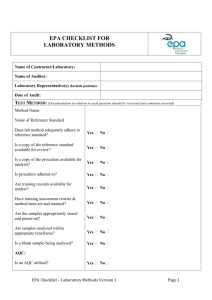

INTERIORS GENERAL NOTES NOTES PERTAIN TO AREAS WITHIN THIS SCOPE OF WORK ONLY. RE: KEYPLAN FOR LIMITS OF WORK. REFER TO INTERIOR FINISH GENERAL NOTES FOR ALL SUBMITTAL AND OR MOCK UP GUIDELINES AND REQUIREMENTS. CONTACT GALLUN SNOW FOR CLARIFICATION IN THE EVENT OF CONTRADICTORY INFORMATION BETWEEN DRAWINGS, LEGEND AND/ OR SPECIFICATIONS. REFER TO FINISH SCHEDULE AND PLAN FOR GENERAL FINISHES. REFER TO ALL INTERIOR FINISH NOTES AND INTERIOR DRAWINGS (INCLUDING PLANS, ELEVATIONS AND DETAILS) FOR COMPLETE INTERIORS INFORMATION. IF COLOR OR FINISH IS NOT SPECIFIED CONTACT GALLUN SNOW FOR CLARIFICATION. CLEAN JOB SITE REMOVING SCRAPS, DEBRIS AND WASTE MATERIALS DAILY. SUBMIT FOUR SAMPLES FOR APPROVAL PER MATERIAL SPECIFIED, LABEL EACH TO MATCH THE FINISH LEGEND DESIGNATION. INCLUDE PRODUCT DATA, SEAMING DIAGRAMS AND SHOP DRAWINGS PRIOR TO PROCUREMENT OR FABRICATION. PROVIDE REPRESENTATIVE SAMPLES FROM ALL DYE LOTS REQUIRED TO COMPLETE INSTALLATION. PROVIDE MINIMUM ONE BOX OVERAGE ON ALL TILE PRODUCTS, ALL SIZES, STYLES AND COLORS. INTERIORS DEMOLITION NOTES REMOVE EXISTING ARTWORK & ACCESSORIES WITHIN THE PROJECT SCOPE AND RETURN TO OWNER FOR STORAGE PRIOR TO DEMOLITION. REPLACE ANY ITEM DEMOLISHED OR DAMAGED BY DEMOLITION AND NOT SPECIFIED FOR DEMOLITION WITH A LIKE ITEM AS APPROVED BY OWNER AT NO ADDITIONAL COST. PROTECT ALL EXISTING FLOOR, WALL, DOOR AND CEILING FINISHES TO REMAIN AND REPAIR ANY DAMAGE AS A RESULT OF DEMOLITION OR CONSTRUCTION. FLOOR FINISH NOTES MILLWORK FINISH NOTES PROVIDE SOLID SURFACE COUNTER TOPS WITH INTEGRAL LIP, AND BACK SPLASH AT ALL SINK COUNTERS. RE: 7&8/ID6.1 CAULK COUNTERS WHERE THEY ABUT WALLS WITH CLEAR CAULK. PROVIDE ALMOND MELAMINE AT SEMI-EXPOSED CASEWORK INTERIORS AS DEFINED BY AWI STANDARDS U.N.O. PROVIDE LAMINATE PL7 AT VERTICAL BASE, EXPOSED SHELVES, AND WALL CABINETS UNO. PROVIDE 3MM PVC EDGE BANDING ON ALL DOOR AND DRAWER FRONT EDGES IN THE COLORS SPECIFIED UNO. PROVIDE 3MM PVC EDGE BANDING ON ALL COUNTERTOP EDGES IN THE COLORS SPECIFIED UNO. PROVIDE LAMINATE [PLAM#] AT ALL EXPOSED CASEWORK INTERIORS UNO. PLASTIC LAMINATE AND SOLID SURFACE COLORS SHALL BE VERIFIED ON ALL APPROVED MILLWORK SHOP DRAWINGS. FOR SUBMITTALS: ON SPECIFIED ACTUAL WOOD SURFACES, PROVIDE THREE 4 IN X 8 IN SAMPLES OF NATURAL AND STAINED WOOD FINISHES. LABEL AND IDENTIFY EACH AS TO LOCATION AND APPLICATION. MILLWORK FINISHES ON SHOP DRAWINGS MUST BE APPROVED BY DESIGNER AND ARCHITECT PRIOR TO PRODUCTION. ALL SOLID SURFACE COUNTERS WITH A SOLID SURFACE EDGE ARE TO BE MOCKED UP IN A 6" X 6" SAMPLE THAT SHOWS THE DIRECTIONALITY AND GRAINING OF THE PRODUCT FOR APPROVAL BY ARCHITECT. WINDOW TREATMENTS NOTES PROVIDE ROLLER SHADES AT ALL EXTERIOR WINDOWS WITHIN SCOPE OF WORK U.N.O. PROVIDE MOCK UP AND SHOP DRAWINGS OF EACH WINDOW COVERING TYPE FOR APPROVAL BY DESIGNER/ARCHITECT BEFORE FABRICATION. PROVIDE A SUBMITTAL SCHEDULE ALLOWING FOR LONG LEAD TIME ITEMS TO PREVENT SUBSTITUTIONS. VERIFY WINDOW CONDITIONS IN FIELD AND PROVIDE SHOP DRAWINGS FOR WINDOW COVERING INSTALLATION AND APPROVAL BY DESIGNER AND ARCHITECT. PROVIDE SHOP DRAWING LAYOUT SHOWING ALL FLOOR PATTERN LOCATIONS, GRAIN DIRECTION AND SEAMING DIAGRAMS. PROVIDE DUAL SHADE MECHANISM INCLUDING BLACK OUT FABRIC SHADE AND SHEER VIEW SHADE AT EACH EXAM ROOM AND ALL EXTERIOR WINDOWS WHERE AN EXAM TABLE IS SHOWN IN THE EQUIPMENT PLAN. INSTALL DIRECTIONAL FLOORING ORIENTED AS SPECIFIED IN THE FINISH PLAN. CONDUCT MOISTURE TESTS ON ALL CONCRETE SLABS WHERE FINISH MATERIALS ARE SCHEDULED. RECORD PASSING MOISTURE LEVELS PRIOR TO START OF INSTALLATION. REFERENCE MANUFACTURERS INSTALLATION SPECIFICATIONS FOR EACH FLOOR FINISH TYPE TO VERIFY REQUIREMENTS. ALIGN TRANSITION OF FLOOR MATERIAL WITH CENTER OF HINGE IN DOORWAY. IN A WRAPPED OPENING WITHOUT HINGES RE: FINISH PLANS FOR TRANSITION LOCATION. MISC. FINISH NOTES PROVIDE BLOCKING FF TO 7'-0" AFF AT ALL WALLS SCHEDULED FOR WALL HUNG EQUIPMENT, SYSTEMS FURNITURE, FLIP DOWN CHARTING, LARGE MARKER OR TACK BOARDS. RE: A6.1, ARCHITECTURAL DRAWINGS FOR BACKING DETAIL. ALL FURNITURE (EQUIPMENT) IS OWNER FURNISHED/ OWNER INSTALLED U.N.O. RE: SHEET ID6.1 FOR TRANSITIONS BETWEEN FLOORING MATERIALS.PROVIDE TRANSITION AS INDICATED BELOW: CARPET TO RESILIENT (LIN): TR1 CERAMIC TILE TO CARPET: TR2 CERAMIC TO RESILIENT (LIN): TR3 PROVIDE CUBICLE CURTAIN TRACK AND CARRIERS AT ALL PATIENT ROOMS, EXAM ROOMS AND OPEN PATIENT BAYS RE: ARCH RCP FOR LOCATIONS AND EXTENT. COORDINATE WITH OWNER, RE: OWNER PROVIDED CUBICLE CURTAINS. HEAT WELD ALL SHEET RESILIENT FLOORING SEAMS AND SEAL. SUBMIT SIGNAGE SHOPS, MESSAGE SCHEDULE AND FINISHES TO OWNER FOR REVIEW AND APPROVAL PRIOR TO FABRICATION. PROVIDE COLOR MATCH HEAT WELD RODS FOR EACH SHEET RESILIENT FLOOR AS SPECIFIED IN FINISH LEGEND. SUBMIT 12" X 12" SAMPLE OF TACK BOARD ASSEMBLY FOR APPROVAL BY ARCHITECT REMOVE EXISTING FLOORING, ADHESIVE AND MASTIC AT ALL EXISTING FLOORING SCHEDULED FOR DEMOLITION. PATCH AND PREP SUBFLOOR TO MEET MANUFACTURER'S REQUIREMENTS FOR NEW FLOORING MATERIALS. FLOAT SUBFLOOR AS NECESSARY TO ALIGN FINISHED SURFACE BETWEEN NEW FLOORING AND EXISTING TO REMAIN. BASE FINISH NOTES PROVIDE 6" HIGH INTEGRAL COVE BASE TO MATCH ADJACENT SHEET FLOORING WITH STAINLESS STEEL TOP CAP AND MECHANICALLY FASTENED CORNERS RE: 5/ID6.1. WHERE SPECIFIED PROVIDE CONTINUOUS LENGTH OF RUBBER BASE WITH FIELD FORMED CORNERS. PROVIDE SANITARY COVE TILE BASE AT ALL CERAMIC TILE IS RE: 5,6/ID6.1. WALL/ DOOR FINISH NOTES PROVIDE WALL FINISHES FROM LOWER TO HIGHER IN THE ORDER LISTED. COORDINATE PRE-INSTALLATION MEETING FOR PATTERNED WALL TILE. PROVIDE SHOP DRAWINGS TO CONFIRM TILE LAYOUT BEFORE INSTALLATION. PATCH AND PREP ALL EXISTING WALLS TO REMAIN FOLLOWING DEMO. CONFIRM EQUIPMENT MOUNTING HEIGHTS WITH ARCHITECT, DESIGNER AND OWNER PRIOR TO RE-INSTALL. PROVIDE ALL CERAMIC TILE TRIM PIECES - BULL NOSE, INSIDE/ OUTSIDE CORNERS, ETC. (PROVIDE 45 DEGREE MITRE AT ALL OUTSIDE CORNERS IF NO BULL NOSE TILE IS AVAILABLE). PROVIDE FULL HEIGHT WALL TILE IN ALL SHOWER SURROUNDS. PROVIDE TILE WAINSCOT 60" (48" AT EXISTING GRAB BARS TO REMAIN) AFF BEHIND AND NEXT TO EACH TOILET. RE: INTERIOR ELEVATIONS FOR WALL TILE PATTERN. PAINT ALL METAL DOORS, VISION PANEL, SIDELIGHT AND WINDOW FRAMES P2 U.N.O. PAINT SHEENS : REFER TO MANUFACTURER'S STANDARD DEFINITION FOR GLOSS RANGE ON THE FOLLOWING PAINT SHEENS: SEMI-GLOSS, EGGSHELL. ALL OUTSIDE CORNERS IN PUBLIC AND CIRCULATION AREAS ARE TO RECEIVE CG1. SUBMIT SHOP DRAWINGS FOR WDPNL1 ABBREVIATIONS AFF CC CDT CF/CI CF/OI CFT CG CL CPT CTB CWT DAP DEMO DIM EP EXIST EXP FF FF&E FURN GL GT IB LIN NIC NTS OF/CI OF/OI PL P RB SAT SS TR TYP UNO VCT WD WDCLG WDPNL WT ABOVE FINISHED FLOOR CUBICLE CURTAIN CERAMIC DECORATIVE TILE CONTRACTOR FURNISHED/CONTRACTOR INSTALLED CONTRACTOR FURNISHED/OWNER INSTALLED CERAMIC FLOOR TILE CORNER GUARD CENTER LINE CARPET CERAMIC TILE BASE CERAMIC WALL TILE DECORATIVE ACRYLIC PANEL DEMOLITION DIMENSION EPOXY PAINT EXISTING EXPOSED FINISH FACE FURNITURE, FIXTURE, AND EQUIPMENT FURNITURE GLASS GROUT INTEGRAL BASE LINOLEUM NOT IN CONTRACT NOT TO SCALE OWNER FURNISHED/CONTRACTOR INSTALLED OWNER FURNISHED/OWNER INSTALLED PLASTIC LAMINATE PAINT RUBBER BASE SUSPENDED ACOUSTICAL TILE SOLID SURFACE TRANSITION TYPICAL UNLESS NOTED OTHERWISE VINYL COMPOSITION TILE WOOD WOOD CEILING WOOD PANEL WINDOW SHADES FINISH LEGEND FLOORING CARPET CPT5 LEES, MENSWEAR, SHIRT GT011, COLOR: 424 LAPEL (BROWN, FIELD); 24"X24" MODULAR TILE; .094" PILE THICKNESS; TUFTED, PATTERNED TIP SHEAR; YARN-DYED ANTRON LEGACY 6,6 NYLON; ICT-RC FIBERGLASS REINFORCED THERMOPLASTIC COMPOSITE BACKING; VERTICAL ASHLAR INSTALLATION. CPT14 LEES, MENSWEAR, JACKET GT012, COLOR: 424 LAPEL (ORANGE, ACCENT); 24"X24" MODULAR TILE; .095" PILE THICKNESS; TUFTED, TEXTURED LOOP; YARN-DYED ANTRON LEGACY 6,6 NYLON; ICT-RC FIBERGLASS REINFORCED THERMOPLASTIC COMPOSITE BACKING; VERTICAL ASHLAR INSTALLATION. CERAMIC FLOOR TILE CFT4 AMERICAN OLEAN, SERIES: AVENUE ONE, COLOR: BROWNSTONE AU04 (BROWN, FIELD); SIZE: 12" x 12" x 3/8" THICK; GROUT: GR4 CFT5 AMERICAN OLEAN, SERIES: UNGLAZED MOSAICS, COLOR: WILLOW SPECKLED A94 (BEIGE); SIZE: 2" x 2" x 1/4" THICK MOSAIC ON MESH SHEET; GROUT: GR3 FLOORING CONTINUED LINOLEUM LIN5 FORBO, MARMOLEUM REAL AUTHENTIC, COLOR: 3174 SAHARA (ORANGE); 2.5MM THICK; WELDING ROD: R3174MC LIN6 FORBO, MARMOLEUM VIVACE, COLOR: 3417 WILD AMAZON (GREEN); 2.5MM THICK; WELDING ROD: R3417MC LIN7 FORBO, MARMOLEUM VIVACE, COLOR: 3412 REMBRANDT PALETTE (RED); 2.5MM THICK; WELDING ROD: R3412MC LIN16 FORBO, MARMOLEUM REAL, COLOR: 3075 SHELL (TAN); 2.5MM THICK; WELDING ROD: R3075MC LIN19 FORBO, MARMOLEUM STRIATO, COLOR: 5220 PLOUGHED ACRE (WOOD LOOK); 2.5MM THICK; WELDING ROD: R5220MC TRANSITION STRIPS & THRESHOLDS TRANSITION STRIPS TR1 BURKE RUBBER MERCER TRANSITIONAL MOULDINGS 152 CARPET TO RESILIENT TRANSITION; COLOR: 523 BLACKBROWN TR2 SCHLUTER RENO-TK; AETK100, SATIN ANODIZED ALUMINUM TR3 SCHLUTER RENO-V; AEVT100B20, SATIN ANODIZED ALUMINUM TR4 FIELD FLOAT LINOLEUM TO MATCH HEIGHT OF VCT WALL BASE INTEGRAL COVE BASE IB6 6" HIGH INTEGRAL BASE TO MATCH ADJACENT SEAMLESS RESILIENT FLOORING IN MATERIAL, PATTERN, COLOR. RUBBER RB1 RB2 BURKE, RUBBER BASE, TYPE TS, 1/8" THICK, COVE, COLOR: 508 TWEED, 6" HIGH BURKE, RUBBER BASE, TYPE TS, 1/8" THICK, COVE, COLOR: 104 FUDGE, 6" HIGH CERAMIC TILE BASE CTB1 AMERICAN OLEAN, SERIES: AVENUE ONE, COVED BASE S36C9T COLOR: PLAYGROUND SAND AU03, SIZE: 6" x 12" x 3/8" THICK; GROUT: GR2 CTB2 AMERICAN OLEAN, SERIES: BRIGHT AND MATTE, COVED BASE A3401, COLOR: COLOR: ALMOND, SIZE: 4.25" x 4.25" x 3/8"; GROUT: GR1 WALL FINISH CERAMIC DECORATIVE TILE CDT1 AMERICAN OLEAN, SERIES: AVENUE ONE, DECORATIVE ACCENT, COLOR: BROWNSTONE/PLAYGROUND SAND AU16, SIZE: 2" x 12" x 3/8" THICK; GR2; RF: _/ID6.1 CDT2 AMERICAN OLEAN, SERIES: LINEA, DECORATIVE LINER, COLOR: ARTICHOKE 0063, SIZE: .5" x 6" x 3/8" THICK; GROUT: GR1; RF: _/ID6.1 CDT3 AMERICAN OLEAN, SERIES: LINEA, DECORATIVE LINER, COLOR: SUMMER RAIN 0081, SIZE: .5" x 6" x 3/8" THICK; GROUT: GR1; RF: _/ID6.1 CDT4 AMERICAN OLEAN, SERIES: LINEA, DECORATIVE LINER, COLOR: NUTMEG 0037, SIZE: .5" x 6" x 3/8"; GROUT: GR1; RE: _/ID6.1 CDT5 AMERICAN OLEAN, SERIES: LINEA, DECORATIVE LINER, COLOR: AUTUMN LEAVES 0027, SIZE: .5" x 6" x 3/8" THICK; GROUT: GR1; RF: _/ID6.1 CERAMIC WALL TILE CWT1 AMERICAN OLEAN, SERIES: AVENUE ONE, COLOR: PLAYGROUND SAND AU03, SIZE: 12" x 24" x 3/8" THICK; GROUT: GROUT: GR2 CWT2 AMERICAN OLEAN, SERIES: AVENUE ONE, BULLNOSE S43C9, COLOR: PLAYGROUND SAND AU03, SIZE: 3" x 12" x 3/8" THICK; GROUT: GR2 CWT3 AMERICAN OLEAN, SERIES: BRIGHT AND MATTE, COLOR: ALMOND, SIZE: 4.25" x 4.25" x 3/8" THICK; GROUT: GROUT: GR1 CWT4 AMERICAN OLEAN, SERIES: BRIGHT AND MATTE BULLNOSE S4449, COLOR: ALMOND, SIZE: 4.25" x 4.25" x 3/8" THICK; GROUT: GR1 CORNER GUARD CG1 C/S ACROVYN, CORNER GUARD, MODEL: SSM-10N, COLOR: ALMOND, SIZE: 90 DEGREE, 2", TO BE INSTALLED TO TOP OF DOOR FRAME UNO PAINT PROVIDE SHERWIN WILLIAMS PROGREEN 200 LOW VOC, 50g/L PAINT MIXTURE FOR: PRIMER, SEMI-GLOSS, AND EGGSHELL SHEENS. 1 COAT PRIMER 2 COATS TOP COAT. (E BEFORE PAINT DESIGNATION FOR EPOXY PAINT. I.E: EP1 = SAME COLOR AS P1 IN EPOXY FORMULATION) P1 SHERWIN WILLIAMS, COLOR: SW6126 NAVAJO WHITE P2 SHERWIN WILLIAMS, COLOR: SW6141 SOFTER TAN P3 BENJAMIN MOORE, COLOR: HC-71 HASBROUCK BROWN P9 SHERWIN WILLIAMS, COLOR: SW6366 AMBITIOUS AMBER P10 BENJAMIN MOORE, COLOR: 2088-10 RED OXIDE P11 PITTSBURG PAINTS, COLOR: 456-5 PALMETTO P13 SHERWIN WILLIAMS, COLOR: SW6367 VIVA GOLD P14 SHERWIN WILLIAMS, COLOR: SW6496 OCEANSIDE P21 SHERWIN WILLIAMS, COLOR: SW6184, AUSTERE GRAY WOOD WALL PANEL WDPNL1 DECOUSTICS, SOLO WOOD PLANKS, NON-PERFORATED, TONGUE AND GROOVE INSTALLATION, PLANKS: 7 9/16" WIDE x 120" LONG; SOLO 8, BEECH (WAITING AREAS) CASEWORK PLASTIC LAMINATE PL1 WILSONART, COLOR: 4673-60 SAFFRON TIGRIS; EDGE BAND: PL3 WILSONART, COLOR: 1787-60 OXIDE; EDGE BAND: PL4 WILSONART, COLOR: 4841-60 DESERT ZEPHYR; EDGE BAND: CANPLAST, INC. COLOR: 86012 PL7 NEVAMAR, COLOR: WM5577E SCANDIA MAPLE; EDGE BAND: CANPLAST, INC. COLOR: 10/03 HARDROCK MAPLE #11; SIZE: 3MM SOLID SURFACE SS2 FORMICA, CARRARA STONE SS7 CORIAN, CINNABAR SS8 DUPONT, ZODIAQ, COLOR: MARRONE EMPERADOR SS9 CORIAN, BRONZITE DECORATIVE ACRYLIC PANEL DAP7 3 - FORM, BAMBOO RINGS DARK, COLOR: NA, GAUGE: 3/8", FINISH SANDSTONE WOOD WD1 SOLID MAPLE STAIN TO MATCH PL7 SPECIALTIES CUBICLE CURTAIN CC2 STANDARD TEXTILES, PATTERN: UNDER THE SEA, COLOR: #02 TREASURE (BY OWNER) GLAZING GL SKYLINE, COLLECTION: WEAVES & TEXTURES, PATTERN SATEEN OPTION CCLEAR TEMPERED, GAUGE: 3/8", FINISH: TWO SIDE PATTERNED (UNPOLISHED), INSTALLATION: STRIPE TO RUN HORIZONTAL, LEAD TIME: 6-8 WEEKS OR APPROVED EQUAL GROUT MAPEI, KERAPOXY, PREMIUM EPOXY MORTAR AND GROUT, 100% SOLIDS HIGH-STRENGTH EPOXY MORTAR AND CHEMICAL RESISTANT NON-SAGGING GROUT SYSTEM, RECOMMENDED GROUT JOINT 1/8" U.N.O. GR1 KERAPOXY COLOR: #14 BISCUIT GR2 KERAPOXY COLOR: #06 HARVEST GR3 KERAPOXY COLOR: #05 CHAMOIS GR4 KERAPOXY COLOR: #42 MOCHA PROVIDE EGGSHELL FINISH FOR ALL OTHER LOCATIONS. WINDOW SHADES WT1 MECHOSHADE, MECHO/5 STANDARD BRACKET, W/O FASCIA, THERMO VEIL, SINGLE, DENSE VERTICAL WEAVE, SHADECLOTH 1000 SERIES, COLOR #1002 BEIGE; APPROVED EQUALS: LUTRON OR DRAPER XD WT2 MECHOSHADE, DOUBLESHADE BRACKETS- #15, W/O FASCIA, DUAL, EQUINOX BLACKOUT SHADECLOTH 0100 SERIES, COLOR: #0104 SANDSTONE; APPROVED EQUALS: LUTRON OR DRAPER XD PROVIDE (4) 8 1/2" X 11" PAINT OUT SAMPLES OF ALL SPECIFIED PAINT IN SPECIFIED GLOSS. CEILINGS PROVIDE A SMOOTH LEVEL 4 DRYWALL FINISH ON ALL GYPSUM WALLS U.N.O. SAT1 SAT2 SAT3 SAT4 WDCLG1 PROVIDE SEMI GLOSS FINISH IN: EXAM ROOMS, NOURISHMENT, SOILED UTILITY, PROCEDURE ROOMS, UTILITY ROOMS, RADIOGRAPHY, JANITOR'S CLOSET, MEDICATION AREAS AND ON ALL PAINTED METAL. PROVIDE A SMOOTH LEVEL 4 DRYWALL FINISH ON ALL GYPSUM BOARD CEILINGS IN ALL TOILET ROOMS, ON SOFFITS ETC. U.N.O. PAINTING WHEN FACTORY-FINISH OR INSTALLER FINISHING IS SPECIFIED FOR METAL TOILET ENCLOSURES, PRE-FINISHED PARTITION SYSTEMS, ACOUSTIC MATERIALS, ARCHITECTURAL WOODWORK AND CASEWORK, ELEVATOR ENTRANCE DOORS AND FRAMES, LIGHT FIXTURES, SWITCHGEAR AND DISTRIBUTION CABINETS. METAL SURFACES OF ANODIZED ALUMINUM, STAINLESS STEEL, CHROMIUM PLATE, COPPER, BRONZE AND SIMILAR FINISHED MATERIALS. PAINT GRILLS, WALL DIFFUSERS, ELECTRICAL PANELS, WALL MOUNTED BOXES, ACCESS PANELS, ETC., WHICH ARE EXPOSED IN FINISHED SPACES TO MATCH THE SURFACE ON WHICH THEY OCCUR. IF THE ITEM IS ON A WALL-COVERED WALL. PROVIDE A CUSTOM PAINT COLOR USED TO MATCH. CONTACT GALLUN SNOW FOR APPROVAL. CEILING FINISH NOTES PAINT SOFFITS P1 U.N.O. PAINT UNDERSIDE AND FACE OF SOFFIT P1 OR ACCENT PAINT AS SCHEDULED. RE: REFLECTED CEILING PLANS A.4 FOR ADDITIONAL SOFFIT AND CEILING FINISH INFORMATION. PAINT ALL GYPBOARD CEILINGS P1 U.N.O. PAINT ALL OPEN STRUCTURE CEILINGS INCLUDING ALL EXPOSED COMPONENTS P1 U.N.O. CENTER CEILING GRID AND TILE LAYOUT IN EACH ROOM. DO NOT INSTALL LESS THAN A 1/2" CEILING TILE. ARMSTRONG, OPTIMA OPEN PLAN, 3250, TEGULAR FINE TEXTURE, 2'-0" x 2'-0" x 1" THICK; 15/16" SQUARE TEGULAR, WHITE (CORRIDORS) ARMSTRONG, ULTIMA SQUARE LAY-IN, 1910, FINE TEXTURE, 2'-0" x 2'-0" x 3/4" THICK; 15/16" SQUARE LAY-IN, WHITE, (EXAMS) ARMSTRONG, HEALTH ZONE ULTIMA , 24" x 24" x 3/4" THICK; 15/16" SQUARE LAY-IN ARMSTRONG, OPTIMA PLANK SQUARE TEGULAR, 24" x 60" x 9/16"; SUPRAFINE XL 9/16" EXPOSED TEE GRID DECOUSTICS, SOLO WOOD PLANKS, PERFORATED, TONGUE AND GROOVE INSTALLATION, PLANKS: 7 9/16" WIDE x 120" LONG; SOLO 8, BEECH (WAITING AREAS) FINISH SCHEDULE REMARKS 1. 2. 3. 4. 5. 6. RE: FINISH PLAN, ID2.1 FOR ACCENT PAINT LOCATIONS RE: ENLARGED FINISH PLAN, ID2.2 FOR FLOOR PATTERN. PROVIDE DUAL WINDOW SHADE (WT2) THIS ROOM INSTALL WALL TILE PATTERN RE: A6.3/4 TILE IN THIS ROOM IS LISTED AS ALTERNATE #2 REPLACE ANY DAMAGED CEILING TILES TO MATCH EXISTING. 5 PLAN SYMBOL KEY NIC 3 4 3 1 3 XXX XX ELEVATION MARKER TYP 3 P13 7 3 P9 4 3 4 4 3 4 4 3 3 3 P13 P13 4 3 4 P13 3 3 1 P_ 4 P_ 4 2 2 1 PROVIDE P2 AT BRACING ON EXTERIOR WALLS IN THIS ROOM 2 PROVIDE FULL HEIGHT AT OUTSIDE CORNERS WHERE PAINT TRANSITIONS 3 RELAMINATE EXISTING CASEWORK AS SPECIFIED ON SHEET ID0.1 4 PROVIDE CC2 WHERE CUBICLE CURTAIN TRACK IS LOCATED AT THE DOOR. RE: CUBICLE CURTAIN SPEC. OWNER FURNISHED. 5 PROVIDE P14 AT BRACING ON EXTERIOR WALLS IN THIS ROOM 6 PATCH & MATCH EXISTING FLOOR, BASE, WALL, AND CEILING FINISHES 7 PROVIDE FR PLYWOOD AT ALL WALLS FOR BACKING 1 P14 4 4 P14 2 INDICATES FINISH KEY NOTE 1 3 3 X FINISH KEY NOTES 4 4 INDICATES WALL FINISH 1 3 3 3 XX 4 6 4 TYP 4 4 4 4 3 CALLOUT MARKER 4 4 3 4 X XXX 1 2 WDPNL1/GL P21 WDPNL1/GL WDPNL1/GL 5 P21 4 4 4 3 1 4 P21 WDPNL1/GL P21 6 6 4 4 4 NIC 6 6 NIC P1 P1 P1 P1 P1 P1 NIC NIC LIN16 LIN7 LIN5 LIN16 PLAN SYMBOL KEY XXX XXX XXX INDICATES FLOOR FINISH TRANSITION INDICATES FLOOR FINISH IN DEFINED AREA 6 LIN7 LIN16 LIN1 ALIGN WITH CORNER LIN16 LIN7 LIN7 LIN6 LIN16 LIN16 LIN16 LIN5 LIN7 LIN16 LIN16 LIN16 LIN5 LIN16 LIN16 LIN16 LIN7 LIN16 LIN7 LIN7 ALIGN WITH CORNER LIN16 LIN16 LIN19 ALIGN WITH CORNER ALIGN WITH CORNER GRAIN LIN7 LIN19 LIN7 LIN16 LIN16 LIN16 ALIGN WITH CORNER GRAIN LIN19 GRAIN LIN16 LIN19 GRAIN LIN16 ALIGN WITH CORNER ALIGN WITH CORNER LIN19 LIN7 ALIGN WITH CORNER LIN5 6 LIN1 ALIGN WITH CORNER LIN 16 LIN 5 CPT14 ALIGN WITH CENTER OF DOORWAY TRANSITION ALIGN WITH CORNER CPT14 CPT5 LIN16 LIN6 ALIGN WITH CORNER LIN6 CPT5 LIN16 LIN5 LIN16 CPT14 ALIGN WITH CENTER ALIGN WITH CORNER NIC P1 P1 CPT5 ALIGN WITH CORNER CPT14 LIN1 6 LIN16 LIN7 LIN5 LIN1 LIN7 NIC 6 P1 P1 P1 P1 NIC SEAL ALL PERIMETER JOINTS WITH CLEAR SILICONE SEALANT. 1 " 2 SOLID SURFACE COUNTERTOP 2" SOLID SURFACE BACKSPLASH INTEGRAL RAISED LIP EDGE - RAISED LIP TO BE A SMOOTH GRADUAL TRANSITION TO COUNTERTOP SURFACE WITH NO SHARP CORNER SOLID SURFACE LIP 4" 1 SOLID SURFACE MATERIAL AT JOINT OF BACKSPLASH AND COUNTERTOP 2" SOLID SURFACE COUNTERTOP 3 " 4 1 " 2 1 3 4" THICK PLYWOOD SUBSTRATE 3 "1 " 4 2 " R1 SOLID SURFACE FASCIA BETWEEN LIP AND SUBSTRATE WALL TILE THIN SET MIN. GROUT JOINT GYP BOARD/CEMENT BACKER 3 MILLWORK CABINET OR BLOCKING RE: ARCH ELEVATIONS/DETAILS SECURE ALL SOLID SURFACE ELEMENTS WITH JOINT ADHESIVE AS REQUIRED, NO VISIBLE SEAMS OR GLUE 1 "1 " 2 2 4" THICK PLYWOOD SUBSTRATE SECURE ALL SOLID SURFACE ELEMENTS WITH JOINT ADHESIVE AS REQUIRED, NO VISIBLE SEAMS OR GLUE WALL TILE WS05 C3B C1 T7 C3B C3B BK2 1 C3B 2 WS07 C3C C1 C1 WS05 CH1 CH1 CH1 C3B C3B C3B C3B EX EX EX EX EX EX EX EX EX C3C C3C C3C C3C C3B C3B EX CH1 CH1 CH1 EX CH1 CH1 EX CH1 C3C CH1 CH1 CH1 CH1 CH1 CH1 C3C FURNITURE KEY NOTES C3C CH1 C3B C3C C3B C3C C3C C3C C3C C3B C3B C3B C3B C3B CH1 C3C C3C C3B C1 C1 C1 C1 C3B CH1 C3B CH1 CH1 CH1 1 C1 C1 F1 C3B F1 C3B C2 C2 1 1 CH1 CH1 C2 C1 C1 C2 C1 C1 C3C C3C C3C WS07 C3C F1 C1 C1 CH1 1 CH1 C1 C1 B1 B1 EX WS05 EX C3B C3B EX C3C C3B C1 C1 F2 C3C C3B 1 C1 C1 EX 1 C3C C1 C3C T2 / A1 L1B C3B WS04 2 C6F C3B C3C C6F CH1 L2A CH1 CH1 C3C 1 L1B CH1 T1 C5B C5B C6E C6E T1 C1 C5B C6E C6E T2 / A1 C5B C5B C5B L1B C5B C5B L2A C6F C6F CC1 CC1 C3C CT1 L1B C5B C5B C3B CC1 C7A C3C CC1 B1 B1 B1 B1 B1 CH1 CH1 CH1 C1 C5B PROVIDE BACKING ATWORKSURFACE MOUNTED TO THE WALL 2 FIELD VERIFY DIMENSION FOR WORKSTATIONS C3B C3B C1 1 C3B