212

advertisement

Guiding Global Placement with Wire Density

Kalliopi Tsota, Cheng-Kok Koh and Venkataramanan Balakrishnan

School of Electrical and Computer Engineering, Purdue University, West Lafayette, IN 47907–2035

{ktsota, chengkok, ragu}@ecn.purdue.edu

Abstract—This paper presents an efficient technique for the

estimation of the routed wirelength during global placement

using the wire density of the net. The proposed method identifies

congested regions of the chip and incorporates the model of

the routed wirelength into the objective function in order to

effectively alleviate these regions from congestion. The method

is integrated in the analytical placement framework and the

two-level structure improves the scalability of the placer and

speeds up the algorithm. The proposed analytical placer provides

the best-so-far average routed wirelength in the IBM version2

benchmark suite.

I. I NTRODUCTION

The placement of cells on the chip area is a difficult

task in VLSI physical design and the minimization of total

routed wirelength is one of the fundamental goals. Moreover,

routability is a key measurement of quality. A placed design

that results in congested regions on the chip often leads to

routing detours and may result in a higher routed wirelength.

In the worst case, it may even not allow successful routing.

Several approaches have been used in the past to address

the issue of routability. To reduce congestion, in [1] the author

modeled the routing supply versus routing demand and incorporated the routing congestion into the objective function of

simulated annealing. In [2], [3] the routability of a placement

solution was improved using allocation of the white space

in congested region during global placement. In [4], [5] the

congestion-driven placement was based on the inflation of cells

that were located in the congested regions. In [6] the authors

made use of linear programming to resolve the conflicts of

multiple congested regions. In [7], [8], Rent’s rule was used to

estimate the routing demand. In [9] the cell placement problem

was formulated as a minimal-cost maximum-flow problem.

The algorithm proposed in [10] obtained a model for the wire

distribution on the chip, using the wire density of the net.

The paper presents a routability-driven global placement

flow. The global placement is performed in a two-level framework and a wirelength estimation technique is used to guide

the entire global placement process. At the first level, the

clusters are placed on the chip area using an effective global

placement algorithm. Then, the clusters are assigned to the

updated positions, obtained from the placement algorithm, and

every cell of the original netlist is located at the center of its

corresponding cluster. At the second level, the cells of the

original netlist are placed on the chip area to further reduce

overlap. An efficient routed wirelength estimation method is

used to determine the wirelength inside the regions of the

chip and guide the placement of the clusters at both levels.

The main contributions of the paper are: (i) The estimation

978-1-4244-2820-5/08/$25.00 ©2008 IEEE

of wirelength in a region; and (ii) The balancing of the cell

density and the wirelength across the placement regions.

In this paper, the wire density of a net is defined as the ratio

of the bounding-box perimeter over the bounding-box area of

the net. If the bounding box of a net overlaps with a region,

it adds to the total wirelength within the region by a factor

equal to the product of the wire density of the net and the

overlap area between the region and the bounding box of the

net. The proposed method makes use of the wire density of

a net to estimate the wire congestion at different regions of

the chip area during the global placement. The objective is to

reduce the wire congestion by modifying the cell density and,

at the same time, distributing the wire uniformly inside the

regions of the chip. The regions characterized as congested

are assigned to lower cell density, whereas the uncongested

regions are allowed to have higher cell density.

During the global placement phase, the placement area is

divided into an array of uniform rectangular global bins. The

wire distribution is independent of the number of wires that

cross the boundary of the bin and therefore not affected by

the bin structure. At the same time, it is not easy to calculate

the wirelength inside the bin, as there are nets that either

have multiple pins or do not reside entirely inside the bin.

The technique for the estimation of wirelength inside the

bin is based on the fact that the wirelength of a multi-pin

net at the interior of a bin is determined from the overlap

area between the two and the wire density of the net. The

wirelength inside the bin is calculated and incorporated into

the objective function. Therefore, the wire density of the net

guides the placement process as the tool of estimating the

wirelength. By penalizing the bins having wirelength higher or

lower than the average, the formulation provides a placement

of cells that does not contain congested regions and obtains

shorter average routed wirelength.

The placer, guided by wire density to estimate wirelength,

obtains shorter average routed wirelength compared to the existing placement tools. The improvement is between 2.2% and

14.6% compared to RUDY [10], APlace [11], CHKS+WSA

[12], mPL-R+WSA [13], mPL6 [14] and ROOSTER [15], for

the circuits of the IBM version2 benchmark suite. The rest of

the paper is organized as follows: The two-level framework

of the algorithm is covered in Section II. Section III gives the

analytical placement formulation. In Section IV, the estimation

technique for the routed wirelength is analyzed. Section V

includes the implementation details and Section VI shows the

experimental results. Section VII concludes the paper.

212

II. A T WO -L EVEL FRAMEWORK

The placement algorithm presented in the paper is performed in a two-level framework. The first level deals with a

netlist of clusters. Initially, the cluster locations are randomly

assigned. The algorithm updates their locations to remove

cluster overlap and uniformly distribute wirelength across the

chip area. At the second level, the cells of the original netlist

are assigned to the locations obtained from the first level

(each cell is located at the center of its corresponding cluster),

and the placement algorithm places the cells on the chip to

further reduce cell overlap and uniformly distribute wirelength.

Therefore, the wirelength estimation technique is incorporated

in the global placement and applied in both levels of the twolevel framework. The two-level framework of the placer can

be easily extended to a multilevel framework.

III. G LOBAL PLACEMENT

The input to the global placer is a circuit netlist, where the

vertices represent the cells and the hyperedges represent the

nets in the circuit. The global placement can be applied to the

original netlist, at the second level of the two-level framework,

or the netlist of clustered cells, at the first level of the two-level

framework. As the goal of a global placement is to determine

approximate locations of the cells, it is not necessary to

enforce the non-overlap constraints strictly. Instead, a popular

formulation is to evenly distribute the cell density throughout

the entire chip. To facilitate such a formulation, the placement

area is divided into uniform bins. Let (x,y) denote the vector of

the cell coordinates, W L(x,y) the wirelength of the placement

and SDg (x,y) the cell density inside bin g. If the goal is to

equalize the cell area in every bin and D is the average cell

area, SDg (x,y) = D. The constrained non-linear optimization

problem formulated in APlace [11], [16] is

min W L(x, y)

subject to SDg (x, y) = D, ∀g.

The problem is usually solved as a sequence of unconstrained optimization problems and the cell density of the bin

is included into the objective function as a weighted penalty

1 2

·

min W L(x,y) +

(SDg (x,y) − D) ,

(1)

2·u g

where u monotonically decreases in the sequence. The wirelength WL is typically evaluated using HPWL, which is a

convex function but not strictly convex. As such, it cannot

be effectively minimized. Also, HPWL is not differentiable.

Being neither strictly convex nor differentiable, the expression

is not amenable to Newton-type methods. The log-sum-exp

(LSE) function [17] is often used to capture the linear HPWL.

This is a continuous, differentiable function and has been

extensively used to approximate and smooth the HPWL.

This paper considers a different approximation function for

the HPWL. The two-variable CHKS smoothing function is

called recursively to approximate the maximum of the pin

coordinates within a net. The negative of the same function

approximates the minimum. The CHKS function, as presented

in [12], [18] constitutes an alternative smoothing method to

the HPWL, and it is as effective as the LSE approximation in

terms of wirelength minimization.

A. Wirelength formulation

The half-perimeter wirelength of a net e ∈ E is expressed

HP W Le = max{xi } − min{xi } + max{yi } − min{yi }. (2)

i∈e

i∈e

i∈e

i∈e

The total HPWL is

HP W L =

HP W Le .

e∈E

The CHKS function [12] is used to smooth the two-variable

maximum function

(x1 − x2 )2 + α2 + x1 + x2

,

CHKS(x1 , x2 ) =

2

where α > 0 is the smoothing parameter. The multi-variable

maximum function, proposed in [18] and used in [12], is

obtained by recursive calls to the two-variable maximum

function

max {x} = max {max {x(1) }, max {x(2) }},

where x(1) , x(2) , is a disjoint partitioning of x. Then, min {x}

was obtained from max {x} approximation as

min{x} = − max{−x}.

This paper follows the definition given in [12]: For a convex

function f : R2 → R define ∀1 ≤ i ≤ n − 1, the function

fi,i+1 : Rn → R by fi,i+1 (x) = f (xi , xi+1 ), and ∀1 ≤ i <

j ≤ n, the function fi,i : Rn → R by fi,i (x) = xi . Moreover,

∀1 ≤ i < j ≤ n and j − i + 1 > 2, let fi,j : Rn → R be

defined by

fi,j (x) = f (fi,k (x), fk+1,j (x)),

where k = i+j

2 .

Therefore, the multi-variable maximum and minimum functions are smoothed and approximated by f1,n which, for sake

of simplicity, is denoted as f in the rest of the paper. The

CHKS function is convex and differentiable, therefore can

be handled by general optimization algorithms. Then, the

HP W Le (2) is expressed as

HP W Le = fx,e + fy,e ,

where fx,e approximates maxi∈e {xi } − mini∈e {xi } and is

obtained by recursive calls to CHKS for the maximum and

minimum x-coordinates of the pins of net e. In the same way,

fy,e approximates maxi∈e {yi } − mini∈e {yi }.

213

B. Cell density formulation

The cell potential is a rectangular function that is smoothed

by the Bell-shaped function as in APlace [11]. Let wv , hv be

the width, height of cell v and wg , hg be the width, height of

bin g. If cell v is located at a horizontal distance dx from the

center of bin g, then the x-overlap between g and v.

⎧

wv +2·wg

2

⎪

],

⎨ 1 − a · dx if dx ∈ [0,

2

2

w

+4·w

w

+2·w

w +4·w

v

g

px (g, v) =

) if dx ∈ [ v 2 g , v 2 g ],

b · (dx −

⎪

⎩ 0 otherwise. 2

where

a=

4

(wv +2·wg )·(wv +4·wg ) , b

=

Bounding box of

net B

Bin

g2

Bounding box

of net A

Bin

g1

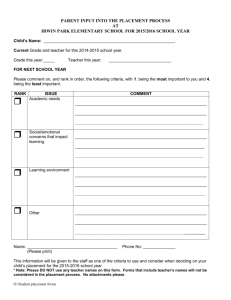

Fig. 1. The global bins g1 and g2 are shown in light gray. The bounding

boxes of nets A and B overlap bins g1 and g2 respectively. The dark lines

represent the routed wirelength of each net.

2

wg ·(wv +4·wg ) ,

so that the function is continuous when dx = w2v + wg .

Similarly, a smoothed cell potential function is defined for

the y-direction. The potential function SDg has the form

SDg (x,y) =

Cv · px (g, v) · py (g, v),

v

where γ is a user defined constant that determines how

much Dg (x,y) deviates from the average D. The optimization

problem (1) can now be rewritten as

where Cv is a normalization factor such that

Av =

Cv · px (g, v) · py (g, v).

min HP W L(x,y) +

g

In other words, each cell has a total area potential equal to its

area.

IV. E STIMATION OF ROUTED WIRELENGTH

A highly congested region in the placement may result

in routing detours around the region and a larger routed

wirelength. Congested areas may also degrade the performance

of the router and even result in an unroutable design. In order

to obtain a global placement that is eventually routable without

increasing the runtime, it is important to efficiently evaluate the

congestion and identify congested regions of the design. That

rules out performing actual routing to determine wirelength

and routing congestion, as routing itself is a difficult problem.

During the global placement stage, the path that will be

used by the router to route the nets remains unknown and

the routing pattern has not yet been obtained. In this paper,

the routed-wirelength within a region of the chip is estimated

based on the bounding box of each net that overlaps the region.

In order to identify the congested regions, it is necessary to

determine the wirelength within each one of these regions. For

a two-pin net, the router will connect the pins by following the

shortest path between them. However, the path the router will

follow in the case of a multi-pin net is not as easy to predict.

There are possibly many paths that all have the same minimum

length for the router to follow. Moreover, the routing paths of

the other nets in the region determine the routing path of the

net.

Let Sdg (x,y) denote the estimated routed wirelength inside

the bin and avgd (x,y) the average estimated routed wirelength.

Then Dg (x,y) is a function of the estimated wirelength inside

bin g and

Dg (x,y) = (1 + γ · (1 −

Sdg (x,y)

)) · D,

avgd (x,y)

1 2

·

(SDg (x,y) − Dg (x,y)) ,

2·u g

where the average cell density D used in APlace has now been

replaced by Dg (x,y).

From (3), if Sdg (x,y) = avgd , Dg (x,y) = D. If

Sdg (x,y) < avgd , the estimated routed wirelength inside

bin g is less than the average and the cell density allowed

inside the bin is higher. Similarly, if Sdg (x,y) > avgd , the

estimated routed wirelength is more than the average and the

cell density allowed inside the bin is lower. Having estimated

the wirelength inside each global bin, the bins that have high

(low) congestion are assigned a lower (higher) cell density.

The wirelength of a net can be approximated by the HPWL.

Since there is a strong correlation between the HPWL and the

routed wirelength of a net, in the case of a net being entirely

inside a global bin, the routed wirelength can be calculated

satisfactorily. However, in the case of a net being only partially

inside the bin, the routed wirelength inside the bin cannot be

determined using the HPWL of the net. There are many paths

outside the bin that connect the pins of the net and the router

may not follow a path passing through the bin.

An example is illustrated in IV, where the bounding box

of net A partially overlaps the global bin g1 (shown in gray)

and the router follows a path (shown with a solid line) that is

located inside the bin. The bounding box of net B is routed

across the global bin g2 . For net B, the path is located outside

the bin. Either one of the two cases may occur and, therefore,

the exact wirelength cannot be calculated in advance. The wire

density of a net is defined

dn (x,y) =

HP W Ln

,

Arean

(4)

where

(3)

HP W Ln = max{xi } − min{xi } + max{yi } − min{yi }

i∈e

214

i∈e

i∈e

i∈e

is the HPWL of the bounding box of the net e, and

Global bin

Arean = (max{xi } − min{xi }) · (max{yi } − min{yi })

i∈e

i∈e

i∈e

y_top

i∈e

is the area of the bounding box of the net.

The algorithm proposed in [10] estimates the routing dedem

(x, y) as the superposition of the rectangle funcmand Drout

tions of all nets, weighted by the wire density of each net. The

rectangle function of a net is equal to one for (x, y) inside the

bounding box of the net and equal to zero otherwise. The

algorithm adapts the demand to the supply at each position;

essentially, the algorithm seeks a placement solution where

the wire density is uniform across the chip. In this paper,

however, the formulation uses the wire density of the net only

to determine the wirelength inside a global bin and, therefore,

it is the wirelength within the bin that is incorporated into

the objective function, not the wire density. In addition, the

optimization is independent of the shape of the bounding box

of the net and the wirelength is independent of the routing

model following the placement.

Taking into consideration the formula for the wire density

of a net (4), it is possible to estimate the routed wirelength

inside bin g for every possible configuration. The estimated

routed wirelength is

dg,e (x,y) = dn (x,y) · Ag,e (x,y),

where dn (x,y) is the wire density of net e and Ag,e (x,y) is

the overlap area between bin g and the bounding box of net e.

The total wirelength inside bin g is the sum of the wirelength

of each net which overlaps the bin either fully or partially.

Thus

dg,e (x,y).

(5)

Sdg (x,y) =

y_bot

x_left

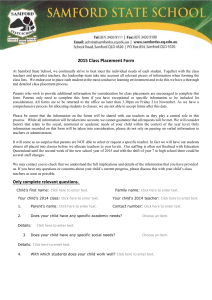

Fig. 2. The global bins are shown in light gray (the bin under consideration

in darker gray) and the bounding box of the net which overlaps with the global

bin is shown in black. Five out of the many different possible configurations

are depicted here.

Following the analysis performed in Section III, let fx,e

be the smoothed function that approximates maxi∈e {xi } −

mini∈e {xi } and fy,e be the smoothed function that approximates maxi∈e {xi } − mini∈e {xi }. The wire density of a net

is written as

dn,e (x,y) =

e

The average bin wirelength is

avgd (x,y) = avgg {Sdg (x,y)}.

Therefore

Dg (x,y) = (1 + γ · (1 −

A. Function smoothing

Ag,e = (horiz overlap) · (vertical overlap),

horiz overlap = CHKS(xright , min xi )+

where

Sdg (x,y) =

fx,e (x,y) + fy,e (x,y)

· Ag,e (x,y)).

(

fx,e (x,y) · fy,e (x,y)

e

Also,

fx,e (x,y) + fy,e (x,y)

avgd (x,y) = avgg {

· Ag,e (x,y))}.

(

fx,e (x,y) · fy,e (x,y)

e

∂fi,j (x)

∂fi,j (x) ∂fi,k (x) ∂fi,j (x) ∂fk+1,j (x)

=

·

+

·

,

∂xl

∂fi,k

∂xl

∂fk+1,j

∂xl

i∈e

+CHKS(−xright , − min xi ),

i∈e

vertical overlap = CHKS(max yi , min yi )+

i∈e

Sdg (x,y)

)) · D,

avgd (x,y)

Most Newton-like optimization solvers require evaluations

of the function value f(x) and its gradient g(x) =

(x) ∂f (x)

∂f (x) T

[ ∂f

∂x1 , ∂x2 , ..., ∂xn ] . To calculate the gradient of f(x)

where

where k = i+j

2 and 1 ≤ l ≤ j. For i ≤ l ≤ k and CHKS

smoothing,

i∈e

+CHKS(max −yi , min −yi )

i∈e

fx,e (x,y) + fy,e (x,y)

.

fx,e (x,y) · fy,e (x,y)

The total wirelength within bin g is

Sdg (x,y) =

(dn,e (x,y) · Ag,e (x,y)).

e

The estimation of the wirelength inside the bin using the

wire density of a net, includes determining the overlap area

Ag,e (x,y). As shown in IV-A, there are different ways in

which the bounding box of a net and the bin overlap. For

example, when the bounding box of the net is located partially

inside and on the right side of the bin as illustrated in IV-A,

the overlapped area between the specified net and the bin is

calculated as

x_right

i∈e

and (xlef t , ybot ) , (xright , ytop ) are the coordinates of the bin.

To smooth the function of the estimated routed wirelength

inside bin g, Sdg (x,y), we use the recursive CHKS function.

215

∂fi,j (x)

1 ∂fi,k (x)

= ·

+

∂xl

2

∂xl

1

fi,k (x) − fk+1,j (x)

∂fi,k (x)

·

·

.

2

2

2

∂xl

(fi,k (x) − fk+1,j (x)) + alpha

To solve the unconstrained optimization problem, one needs

to calculate the gradient of Dg , dn . The gradient of Dg is

calculated as

∂Dg (x,y)

= −γ · D ·

∂xl

∂Sdg (x,y)

∂xl

∂maxd (x,y)

∂xl

,

∂Dg (x,y)

= −γ · D ·

∂yl

∂Sdg (x,y)

∂yl

∂maxd (x,y)

∂yl

.

The gradient of dn (x,y) is calculated as

∂fx,e (x,y)

∂ fx,e (x,y) + fy,e (x,y)

) = − 2 ∂xl ,

(

∂xl fx,e (x,y) · fy,e (x,y)

fx,e (x,y)

∂fy,e (x,y)

∂ fx,e (x,y) + fy,e (x,y)

∂y

)=− 2 l .

(

∂yl fx,e (x,y) · fy,e (x,y)

fy,e (x,y)

V. I MPLEMENTATION

The placement algorithm is applied in a two-level framework as explained in Section II. The global placer places the

clusters at the first level and the cells at the second level.

For this work, the clusters were obtained from the K-way

partitioning of the original circuit netlist using the publicly

available software hMetis [19]–[21]. The hMetis algorithm

performs K-way partitioning of the circuit netlist with the

objective of reducing the number of edgecuts among the

partitions. The hybrid first choice scheme in hMetis is used

for the grouping of the cells. The partitioning of the netlist is

obtained after N = 5 runs of the hMetis algorithm and the

partition with the smallest edgecut is selected. The original

netlist is clustered to a number of clusters such that the number

of cells inside each cluster is between 1% and 5% of the

number of cells in the netlist. Each cluster is shaped as a

square, with its area being equal to the sum of the areas of the

cells that belong to the cluster. The cells are confined inside

the cluster area of their corresponding cluster and the input

to the placement algorithm is the partitioning of the circuit

netlist.

At both levels of the framework, the routed wirelength

estimation technique guides the placement process. The unconstrained optimization problem is solved using L-BFGS-B,

a publicly available quasi-Newton solver with boundary constraints, as described in [22]. The implementation of the solver

is in the default mode. The two-level framework includes a

multi-grid structuresimilar to the one in [12] and the same

(SDg −Dg )2

. The initial weight of the

stopping criterion

g

density penalty is

∂SDg

∂SDg

1

xi ,yi

g |SDg − Dg | · (| ∂xi | + | ∂yj |)

+

u= ∗

∂W L

∂W L

2

xi ,yj (| ∂xi | + | ∂yj |)

(6)

∂Dg

∂Dg

1

xi ,yi

g |SDg − Dg | · (| ∂xi | + | ∂yj |)

∗

.

∂W L

∂W L

2

xi ,yj (| ∂xi | + | ∂yj |)

After the initialization, u is halved in every iteration. At the

end of the global placement, the detailed placer mPL-R+WSA

[13] is used to legalize the placement.

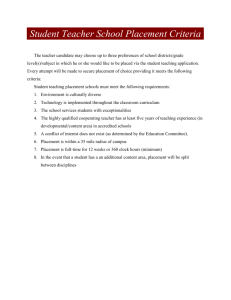

VI. E XPERIMENTAL RESULTS

The results are based on sixteen IBM version 2 easy

and hard benchmarks and show the impact of routabilitydriven standard-cell placement on the routed wirelength. All

experiments were performed on a 3GHz Pentium 4 CPU with

3GHz memory. Table 1 includes the routed wirelengths, as

well as the CPU times for placement compared to mPLR+WSA [13], mPL6 [14], CHKS+WSA [12], RUDY [10],

ROOSTER [15] and APlace [11]. For each placement tool, the

first column, labeled “r-WL”, shows the routed wirelength on

each benchmark after routing the placed design using Cadence

WRoute. The second column, labeled “p-CPU”, shows the

CPU times for placement.

The placement solutions of the proposed approach were

routed with CADENCE WRoute 5.3 in default configuration.

The routed wirelengths of circuits placed with mPL-R+WSA,

mPL6 and CHKS+WSA are as reported in [12] (routed

with CADENCE WRoute 5.3) and the routed wirelengths of

circuits placed with RUDY, ROOSTER and APlace (routed

with CADENCE WRoute 2.3.32) are as reported in [10].

The placement solutions obtained from the proposed approach

result in reductions in the total routed wirelength by 14.56%,

5.48%, 5.55%, 2.17%, 9.68% and 8.53%, compared to mPLR+WSA, mPL6, CHKS+WSA, RUDY, ROOSTER and APlace

respectively. Compared to RUDY, our algorithm obtained

shorter routed wirelength in 12 out of the 16 benchmarks.

In Table 1, the row labeled “r-WL%improv.” shows the improvements in the total routed wirelength obtained from our

placer over those of other placement tools.

The placement time of every placement tool is defined

as the total CPU time to perform global/detailed placement

and legalization. The placement CPU times for mPL-R+WSA,

mPL6, CHKS+WSA and APlace are obtained from our runs

of the respective executables. For our placement algorithm, the

placement CPU times also include the time to run hMetis. The

proposed algorithm results in reductions in the placement CPU

time by 52.13%, 8.29%, 45.61% and 63.50% respectively. The

CPU times for ROOSTER were not reported in [10] and are,

therefore, not included in Table 1. The CPU time for RUDY

is obtained on a 2.2 GHz AMD Athlon Opteron 248 machine

in [10]; therefore, no direct comparison with the runtime of

RUDY and ROOSTER can be made at this point.

VII. C ONCLUSION

The paper proposes a global placement flow guided by an

efficient routed wirelength estimation method. The overlap

between the bounding box of a net and a global bin, weighted

by the wire density of the net, estimates the wirelength within

the corresponding global bin and overcomes the difficulty of

determining the wirelength inside a bin for the case of multipin nets. At the same time, the two-level framework reduces

the total runtime of the placer. The result is an algorithm

that obtains the best average routed wirelenghts in the IBM

version2 benchmark suite.

216

TABLE I

ROUTABILITY R ESULTS ON IBM VS .2 S TANDARD C ELL P LACEMENT B ENCHMARKS

Proposed

mPL-R+WSA

mPL6

CHKS+WSA

RUDY

ROOSTER

APlace

r-WL p-CPU r-WL [12] p-CPU r-WL [12] p-CPU r-WL [12] p-CPU r-WL [10] p-CPU [10] r-WL [10] r-WL [10] p-CPU

(m) (s)

(m)

(s)

(m)

(s)

(m)

(s)

(m)

(s)

(m)

(m)

(s)

ibm01e 0.64 132

0.77

216

0.76

109

0.78

233

0.68

34

0.72

0.79

292

ibm01h 0.64 117

0.74

221

0.76

108

0.79

223

0.68

33

0.73

0.73

181

ibm02e 1.74 249

1.88

491

1.79

234

1.83

399

1.85

67

2.00

1.85

355

ibm02h 1.77 247

1.98

513

1.90

217

1.91

394

1.99

68

1.98

1.97

342

ibm07e 3.59 536

4.26

911

3.65

515

3.76

819

3.60

176

3.95

3.98

1324

ibm07h 3.69 496

4.36

897

4.68

503

3.70

859

3.63

183

4.09

4.14

1419

ibm08e 3.91 614

4.54

1396

4.11

630

4.12

1042

4.04

223

4.23

3.96

1485

ibm08h 3.87 574

4.45

1386

4.05

599

4.05

1088

3.96

220

4.24

3.96

1667

ibm09e 2.95 572

3.48

1105

3.19

606

3.12

1213

2.90

216

3.20

3.10

1452

ibm09h 2.96 616

3.61

1034

3.11

571

3.07

1047

2.92

211

3.21

3.10

1612

ibm10e 5.83 874

6.78

1723

6.10

876

6.44

1390

5.81

307

6.42

6.18

1535

ibm10h 5.71 793

6.69

1697

5.96

839

5.81

1292

5.78

314

6.54

6.17

4550

ibm11e 4.31 737

5.10

1304

4.56

802

4.46

1368

4.41

301

4.75

4.76

2277

ibm11h 4.33 689

5.11

1283

4.46

793

4.39

1257

4.40

308

4.72

4.82

2464

ibm12e 8.33 958

10.43

2104

8.77

1025

8.65

1606

8.43

341

9.33

8.60

4241

ibm12h 8.23 1056

10.03

2022

8.62

970

8.28

1428

8.47

345

9.28

8.81

4274

%improv.

14.56% 48.16% 5.48% 0.41% 5.55% 41.14% 2.17%

N/A

9.68%

8.53% 60.49%

ACKNOWLEDGMENT

This research was supported in part by SRC (Task ID

1822.001).

R EFERENCES

[1] C.-L. E. Cheng, “RISA: Accurate and efficient placement routability

modeling,” in Proc. IEEE/ACM International Conference on ComputerAided Design, San Jose, California, Nov. 1994, pp. 690–695.

[2] M. Wang, X. Yang, and M. Sarrafzadeh, “Congestion minimization

during placement,” IEEE Trans. Computer-Aided Design, vol. 19, pp.

1140–1148, Oct. 2000.

[3] J. Lou, T. S. Krishnamoorthy, and H. S. Sheng, “Estimating routing

congestion using probabilistic analysis,” in Proc. ACM/SIGDA International Symposium on Physical Design, Sonoma, California, Jan. 2001,

pp. 112–117.

[4] W. Hou, H. Yu, X. Hong, Y. Cai, W. Wu, J. Gu, and W. Kao, “A

new congestion-driven placement algorithm based on cell inflation,” in

Proc. Asia and South Pacific Design Automation Conference, Yokohama,

Japan, Jan. 2001, pp. 605–608.

[5] U. Brenner and A. Rohe, “An effective congestion-driven placement

framework,” in Proc. ACM/SIGDA International Symposium on Physical

Design, San Diego, California, Jan. 2002, pp. 6–11.

[6] Z. Li, W. Wu, and X. Hong, “Congestion-driven incremental placement

algorithm for standard cell layout,” in Proc. IEEE/ACM Asia and South

Pacific Design Automation Conference, Kitakyushu, Japan, Jan. 2003,

pp. 723–728.

[7] X. Yang, R. Kashner, and M. Sarrafzadeh, “Congestion estimation during

top-down placement,” IEEE Trans. Computer-Aided Design, vol. 21, pp.

72–80, Jan. 2002.

[8] B. Hu and M. Marek-Sadowska, “Congestion minimization during placement without estimation,” in Proc. IEEE/ACM International Conference

on Computer-Aided Design, San Jose, California, Nov. 2002, pp. 739–

745.

[9] M. Wang and M. Sarrafzadeh, “Modeling and minimization of routing

congestion,” in Proc. IEEE/ACM Asia and South Pacific Design Automation Conference, Yokohama, Japan, Jan. 2000, pp. 185–290.

[10] P. Spindler and F. Johannes, “Fast and accurate routing demand estimation for efficient routability-driven placement,” in Proc. Design

Automation and Test in Europe Conference, Nice, France, Apr. 2007,

pp. 1–6.

[11] A. B. Kahng and Q. Wang, “Implementation and extensibility of an

analytic placer,” IEEE Trans. Computer-Aided Design, vol. 24, pp. 734–

747, May 2005.

[12] C. Li and C.-K. Koh, “Recursive function smoothing of half-perimeter

wirelength for analytical placement,” in Proc. International Symposium

on Quality Electronic Design, San Jose, California, Mar. 2007, pp. 829–

834.

[13] C. Li, M. Xie, C.-K. Koh, J. Cong, and P. H. Madden, “Routabilitydriven placement and white space allocation,” in Proc. International

Conference on Computer-Aided Design, San Jose, California, Nov. 2004,

pp. 394–401.

[14] T. Chan, J. Cong, M. Romesis, J. R. Shinnerl, K. Sze, and M. Xie,

“mPL6: A robust multilevel mixed-size placement engine,” in Proc.

ACM/SIGDA International Symposium on Physical Design, San Fransisco, California, Apr. 2005, pp. 227–229.

[15] J. A. Roy and I. L. Markov, “Seeing the forest and the trees: Steiner

wirelength optimization in placement,” IEEE Trans. Computer-Aided

Design, vol. 26, pp. 632–644, Apr. 2007.

[16] A. B. Kahng, S. Reda, and Q. Wang, “Architecture and details of a highquality, large-scale analytical placer,” in Proc. IEEE/ACM International

Conference on Computer-Aided Design, San Jose, California, Nov. 2005,

pp. 891–898.

[17] W. Naylor, R. Donelly, and L. Sha, “Non-linear optimization system and

method for wire length and delay optimization for an automatic electric

circuit placer,” U.S. Patent 6 301 693, Oct. 09, 2001.

[18] S. Birbil, S. Fang, H. Frenk, and S. Zhang, “Recursive approximation

of the high-dimensional max function,” Department of Systems Engineering and Engineering Management SEEM, The Chinese University

of Hong Kong, HK, Tech. Rep. SEEM 2002-12, Dec. 2002.

[19] G. Karypis and V. Kumar, “Multilevel K-way hypergraph partitioning,”

IEEE Trans. VLSI Syst., vol. 11, pp. 285–300, Jan. 2000.

[20] G. Karypis, R. Aggarwal, V. Kumar, and S.Shekhar, “Multilevel K-way

hypergraph partitioning: Applications in VLSI domain,” IEEE Trans.

VLSI Syst., vol. 7, pp. 69–79, Mar. 1999.

[21] N. Selvakkumaran and G. Karypis, “Multi-objective hypergraph partitioning algorithms for cut and maximum subdomain degree minimization,” IEEE Trans. Computer-Aided Design, vol. 25, pp. 504–517, Mar.

2006.

[22] C. Zhu, R. Byrd, and J. Nocedal, “L-BFGS-B, FORTRAN routines

for large-scale bound constrained optimization,” ACM Transactions on

Mathematical Software, vol. 23, pp. 550–560, Dec. 1997.

217