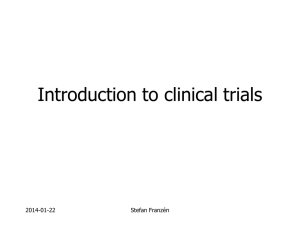

ICH guidelines for the production of biologicals

advertisement

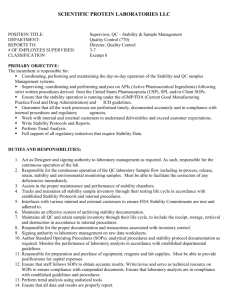

“ICH guidelines for the production of biologicals” ICH Q8, Q9, Q10, & Q11 QbD ICH Q7A Lisa Gonzales- Sr. Regulatory Compliance Specialist GE Healthcare Life Science- FAST TRAK Email: Lisa.Gonzales@ge.com Overview Guidelines- ICH Q8, Q9, Q10 & Q11 Quality by Design (QbD) Q7A 2/ Rio UFRJ- ICH Guidelines / August 6, 2009 “Pharmaceutical cGMP for the 21st Century: A Risk-Based Approach” Initiative- Aug. 2002 Integrate quality systems and risk management approaches into existing programs Adopt modern and innovative manufacturing technology Integrate pre-approval review and cGMP programs and achieve more consistent application across agency organization components Use existing and emerging science and analysis to ensure that limited resources address important quality issues, especially predicted or identifiable health risks Intended to modernize FDA’s regulation of pharmaceutical quality for veterinary and human drugs and select human biological products such as vaccines 3/ Rio UFRJ- ICH Guidelines / August 6, 2009 Risk-Based Approach to Regulate Pharmaceutical Manufacturing To keep pace with the many advances in manufacturing quality management To enable the Agency to more effectively allocate its limited regulatory resources The approach will be applied to the review, compliance, and inspectional components of FDA regulation This approach will help the Agency predict where its inspections are likely to achieve the greatest public health impact 4/ Rio UFRJ- ICH Guidelines / August 6, 2009 International Conference on Harmonization (ICH) • • • • Harmonization process- founded April 1990 US, EU, & Japan Six Parties (Expert Working Groups- EWGs) Technical Topics- Safety, Quality, Efficacy, Multidisciplinary • 5 step guideline process 5/ Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Guideline Interface P R O D U C T L I F E C Y C L E Pharmaceutical Quality Risk Pharmaceutical Development Management Quality Systems Q10 Q8 Q9 Concept Paper Q11 Pharmaceutical Development Technology Transfer Manufacturing Enhanced product & process understanding Risk management Jeffrey Blumenstein, Pfizer Robust quality systems Harmonize submissions 6/ Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q8- Pharmaceutical Development Intended to provide a comprehensive understanding of the product and manufacturing process for reviewers and inspectors Indicates areas where the demonstration of greater understanding of pharmaceutical and manufacturing sciences can create a basis for flexible regulatory approaches The degree of regulatory flexibility is based on the level of relevant scientific knowledge provided (not the volume of data) 7/ Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q8- Pharmaceutical Development Goal: design a quality product and its manufacturing process to consistently deliver the intended performance of the product. Information and knowledge gained from development studies and manufacturing experience provide: • Scientific understanding to support the establishment of the design space, specifications, and manufacturing controls. • Basis for risk management 8/ Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q8(R1)- Pharmaceutical Development Revisions 1 Pharmaceutical development should include, the following elements: • Defining the target product profile as it relates to Q, S and E • Identifying critical quality attributes (CQAs) of the drug product, so that those product characteristics having an impact on product quality can be studied and controlled • Determining the quality attributes of the drug substance, excipients etc. to deliver drug product of the desired quality • Selecting an appropriate manufacturing process • Identifying a control strategy 9/ Rio UFRJ- ICH Guidelines / August 6, 2009 nt The path towards the desired state is unfamiliar to many while the current state provides the comfort of predictability rre cu At the end of the cGMP initiative, the pharmaceutical community has arrived at a crossroad: one path leads towards the desired state* and the other maintains the current state de si r ed FDA Challenge to Industry FDA hopes the pharmaceutical industry will choose to move towards the desired state *pharmaceutical development using QbD approach Marion Weinreb, “Quality by Design” April 2008 10 / Rio UFRJ- ICH Guidelines / August 6, 2009 Approaches to Pharmaceutical Development Minimal Approach (current) Enhanced (QbD) Approach (desired) Development Development • • Mainly empirical Developmental research often conducted one variable at a time • • • • Manufacturing Process • • • Fixed Validation primarily based on initial full-scale batches Focus on optimization and reproducibility Systematic, relating mechanistic understanding of input material attributes and process parameters to drug product CQAs Multivariate experiments to understand product and process Establishment of design space PAT tools utilized Manufacturing Process • • • • Adjustable within design space Lifecycle approach to validation and, ideally, continuous process verification Focus on control strategy and robustness Use of statistical process control methods ICH Q8(R1)- Appendix 1 11 / Rio UFRJ- ICH Guidelines / August 6, 2009 Benefits of the “Enhanced Approach” • Post- approval CMC regulatory submissions Reduce • Uncertainty & Risk Improve • Recalls and manufacturing failures • Regulatory flexibility • Process understanding “DIRFT” • Application of technology: e.g., PAT & NIR • Costs • Quality • Regulatory burden • Regulatory review criteria • Low value regulatory and/or compliance exercises • Scientific/technical literacy among regulators • Need for Process Validation • Development efficiency • Documentation • Global harmonization Marion Weinreb, “Quality by Design” April 2008 12 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q9- Quality Risk Management Outlines approaches for producing quality pharmaceutical products using science and risk management Intended to provide a practical risk management toolbox implementation of the pharmaceutical development (Q8) and quality systems (Q10) • to evolve a more harmonized and flexible quality oversight process Applies to drug substances, drug products, biological and biotechnological products Supports science-based decision making throughout the product lifecycle • Effective and consistent risk-based decisions − “Can improve decision making if a quality problem arises” • Regulatory authorities and industry − Provides regulators with greater assurance of a company’s ability to mitigate potential risks − Impacts direct regulatory oversight- extent and level 13 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q9- Principles Of Quality Risk Management Risk- combination of the probability of occurrence of harm and the severity of that harm Principles: • The evaluation of the risk to quality should be based on scientific knowledge and ultimately link to the protection of the patient • The level of effort, formality, and documentation of the quality risk management process should be commensurate with the level of risk − Aseptic processing- usually high risk − Stable API with minimal degradation in product formulaprobable low risk for stability 14 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q9- Risk Management Process 15 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q10 Pharmaceutical Quality System Q10 incorporates the concepts behind ICH Q8 “Pharmaceutical Development” and ICH Q9 “Quality Risk Management” by providing a model for a pharmaceutical quality system that can be implemented throughout a product life cycle Q10 is meant to complement and add to current good manufacturing practices The overall goal is to: • facilitate innovation and continual improvement • strengthen the link between pharmaceutical development and manufacturing activities Angie Drakulich ePT--the Electronic Newsletter of Pharmaceutical Technology, June 2008 16 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q10 Pharmaceutical Quality System: Objectives Outlines expectations for the Pharmaceutical Quality Systems and how they can be applied in the management of the: • Design space • Risk assessment Ensure that quality standards are met over the lifecycle of the product • Quality attributes to meet patient needs • Establish and maintain a state of control − Process performance and product quality • Facilitate continual improvement − Product quality, process improvements, reduce variability, innovations, enhance quality system “PQLI Design Space” ISPE May 2008John Lepore & James Spavins 17 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q11- Development and Manufacture of Drug Substances Concept Paper- Key items Requirements harmonization High level technical guidance relevant to the design, development, and manufacture of drug substances as part of a total control strategy Provide guidance for drug substances (Q6A & Q6B) Identify similarities and differences between biologics and chemical entities 18 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q11- Development and Manufacture of Drug Substances: Guideline Goals Harmonize submissions • What goes into the CTD • Facilitate regulatory evaluation process Outline science-based concepts Offer and recommend approaches for demonstrating process and product understanding Address the complexity of different manufacturing process & products Address systematic and enhanced approaches (including design space, control strategies, & real-time release) 19 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q11- Development and Manufacture of Drug Substances: Challenges Biologics vs. Chemical Entities Development Approach • Systematic • Enhanced Manufacturing • Validation Level of Detail • Enough to be useful • Not so much to be prescriptive 20 / Rio UFRJ- ICH Guidelines / August 6, 2009 Quality by Design (QbD) Definitions Critical Quality Attribute (CQA): A physical, chemical, biological or microbiological property or characteristic that should be within an appropriate limit, range, or distribution to ensure the desired product quality Critical Process Parameter: A process parameter whose variability has an impact on a critical quality attribute and therefore should be monitored or controlled to ensure the process produces the desired quality Proven Acceptable Range: A characterized range of a process parameter for which operation within this range, while keeping other parameters constant, will result in producing a material meeting relevant quality criteria Quality by Design: A systematic approach to development that begins with predefined objectives and emphasizes product and process understanding and process control, based on sound science and quality risk management Real-time release: The ability to evaluate and ensure the acceptable quality of in-process and/or final product based on process data, which typically include a valid combination of assessed material attributes and process controls. ICH Q8(R1)- Pharmaceutical Development Revisions 1 22 / Rio UFRJ- ICH Guidelines / August 6, 2009 Quality by Design is • Designing and developing a product and associated manufacturing processes that will be used during product development to ensure that the product consistently attains a predefined quality at the end of the manufacturing process • Quality by design, in conjunction with a quality system, provides a sound framework for the transfer of product knowledge and process understanding from drug development to the commercial manufacturing processes and for post-development changes and optimization Guidance for Industry: Quality Systems Approach to Pharmaceutical Current Good Manufacturing Practice Regulations Sept 2006 QbD is a systematic approach to development 23 / Rio UFRJ- ICH Guidelines / August 6, 2009 Quality by Design is “…products and processes that make them are designed in advance to meet their product quality specifications and process control requirements.” “…is based on solid science, valid statistical tools, and sound management techniques that have proven their industrial value for many decades.” This includes: Product profiling Experimental design Goal: to apply these tools in a structured manner Process mapping Risk assessment Automated process controls Torbeck and Branning BioPharm Int’l May 2009 24 / Rio UFRJ- ICH Guidelines / August 6, 2009 Quality by Design Approach A systematic evaluation, understanding and refining of the formulation and manufacturing process, including: • Identifying, through e.g., prior knowledge, experimentation, and risk assessment, the material attributes and process parameters that can have an effect on product CQAs • Determining the functional relationships that link material attributes and process parameters to product CQAs Using the enhanced process understanding in combination with quality risk management to establish an appropriate control strategy which can, for example, include a proposal for design space(s) and/or real-time release As a result, this more systematic approach could facilitate continual improvement and innovation throughout the product lifecycle (See ICH Q10 Pharmaceutical Quality System). ICH Q8(R1)- Pharmaceutical Development Revisions 1 25 / Rio UFRJ- ICH Guidelines / August 6, 2009 QbD Structure Establishing the relationship between quality attributes and clinical performance Allows more effective dialogue between industry and regulator during review process* • Shows the connection between Design Space, Criticality and Control Strategy • Reducing change filings snags *“PQLI Design Space” ISPE May 2008John Lepore & James Spavins 26 / Rio UFRJ- ICH Guidelines / August 6, 2009 Regulatory Flexibility: Why? Facilitate continuous improvement and innovation to improve quality, efficiency, knowledge, and availability High level of process understanding and control capability can further improve our ability to ensure quality on every batch • compared to a validated process with insufficient understanding and for which “state of control" is based primarily on compendial testing The PAT Guidance CPG 7132c.08 27 / Rio UFRJ- ICH Guidelines / August 6, 2009 Regulatory Flexibility: How? Quality by design • Structured product and process development • Process understanding and control capability • Design space Integration of prior knowledge and pharmaceutical development into C, M, C submission and review • Present the knowledge gained to provide a more comprehensive understanding of the product and manufacturing process for reviewers and inspectors • Risk based assessment and investigations and knowledge sharing (over a product’s life cycle) The PAT Guidance ICH Q8 (9 &10) CPG 7132c.08 28 / Rio UFRJ- ICH Guidelines / August 6, 2009 Risk Management Steps Risk assessment • Risk Assessment 1. What might go wrong? • Risk Control 2. What is the likelihood (probability) it will go wrong? • Risk Communication • Risk Review 3. What are the consequences (severity)? ICH Q9, Quality Risk Management Types of risk: patient safety, regulatory, business 29 / Rio UFRJ- ICH Guidelines / August 6, 2009 Quality by Design Concept • Quality cannot be tested into products. • It has to be built in by design ICH Q8, Pharmaceutical Development, May 2006 This design incorporates knowledge of the product and the process to ensure all critical quality parameters are adequately controlled. Barry Cherney, Deputy Director, DTP/OBP/CDER, Oral Presentation, Quality by Design: A Perspective From the Office of Biotechnology Products, PDA Annual Meeting, April 2006 30 / Rio UFRJ- ICH Guidelines / August 6, 2009 “Design Space” The established range of process parameters that has been demonstrated to provide assurance of quality Working within the design space is not generally considered as a change of the approved ranges for process parameters… Movement out of the design space is considered to be a change and would normally initiate a regulatory post-approval change process ICH Q8, Pharmaceutical Development, May 2006 31 / Rio UFRJ- ICH Guidelines / August 6, 2009 Design Space… “Is linked to criticality through the results of risk assessment, which differentiates between those product attributes and process parameters that are critical to product quality” Once Critical Quality Attributes and Critical Process Parameters are identified and understood, they will need to be controlled “PQLI Design Space” ISPE May 2008John Lepore & James Spavins 32 / Rio UFRJ- ICH Guidelines / August 6, 2009 A Process is well understood when… All critical sources of variability are identified and explained Variability is managed by the process Product quality attributes can be accurately and reliably predicted over the design space … The PAT Guidance 33 / Rio UFRJ- ICH Guidelines / August 6, 2009 Process Robustness • The ability of a process to demonstrate acceptable quality and performance while tolerating variability in inputs • Requires − Robustness/characterization studies utilizing DoE − Understanding manufacturing capabilities in development • Enables definition of “design space” 34 / Rio UFRJ- ICH Guidelines / August 6, 2009 Process Robustness/Characterization Studies These studies provide a further understanding of the relationship between process and product • identify critical parameters • identify limits of each parameter • test to limits • test to failure, where appropriate • results not predefined Adapted from A. Mire-Sluis, Principal Advisor to Director-Product Quality OTTR, CBER, FDA IBC Process Validation for Biologicals, March 2003 35 / Rio UFRJ- ICH Guidelines / August 6, 2009 Design Space for Biotech Products Characterization Range Acceptable variability in Key & Critical Quality Attributes Acceptable Range Operating Range (CQAs) Process characterization studies 36 / Guidelines / Rathore, Branning, Cecchini (April 2007)Rio UFRJ- ICH August 6, 2009 Quality Life Cycle Propose Design- Evaluation (Quality by Design) Identify (Critical/Key Parameters & Ranges) Optimize (Continuous Improvement Innovation) Change Control Monitor Post-Approval Knowledge Base Product-specific Process-specific Quality Risks Development Studies Process Characterization (DOE, EOF, robustness) Risk assessment (FMEA) Confirm (Control/Predict) Conformance Lots “Validation Studies” Patrick Swann, Ph.D. FDA-CDER, Quality by Design for 37 / Biopharmaceuticals: Concepts and Implementation. Rio UFRJ- ICH Guidelines / PDA Workshop May 2007 August 6, 2009 Design Space Process validation Design Space Robustness Characterization Quality by Design Risk Assessment Process Understanding Manufacturing of licensed product PD 38 / Rio UFRJ- ICH Guidelines / August 6, 2009 Where are we today? *Early development: Knowledge for QbD is very limited or nonexistent Licensed products: Knowledge is often limited for many biotech products Quality by design is NOT quality by control Quality by design enables rational design • e.g., protein engineering *Adapted from Barry Cherney, Deputy Director, DTP/OBP/CDER Oral Presentation, Quality by Design: A Perspective From the Office of Biotechnology Products, PDA Annual Meeting, April 2006 **The QbD approach is still eyed with caution. Many voiced concerns that they would invest time and resources in a QbD approach and regulators would still rigidly link specifications to clinical experience. “We have very little experience with QbD, but we are interested in getting some.” Steve Kozlowski, MD, CDER, FDA **BioQuality Feb. 2008: California Separation Science Society- Wash. DC Jan 2008 meeting 39 / Rio UFRJ- ICH Guidelines / August 6, 2009 QbD Case Study- Regulatory Emphasis & Lifecycle Validation Thinking A firm recently received an FDA injunction. Judge’s order: “defendant shall establish and follow scientific product development and manufacturing process design procedures…to control all significant variables, including material attributes and processing parameters, affecting the process materials and final drug product specifications and quality attributes. ” Demonstration of a firm manufacturing multiple products not in a state of control. Key is lack of process validation and related issues• Development, science, technology, use of investigations, handling deviations, etc. FDA CDER Official ISPE Conference June 2009 International Pharmaceutical Quality May/June 2009 40 / Rio UFRJ- ICH Guidelines / August 6, 2009 Successful Implementation of QbD Product meets patient needs Process consistently meets its CQAs Understood impact of formulation components and process parameters on quality Identification and control of critical sources of process variability (using PAT) Process continually monitored and updated to assure consistent quality over time Will require multi-disciplinary and multi-functional teams working together Meet FDA expectations Reduce Cost 41 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q7A GMP Guidance for Active Pharmaceutical Ingredients ICH Q7A Objective Provide guidance regarding good manufacturing practice (GMP) for the manufacturing of active pharmaceutical ingredients (APIs) under an appropriate system for managing quality. Define manufacturing operations to include: • Receipt of materials • Production • Packaging • Repackaging • Labeling and relabeling • Quality control • Release • Storage • Distribution of APIs and the related controls 43 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q7A- Section 18 SPECIFIC GUIDANCE FOR APIs MANUFACTURED BY CELL CULTURE/FERMENTATION Covers cell culture, fermentation (CCF), tissue or animal sources including transgenic animals Early process steps may be subject to GMP but are not covered by Q7A (e.g., cell banking) Vaccines are not included Should not use as a stand-alone section 44 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q7A- Section 18: Cell Culture and Fermentation All previous sections apply to CCF but some issues not in adequate detail Complexity: • Inherent heterogeneity • Full characterization is difficult • Contamination potential with infectious agents • Sensitivity to subtle or minor process changes − Changes in the process, facilities or equipment may lead to unexpected product quality • Manufacturing process contributes to product definition • Process includes facility, equipment, quality of materials 45 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q7A- Section 18: Cell Culture and Fermentation Doesn’t cover: • Cell bank creation (ICH Q5D) • Nature of the organism used in manufacturing or herd maintenance differences • Descriptions of different systems (roller bottles, fermentors, bioreactors, etc.) transfer methods or monitoring information • Custom features- inducible or selection systems 46 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q7A- Section 18: Cell Culture and Fermentation Greater controls • To prevent (and detect) contamination − Monitor endotoxin & bioburden for materials and/or process o Manufacturer defines acceptable limits at each stage − Design adequate ventilation and exhaust systems • For biotechnology products than classical fermentation • For classified environments and EM programs • Validated reprocessing steps • Equipment sterilization between batches (cleaning validation section 12.7) • Water quality (Purified Water or WFI) • Viral removal/inactivation − Critical steps should be under validated parameters − Pre and post inactivation activities clearly defined (SOPs, equipment, segregation) − Go to Q5A 47 / Rio UFRJ- ICH Guidelines / August 6, 2009 ICH Q7A- Section 19 APIs FOR USE IN CLINICAL TRIALS Why is there a special section? • Processes and controls change during development • Few batches may be identically produced • Batches frequently produced in small noncommercial scale equipment 48 / Rio UFRJ- ICH Guidelines / August 6, 2009 Final notes-1 Know thy process, know thy product Regulatory Emphasis & Lifecycle Validation Thinking • Cost of Quality System failure and not implementing ICH guidelines through product lifecycle Q7A- default international standard for GMP in the API industry • FDA can’t enforce but is a position of high influence IPQ predicts Q8, annex, Q9, & Q10 will become an FDA expectation 49 / Rio UFRJ- ICH Guidelines / August 6, 2009 Final notes-2 Regulatory Quality System Quality Risk Management Q9 If your company has: • Good design and control strategies • Good Risk Management Practices • Good Quality Systems Pharmaceutical Development Quality by Design Q8 Pharmaceutical Quality System Q10 Decreased: 9 Regulatory oversight 9 Submissions for changes/variations 9 Inspection of Quality Systems 50 / Rio UFRJ- ICH Guidelines / August 6, 2009 O Fim 51 / Rio UFRJ- ICH Guidelines / August 6, 2009