Knowledge and continuous innovation

The current issue and full text archive of this journal is available at http://www.emerald-library.com/ft

IJOPM

21,4

490

Knowledge and continuous innovation

The CIMA methodology

Harry Boer

Aalborg University, Denmark

Sarah Caffyn

CENTRIM University of Brighton, UK

Mariano Corso

University of Pisa, Italy

Paul Coughlan

Trinity College, Dublin, Ireland

Jose Gieskes

Twente University, Enschede, The Netherlands

Mats Magnusson

Chalmers University, GoÈteborg, Sweden

Sara Pavesi and Stefano Ronchi

Politecnico di Milano, Italy

Keywords New product development, Innovation, Kaizen, Learning

Abstract Competition today is forcing companies to increase their effectiveness through exploiting synergy and learning in product innovation. Literature, however, is still mainly focused on how product development projects, seen largely as isolated efforts, should be organised and managed. This article proposes a model to describe and explain how companies can gain a substantive competitive advantage by extending their innovation efforts to other phases of the product life cycle and by facilitating knowledge transfer and learning both within the company and with other partner organisations. The model is based on collaborative research by the authors, based on their involvement in the Euro-Australian co-operation project CIMA (Euro-Australian co-operation centre for Continuous Improvement and innovation MAnagement).

Introduction

To survive in a demanding and turbulent competitive environment companies are investing a growing amount of resources and managerial attention in product innovation. With pressures to reduce product development intervals and to increase the frequency of new product introductions, this attention is more and more continuous and the efforts involve partners outside the

International Journal of Operations &

Production Management,

Vol. 21 No. 4, 2001, pp. 490-503.

# MCB University Press, 0144-3577

Many people contributed to this article through their involvement in the CIMA-project, by triggering and challenging the authors' thinking in previous discussions, or in the form of useful comments on draft versions of the article. All these contributions are gratefully acknowledged and in particular those from Roberto Verganti and Emilio Bartezzaghi

(Politecnico di Milano); Niklas Sundgren (CORE-Chalmers University, GoÈteborg), Ross

Chapman and Paul Hyland (University of Western Sydney at Macarthur).

organisational boundaries, often on a global basis. Yet, with few exceptions, for example, Meyer and Utterback (1993) and Sundgren (1998), the literature remains focused on the management and organisation of new product development (NPD) projects as isolated efforts. An alternative perspective developed by Bartezzaghi et al . (1997a, b) proposes NPD projects as discrete steps within a more comprehensive process of continuous product innovation

(CPI). As well as focusing on products in a family context, CPI includes all the phases of the product life cycle that follow the launch in the market place.

Evidence from best practice companies, for instance, shows how manufacturing, maintenance and service, though not integral parts of the development phase, can still provide valuable feedback and additional opportunities to innovate future related products. From this perspective then, product innovation is a continuous and cross-functional process involving and integrating a broad range of different competencies inside and outside the organisational boundaries. Mastering the sharing and transfer of knowledge within this process requires new managerial skills, but can become a powerful competitive weapon. This article proposes a methodology, based on a behavioural model, to help companies facilitate knowledge transfer and foster learning in the process of CPI.

In the next section, the research setting will be defined, introducing the concept of continuous product innovation and focusing on how knowledge can be generated and transferred within the process of CPI. Subsequently, the

CIMA methodology will be introduced, and in particular the underlying behavioural model which explains how management can foster continuous improvement and learning in CPI. Then, three cases will be reported to show how the methodology was used in companies to prompt managerial actions to improve continuous improvement and learning in their product innovation activities. The paper will conclude with the main managerial implications arising from the work so far, as well as suggestions for further development.

The research reported here started as part of the Euro-Australian cooperation project CIMA (Euro-Australian co-operation centre for Continuous

Improvement and innovation Management ESPRIT 26056). The objective of

CIMA was to facilitate co-operation and knowledge/technology transfer between European and Australian organisations, through:

(1) The establishment of a Co-operation Centre, with sites in Europe and

Australia, which were to promote and support bilateral activities between the two continents involving mutual learning and technology and knowledge transfer.

(2) The development of a first Euro-Australian ``trial'' project, involving consortium of five European and three Australian research centres, aimed at developing a methodology to support companies in managing learning and continuous improvement in product innovation.

This article describes some of the results of the CIMA trial project, focusing in particular on the development of the methodology of learning in product innovation (PI), and reporting on its first applications in companies in Italy,

Sweden and The Netherlands.

Knowledge and continuous innovation

491

IJOPM

21,4

492

Knowledge management in PI

A model of CPI

Since the early 1970s, managerial and scientific interest in (product) innovation has increased rapidly, with publications focusing, initially, on aspects such as factors of success and failure, the diffusion of innovations, innovation roles, and organisational characteristics beneficial (or detrimental) to different stages of the innovation process. During the 1980s, various researchers started to call for more process-oriented research, believing that the successful management of innovation also depends on a thorough understanding of what is really happening during innovation processes. As a consequence, a plethora of process models of product innovation was proposed which, however, mostly focussed on the management of the NPD process (see e.g. Saren, 1984).

Towards the end of the 1980s, quality and speed, in addition to price, emerged as order winners or even qualifiers in many markets (e.g. Smith and Reinertsen,

1991). In response, concurrent engineering was thought to represent a long lasting paradigm for product innovation management. Integration among different phases of a project, heavy-weight project management and project team autonomy were considered as synonymous with best practices. By the mid 1990s, a new stream of studies emerged which enlarged this perspective, proposing that a focus on single projects is not enough to stay competitive.

Rather, success depends even more on exploiting synergy among projects, for example by fostering commonality and reusing design solutions over time

(Wheelwright and Sasser, 1989; Wheelwright and Clark, 1992; De Maio et al.

,

1994; Cusumano and Nobeoka, 1992). Correspondingly, attention progressively shifted from single projects to families of projects (Meyer and Utterback, 1993;

Sanderson and Uzumeri, 1995) and to the process of learning and knowledge transfer and reuse (Imai et al., 1988; Bartezzagi et al., 1997a; Sundgren, 1998).

These streams of literature, however, consider PI as occurring only within the boundaries of the product development process. Downstream phases in the product life cycle are still important for innovation but only as long as they represent valuable sources of information or constraints that should be anticipated and considered during development (Clark and Fujimoto, 1991).

However, evidence is emerging that other phases in the product life cycle (such as for instance manufacturing, consumption and maintenance) are not only sources of information. They may actually present additional opportunities to innovate products. This is a direct consequence of rapid product development and time to market reduction where companies, especially in rapidly shifting environments, deliberately release products that are not fully optimised. For example, in the software industry, platform package releases are followed frequently by a rapid, almost continuous, stream of enhanced releases, which have major bugs fixed and features optimised.

The concept and the boundaries of PI are therefore changing dramatically.

Feedbacks and opportunities coming in from the later field phases are stored not only for feeding next generation product development projects, but also as valuable opportunities for PI within a product life cycle. These two dimensions are combined in the model of CPI proposed by Bartezzaghi et al.

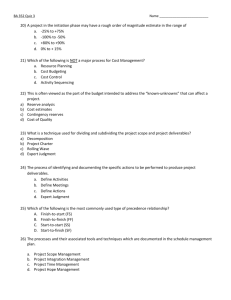

(1997b) (see

Figure 1). In their view, first, CPI embraces not only NPD (concept, product and

Knowledge and continuous innovation

493 process design, and product launch), but also subsequent phases in product life cycle (improvement in manufacturing, customisation in sales and installation, and enhancements and upgrading during product use). Second, they suggest a move from the traditional perspective of single products to that of product families. Consequently, at the level of the product family, the CPI process includes all the interactions among products in the family. Hence, innovation may concern a product that is in its development phase, a product that has been already released to market, or a transfer of solutions between products. In the next section, we will focus on the last of these concerns, knowledge transfer.

Knowledge transfer in CPI

The emerging literature on knowledge management includes five dimensions that should be taken into account when analysing knowledge transfer in CPI:

(1) The setting of knowledge transfer.

(2) Level of dissemination.

(3) The scope of knowledge.

(4) The degree of abstraction and generalisation.

(5) The degree of articulation or embodiment.

These five dimensions can help in interpreting the process of acquiring, transferring, consolidating and applying knowledge in order to design appropriate enablers to foster and sustain it. We will discuss each dimension in turn.

The first dimension concerns the setting (routes, directions) of knowledge transfer. In the CPI model, nine main directions or routes of improvement and

Figure 1.

Main directions for knowledge transfer in the CPI process

IJOPM

21,4

494 learning are distinguished (arrows 1 to 9 in Figure 1). Categorically, the first three routes concern knowledge transfer within the same product life cycle. The remaining six routes concern transfer between different products in the same family. See Corso (forthcoming) for further details on the nine routes.

In brief:

(1) Intra-product transfer in development: knowledge is transferred from one phase of the development project to another.

(2) Intra-product transfer from development to field: knowledge is transferred from the development project to the operations of the organisation.

(3) Intra-product transfer in field: knowledge is transferred between different in-field activities, e.g. from maintenance to production

(improvement).

(4) Intra-phase transfer in development: knowledge is transferred from the development phase of one PI project to that of another.

(5) Inter-phase transfer in development: knowledge is transferred from one phase of a PI project to another phase of another, usually subsequent, project, e.g. early experience with one product to the development phase of the next product.

(6) Intra-phase transfer in field: transfer of knowledge on the same kind of in-field activities related to different products.

(7) Inter-phase transfer in field: knowledge on different in-field phases is exchanged between products/projects.

(8) Inter-product transfer from field to development: knowledge acquired from field activities is transferred to the development of new products.

(9) Inter-product transfer from development to field: transfer of knowledge generated during the development of new products to improve products already launched.

All these routes present a potential for learning and innovation which, however, can be exploited only by actively designing, implementing and managing adequate mechanisms to enable this transfer of knowledge. Each knowledge transfer route can be fostered by particular enablers whose successful implementation strongly depends on the actors involved, the way they influence the process, and on the type of knowledge involved.

The second dimension of knowledge is its level of dissemination. Depending on the specific culture of the organisation, emphasis can be placed on sharing knowledge and fostering learning at different levels: from individuals, to groups, to the organisation as a whole or even the inter-organisational system.

The third dimension, is the scope of knowledge. This scope can range from component knowledge, which refers to the mastering of specialist skills and technologies and their embodiment into components, to architectural knowledge, which refers to how components and skills are integrated and linked together into a coherent whole (Henderson and Clark, 1990).

A fourth dimension of knowledge concerns the degree of abstraction and generalisation (scope of applicability to different situations) (Arora and

Gambardella, 1994).

The fifth and final dimension is the degree of articulation or embodiment. In order to facilitate knowledge transfer and to prevent its drain, organisations can embody knowledge in vehicles such as design solutions (e.g. components and architectures), standard methodologies and procedures, or organisational structure and routines (Nelson and Winter, 1982). Such embodied knowledge is more easily transferable (Barney, 1991; Itami, 1987). In contrast, tacit knowledge is more effective but difficult to imitate (Collis and Montgomery,

1995). Companies, therefore, need to be able to effectively manage both the processes of embodiment of tacit knowledge into articulated forms as well as internalisation of articulated knowledge into tacit forms (Hedlund, 1994;

Nonaka, 1991). Awareness and explicitation, moreover, are fundamental in order to enable knowledge to be questioned and, if necessary, changed (Bohn,

1994).

In the next section, the CIMA methodology to support the management and improvement of learning in CPI will be introduced.

Supporting knowledge management in PI: the CIMA methodology

The CIMA methodology is designed to be used by researchers acting as facilitators to help companies in fostering and sustaining the process of learning and knowledge management in CPI. The methodology comprises four closely related elements:

(1) The CIMA process, aimed at mapping the current level of learning and knowledge management within product innovation, identifying strengths and weaknesses and then suggesting enabling mechanisms which can be implemented by the company to stimulate continuous improvement and learning, depending on specific contingencies. The process has been applied in three different modes (and several variants): action research, single-company or multi-company workshops (with either a paper-based or electronic questionnaire), and remote setting

(also either with paper-based or electronic questionnaire). See Coughlan et al.

(2000) for further details.

(2) The CIMA model, a behavioural model of learning in CPI, the main conceptual underpinning of the methodology.

(3) The self-administered CIMA questionnaire, which is essentially an operationalisation of the CIMA model, to collect data on user companies.

The questionnaire is available in two formats, on paper and on diskette.

(4) The CIMA knowledge base in which all the data are stored. The knowledge base provides the basis for intra-firm and inter-firm comparison leading to company-specific suggestions for improvement.

The next subsection will focus on the CIMA model as an explanatory model for learning in CPI.

Knowledge and continuous innovation

495

IJOPM

21,4

496

The CIMA behavioural model of learning in CPI

The first version of the CIMA model was developed to reflect a wide range of theoretical perspectives on innovation, NPD, learning, continuous improvement, organisation theory and performance measurement. The model was then piloted in a couple of exploratory in-depth case studies. Subsequently, the model was refined and then applied again in over 80 companies in Europe and Australia using the CIMA process and questionnaire referred to above.

Along the way, the CIMA knowledge base was gradually filled, which allowed for ever-better feedback and suggestions to the user companies. The refined

CIMA model is presented briefly in the remainder of this section.

The CIMA behavioural model helps to describe and analyse the learning and knowledge generation processes within PI in terms of a number of interrelated variables. From the analysis, company-specific guidelines for improving learning and knowledge generation processes can be developed to assist managers in sharing and learning from experiences of improvement practices with a view, ultimately, to improving PI performance. The variables distinguished are:

.

continuous Innovation performance;

.

.

.

.

behaviours underpinning continuous innovation and learning within PI; levers that can foster these behaviours; continuous learning/innovation capabilities; company-specific contingencies.

The relationships between these variables are illustrated in Figure 2.

Operationalisation of the CIMA model

Based on the literature and the first set of case studies, the variables in the model were operationalised as follows. See Corso and Pavesi (2000) for further details.

Performance is the result of improvement activities carried out in the PI process. This variable was operationalised and measured in terms of:

P1 Improvement generation.

P2 Improvement coherence with corporate goals.

Figure 2.

Elements in the CIMA behavioural model of learning in CPI

P3 Improvement diffusion within the same PI process, both within and across organisational boundaries.

P4 Improvement diffusion between different PI processes, both within and across organisational boundaries.

P5 Improvement consolidation.

Improvement performance is achieved through a set of eight discrete behaviours enacted by individuals:

B1 Individuals and groups use the organisation's strategic goals and objectives to focus and prioritise their improvement and learning activities.

B2 Individuals and groups use innovation processes as opportunities to develop knowledge.

B3 Individuals use part of available time/resources to experiment new solutions.

B4 Individuals integrate knowledge between all different phases of product innovation.

B5 Individuals transfer knowledge between different PI processes.

B6 Individuals abstract knowledge from experience and generalise it for application to new processes.

B7 Individuals embed knowledge into vehicles.

B8 Individuals assimilate and internalise knowledge from external sources.

These behaviours can be influenced by the implementation and application of levers, or mechanisms that managers can use when managing the PI process.

These levers may be in evidence even though managers may not be trying consciously to stimulate learning. If appropriately oriented, however, these levers can have a substantial influence on the attitudes and practices of individuals in creating, storing and transferring knowledge. Eight categories of levers have been identified:

L1 Product family strategies.

L2 Innovation process definition.

L3 Organisational integration mechanisms.

L4 Human resource management policies.

L5 Project planning and control.

L6 Performance measurement.

L7 Design tools and methods.

L8 Computer-based technologies.

The capabilities can be described as integrated stocks of resources that are accumulated over time through learning, or established through deliberate decisions. These stocks of resources include internalised behaviours, technical

Knowledge and continuous innovation

497

IJOPM

21,4

498 skills, organisational routines, and corporate assets such as information systems, databases, libraries, tools, and handbooks. The level of a company's

CI capabilities determines the efforts that are needed to stimulate the corresponding behaviours. In the model the following classes were distinguished:

C1 Knowledge generation capability.

C2 Learning alignment capability.

C3 Capability to integrate knowledge within PI process.

C4 Capability to transfer and diffuse knowledge between PI processes.

C5 Knowledge consolidation capability.

Finally, contingencies are factors that influence the choice of levers to foster behaviours. Among the contingent factors distinguished in the model are exogenous variables such as the market situation of the company, and endogenous factors such as company size, and product and process complexity.

In addition to the operationalised variables, the model proposes a theory in the form of hypothesised or tested relationships between the variables. The first version of the model was based entirely on the literature and on the experience of the researchers. The pilot studies added variables, removed others, and confirmed, rejected or changed the originally-hypothesised relationships between them. The subsequent series of more than 80 case studies has improved and enriched the model. In the next section, three examples of the application of the CIMA model are reported.

Interpreting cases through the CIMA model

To date, the CIMA methodology (including the process, model, questionnaire and knowledge base) described in the previous section has been applied in more than 80 companies in order to suggest specific mechanisms that can be implemented to foster behaviours and, through that, achieve higher levels of

CPI performance. In this section, results from three applications of the CIMA methodology are reported: company X in Italy, company Y in Sweden, and company Z in The Netherlands. In each case, data were gathered during semistructured interviews with the main actors in each company's CPI process, using a common questionnaire. For the Italian case, company X, a PC-diskette version of the questionnaire was used allowing for immediate feedback to the company. The case summary below will include one of the diagrams used in the methodology. We will outline the observations in each case in turn.

Company X (Italy)

Company X competed in the tractor industry which was characterised by increasing concentration and globalisation. A strong emphasis on the renewal and enlargement of the product range, and a recognised excellence in product design allowed company X to survive and grow in an industry dominated by larger competitors with correspondingly greater technical and financial resources.

Once a country-based company with strong roots in its local environment,

company X had recently taken over a number of its traditional competitors becoming one of the world leaders in its segment, with a broad portfolio of famous tractor marks. The resulting increased size and complexity and the competitive pressure both for reduced time-to-market and for improved use of critical resources, required a quantum leap in the effectiveness of knowledge sharing and capitalisation over time across different sites and product families.

The CIMA methodology highlighted integration and improvement diffusion within the PI process (P3) as the key performance area to be addressed and, correspondingly, behaviour B4 (Individuals integrate knowledge between all different phases of PI) as the key behaviour to enhance. This finding is illustrated in Figure 3. A joint diagnosis with the company's managers outlined how weaknesses in this behaviour were responsible for rework, design changes during the production phase and other critical effects that were hardly considered by the R&D department.

Drawing examples of management practices in similar cases from the CIMA knowledge base, alternative interventions were discussed and finally an integrated plan of actions on four different levers was decided. Through L3, organisational integration mechanisms, the project manager's role and that of the project work team were redesigned. Through L1, a product platform strategy was introduced. Furthermore, a structured database to store and retrieve project knowledge throughout the company was implemented, which was a combination of levers L7 and L8.

Knowledge and continuous innovation

499

Figure 3.

Company X synoptic diagram

IJOPM

21,4

500

Company Y (Sweden)

At company Y, a leading global company in the telecommunications industry, an R&D centre located in Sweden was studied. This centre, which specialised in a particular technological field, organisationally was part of a larger unit, but was geographically isolated from the rest of the company. The R&D centre had been established a few years previously in an attempt to retain skilled engineers by providing interesting jobs in an attractive environment. The centre performed R&D tasks on projects spanning several organisational units.

Time was the main performance parameter in this extremely dynamic industry and, correspondingly, the requirements for effective and timely co-ordination were substantial.

Using the CIMA methodology to map the CPI process, it was seen that, in general, the R&D centre performed well with respect to knowledge transfer and learning. The area that emerged as the most important to attend to was coherence of improvements with corporate goals (P2). This shortcoming pointed to the importance of enhancing the frequency and diffusion of behaviour B1, individuals and groups use the organisation's strategic goals and objectives to focus and prioritise their improvement and learning activities in the innovation process. The relatively limited evidence of this behaviour was discussed with the site manager, who thought that it was most likely a result of their way of working. Performing rather clearly demarcated tasks within large projects made it difficult for the employees involved to have a clear picture of strategies and goals at a company level. Two factors were seen to contribute to this problem. First, a clearly communicated product family strategy (L1) was lacking. To some extent this was explained by the unit's short history, a constant lack of time, and an outspoken opportunistic orientation. Furthermore, there was a limited focus on process improvements (C4). The latter was further complicated by integration problems between the units involved in R&D, which were due to geographical distances and different interpretations of company-wide models and processes.

The mapping and the subsequent analysis revealed clearly a need for an increased use of a product platform strategy (L1). In addition, the introduction of new performance measurements (L6) that could take knowledge transfer and learning into account in a more explicit way was recommended.

Company Z (The Netherlands)

Company Z was a large Dutch company, specialised in designing and producing integrated defence systems for command and control, sensor and communications purposes. Some of the most important contingencies were:

(1) Product and market complexity, articulated in:

.

.

high internal complexity due to size, dimension, lead-time and life; expectancy of the systems, which were developed by different partners and (sub) contractors, and then integrated; high external complexity, due to different goals of partners, which were related, amongst others, to political constraints.

(2) High technology innovation: defence-industry was highly innovative, combining IT, radar-technology with naval systems expertise.

(3) High political complexity, due to decision-making process and national government and industrial interests.

The CIMA methodology was used for mapping and analysing three related projects. This exercise led to the conclusion that process improvement was heavily emphasised at the expense of B3 (individuals use part of available time/ resources to experiment with new solutions) and B4 (individuals integrate knowledge among all different phases of product innovation). It was also concluded that there was neither an explicitly articulated product family strategy (L4) nor, more generally, a PI strategy. However, when looking at daily practice, the conclusion was that there was a more or less clear emergent strategy with implicit goals.

Drawing examples of levers from the other CIMA cases of companies with similar contingencies, possible interventions based on various levers were identified. Human resource management activities (L4) such as the development of specialist skills, departmental assessment and development plans, could contribute to intensifying B3 (individuals use part of available time/resources to experiment with new solutions). Furthermore, it was felt that

L5 (project planning and control systems directed at improvement projects) and

L6, performance measurement (feedback systems, benchmarking activities, measures for creativity e.g. number of improvements proposed) could impact also on B3.

In order to improve B4, (individuals integrate knowledge among all different phases of PI), three levers were discussed. L2 (innovation process definition) could diffuse the activities involved in developing and implementing a new innovation process quicker and to a wider part of the company. Through L3, organisational integration mechanisms, temporary teams and/or liaison roles and cross-disciplinary meetings could be established. Finally, through L4, human resource management concepts, job rotation could spread the results of the new PI process and, through that, stimulate, diffuse and increase the frequency of favourable behaviours.

The conclusion was that explicit use of levers that related to the transfer of knowledge within the PI process and between PI projects/processes could support improvement of the PI process.

Conclusions: managerial implications and future development of the

CIMA methodology

This article has presented some interim results of the application of the CIMA methodology. In its current form, the methodology provides a structured, stepby-step approach to mapping the user company's current level of learning within PI, identifying strengths and weaknesses and then suggesting enabling mechanisms which can be implemented by the company to stimulate continuous improvement and learning, depending on specific contingencies.

This process is supported by a behavioural model, explaining relationships between learning behaviours and outcomes, capacities enabling these

Knowledge and continuous innovation

501

IJOPM

21,4

502 behaviours, levers that managers can use to change existing or promote new behaviours, and contingencies affecting this whole set of relationships.

Furthermore, this model is operationalised and available as a questionnaire in various different modes. Finally there is a knowledge base comprising the data of over 80 companies.

Experience with its application thus far shows that the methodology is not only usable by companies, even in a remote setting, but also yields useful results for them in the form of an increased understanding of the strengths and weaknesses of their PI ``system'' and suggestions for improvement. In this article three case studies were used to demonstrate the usefulness of the methodology. As the number of cases analysed grows over time, the richness and robustness of the analysis of and recommendations to subsequent companies will improve.

In the future, application of the tool will be complemented with an automated data collection and report generation system, linked to the knowledge base in which also the actions undertaken by every company will be included. Using feedback from companies and facilitators assisting the implementation, the methodology will be refined and consolidated. Moreover the enlargement of the user network and of the CIMA knowledge base will provide the opportunity to analyse and study the application of levers in very different (contingent) situations. Exchange of knowledge and experiences is thus facilitated, as well as allowing for essential benchmarking.

References

Arora, A. and Gambardella, A. (1994), ``The changing technology of technological change: general and abstract knowledge and the division of innovative labour'', Research Policy ,

Vol. 23, pp. 523-32.

Barney, J.B. (1991), ``Organization resources and sustained competitive advantage'', Journal of

Management , Vol. 1, pp. 99-120.

Bartezzaghi, E., Corso, M. and Verganti, R. (1997a), ``Continuous improvement and inter-project learning in new product development'', International Journal of Technology Management ,

Vol. 14 No. 1, pp. 116-38.

Bartezzaghi, E., Corso, M. and Verganti, R. (1997b), ``Managing knowledge in continuous product innovation'', Proceedings 5th International Product Development Management Conference ,

EIASM, Como.

Bohn, R.E. (1994), ``Measuring and managing technological knowledge'', Sloan Management

Review , Fall.

Clark, K.B. and Fujimoto, T. (1991), Product Development Performance. Strategy, Organization, and Management in the World Auto Industry , Harvard Business School Press, Boston,

MA.

Collis, D.J. and Montgomery, C.A. (1995), ``Competing on resources: strategy in the 1990s'',

Harvard Business Review , July-August, pp. 118-28.

Corso, M. (forthcoming), ``From product development to continuous product innovation: mapping the routes of corporate knowledge'', International Journal of Technology Management .

Corso, M. and Pavesi, S. (2000), ``How management can foster continuous product innovation'',

Integrated Manufacturing Systems , Vol. 11 No. 3, pp. 199-211.

Coughlan, P., Harbison, A., Corso, M., Pavesi, S., Ronchi, S., Caffyn, S., Magnusson, M., Sundgren,

N., Boer, H., Gieskes, J., Chapman, R. and Hyland, P. (2000), ``Developing continuous innovation as an organisation-wide process'', Proceedings 7th International EurOMA

Conference , 5-6 July, Ghent.

Cusumano, M.A. and Nobeoka, K. (1992), ``Strategy, structure and performance in product development: observations from the auto industry'', Research Policy , Vol. 21.

De Maio, A., Verganti, R. and Corso, M. (1994), ``A multi-project management framework for new product development'', European Journal of Operational Research , Vol. 78, pp. 178-91.

Hedlund, G. (1994), ``A model of knowledge management and the N-form corporation'', Strategic

Management Journal , Vol. 15, pp. 73-90.

Henderson, R.M. and Clark, K.B. (1990), ``Architectural innovation: the reconfiguration of existing product technologies and the failure of established firms'', Administrative Science

Quarterly , Vol. 35, pp. 9-30.

Imai, K., Nonaka, I. and Takeuchi, H. (1988), ``Managing the new product development process: how Japanese companies learn and unlearn'', in Clark, K.B., Hayes, R.H. and

Lorenz, C. (Eds), The Uneasy Alliance: Managing the Productivity-Technology Dilemma ,

Harvard Business School Press, Boston, MA, pp. 337-75.

Itami, H. (1987), Mobilizing Invisible Assets , Harvard University Press, Cambridge, MA.

Meyer, M.H. and Utterback, J.M. (1993), ``The product family and the dynamics of core capability'', Sloan Management Review , Spring, pp. 29-47.

Nelson, R.R. and Winter, S.G. (1982), An Evolutionary Theory of Economic Change , Harvard

University Press, New York, NY.

Nonaka, I. (1991), ``The knowledge-creating company'', Harvard Business Review , November-

December, pp. 96-104.

Sanderson, S. and Uzumeri, M. (1995), ``Managing product families: the case of the Sony walkman'', Research Policy , Vol. 24, pp. 761-82.

Saren, M.A. (1984), ``A classification and review of models of the intra-firm innovation process'',

R&D Management , Vol. 14 No. 1, pp. 11-24.

Smith, P.G. and Reinertsen, D.G. (1991), Developing Products in Half the Time , Van Nostrand

Reinhold, New York, NY.

Sundgren, N. (1998), Product Platform Development ± Managerial Issues in Manufacturing

Firms , Chalmers University of Technology, GoÈteborg.

Wheelwright, S.C. and Clark, K.B. (1992), ``Creating plan to focus product development'', Harvard

Business Review , March-April, pp. 70-92.

Wheelwright, S.C. and Sasser, W.E. (1989), ``The new product development map'', Harvard

Business Review , May-June, pp. 112-23.

Knowledge and continuous innovation

503