General Chemistry 101 Lab Manual: Environmental Focus

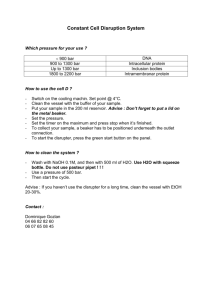

advertisement