Appleton Manufacturing Company Jackson Street Incorporated

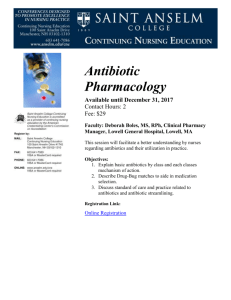

advertisement

Appleton Manufacturing Company

Jackson Street

Incorporated 1828

TABLE OF CONTENTS

Research Report:

Founding and Initial Development:

Millyard Development: 1833-1843

Turbine Experiments: 1844

Millyard Development: 1845-1872

Millyard Development: 1873-1904

Millyard Development: 1905-1918

Corporate History

after 1918

Archeological Comment

Figures (1-23 )

Footnotes

Bibliography

Inventory Forms:

Mill No. 1

Mill No. 2

Dye House

Mill No. 3

Mill No. 4

Office Building

No. 1 Cotton House

"New Mill"--Mill No. 5

No. 5 Extension

Mill No. 6

Building No. 7

Stable

Site of Coal Pocket

Turbine Building and Boiler House

1828-1832

1

5

5

6

8

10

13

14

15

±i

Research Report

Appleton Manufacturing Company

Jackson Street

Incorporated 1828

Founding and Initial Development:

1828-1832

The Appleton Manufacturing Company, also called the Appleton

Company, was incorporated on February 4, 1828 by Thomas H.

Perkins, Ebenezer Francis and Samuel Appleton "for the purpose of manufacturing cotton and woollen goods, in the town

of Lowell." It had a capital of $500,000 which was increased

in 1839 to $600,000.

In a sketch of the life of Patrick T.

Jackson, John A. Lowell explains why the Appleton Company

was started:

Mr. Moody had recently introduced some important

improvements in machinery, and was satisfied

that great saving might be made, and a higher

rate of speed advantageously adopted. Mr. Jackson

proposed to establish a company at Lowell, to be

called the Appleton Company and adopt the new

machinery ( 1) .

Interlocking directorships characterized the manufacturing

companies founded on the Merrimack Manufacturing Company's

model during the early years of Lowell and included the

Locks and Canals Company, whose directors were essentially

those of the Merrimack Company.

The Appleton was no exception.

In 1828, for instance, three of the five Locks and

Canals Company directors were also directors of the new

company: P. T. Jackson, J. Thorndike, Jr., and Nathan

Appleton. By 1832, Henry Cabot, P. T. Jackson and George

Lyman again held positions on both.

The practice

continued for many years.

Several of the Appleton's

directors were involved in the management of the other

companies as well.

Likewise the manufacturing companies

had many of the same shareholders.

The "parcel of land", which the new company purchased from

the Proprietors of the Locks and Canals on Merrimack River

in 1828,.. lay on the island between the new Hamilton Canal

and the Pawtucket Canal and abutted the Hamilton Manufacturing

Company, ~o the east, which was incorporated in 1825 (2).

With the mill sites, the Appleton also acquired two mill

privileges "of the power described in the annexed proposals'~

(3).

Of interest is the fact that the first indenture

'

.

Appleton Manufacturi.ng Co.

-2-

(of March 15, 1828) between the Proprietors and Appleton

reserved "to the grantors and their assigns a right to

attach to said Wall of the Main--ie.

Pawtucket--Canal

a towing path for the canal~ giving us a good idea of the

motive power by which barges carrying goods were propelled

to and from the mills.

By the end of 1828, the Appleton Company had . ,_ commenced

operations in No. 1 and No. 2 Mills, making heavy sheetings

which became "such a popular article for use at home and

for exportation'' (4).

Power was supplied by raceways

which carried water from the Hamilton Canal to the Appleton's

breast wheels.

The water, after it had passed through the

wheelpits, was discharged thirteen feet below into the lower

level of the Pawtucket Canal,which ran along the back of the

Appleton

millyard. According to Joshua Merrill, a wellknown Lowell teacher and books.e'd.J.er,

the Appleton Mills

were erected by one . Cap~ John Bassett, "a distinguished

master-builder" (5).

Bassett was not listed in the Lowell

Directory when it commenced publication in 1832, but he had

apparently been a prominent builder in the Chelmsford.;.Lowell

area.

Unfortunately Bassett has proven a very elusive

figure to track down.

One indirect reference to him states:

"On the 27th of August, 1824, young Peabody [later Mayor

Josiah G. Peabody] came to Lowell for the purpose of learning the trade of house-carpenter and builder, and engaged

himself to Capt. John Bassett--a man for many years

universally known in this region"

(6).

Bassett may have carried out the construction of the Appleton

Mills, under contract to the Proprietors of Locks and Canals.

Generally,the Locks and Canals Company, which included the

Lowell Machine Shop, built the mills, machinery, furniture,

houses, etc. for each newly incorporated company (7).

The

Machine Shop evidently did build the Appleton's machinery,

but the construction of the mills themselves seems, as was

sometimes the case, to have been contracted out to another

party. This is not surprising in that the time of Appleton's

incorporation was an extremely busy period f6r the Lowell

Machine Shop, the "Shop that Built a City," as Gibb calls it.

In 1828 one of the original Merrimack Manufacturing Company

mills burned, necessitating its reconstruction and the building of new machinery. Meanwhile,the Hamilton Manufacturing

Company was also waiting for mills and machinery.

Thus the

contract · to build the Appleton Mills must have been awarded

to Bassett, with Kirk Boott, the Locks and Canals agent,

perhaps overseeing the work as it went forward and offering

advice or men as needed.

Appleton Manufacturing Co.

-3-

The Appleton mill buildings and the millyard layout were of

the type developed by the Boston Associates in Waltham and

standardized to a great degree in their Lowell plan. To

this early construction period belonged not only the first

two Appleton mills, each with two separate picker houses,

but also two secondary buildings on the Hamilton Canal

(Fig. 1), both of them to the left of the entrance to the

yard (8). By 1834 or 1835 a third building had been added

on the canal and to the right of the entrance (9).

Presumably the functions of cotton house and storehouse, counting

house, and repair shop were distributed among the three.

These, at any rate, were the functions assigfied them on an

1878 insurance plan. Moreover, this is the distribution of

buildings and functions seen in the majority of the other

millyards developed in Lowell on the Merrimack model during

the 1820s and 1830s. The counting house and repair shop

very often occupied positions on either side of the yard

entrance.

Three long, brick boarding house blocks ranging between

Jackson and Middlesex Streets also dated to the earliest

building period of the Appleton Company. Merrill, then

teacher at the Hamilton Corporation School, reminisced about

the Appleton many years later:

During the su~er of 1828, the Appleton Mills were

put in operation, and their boarding houses filled

with tenants, and a few houses were built on

Appleton Street; consequently my school was very

much larger than it was the previous winters-numbering in 1828, 169 scholars (10).

The first two Appleton mills were about 156 feet long by

45 feet wide (11).

They were four stories in height with

clerestory monitor roofs.

Richark Arkwright's use of the

clerestory monitor in his Lower Mill at Cromford, England

was apparently unique in eighteenth century English

industrial buildings but it became a frequently used form

in early American mills (lla). Finished granite lintels

and sills ornamented the mill windows,which were set quite

close to the wall thus maintaining the flat continuity of

the wall plane.

In proportions, materials, and detailing

the Appleton mills continued to show the sympathetic adaptation of the Federal style to utilitarian structures which

had characterized the Boston Associates' mills at Waltham.

This style of mill building was prevalent in Lowell from

the 1820s through the 1840s,with only occasional reference

to the Greek Revival style which became popular in other

Appleton Manufacturing Co.

types of buildings

most- likely in the

two Appleton mills

roofs put on them

-4-

after about 1820. At some later date,

1860s, and certainly by 1880, the first

were raised one story and shallow-pitched

(12) .

Attached to the center of each mill, on hhe long side facing

the millyard, was an outside stair tower of brick which rose

to the level of ,: the clerestory windows. Among the earliest

appearances of this feature in America was that on the

Boston Manufacturing Company's second mill at Waltham.

It

was to become a standard in n i neteenth century American

mill construction and often the tower housed a loading

platform and toilets on each floor, in addition to stairs.

The Appleton boarding house blocks, like the mills, were

primarily Federal in stylistic origin, though simple post

and lintel doorways and some molding details seem to show

an awareness of the Greek Revival. Three stories in height,

plus a raised basement, they had gabled roofs with twin,

parapet-linked chimneys at each end of the building and

dividing the separate boarding house units.

By 1832, the Appleton Company was equipped with 9,500 spindles and 350 looms .. About 1,500,000 pounds of cotton were

used per week to manufacture nearly 4,000,000 yards of cloth

a year. About 475 women and 60 men were employed (13).

In

September of 1832, Appleton purchased two additional mill

powers from the Proprietors of Locks and Canals (14).

By

1836 the number of spindles had increased to 11,500 and the

looms to 380, still in two mills, and the number of female

operatives had risen to 575. The cloth produced annually

likewise increased to 5,200,000 yards (15).

As the efficiency of the machinery increased,the number of

women employed decreased.

In 1842, for instance, only 470

females were employed although the Appleton had 11,776

spindles and 400 looms by that date.

The number of men

employed had increased slightly to 65. The yardage produced at first remained the same (as the work force

lessened initially) and then made steady gains with

improvements in technology.

In 1842 the Appleton continued

to make sheetings and shirtings of No. 14 yarn (16).

In

June of the following year, the company purchased another

mill power, followed by an additional one-half mill power

in November, for a total of five and one-half (17).

Appleton Manufacturing Co.

Millyard Development:

-5-

1833-1843

Beard and Hoar's 1841 "Map of Lowell" shows two additional

buildings constructed in the Appleton yard since 1832.

One, discussed above, was on the Hamilton Canal, making a

total of three structures ranged along the front of the

yard. The second building shown in 1841, but not in 1832,

was on the Pawtucket Canal behind Mill No. 2, and occupied

the site of a later Boiler House and an even later Dye House.

It was most probably a Picker House on the edge of the

water and in the rear of the millyard, isolated to guard

against the possible spread of fire.

The cotton picking

process was a highly flammable one and the extreme concern

with fire caused a number of the "second phase" of picker

houses to be placed in a similar isolated, waterside location in other Lowell millyards.

This second Appleton

Picker House would have been the successor to the four

earlier picker buildings. These were small, two-story,

fireproofed buildings (two to each mill usually) set off

a few feet from the front mill wall, probably with a blank

wall toward the adjacent mill. Finally, in 1843 or 1844

Appleton built what was evidently a "third phase" Picker

House. Constructed of brick, as its predecessors had been,

it was located at ~ight angles to Appleton's Mill

No. 2, near its west end.

This building is shown on

the ca. 1845 view of the Appleton yard (Fig. 2) in the left

foreground.

It appears to be in what Hill calls the "old

style of mill architecture" when referring to the

Massachusetts Cotton Mills' picker building.

It seems, in

other words, more Federal Style in its detailing in comparison to the infill building of almost the same date

between Mills No. l and No. 2.

The latter with its

emphatic pediment is more Greek Revival in tone.

Turbine Experiments:

1844

The first experiments with the turbines developed by Uriah

A. Boyden were conducted at the Appleton Manufacturing

Company. · A Bostonian, Boyden had been a surveyor for the

Locks and Canals Company until 1834 and had continued his

studies of water power technology after going on to other

jobs. He was also, for instance, a surveyor for the Boston

and Lowell Railroad during the 1830s.

In 1844, after careful study of the theory of the Fourneyron

turbine, Boyden applied to the Appleton agent, George Motley,

Appleton Manufacturing Co.

-6-

to permit him to construct a turbine wheel for the company's

new Picker House. This was the first turbine put in operation in Lowell. When it was completed, James B. Francis

assisted at its test and observed the increase in ~ower it

afforded while occupying less space than a breast wheel.

Boyden's patents were thus purchased by the Proprietors of

Locks and Canals and it was on Boyden's turbines that

Francis conducted his famous experiments over the following

decades. The experiments at Tremont Mills in 1855 are

perhaps the best known. Under pressure from the Locks and

Canals Company, the Lowell manufacturing companies steadily

replaced breast wheels in all their Lowell mills following

the successful experiments at Appleton. There were five in

that company alone by 1856 (18). Francis, in the preface

to the 1868 edition of his Lowell Hydraulic Experiments,

wrote:

"The author takes this opportunity of acknowledging

his obligations to Mr. Uriah A. Boyden of Boston, for useful

suggestions during the last twenty-five years, on almost

every subject discussed in this volume" (19).

Millyard Development:

1845-1872

In about 1845-1846 the Appleton Company constructed a third

mill building in the seventy-five foot space between their

Mills No. 1 and No. 2, as did many of the other manufacturing

companies during the mid-1840s.

The need to expand existing

facilities and a greater confidence in the ability to prevent

fire from spreading were evidently the motives behind this

development.

By the early 1840s, wrought-iron, high-speed

shafting was in use, as was the heavy, slow-burning method

of interior wooden framing developed during the late 1830s.

The appearance of this infill building is recorded in a view

that purports to represent the yard in 1845 (Fig. 2) and in

one of the vignettes which framed Sidney & Neff's 1850 Plan

Lowell (Fig. 3). It functioned visually as an emphatic,

projecting pavilion between the two older mills. Its broad,

heavy pediment is rather Greek Revival in proportion though

the cornice does not extend all the way across the gable end.

An 1880 view of the third mill gives a good idea of its mass

in relation to the two buildings which it now joined (Fig. 4).

Perhaps late eighteenth century mills in England or Scotland

served as "stylistic prototypes for the American builders

when it carne time to join two earlier mills by a connecting

unit. Arkwright's mills at New Lanark, Scotland (ca. 1785),

for instance, were extended rectangles accentuated at the

Appleton Manufacturing Co.

-7-

center of both long sides by a projecting pavilion . [Fig. 2a].

For some reason neither the Lowell Directory nor the

"statistics of Lowell Manufacturing," published yearly by

the local newspaper, record the Appleton Company as having

three mills until 1853. Frank Hill, however, writes that a

third mill was added in 1846 (20), and the building in

question was referred to in later years as Mill No. 3. Moreover, the mid-184~saw the second major construction phase

in Lowell mill building during which many companies built

just such infill structures between pairs of their earlier

mills.

The Tremont and the Suffolk Companies are examples.

The new Appleton building may well have functioned as a mill

from the beginning without being designated by a number until

1853. A similar situation in which a mill was in operation

long before it was "published" existed at other companies,

such as the Boott. Finally, neither the directory nor the

newspaper information is of course wholly reliable. Other

statistical evidence, besides the number of mills, does

appear to support the contention that a third mill was in

operation well before 1853. The number of spindles in use

by the Appleton increased from 11,776 in 1844 to 17,920

in 1849 (figures far 1847 are not available), strongly

suggesting the presence of a third mill by 1849. Also, the

additional one-and-one-half mill powers were purchased in

1843.

[See Above.]

The number of looms rose from 499 in

1844 to 600 in 1849, then to 700 by 1853. Four hundred

women and 120 men were employed in 1849 and 1853, .whereas

there had been 340 women and 65 men in the Appleton work

force in 1844. The company continued to make sheetings and

shirtings

(No. 14), at a rate of 150,000 ¥ards per week in

185 3.

Accordingto Frank Hill, the Appleton Company next constructed

a mill in 1861. Perhaps this was the building shown as the

easterly "L" off Mill No. 1 on the 1878 insurance plan.

This

building is shown on the 1868 map of Lowell but not on the

1850 map.

In this case, none of the statistics available

seem to support the existence of an additional mill in

1861. Not until 1872 does the number of spindles (27,568)

and looms (788) show a really noticeable increase (cf. 19,872

spindles and 707 looms during the 1861-1866 period) .

Perhaps the Appleton, like many of the other companies during

the Civil War period, took the opportunity afforded by reduced

Appleton Manufacturing Co.

-8-

activity to update their mills.

This might account for

Hill's information. However, the Appleton suffered less

during this period than many of the others and in fact

produced the same amount of cloth every week (160,000 yards)

from 1860 through 1865, with a drop coming only in 1866

(to 130,000 yards), followed by recovery in 1868. In that

year drillings were added to the sheetings and shirtings

already in production.

Millyard Development:

1873-1904

Production did not increase noticeably until about 1875 when

the Appleton New Mill, built in 1873, was in full operation.

A spinning and weaving mill, it was entirely powered by steam.

The Appleton Company, unlike several of the other cotton

manufacturing companies in Lowell, did not alter its machinery in order to produce woolen cloth during the war period

and, therefore, suffered less disruption and financial loss

both during and after the war. By 1876 the Appleton was

operating with 41,088 spindles and 1,202 looms and producing

200,000 yards a week of sheetings, drilling9, and shirtings.

The number of employees was up to 450 women and 250 men.

Both duck and colo ~ed hosiery yarns had been added to the

manufactures by 1884, at which time 45,064 ·, spindles and

1,224 looms were in operation, producing 280,000 yards of

cloth per week.

The Appleton New Mill is a five-story, brick structure,

basically Italianate in style, with three towers ranged

symmetrically along its front (Jackson Street) facade (Fig.5).

The central tower is five stories, the other two are six.

The building rests on a granite water table which is stepped

slightly to accommodate the slight westerly rise of the site.

Sills of rock ~ faced granite and simple segmental arches

accent the windows, except on the fifth floor.

There, the

windows have projecting Italianate arched caps which, being

joined by smaller arches between each window, sustain a continuous rhythmic progression J - broken only by the three towers.

Directly above is the corbelled brick cornice. The lack of

arched window caps over the windows on the first four stories

is quite unusual as early as 1873. It seems to look forward

to a later nineteenth and early twentieth centu ~i t t pe 'Of

window treatment such as that used on the 191 5. addition to

the New Mill at the corner of Jackson and Revere Streets.

The Hamilton Manufacturing Company Storehouses toward the

Appleton Manufacturing Co.

-9-

opposite end of Jackson Street exemplifies the sort of

window treatment which was usual in the 1870s and into

the 1880s. There, windows in each floor have the projecting Italianate caps.

As is usually the case, the decorative elements on the

stairtowers are more concentrated than on the remainder of

the building, with a granite stringcourse between the first

and second and the third and fourth stories, and paired

windows set within recessed brick panels. These panels

are framed by brick piers which are carried up into a

rather elaborate cornice.

Instead of sixth floor windows, the

center tower has granite plaques set into the space between

a secondary cornice, at the level of the actual building

roof, and the tower cornice. The plaques on the east and

west sides of the tower read "Appleton." The one · across

the front reads "1828-1873."

An imposing walkway bridges Jackson Street, linking the

third story of the center tower and Mill No. 4 in the millyard across the street. The bridge is of frame construction,

with Italianate detailing and board and batten sheathing.

Its paired, Italianate windows echo the style of the New

Mill. No doubt tha walkway was constructed at the same

time as the New Mill and was retained during the early

twentieth century reconstruction of the Appleton millyard.

Behind the New Mill are both a one-story brick boiler

house complex and a turbine house, likewise brick and onestory. Both are early twentieth century additions to the

structure.

In 1888 the Appleton Company was listed in the Lowell

Directory as having five mills in operation, rather than

four as previously, with 50,280 spindles and 1,480 looms

rather than the 45,064 spindles and 1,224 looms listed in

1887. The manufactures continued to be sheetings, drillings,

shirtings, and duck. Four hundred and sixty women and 260

men were employed in 1888. As there is no documentary

evidence of new construction at that time, the fifth mill

must have been a new use of a pre-existing building.

The Appleton Company, responding to an increasing demand

for business blocks on Middlesex Street, in 1889 disposed

of the sontherly half of the company-owned block between

Robeson and Hamilton Streets,on which stood its three boarding houses (21). Before doing so, however, they cut a

narrow street from east to west halfWay between Jackson and

Appleton Manufacturing Co.

-10 -

Middlesex Streets, thus physically dividing the block in

half. The southerly segments of two of the houses were

demolished and the property sold to several individuals

who constructed business and residential buildings along

Middlesex Street. The Marston Block, for instance, rose

at the corner of Middlesex and Hamilton (later Marston)

Streets. The southern half of the boarding house nearest

Robeson Street was sold intact, while its northern segment,

still Appleton property, was razed. On this site at the

corner of Robeson and Jackson Streets was erected a large,

six-story brick mill and storehouse (Appleton Mill No. 6).

Elements of the southern segment of the boarding house at

the corner of Robeson and Middlesex appear to remain within

the fabric of the building presently at 207 Middlesex

Street.

[See Inventory Form on 207 Middlesex Street.]

The northern halves of the other two boarding houses (Nos.

204-206 and 286-288 Jackson Street) remained intact and

Appleton owned. By 1906, howev~,they too had been

demolished and the entire northern half of the block

between Robeson and Hamilton Streets was occupied by the

enormous (97 by 306 foot) Appleton Company Mill No. 6,

constructed of brick. The later segment, like the earlier,

is six stories tall. Both segments have tall windows on

the first two flooLs, and much shorter windows above.

On

the earlier portion of Mill No. 6, these upper windows

are widely spaced, suggesting the upper floors were

designed as storage space. The 1920 Insurance Survey bears

out this difference, showing manufacturing activities on

the lower floors and storage on the upper levels.

Between 1896 and 1906 Appleton had also built a narrow row

of shops on Middlesex Street, running the entire length of

the block between Revere and Robeson Streets.

A few changes had also taken place in the millyard by this

date. The Picker House west of old Mill No. 2 had been

extended out to the very edge of the canal by 1896, and a

Dye House built along the canal north of No. 2. Presumabl~

the regulation in the 1828 indenture between the Appleton

Company and the Locks and Canals Company which prohibited

building within ten feet of the Pawtucket Canal was no longer

in force by this date.

Millyard Development:

1905-1918

Only the five-story Appleton New Mill (1873) remains of all

the nineteenth-century buildings erected by the company, with

Appleton Manufacturing Co.

-11-

the possible exception of the first two stories of Cotton

House No. 1. The entire nineteenth century Appleton millyard was demolished and reconstructed between 1905 and 1918

under the direction of Alexander G. Cumnock, who became

treasurer of the company on February 17, 1898 after thirty

years as the Boott Mills agent. According to Coburn, the

company "was in a bankrupt condition, with worn out machinery

and old buildings, some of them dating back to 1828" when

Cumnock took over.

"The principal product of the mills was

sheetings which could not be successfully manufactured in

competition with southern mills" (22). Apparently Appleton

had been in trouble for a nurober of years, prompting Hurd

to write in 1890:

"The average of its annual dividends ...

for the last twelve years have been less than 4 ~ 1/2 % " (23).

Appleton in fact stopped advertising (though it was still

listed) in the ~owell Dire~tory in 1891 and resumed only

after the reorganization and reconstruction were well underway. Under Cumnock, the Appleton product was changed from

sheetings to colored nap goods and, according to Coburn, the

company's "trademark was copyrighted in thirty-two foreign

countries with a constantly increasing busines~ (24).

The extensive building activity carried out in the Appleton

yard between .1904 and 1920 is recorded in the City of Lowell

BuildingsDepartment.

The following is a list of the dates,

purposes, and costs recorded on building permits for which

the company applied:

Dec. 1904, "for manufacturing and storehouse" ( $30,000) ;.

June 1905, "for manufacturing"($35,000);

April 1907, "Brick Mill" ($10, 000);

April 1909, "Pawtucket Canal. Add Dye House" ($12,000);

Nov. 1909, "Add--Boiler House" ($3,800);

Dec. 1910, Jackson corner King Street.

"Build twostory brick stable" ($7,500);

April 1912, "Build 5 story mill" ($80,000);

June 1915, Jackson, corner Revere Street, "Build

·' Storehouse" ($75,000);

Jan. 1916, "Build Brick Mill" ($10 ,000);

March 1916, "Build add. to Dyehouse" ' ($11,000);

June 1918, Jackson, corner Revere Street, "Build

Manufacturing Building" ($32,000);

Jan. 1920, "Raising Building 2 stories" ($40, 000).

The estimated cost noted with each building entry gives some

idea of the relative size of each project.

The Appleton millyard as it now stands is, in short, a composite of earlytwentieth century utilitarian brick mill structures, the

majority of them five to six stories in height.

The exception

Appleton Manufacturing Co.

-12-

is a ten-story reinforced concrete storehouse with brick and

glass hung walls of a style popularized by the architect

Albert Kahn throughout the United States during the early

twentieth century. This must be the$75,000 storehouse

constructed inl91S. Known as Storehouse No. 7, it stands

at the corner of Jackson and Revere Streets, west of the

five-story brick and granite trim addition to the Appleton

New Mill built in 1918. Also belonging to the early-twentieth century building period is the t\om-story brick stable

built by Appleton in 1910 on King Stree~ near the corner of

Jackson Street. This still stands, in somewhat altered

condition.

The entire Appleton complex is clearly shown on

an Insurance Survey of November 17, 1920 (Figs. 11 ·, , 12).

The following buildings now stand in the Appleton millyard

proper. Mill No. 1, on the Hamilton Canal, is a six-story

brick structure, 100 by 207 feet, with a very slightly

pitched roof.

Large, plain wooden brackets support the roof

overhang above a corbelled cornice. Segmentally arched

windows have quarry-faced granite sills. Across the yard

entrance from No. 1, and also running along the Hamilton

Canal, is the ell of Mill No. 4, also called the office

building.

The main segment of No. 4, 88 by 120 feet, then

runs back (north) ~rom the canal until it connects with Mill

No. 3. Together No. 3 and No. 4 form the \•!estern boundary

of the Appleton yard.

The ell of No. 4 housed the mill office

on the second floo~ adjacent to the yard entrance.

Stylistically, No. 4 is very similar to No. 1, with one interesting

exception. Windows on the third floor of the west side of

Mill No. 4 have flush granite lintels rather than segmental

arches. This notably conservative and traditional element

may have resulted from Cumnock ordering the reuse of materials

from an earlier Appleton building, or this may be a

fragment remaining from an earlier wall of an Appleton

building which was similar in style to the Lowell Machine

Shop structure adjoining it (Fig. lOa). This limited use

of granite lintels on a building otherwise having seqmental

arches over the windows is curious.

From the exterior

the portion of wall into which these windows are set does not

appear to be earlier than the remainder of the west wall of

No. 4 Mill.

I

On the interior of the yard, built into the angle formed by

the offioe building and No. 4 Mill, is the six-story brick

Cotton House No. 1, 78 by 165 feet.

On the first four

stories, this has the very small, arched windows characteristic of the nineteenth-century storehouses built by many

Appleton Manufacturing Co.

-13-

of the Lowell manufacturing companies. This lower portion

of the building was constructed sometime between 1896 and

1906 (it appears for the first time on the 1906 Lowell

Atlas), while a January, 1920 permit to raise a building two

stories probably refers to this storehouse.

The style of

the two added floors is that seen in the remainder of the

yard proper.

The 75 by 423foot Appleton Mill No. 2 extends the entire

length of the inner millyard. Built of brick six stories

high, it is of the same style as the others.

Its windows

have granite sills and are capped by segmental arches.

No. 2 ell is a 42 by 57 foot, five-story building betweenHills

No. 1 and No. 2, on the boundary line between Appleton and

Hamilton.

The 52 by 430 foot, two-story, brick Dye House

running along the Pawtucket Canal behind Mill No. 2 also

still stands.

Corporate History

After 1918

The Appleton Company continued to be listed in the Lowell

Directory through 1933. Four years earlier, however, The

American Wool and Gatton Reporter described the "great

Appleton Company " as '\.vholly out of business in Massachusetts.

They have 1,500,000 square feet of floor space in the

Appleton Company mills and only 115,000 square feet has it

been possible to rent" (25). The company leased space to

various concerns, and from 1934 until 1950 the directory

listing for the Appleton Company at 217 Jackson Street

reads "industrial real estate."

Meanwhile in 1944, Jackson Properties, Inc., also at 217

Jackson Street, purchased from the Appleton Company the

entire real estate, buildings, equipment, and operating

supplies of their Lowell plant.

In May of 1975, Jackson

Properties sold the former Appleton Company complex to

James T. Lichoulas, a trustee of the Appleton Trust (26).

Today the plant is used for warehousing, light manufacturing

and other commercial enterprises. Much of it is vacant.

Of interestis the fact that Lichoulas, and Jackson Properties

before him, have continued to pay rent to the Proprietors

of Locks and Canals on Merrimack River for all of the

original Appleton Company mill powers. Mill privileges

distributed by the Proprietors during the nineteenth century

to the Lowell textile companies have reverted to the Locks

and Canals Company in every other case but one, that of

the Lawrence Manufacturing Company. The Lawrence plant

APpleton Manufacturing Co.

-14-

retains8& 20/30ths of its original mill powers, while

Lichoulas continues to lease all ofthe .11 & 25/30ths

mill powers which the Appleton Company obtained during

the nineteenth century.

In 1978 ten Appleton turbines

were still in place.

They presumably still are.

According

to Molloy, the two oldest are McCormack horizontal turbines

of 1901 and the two latest are horizontally mounted Hunt

wheels (28).

Archeological Comment

This millyard remains largely intact.

Successive razing

and rebuilding likely has obliterated most remains of

previous periods. Although it i£ possible that elements

of early structures are incorporated into present structures,

this property has a low potential for yielding significant

archeological remains.

. i_ ..... .. ...... 1 .

II

'

· ········ •

...

.'

( '·

,

.-,-··

f '"

•••

..

w ..

r' .

····,,·

'

.•........

·.·

_

· ···~····- ~;

...

~-· ...

.

•

.

APPLETON MILLS.

Figure 2

View of Appleton Mills,

March 1884.

j,

F IG UHE

184~

'

j

1845.

from the Bay State Monthly, v. 1, No. III,

AI\·IER IC AN BU ILDINGS AND T IIEIR AR C III TF. CT S

l

g . David Dale and Richard Af'kwright.

M ills. New Larw rk, Scotland , 1785.

Figure 2a

David Dale and Richard Arkwright's Mills in New Lanark, Scotland, 1785.

From William H. Pierson, Jr., American Buildings and Their Architects:

Technology and the Picturesque, The Corporate and the Early Gothic Styles,

1978, p. 34.

Figure 3

Appleton Mills.

Vignette from border of Sidney & Neff's

"Plan of Lowell,"

1850.

Figure 4

Appleton Yard, 1880.

Hill, Lowell Illustrated, 1884, p. 74.

.

. '

~

I

-\

~

Figure 5

Appleton New Mill, built l873.

1902, facing p. 88.

City of Lowell, Board of Trade Publication,

Figure 6

View on Middlesex Street showing Appleton Company boarding houses standing among

bter commercial buildings (right side of street). City of Lowell, Board of Trade

Publication, 1902, facing p. 32.

THE APPLETON l\1ILLS 7 FROM THE TOP OF

No. 6

Ph oto by Will R oun<ls

l\iiLL OF THE HA:IlfiLTON 00:Il1P AJ\'Y

Figure 7

The Appleton Mills, from the top of No. 6 Mill of the Hamilton Company.

Manual of the Lowell Board of Trade, Report •.. for the year ending

January 1, 1905, p. 102.

Figure 8

The Appleton Mills--Looking up Jackson Street.

of Trade, ... 1905, p. 92.

Manual of the Lowell Board

APPL ETON ~!ANUFACTURING COMPANY

70,0(\0 ::ipindlcs

2,500 Empluycc•

Figure 9

Appleton Manufacturing Company from roof of Appleton Storehouse on Jackson

Street. Lowell Board of Trade Year Book, 1911-1912, p. 84.

[

'I ,

-·

-(

:

Figure 10

View of the Appleton mills from the southwest. Above the partially demolished

Machine Shop building on the left foreground, the flat granite lintels on the

west wall, third floor of Appleton Mill No. 4 are visible.

U. of Lowell Library, Special Collections, Locks and Canals photo #2664

(March 2, 1932).

.l

Figure 11

Appleton Company, Lowell, Mass. Insurance Survey, November 17, 1920.

U. of Lowell Library, Special Collections, Proprietors of Locks and

Canals Photo file #1760-H.

CONFIDomAL

:f

;::;:

1:

~­

...

to.S.

"~-.fll.

~

-

~

~'i:...'"'i:it:.-

,;;.~ ......... -"!\

·

tr ..-...

T

·.

· -

-

I

I_,_._

"""'---""""'=--.;-~--~!'~----"""""-t>o-_~______..t____..· -~

.

,J:

-

~-- :

~

Non& ·

·-"'

l

Figure 12

Appleton Company, Lowell, Mass. Insurance Survey, November 17, 1920. U. of Lowell

Library, Special Collections, Proprietors of Locks and Canals Photo file #1760-F.

~~~

-H ~. 1~ fY\ ""'"{"awe:..._,

c.....

C A l\ 1 /'\

'

L.

J

- - - - --- ----t

1 -l-- ..

- //

-:I~

A

A,

~

Sketch based on Atlas ot

A.

Lo~ell,

\-1.

1879, Plate D.

+t.

Building labels from 1875 Insurance Survey

+I.

- ---

I

I

I

I

·/ J

~· c-'-'-~I

A TLI\-s

?

c

+=-

L A-";E:-

L

I

~~~

~----_

--- --·--_

----------_

-·-·-·------_

- -· ·-- --·-------l

b

.,..--·

~ ~·T~,.;> cJ~E~---

:

~-.----'

1 Pitku

1 -H o .

L

~-- ---

I olt ... ~ o. I

0

.t ,

I V a , ')..

- -

I ---

t~,- - - - - - - - - t ~c.J_ .

1

01

k> •. I

:

' - - - - - - - -1

I

J

I___ •·--"'""--...,....-----.

r- --------·--------------------

I

'

I 1\.) co. 3.

j

1

I

'-~---r--,---~

1...----.-Jl

1-..l

.- J

~~~

-<of) '

v~

.

CJ

1\) •

I

~

[

r-1: -----· 'z ----

C:.l

-- ---~------·

,.

~o.

\\

tiA.t\41 t ·~ .tI)

\.\> ~.-..'ll.a "'4..

C.oa.l

] n~.I11_-~n _--,~-·.

_j ·-·-1,

-

I

·

""

.._

J,.

!1

~

· 1

II

--.J l !iIl )III ---·

I __

i

.3

r

L_j

....____,;, _, ____ .1_.:J.__..i__L_.C _ ___

Sketch based on Atlas of Lowell, 1896, Plate 5.

'.

~

.t:

I,

t

r ·l

~

n

_j

_j

·J

~----

I

I

0

,.....----.

--

•

-,.--..

....._

s~v\.

Figure 15

Atlas of Lowell, 1924, plate 3A.

I

I

·.-.

Figure 16

Atlas of Lowell, 1936, plate 4.

. '· ·.··

\-·'.":~

,,r.___

Figure 16a

Atlas of Lowell, 1936, plate 5.

AD V E R .T I SIN G

A}lpl~)riri

·.-,.<

,..

325

D E P A R T MEN).

tQJli·Pany,

.

;._:~:''" ~ ~ 5 .....

JA..CKSON STREET.

-·

··' i

~··

.;

'

.

J

INCORPORATED, 182B.

CAPITAL ·

$600,000•

.-

GEORGE lUOTLEY, Agent. ·

ARTH1JR L. DEVENS~ 1.'reasurer,

22 FRANKLIN BT.RF,:ET, BOSTON.

A. D. ROBINSON·; · Pay1nader.

Spindles . . ·.• _ •.• .• • • • . • .. •.• ; : •• ·. • . .• . .. . . ·. . 19,872

l

Looms

.. .

. ...

•• , . : . . • • • . . . • • , . . . . • • • . . . . • . . . . . . • 717

Females ·employed . ·• • . · . . . : • . . . . . . . . • . . . . . . 400

Males employed • . • . . . . . • . • . . . • . . • . • . • . . . . · . . :·120

Yards m.ade per w-eek . . . • . • • . • . • . • . . • . • .130,000

Cotton oons-..m.ed per w-eek, lbs. • . . • . . - . . - . 50,000

Kind of" Goods made •. Sheetings &

Shirtings;:J..4· to 20

.NUMBER OF l\ULLS R.UN BY ·THIS COMPANY ARE THREE.

J>ay-Day, -week at'ter laat Saturday In each montli,

Figure 17

Lowell

Director~

1866, p. 325.

447 -

MANUFACTURING COliPANIES.

APPLETON_. : CO~PANY,

JACKSON. STREET.

: INOORPORATED, 1828. .

'

.

•

•

•

'

I

~

'.

CAPITAL,

. ... • •

..

• -•

. . . ..

• •

$600,000 .

· G~ORGE MOTLEY,· _Treasurer,

rO·

5 Pe~berton<Squa~~· Boston: .

J. H. SAWYER, Superintendent. .

,

" , '.'I·

.· 1.': A. -H; ROBINSO~,

Paymaster.

Spindies. ~ . ; .•.. ; .... ~ ·••••• ; •••• ~ ·•.••. ; . . . • . •

2'1,568

· -'188

Looms . ~- ..... ·. ..... ~ : . :•.. ~ ·• ~- .••..••• : . ...•• ; .. ·

Females ·employed .. ,. ...••..••..•....• : . . . . . . .

400 '

.

120 '

Males. employed.·.·..•.. : ~ .. .. ................... ,

160,000 :

Yards m~de per week...................... . ...

Cotton consumed ·per week, lbs .. : ., . .':. . . . . . . . .

'1'0,000

Manufacture Sheetings, Drillings, and-Shirtings, ... ·. . -No. 14

Nu'£!lberof.: Mills ·run ·by this Company are Four; ·

·" PAY•DAY1 WEEK

Al~rEB

LAST SATURDAY IN EACH l!ONTII.

Figure 18

The "New Mill" is reflected in the four mills reported in this advertisement,

but the number of looms and number of employees does not increase substantially until a few years later, reflecting a delay in bringing that mill into

full operation. Lowell Directory, 1874, p.447.

·INCORPORATED 1828.

I

- ·· o ·

i

Capital, - , ·- ·· - · $600,000.

l

·

- o - ·..

'

;

~

t

J A~~s --.~,

'

:.

' f

r.

.

-~u_ PE.E_ : . ~reasurer,

·

19 Exchange Place; · Boston.

l .~· H. SA~YER:·.super~ten~~~nt:s ., :·. ·.

I

.. • . . ·- -

· A. H. ROBINSON, Paymaster.

. - o -·.

·sp1'n dies.· ·, ·...••

· · · · ,.· ·...

· •...

· · ·...

· · ·, ·. ·.....

· · · ·. ·........ . . .

I

Looms ·. ~ ~ . ·; ·. ·. , . >~

•

·

•

. 41,088

1,202

.., .. ·.-, ·.: .. ·..:::: .. ~., .....

employed: ..;:::. :.: ::: •., ............ 450

em.ployed::--: .·.. ~. ::·:·.;.. :~ , .' ............'. 250

Yards made'per week.:::: : .. ~; : ............. .. 200,000

Cotton consn.med per week, i!,o~nds,. . . . . . ... . . . . . 96,000

Females

Mal es

• ~ 1! ~

•

l •

,".

1

t

·.

..

1

lmnufmcturo Sheet~n~s, ~rillin~s, mnd Shirtings~

I1

. .N~b~r of!~11~ ~- by this Company 8J'& _Fo~.

f

.

l

1.

I

.

". "'",·

.~

o\

·,

~·· ,

, ,'

~

•, •

_:'

1J

•) ,

1

a:

.;, •, f'

.

-o---

Pay~D_ay,.weelc after last ~atu.;d~~ tn ~ach ·month.

.•

Figure 19

The 1876 Appleton statistics reflect the increases associated with the full

operation of Mill No. 4, the "New Mill" of 1873. Lowell Directory, 1876.

749

JACKSCN STREET.

INCORPORATED 1828.

/

·CAPITAL,

a

a

$SOO,OOO.

JAMES A. DUPEE, Treasurer.

No. 95 Milk Street, Boston.

UPHAM, TUCKER, & CO., SELLING AGENTS,.

BOSTON AND NEW YORK.

DANIEL ·WRIGHT, Superintendent.

J. F. SCHOLFIELD, Asst. Supt.

D. E. STIMPSOr~, Paymaster.

Spindles ................ . ..........• ·• . . . . . . . . . . 45,064

Looms............... . .........................

1,224

Females employed... . . . . . . . . . . . . . . . . . . . . . . . . . • .

600

Males employed.. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .

27 5

Yards made. per week ............ ·.............. 280,000

Cotton consumed per week, pounds .............. 107,000

Manufacture Sheetings, Drillings~ Shirtings,

Duck, and Colored Hosiery Yarns.

NUMBER OF MILLS RUN BY TillS COMPANY ARE FOUR.

Figure 20

Lowell Directory, 1886, p. 749.

I

907

MAN UFACTUI:trNG COi\IPANIES.

l

JACKSON STREET.

lX CHJCt•ott.'\.T E H

CAPIT

L, -

-

J.S2.S

$600,000

Lours ilo<BESON, 'I'<RE~SU11E11,

78 CHAUNCY . STREET, BOSTON .

~

~

DANA, TUCKER, & CO., Selling Agents,

B.OSTON, NEW YORK and PHILADELPHIA.

CHARLES H. RICHARDSON, AGENT.

D. E. STIMPSON. PAYMASTER.

Spindles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50,280

Looms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1,639

F emales employed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

500

Males employed ..... ... . . ..... , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

275

Yards made · per week. . ..... .. ............ .... ......... . . . . . . . . .

~~35 , 000

Cotton consumed per week, pounds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

120,000

:Iv.I:ANUFACTU::RE

SHEETINGS, DRilliNGS AND SHIRTINGS .

.j·

Nmu lm· of Jrilt• ll•m by tl•b Cmnpnny, F'Lv • .

j _,

Figure 21

Lowell Directory, 1891, p. 907.

l

·---~!

;"

APPLETON COMPANY:-

·c

JACKSON

STREET - .

'l

.

•. - ·

1·· ·

·,.

.

. ':· __INCORPORATED

1828

..

CAPITAL ·

.A. G. CUMNOC:Kt Treas.:

. F. .A~ BOWEN, Superintendent ~

1 W. M. SHERWELL, Paymaster: ::

.

CATLIN

.

'

-i-·

~~;:_;{

.- CO.~ s.,;;_!ling A g e n t s

&

Ne-w

~

.

York

a n .d

Boston

.. ~ .lt.\NUFACTURERS OF .. ..

.

Fancy . Goods 1n Great Variety

~

- -4.0::::~ .

Figure 22

Lowell Direc tory, 1908 , p. 896.

[

··;

·l"

. r

·.;.

Figure 23

Top: Regulations for Occupants of Appleton Company boa rding houses.

Bottom: Rent receipt from a boarding house keeper for the Appleton Company, 1869.

U. of Lowell Library, Special Collections.

l

-15-

Appleton Manufacturing Co.

Footnotes

1)

John A. Lowell, "Patrick T. Jackson," Contributions/Old

Residents', v. I, p. 202.

2)

North Middlesex Registry, Record Book 7, p. 243.

15, 1828).

3)

Ibid., Record Book 7, p. 231.

4)

"Letters of Samuel Batchelder," Contributions/Old

Residents', v. 1, p. 16.

5)

Joshua Merrill, "School District No. 5."

Old Residents', v. 1, pp. 27-28.

6)

"The Mayors of Lowell,"

v. 1, p. 172.

7)

Gibb, The Saco-Lowell Shops, pp. 72-73.

8)

Benjamin Mather, "Plan of Lowell,"l832.

9)

U. A. Boyden · and Philander Anderson, "Plan of Lowell

Village," 1834-35.

(March

Contributions/

Contributions/Old Residents',

10) Joshua Merrill, "School District No. 5·," Contributions/

Old Residents', v. 1, p. 30.

11) Insurance Plan: Mill Yard of the Appleton Company,

Lowell, Mass., 18 7 8. Special Collections, U. of Lowell.

llA) Pierson, American Buildings and Their Architects.

Technology and the Picturesque, p. 33.

12) Hill, Lowell Illustrated, p. 74.

13) Lowell Directory, 1832, p. 6.

14) North Middlesex Registry, Record Book 17, p. 318.

15) Lowell Directory, 1836, p. 8.

16) Lowell Directory, 1842, p. 21.

Appleton Manufacturing Co.

-16-

17)

North Middlesex Registry, Record Book 38, p. 249 and

Record Book 44, p. 44.

18)

Statistics of Lowell Manufactures.

U. of Lowell.

19)

James B. Francis, Lowell Hydraulic Experiments. New York:

D. Van Nostrand, 1868. n.p.

20)

Hill, Lowell Illustrated, p. 75.

21)

Souvenir, p. 87.

22)

Coburn, History of Lowell, v. III, p. 420.

23)

Hurd, History of Middlesex County, v. II, p. 75.

24)

Coburn, History of Lowell, v. III, p. 420

25)

Quoted in King Cotton is Sick, Claudius T. Murchison,

Chapel Hill ~ U. of North Carolina Press, 1930.

26)

North Middlesex Registry, Record Book 2147, p. 513.

27)

Molloy, Lower Merrimack River Valley, p. 49.

Special Collections,

Appleton Manufacturing Co.

-17-

Bibliography

Charters,Additional Acts, and other Documents Relating to

the Proprietors of the Locks and Cahals on Merrimack River ...

and the Manufacturing Companies at Lowell .... Cambridge:

Allen and Farnham, Printers, 1857.

City of Lowell Atlases:

1879, 1896, 1906, 1924, 1936.

City of Lowell Buildings Department Records.

City of Lowell Directories:

1832 to present.

City of Lowell, Mass., Its Commercial and Financial Resources;

Souvenir of the Lowell Morning Mail, Lowell, 1890.

Coburn, Frederick ~. History of Lowell and Its People.

York: Lewis Historical Publishing Company, 1920.

New

Cowley, Charles. A Handbook of Business in Lowell, with a

History of the City. Lowell: E. D. Green, 1856.

Cowley, Charles. · A History of Lowell. Lowell: B. C. Sargent

and J. Merrill & Son, 1868.

Eno, Arthur L., Jr., Ed. Cotton was King. A History of Lowell,

Massachusetts. Manchester, N. H.

New Hampshire Publishing

Company, 1976.

Gibb, George Sweet. The Saco-Lowell Shops, 1813-1949.

Cambridge: Harvard University Press, 1950.

Handbook for the Visiter [sic] to Lowell.

Hill, Frank P. Lowell Illustrated.

Lowell:

1884.

Hurd, D. Hamilton. History of Middlesex County , Massachusetts.

Philadelphia: J. W. Lewis & Co., 1890.

Illustrated History of Lowell and Vicinity, Massachusetts,

done by divers hands. Lowell: Courier-Citizen Company,

1897.

Kenngott, George F. The Record of a City.

MacMillan Company, 1912.

New York:

The

Appleton Manufacturing Co.

- 18-

"Letters of Samuel Batchelder," Contributions of the Old

Residents' Historical Associatiott, y. I (1879), pp. 10-17.

Lowell, John.

"Patrick T. Jackson," Contributions of the

Old Residents' Historical Association, v. I (1879), pp. 189211.

Lowell of Today.

Lowell Daily Citizen, 1893.

Lowell Year Book, Nos. 1-10.

(1882-1893).

Morning Mail Company, 1882-93.

Lowell:

The

Merrill, Jdshua. "School District No. 5," Contributions of

the Old Residents' Historical Association, v. I, pp. 25-41.

Miles, Henry A. Lowell As It Was, And As It Is (1845).

Reprint--New York: Arno Press, 1972.

Molloy, Peter M. The Lower Merrimack River Valley. North

Andover, Mass.: Merrimack Valley Textile Museum, 1978.

Murchison, Claud mus T. King Cotton is Sick.

University of North Carolina Press, 1930.

Chapel Hi ll:

Pierson, William H., Jr. American Buildings and Their Architects.

Technology and the Picturesque. The Corporate and the Early

Gothic Styles. Garden City, New York: Doubleday & Co., Inc.,

1978.

Selections, Historical and General, Mostly Concerning Lowell

and Vicinity. Largely from the Lowell Newspapers of the past

thirty years. Lowell: 1894.

[Scrapbook in three volumes

Special Collections, U. of Lowell.]

Special Collections, U. of Lowell. Maps, Insurance Plans,

picture file, document file.

Statistics of Lowell Manufactures.

[Pamphlets and document

file, Special Collections, U. of Lowell.]