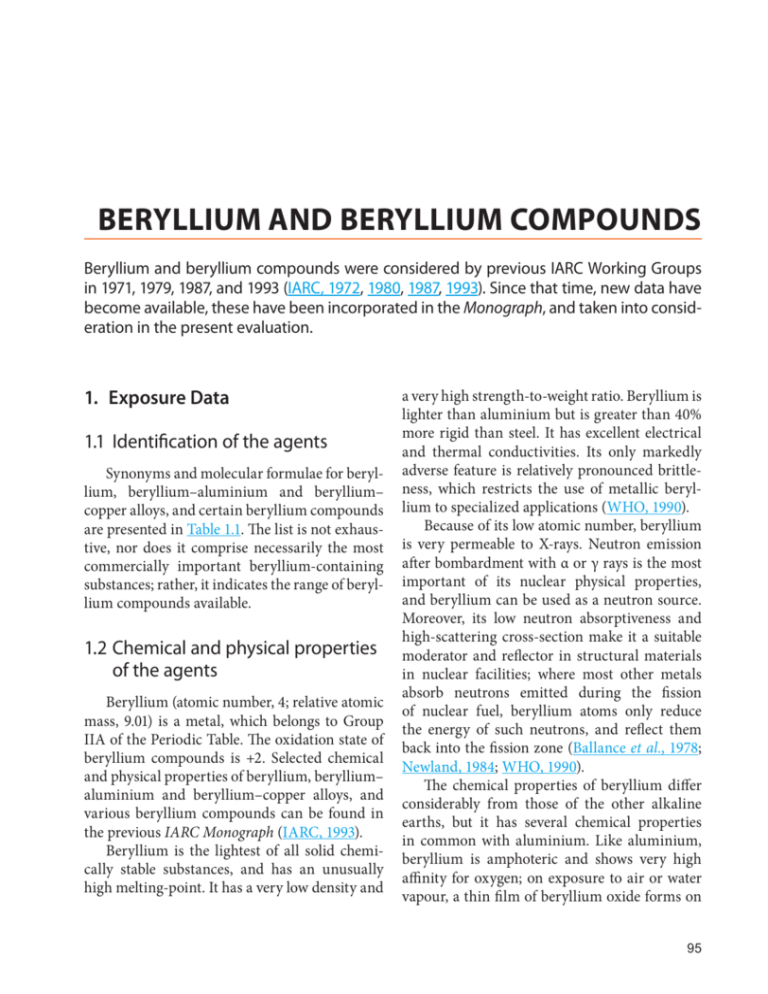

beryllium and beryllium compounds

advertisement