know your steel

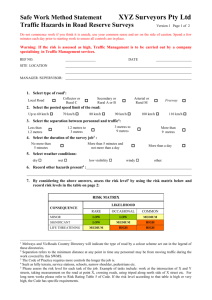

advertisement