SOLICITATION NO. FA4417-15-R-0027 - Green

advertisement

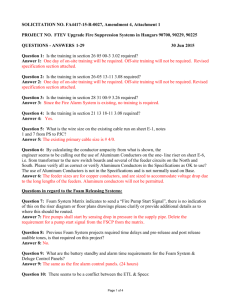

SOLICITATION NO. FA4417-15-R-0027, Amendment 3, Attachment 1 PROJECT NO. FTEV Upgrade Fire Suppression Systems in Hangars 90700, 90229, 90225 QUESTIONS - ANSWERS 1-28 25 Jun 2015 Question 1: Is the training in section 26 05 00-3 3.02 required? Answer 1: One day of on-site training will be required. Off-site training will not be required. Revised specification section attached. Question 2: Is the training in section 26-05 13-11 3.08 required? Answer 2: One day of on-site training will be required. Off-site training will not be required. Revised specification section attached. Question 3: Is the training in section 28 31 00-9 3.26 required? Answer 3: Since the Fire Alarm System is existing, no training is required. Question 4: Is the training in section 21 13 18-11 3.08 required? Answer 4: Yes. Question 5: What is the wire size on the existing cable run on sheet E-1, notes 1 and 7 from PS to PJC? Answer 5: The existing primary cable size is # 4/0. Question 6: By calculating the conductor ampacity from what is shown, the engineer seems to be calling out the use of Aluminum Conductors on the one- line riser on sheet E-6, i.e. from transformer to the new switch boards and several of the feeder circuits on the North and South. Please verify all as correct or verify Aluminum Conductors in the Specifications as OK to use? The use of Aluminum Conductors is not in the Specifications and is not normally used on Base. Answer 6: The feeder sizes are for copper conductors, and are sized to accommodate voltage drop due to the long lengths of the feeders. Aluminum conductors will not be permitted. Questions in regard to the Foam Releasing Systems: Question 7: Foam System Matrix indicates to send a “Fire Pump Start Signal”, there is no indication of this on the riser diagram or floor plans drawings please clarify or provide additional details as to where this should be routed. Answer 7: Fire pumps shall start by sensing drop in pressure in the supply pipe. Delete the requirement for a pump start signal from the FSCP from the matrix. Question 8: Previous Foam System projects required time delays and pre-release and post release audible tones, is that required on this project? Answer 8: No. Question 9: What are the battery standby and alarm time requirements for the Foam System & Deluge Control Panels? Answer 9: The same as the fire alarm control panels. (24 hours) Page 1 of 4 Question 10: There seems to be a conflict between the ETL & Specs: ETL 02-15 – A1.3.5.3.1 Connect low-level optical detectors to the FSCP. Arrange for alarm notification only; do not use optical detection to activate any fire suppression system. Spec Section 21 13 18: 2.13.E – “With the exception of a manual foam release station the cross-zoning of two optical flame detectors in the hangar bay is required to release the foam suppression system.” Which is correct? Answer 10: The specification is correct. (The ETL is being modified by AFCEC but the final version has not been published yet.) To clarify: The only two ways to release the foam are (1) two optical flame detectors sensing a flame OR (2) manual pull station. Question 11: 21 13 18: 2.12.B- “In certain situations a redundant foam suppression control panel may be needed, verify redundancy requirements with agency and mission.” Are redundant controls required? Answer 11: No. Question 12: 21 13 18: 2.13 – Systems Components Addressable Devices. It is my understanding that the devices (releasing stations, abort stations, heat detectors, etc) used with Det-Tronics EQP are not addressable devices with the exception of the optical flame detectors. They would be conventional devices connected individually back to an 8 point I/O module. I don’t believe paragraph A, B, C, & D would apply this system, is that acceptable? Answer 12: The Det-Tronics EQP is to be provided with the ASH module, which will allow for the addressable devices from Apollo to be installed. Question 13: 21 13 18: 2.15-A – Alarm/Strobes: “Provide blue beacons not less than 400cd (208/120VAC) powered from the FSCP.” 21 13 18: 2.15-B – “Each Horn and strobe shall be continuously supervised.” Typically visual notification appliance would be 24V DC powered and supervised from the FSCP. The FSCP cannot supervise an AC notification appliance. Please clarify this requirement? Answer 13: The appliances should be 24V D.C. Question 14: 21 13 18: 3.04.A.5 States all wiring for the system to be solid wires. – Det-Tronics uses and recommends stranded wiring. Will this be allowed? Answer 14: The stranded wire will be allowed for the Det-Tronics installation. Question 15: 21 13 18: 3.04.F – all address modules will be integrated with the device. The DetTronics EQP system does not use devices with integrated addressable modules except for optical fire detectors. They use an 8 Point I/O Controller, is this acceptable? Answer 15: Yes Question 16: 21 13 18: 3.04.D – All circuits shall be installed Class A. Will this apply to individual devices wired directly back to the 8 point I/O modules? Answer 16: Yes Question 17: Building 90029- Clam Shell Deluge System- Is the control panel for this system to be Page 2 of 4 the same as specified in Spec Section 21 13 18? Answer 17: Yes. Provide a Det-Tronics release panel for the Clam Shell system also. Question 18: Building 90029 - There is a Clamshell manual pull station detail (FP-10) and the device is show on the riser diagram, but I do not see it on the floor plan. Can you provide quantity and locations? Answer 18: The quantity is one. The pull station is shown on sheet FP-7, near note number 7, shown as a solid black rectangle. Question 19: Building 90029 - Does the Clamshell deluge system require audible or visual annunciation? Answer 19: Similar to the wet pipe sprinkler system – when the clam shell system is activated it sends a signal to the fire alarm control panel (as noted in the Sequence of Operation on sheet FP-12). This panel then sends out audible and visual annunciation. The clam shell system does not have its own annunciation. Question 20: Building 90225 - How high does the Class 1 Div. 1 atmosphere extend in the hangar? Answer 20: The entire hangar from floor to roof. Question 21: Ref: Mechanical - In building 90029, there are two sprinkler systems that are shut off and out of service. Are there existing problems with these systems that we need to incorporate into our pricing? Answer 21: The contractor shall be providing a new riser for all systems. The piping and heads to remain are functional. The contractor shall report any conditions that exist that preclude a complete and working fire protection system after the project is complete. Existing problems with the parts of the system to remain are not anticipated. Question 22: Ref: Mechanical - Specification section 02 41 19 Part 1 1.01 Summary #7 states, existing fire suppression system must remain active. Drawing G-1 Work Phasing Notes state, shut down hanger bay for 100 days. Can we shut the fire system off for the 100 day work schedule? Answer 22: Sheet G-1 is correct, the fire system can be shut down for 100 days. Specification section 02 41 19 is intended only for the portion of work in Hangar 90700 (Project FTEV 14-1057). Question 23: Ref: Mechanical - Specifications state to conform to UFC 3-600-01. Section 21 13 00 Part 2 Piping Materials “B” #1 states to use Galvanized pipe and fittings. UFC 3-600-01 Section 42.3.2 states Galvanized piping is not permitted for use in wet, dry or pre-action systems. Please clarify. Answer 23: Do not use galvanized piping. Question 24: Ref: Mechanical - Building 90029 FP-3 Upper Level Note #1 states that piping shall be cleaned and rinsed. Is this intended for the interior only or is it for both interior and exterior? Answer 24: Interior only. Question 25: Ref: Electrical - General note #1 on drawing E-2 states that circuit breakers, fuses, switchboard, panelboard, conduit bushings, LB fittings and conduit nipples are to be turned over to the electrical shop after demolition. Due to the sizes of some of the existing electrical gear they will need to be dismantled and possibly cut up so they can be removed. Please clarify that this is acceptable. Answer 25: The note requires that “switchboard and panelboard lugs” be turned over to the Government. The switchboards and panelboards will be removed from the site and disposed of by the Page 3 of 4 Contractor. Question 26: The 2012 IBC requires that Facilities within Site Class C through F, based on the Occupancy Category require “Seismic Restraint”. Are these Hangars located within one of these Site Classes? Answer 26: No. Question 27: The Contract Documents state there will be liquated damages for exceeding the shutdown period(s) of Hanger 90029 - 100 calendar days; Hanger 90700 - 30 calendar days; and Hanger 9025 100 calendar days. Can the Contractor perform any work inside the Hanger while aircraft and Government operations are also in the Hanger(s), prior to the shutdown(s)? Or, must all work within the hangar bay be completed during the shutdowns. For example, while the existing FA & FP systems are still in operation and the Government is utilizing the hangar, can the contractor install preliminary work (pipe, conduit, etc.) if such does not interfere with Government operations and such does not affect the existing FP and FA system integrity? Answer 27 As stated on the drawing cover sheet, the contractor can begin work on the hangars outside of the shutdown time periods that does not affect the hangar bays or impact the mission. The shutdown periods cannot begin until the contractor has all materials on-site. Work for Hangars 90029 and 90225, inside the hangar bays or work impacting the use of the hangars, cannot begin until the shutdown periods has started. Work for Hangar 90700 outside of the shutdown period can be accomplished with normal restrictions of operating in an active hangar bay. Question 28: In regards to the answer to Questions #1 and #2 there is no training on these items available that we know of, therefore the one day on-site training maybe impossible for the contractor to provide. At this time, we do not know of any one equipment manufacturer that will or has the capacity to do this training. And if there is such a thing please provide us at least 3-manufactures that can do this. Answer 28 Specifications have been updated to allow the contractor to provide the training using a manufacturer representative or an individual trained by the manufacturer. Page 4 of 4