SOLIDWORKS MOLD DESIGN

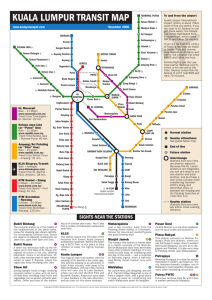

advertisement

(605704-H) SOLIDWORKS MOLD DESIGN Duration Time Methodology Target : : : : Prerequisite : Objective : 3 days 9:00am – 5:00pm Practical hands-on with using computers, lecturing, discussions and case studies Application Engineer R&D Engineer Product Designer or Engineer Industrial Engineer To ensure a consistent learning experience for all students, participants should have: • Mechanical Design Experience Experience with the Windows™ Operating System. • • Basic understanding of part design and drafting. • Attended both SolidWorks Essentials & Advanced Part Modeling. Mold Design course will discuss about the fundamental techniques for mold creation. This will include:• Using specific DRAFT and UNDERCUT detection tools to analyze plastic models Using a general workflow for core/cavity creation – parting line, shut-off surface, parting • surface and tooling splits. From the undercut detection, learn about creating side core, lifter and sub-inserts using • the core function. • Incorporate surfacing techniques to create advanced parting surface for complicated models. PETALING JAYA PENANG JOHOR 22A, Jalan PJS 1/46 68A, Jalan Perai Jaya 4 11-A, Jalan Jati 2, 46150 Petaling Jaya 13700 Prai Taman Nusa Bestari Jaya, Selangor Penang 79150, Johor Tel: + 60 3 – 7783 6866 Tel : + 60 4 – 399 5571 Tel: + 60 7 – 512 7978 Fax: + 60 3 – 7781 1185 Fax : + 60 4 – 399 5572 Fax: + 60 7 – 512 2162 1300-88-2797 | training@cadcam.com.my | www.cadcam.com.my (605704-H) Course Outline: Day 1 Lesson 1: Core and Cavity • Core and Cavity Mold Design • Case Study: A simple Two Plate Mold Design • SolidWorks Mold Tools • Mold Analysis Tools • Analyzing Draft on a Model • Draft Analysis Colors • Adding Draft • Scale the Part to Allow for Shrinkage • • • • • • • • Determine the Parting Lines Manual Selection of Parting Lines Automation Modeling the Parting Surface Smoothing the Parting Surface Surface Bodies Interlocking the Mold Tooling Creating the Mold Tooling Lesson 2: Multiple Parting Directions • Trapped Molding Areas • Side Cores • Lifters • Feature Freeze • • • • Core Pins Case Study: Electrode Design Electrode Clearances Keeping the Sharp Edges Lesson 3: Importing and Repairing Geometry • Beyond the Basics • Importing Data • 3D Model Types • • • • • • • • Why do Imports Fail? Diagnosis and Repair Case Study: Repairing and Editing imported Geometry Checking Solid Bodies Making Copies of Faces Case Study: Import Diagnostics Repairing Gaps Repairing Faces • • • • • Shut-Off Surfaces Parting Surfaces Tooling Split Seeing Inside the Mold Case Study: Splitting a Part • Interlock Surfaces • • Case Study: Mixer handle Case Study: Manual Parting Surface • • • • • • Definitions Case Study: Solids vs. Surfaces Terminology File Translator Modeling Systems File Translation Lesson 4: Parting Lines and Shut-Off Surfaces • Case Study: Mixer Base • Draft Analysis Options • Parting Line • Core and Cavity Surfaces Day 2 Lesson 5: Repairs and Surfaces • Case Study: Plastic Bezel of a Cordless Drill • Creating New Drafted Faces Lesson 6: Using Surfaces • Surfaces in Mold Making • Case Study: Router Bottom • The Mixer PETALING JAYA PENANG JOHOR 22A, Jalan PJS 1/46 68A, Jalan Perai Jaya 4 11-A, Jalan Jati 2, 46150 Petaling Jaya 13700 Prai Taman Nusa Bestari Jaya, Selangor Penang 79150, Johor Tel: + 60 3 – 7783 6866 Tel : + 60 4 – 399 5571 Tel: + 60 7 – 512 7978 Fax: + 60 3 – 7781 1185 Fax : + 60 4 – 399 5572 Fax: + 60 7 – 512 2162 1300-88-2797 | training@cadcam.com.my | www.cadcam.com.my (605704-H) Lesson 7: Reusable Data • Reusing Data • Design Library • Task Pane • 3D ContentCentral • Smarts Components Day 3 Lesson 8: Alternate Methods for Mold Design • Alternate Methods for Mold Design • Using Combine and Split • Creating a Cavity • Manually Creating Shut-off Surfaces Lesson 9: Making a Complete Mold • Case Study: Making A Complete Mold • Developing a Plan • Modeling Repairs • Mold Split Folders • Runners and Gates • Side Cores • Core Pins • Creating Individual Parts • • • • Library Features Creating a library Feature Configurations in Library Features Case Study: Water Line • • • Using Surfaces Using the Up To Surface Method Using the Split Method • • • • • • • Mold Base Organizing the Assembly Modifying the Lifters Ejector Pins Cooling the Drawing Making Changes Completing the Process PETALING JAYA PENANG JOHOR 22A, Jalan PJS 1/46 68A, Jalan Perai Jaya 4 11-A, Jalan Jati 2, 46150 Petaling Jaya 13700 Prai Taman Nusa Bestari Jaya, Selangor Penang 79150, Johor Tel: + 60 3 – 7783 6866 Tel : + 60 4 – 399 5571 Tel: + 60 7 – 512 7978 Fax: + 60 3 – 7781 1185 Fax : + 60 4 – 399 5572 Fax: + 60 7 – 512 2162 1300-88-2797 | training@cadcam.com.my | www.cadcam.com.my