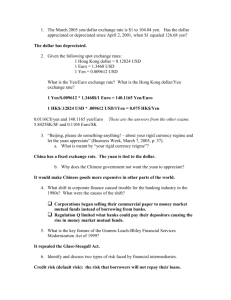

EXERCISE 5-26 (15 MINUTES) 1. Material

advertisement

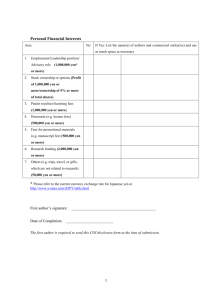

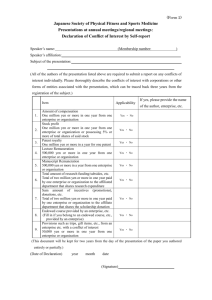

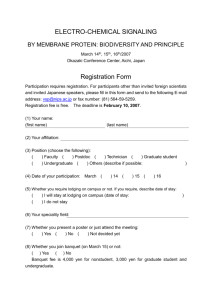

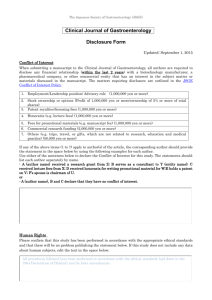

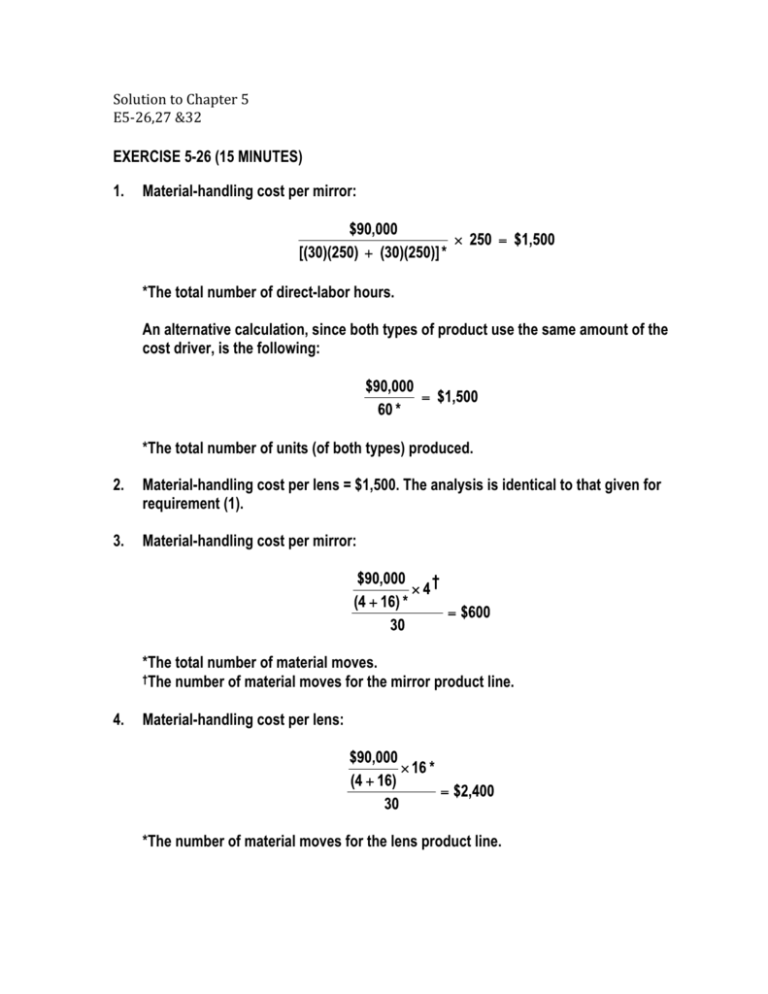

Solution to Chapter 5 E5‐26,27 &32 EXERCISE 5-26 (15 MINUTES) 1. Material-handling cost per mirror: *The total number of direct-labor hours. An alternative calculation, since both types of product use the same amount of the cost driver, is the following: *The total number of units (of both types) produced. 2. Material-handling cost per lens = $1,500. The analysis is identical to that given for requirement (1). 3. Material-handling cost per mirror: *The total number of material moves. †The number of material moves for the mirror product line. 4. Material-handling cost per lens: *The number of material moves for the lens product line. EXERCISE 5-27 (20 MINUTES) There is no single correct answer to this exercise. There are many reasonable solutions. Cost pool 1: Raw materials and components ...................................................................... Inspection ......................................................................................................... Total.................................................................................................................... 3,835,000 yen 39,000 yen 3,874,000 yen Cost driver: raw-material cost Cost pool 2: Depreciation, machinery................................................................................... Electricity, machinery ....................................................................................... Equipment maintenance, wages...................................................................... Equipment maintenance, parts........................................................................ Total.................................................................................................................... 1,820,000 yen 156,000 yen 195,000 yen 39,000 yen 2,210,000 yen Cost driver: number of units produced. Cost pool 3: Setup wages ...................................................................................................... Total.................................................................................................................... 52,000 yen 52,000 yen Cost driver: number of production runs. Cost pool 4: Engineering design........................................................................................... Total.................................................................................................................... Cost driver: number of parts in a product. 793,000 yen 793,000 yen EXERCISE 5-27 (CONTINUED) Cost pool 5: Depreciation, plant............................................................................................ Insurance, plant................................................................................................. Electricity, light ................................................................................................. Custodial wages, plant ..................................................................................... Property taxes ................................................................................................... Natural gas, heating.......................................................................................... Total.................................................................................................................... 910,000 yen 780,000 yen 78,000 yen 52,000 yen 156,000 yen 39,000 yen 2,015,000 yen Cost driver: for costs allocated to support departments, square footage; for costs assigned to products, number of units produced. EXERCISE 5-32 (20 MINUTES) The activities of the Seneca Falls Winery may be classified as follows: U: Unit-level B: Batch-level P: Product-sustaining-level F: Facility-level EXERCISE 5-32 (CONTINUED) Activity (1) (2) (3) (4) (5) (6) (7) (8) (9) (10) Classification P P P P P P P B B B Activity (11) (12) (13) (14) (15) (16) (17) (18) (19) Classification B B U U U U B F F