The End of the Pencil, The End of Mathematics?

advertisement

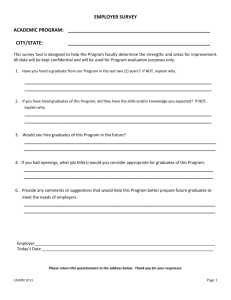

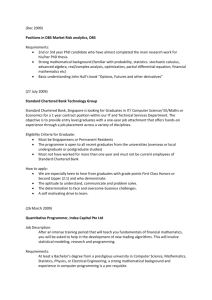

Engineering Design in the 21st Century The end of mathematics? The end of the pencil? JWH Price, Mechanical Engineering Department 1 Comment on current courses One of the comments by employers is that graduates are not employment ready – significant additional training is required. Wouldn't it be nice to think our graduates were so advanced that they could bring new ideas to the employers. Engineering design is one area where our graduates could run ahead, but … John Price, Mechanical Engineering 2 Current text books The two dominant text books in Mechanical Engineering are RC Juvinall and KM Marshek, Fundamentals of machine component design, John Wiley, New York, 3rd edition, 2003 and JE Shigley, CR Mischke, RG Budynas, Mechanical engineering design, 7th ed., McGrawHill, New York, 2004 These may be the only texts that students buy on this subject during their degree John Price, Mechanical Engineering 3 The nature of these books Basically the books comprise: First half: Design against failure Materials, stresses, deflections, various failure criteria. Second half: Mechanical elements Joining methods, springs, gears etc. John Price, Mechanical Engineering 4 How do they compare to professional practice? The books are very introductory The methods are 50 years old They are basically metallic and heavy industry in orientation No significant discussion of computation methods No introduction to Standards John Price, Mechanical Engineering 5 21st Century Industrial practice Large interdisciplinary teams Digital collaboration tools Design conducted in virtual space Uses ready-made designs or suppliers designs. Prior art is normally available. Large scale analysis tools involved Major verification activities required John Price, Mechanical Engineering 6 Dominance of nontraditional drivers Financial drivers Style and Market drivers Manufacturing supply chain and assembly visualisation Project visualisation Prudential and legal conformance John Price, Mechanical Engineering 7 How can our degrees respond? In Levels 3 and 4 try to create more realistic design environments Take the emphasis off fundamentals and move to rapid design approaches Develop multidisciplinary design subjects Integrate Analysis and Collaboration tools into the subject. John Price, Mechanical Engineering 8 Verification as a key issue Anecdotal evidence an author’s experience indicates that the reliability of engineer’s mathematics has not improved by using complex analysis tools. There is a risk associated with producing beautiful pictures – they look good but may be wrong. Thus There is still a need to understand the fundamentals Engagement with the physical world is becoming a major issue. These things must be part of a design based degree John Price, Mechanical Engineering 9 How much do we need to teach the basics? Do graduates need to know the mathematics behind the programs? Do they need to be able to operate with a pencil? Or should we rush over these to get to the employer’s gold – graduates who produce value from day 1. John Price, Mechanical Engineering 10 What are the answers? With the pencil: perhaps we get rid of it. Drawings are becoming a thing of the past; for little workshops. With the mathematics: Perhaps for some streams of students the courses can be changed. The time can be better used in going for real design simulation and verification approaches. John Price, Mechanical Engineering 11 Design in the degree. Design and in particular digital design techniques, are a major interest of students. The students run ahead of the lecturers in these subjects, they even know more than the lecturers. (This is virtually unknown in other subjects). Very important to tie back to the physical world – real failure, real manufacturing – but resources for this are expensive. Need to emphasize verification and not focus on the pictures and bright reports. Probably the best preparation for employment. John Price, Mechanical Engineering 12 Taking these ideas seriously Create an elective degree: at least one year of the degree would be spent on design Making and testing prototypes would be required Very free access to collaboration, 3D modeling, manufacturing and analysis software would be essential John Price, Mechanical Engineering 13 Unfortunately, Assessment Multidisciplinary groups working with companies are a very nice way to go If we use such groups there are issues of assessment Individual assessment by exam produces the issue of how design can be done without free access to information. John Price, Mechanical Engineering 14