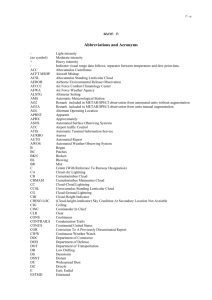

chapter seven — design standards for licensed aerodromes

advertisement