PROVINCIAL PLAN OF TRAINING FOR THE BOOM TRUCK

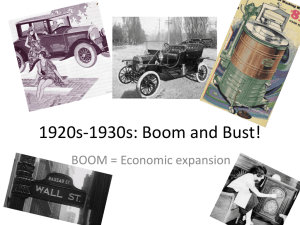

advertisement