Detailed Work Plan & Activity Schedule of BJRI

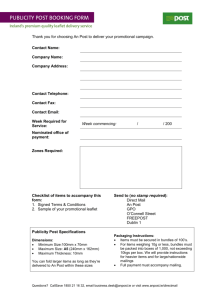

advertisement