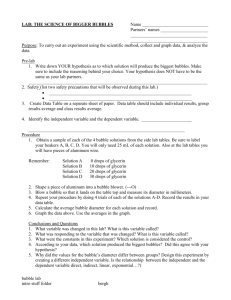

experimental study of a bubbling fluidized bed with a rotating

advertisement