May 2009 - ICW Group

advertisement

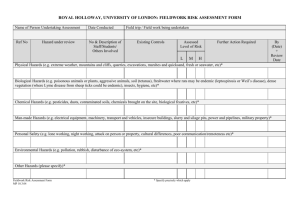

Risk Management May 2009 Newsletter The Color of Safety Creating Safety Awareness with Color In today’s work environment there are diverse cultures and multiple languages spoken. It is truly a challenge to reinforce the importance of safety with every employee. However, one universal constant has the ability to reach every employee without speaking a single word—“Color”. This article will discuss how colors can be used to educate employees in safety awareness and help prevent workplace accidents. Countless studies have shown that colors have the ability to invoke a variety of moods. Light colors, such as off whites and pastels, make objects seem lighter in weight, areas seem more spacious, and, usually, will give people a psychological lift. You may have heard how the prison industry painted cells pink to calm inmates or how some college sports teams painted the locker rooms of the visiting teams to invoke a sense of weakness. Ancient cultures used colors to heal: red to increase circulation, blue to soothe illness and treat pain, and orange to increase energy levels. Federal OSHA developed and adopted standard colors for manufacturing facilities and machinery that provide a “Universal Language” to all workers. The American National Standards Institute (ANSI) also developed standards for color and meaning (ANSI Z545.1. Color Codes.) These standards have been adopted and promoted by the Occupational Safety and Health Administration (OSHA) to protect workers. The Color Coding chart indicates how each color can be used to warn workers of hazardous machinery parts, signify the nature of hazards, and designate the location of safety equipment and first aid supplies. OSHA SAFETY COLOR CODES * American National Standard Z53.1 Safety Code for Marking Physical Hazards and the Identification of Certain Equipment Fire: Protection equipment and apparatus, including fire-alarm, fire blanket boxes, fire extinguishers and fire pumps. Danger: Safety cans or other portable containers of flammable Liquids, stop buttons and emergency stop bars on hazardous machines. Identifies fire protection, danger and emergency stops. Dangerous equipment: Parts of machines and equipment that may cut, crush, shock, or otherwise injure. Highlights dangerous parts of machinery or energized equipment. Caution: Physical hazards such as stumbling, falling, tripping, striking against, and being caught in between. Marks hazards that may result in accidents from slipping, falling or striking against. Flammable liquid storage cabinets - Material handling equipment such as Fork lifts and gantry cranes. Safety; First-Aid equipment. Designates the location of First Aid or safety equipment such as emergency respirators. Used for informational signs and bulletin boards. Warning: Caution limited to warning against starting, using, or moving equipment under repair. Warning: Caution limited to warning against starting, using, or moving equipment under repair. Boundaries of traffic aisles, stairways (risers, direction, and border limit lines.) And directional signs. Used in combination as stripes or checks for traffic markings. Radiation: X Ray, alpha, beta, gamma, neutron, proton radiation. N/A Regulations (Standards - 29 CFR) Safety color code for marking physical hazards. - 1910.144 * The ANSI Z535 Series provides the specifications and requirements to establish uniformity of safety color coding, environmental / facility safety signs and communicating safety symbols. It also enables the design, application, use and placement of product safety signs, labels, safety tags and barricade tape. www.icwgroup.com | 800.877.1111 “We see strong client relationships being built on trusted advice. ” — Kevin Prior, CEO Orange, for example, warns workers of dangerous parts of machinery or energized equipment which may cut, crush, or otherwise injure the worker. Pulleys, gears, rollers, cutting devices, and exposed edges of equipment are often painted orange. Red carries multiple designations but generally warns of extreme hazards. For example, red means “Danger” and “Stop.” Red is the standard color for emergency stop buttons, bars, and electrical equipment. Red also designates the location of fire protection equipment and apparatus such as fire alarm boxes, fire extinguishers, and industrial fire hydrants. In addition, red is the standard color for safety cans and other portable containers of flammable liquids. Yellow identifies physical hazards such as stumbling, falling, tripping, striking against, and being caught in between. Often safety railings, catwalks, forklifts and changes in elevation are marked in yellow. The benefit of standardizing color codes is to provide uniform training, especially for workers that move from one job to another. Using color also eliminates the need for excessive written descriptions and signs that may actually create new safety problems. Color is the universal language of safety, bypassing cultural differences and language barriers, with a silent warning. The next time you walk through your facility or visit other sites, look for Colors, they will teach you about safety without whispering a word. More information on color coding for safety is available at: http://www.engineeringtoolbox.com/safety-signals-d_359.html http://www.efuse.com/Design/colorful1.html http://www.uhh.hawaii.edu/academics/hohonu/writing.php?id=73 http://agsafety.tamu.edu/THE%20COLOR%20OF%20SAFETY.pdf Special thanks to Kendra Van Wagner and Texas A&M University System for their articles, as well as the American National Standards Institutes schedule of safety colors marking physical hazards. www.icwgroup.com | 800.877.1111 Risk Management May 2009 Newsletter