february 5-11, 2016 | the rio las vegas - SeminarFest

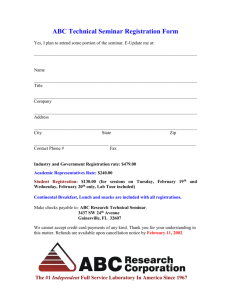

advertisement