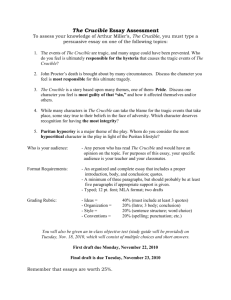

stationary and tilting crucible melting furnaces

advertisement

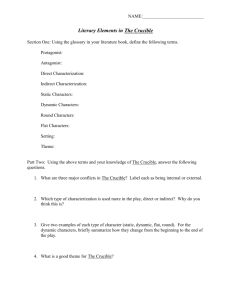

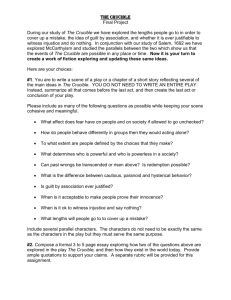

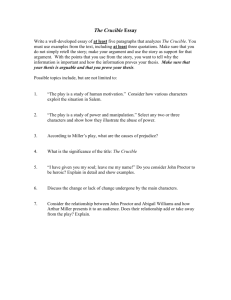

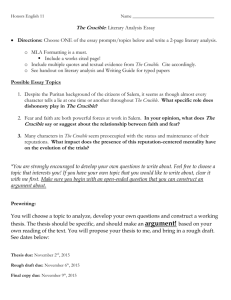

m STATIONARY AND TILTING CRUCIBLE MELTING FURNACES For Aluminum, Brass, Bronze, Copper, Gold, Monel Metal, Nickel, Silver and other Non-Ferrous Metals Oil or Gas Fuel O R melting brass and other nonferrous metals in crucibles, with oil or gas fuel, w e manufacture three different sizes of Stationary Crucible Furnaces and four different sizes of Tilting Crucible Furnaces as listed on page 4. v In the operation of these furnaces the most important requirement to be met is, of course, the production of properly melted metal. O f hardly less importance is the operating cost, which is low because of the long life of crucible and furnace lining and the economy of fuel. T h e furnaces are designed to afford ample room for combustion Fig. 2. BATTERY OF STATIONARY CRUCIBLE MELTING FURNACES Grating over firing pit removed to show the arrangement of burners and piping. The flue is in the rear of the furnaces and the chimney outside of building. around the base of the crucible, which assures good melting with hot metal at the bottom and without blast on the crucible. Fig. 1. STATIONARY CRUCIBLE MELTING FURNACE The stationary furnace, Fig. 1, is of a construction similar to the ordinary coal or coke-fired crucible furnace. T h e furnace body consists of a steel shell with cast iron top and bottom plates, steel angles on the corners, and is lined with standardfirebrick and tiles. T h e crucible chamber is covered with one large and one small circular tile, each having a steel band around the outside and a hole through the center. T h e small tile also has a bale for easy removal, so that additions m a y be m a d e and stirring conducted through the hole in the large tile without opening up the entire chamber. W h e n the charge is ready to pour, both tiles m a y be s w u n g to one side by an easy movement of the lever. A tap hole is proCopynghted 1922 . s. ROCKWELL C< May, 1922 No. 243 vided on the front for the removal of any metal that m a y be spilled in the furnace. T h e burner is also located on the front within easy reach of the melter. None of the ironwork is exposed to injurious heat. The vent opening is on the back. If the furnaces are set in a pit. the spent gases m a y be carried to a chimney as in the usual practice with coal and coke furnaces (see Figs. 2, 3 and 4 ) . If operated in single units, the furnaces m a y be placed above OIL MAIN [ ((• ) / * ^ MRIN floor and vented through the cover tiles without connection to chimney j see Fig. 1). SIDE ELEVATION OF B A T T E R Y O S T A T I O N A R Y MELTING F U R N A C E 5 . T h e operation of the furnace is not depend- Fig. 3 ent upon chimney draft and is in no w a y influenced by wind or weather. covered without loss. There are no ashes to deal with. Repairs may be easily and quickly made in the same manner as for coal or coke Furnaces for larger crucibles can be built furnaces. to order. fllR c Standard crucibles are used—sizes from 20 to 100, according to size of furnace (see table on page 41. T h e crucible is lifted out to pour, the same as from a coal or coke furnace, and there is no transfer of metal to a ladle or other crucible to convey to the mould, as from a tilting furnace. If a crucible should break and the metal run into the chamber, it m a y be tapped out and re- T h e tilting crucible furnace is m a d e in single and double-chamber forms, Figs. 5 to 10, the former for 200 and 400 pound crucibles and the latter for 800 and 1600 pound crucibles. Each type consists of an elliptical steel shell with cast iron top and bottom plates. FLOOR LINE LONGITUDINAL ELEVATION A N D 5ECTION OF B A T T E R Y OF STATIONARY MELTING Fig. 4 FURNACES Fig. 5. SINGLE C H A M B E R TILTING CRUCIBLE MELTING F U R N A C E Fig. 6. D O U B L E C H A M B E R TILTING CRUCIBLE MELTING F U R N A C E The lining is made up entirely offiretiles. laid up in inner and outer courses, so that only the inner course need be renewed when burned out and the outer courses left undisturbed. The single-chamber furnace is provided with one burner, the double-chamber furnace with two burners, placed at the top and discharging downward toward the bottom of the furnace, producing ample heat at this point. The spent gases pass upward around the crucible and are vented at the top through the cover tile. A hood m a y be placed above the furnace to carry the spent gases out of the building. The cover tilts with the furnace and remains in place while pouring (see Fig. 6), thus protecting the metal and the melter. It m a y be lifted, for charging, by the hand lever as shown in Fig. 9. Thefirealso may be continued while pouring, if desired. All or any part of the charge may be poured or held without chilling. The crucible need not be removed from the furnace during its lifetime. Cold air cannot reach it at any time. There is no blast against the crucible and the heat at the bottom is ample. Any metal spilled in the furnace may be poured from the tap hole in the back without loss. fc r^JEI iu i Fig. 7. ELEVATION OF SINGLE C H A M B E R FURNACE IN CROSS SECTION—SIZES NOS. 1 A N D 2 Fig. 8. PLAN OF SINGLE CHAMBER FURNACE IN CROSS SECTIONSIZES NOS. 1 A N D 2 CARNEGIE LIBRARY C N&NfSj *y 3 1812 04050 8484 Fig. 10. PLAN OF DOUBLE CHAMBER FURNACE IN CROSS SECTIONSIZES NOS. 3 A N D 4 Fig. 9. ELEVATION OF DOUBLE CHAMBER FURNACE IN CROSS SECTION-SIZES NOS. 3 A N D 4 STANDARD SIZES OF STATIONARY AND TILTING CRUCIBLE MELTING FURNACES TILTING STATIONARY Furnace Number ., 67 'Standard crucible number .. . Diam. of crucible at top, inside, inches. 68 20 to 40 1 69 50 to 70 2 3 4 80 to 100 8 10 12'.L16 200 400 800 1600 Floor space, inches 34x68 36x70 42x90 44x94 Air pipe connection, inches 2', 3 4 4 i, \/ i., i^ Oil pipe connection at burner, inches f" t t t Oil consumption per 1110 pounds metal .... 8 to 16 8 to 16 8to 16 8 to 16 8 to 16 8 to 16 8 to 16 Air pressure required at burner, ounces 120 175 250 200 300 400 600 Air volume required, cubic feet per minute . 2230 2510 3350 2900 3400 5500 5700 Weight lined complete, pounds 800 900 1050 Shipped lined complete Weight of all ironwork only, pounds 22 27 30 52 56 76 78 Shipping space, cubic feet Marlev Marvel Martyr M a c a w Mallet Mango Marrow Code word for larger crucibles can be built to order. *Furnaces Oil pressure M U S T be uniform—5 pounds per square inch or over will do. iOil required to melt 10H pounds of metal will vary according to kind of metal and the attention and promptness 1 Mth which it is melted i poured. For ordinary brass mixtures from 2 to 5 gallons is a fair average. •Air pressure as well as oil or gas pressure must be uniform. State available pressures of each with order. If gas is used, state kind and at what pressure. Seven gallons of oil equal 1000 cubic feet of natural gas. Five gallons of oil equal 1000 cubic feet of city gas. 60 to 120 37x28 2 150 to 210 40x32 2V6 240 to 300 45x36 2K "FURNACE AND FUEL TO SUIT CONDITIONS"— is our rule governing consideration of new or improvement of existing industrial heating equipment to suit your needs under your plant conditions. We make inspection of plant, devise methods of heating and handling material, furnish complete industrial heating equipment adapted to your particular plant conditions, and guarantee results, using coal, oil, gas or electricity, as your best interests require. W. S. ROCKWELL COMPANY Furnace Engineers and Contractors 50 CHURCH STREET NEW YORK (Hudson Terminal Bldg.) Works: Newark, N. J. Branches: Chicago Cleveland Detroit Ellsworth Bldg. British Representative: No.'243 Engineers' Bldg. G I B B O N S BROS., Ltd. , 4 Majestic Bldg. Dudley, W o r e , England