e-Learning Solutions

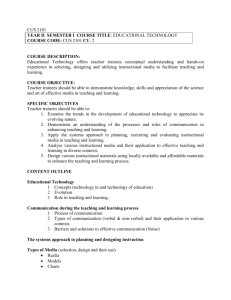

advertisement