Advanced Repetitive Scheduling

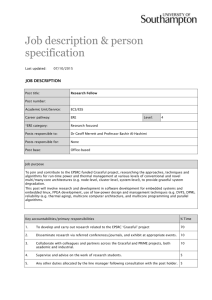

advertisement