Soft Contact Lens - Faculty & Research

advertisement

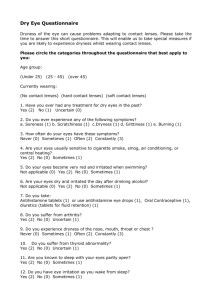

EIS – Final Project, Fall 2009 Soft Contact Lens Seeing a brighter future Dane Callow Javier Garcia Teruel Ziv Gelfer Brandon Lee Yoko Warita Yaron Zimmerman Soft Contact Lens – Seeing a brighter future 1 EIS – Final Project, Fall 2009 Contents 1 Introduction ........................................................................................................................................... 3 2 Vision Correction Market ..................................................................................................................... 3 2.1 Eye Glasses ................................................................................................................................... 4 2.2 Contact Lens ................................................................................................................................. 5 2.2.1 Hard contact lens................................................................................................................... 6 2.2.2 Soft Contact Lens .................................................................................................................. 7 2.3 3 Contact Lens Timeline .................................................................................................................. 8 Acuvue ................................................................................................................................................ 10 3.1 Positioning in 1986 ..................................................................................................................... 10 3.2 Value Creation & Value Capture ................................................................................................ 11 3.3 Innovation, Marketing & Supply Chain Strategy ....................................................................... 13 3.3.1 Innovation ........................................................................................................................... 13 3.3.2 Sales & Marketing ............................................................................................................... 14 3.3.3 Manufacturing and Distribution ......................................................................................... 16 3.4 Positioning in 1995 ..................................................................................................................... 17 4 Summary ............................................................................................................................................. 20 5 Contact Lens future and potential ECO systems................................................................................. 21 Soft Contact Lens – Seeing a brighter future 2 EIS – Final Project, Fall 2009 1 Introduction Refractive errors of the eye have existed since the dawn of humanity. Whereas back in the early days it was not a problem spotting a mammoth even if you were short sighted, in the modern world there has always been a demand for corrective eye techniques. Wearable eye glasses were invented in the 13th century and are widely used up to this day. Attempts to develop contact lens started as early as the 17th century which at that time was more a concept than a plausible product, most of the original ideas at that time evolved around using sclera lenses. Only in 1949 the first corneal lenses appeared. During the 1960‟s contact lens (PMMA) were widely used for the first time, however they had many disadvantages. With the development of technology and materials science during the 80‟s and 90‟s contact lens have started to become a more and more appealing substitute for glasses. Our analysis focuses mainly on Acuavue – a brand of Johnson & Jonson which was first introduced in 1986. We start with a general introduction to the vision correction market and then look more closely at the soft contact lens and disposable contact lens markets (today all soft lens are also disposable) and finally concentrate on how the technology of disposable contact lens was introduced to the market by Acuvue. 2 Vision Correction Market According to a patient population study done in 1994, approximately 146 million people in the United States required vision correction eyewear; we can assume that this number has increased in the last 15 years due to the increased aging population versus mortality rates. If you were one of these 146 million people you had two options available to correct your vision; eyeglasses or contact lenses. There are additional choices within each of these branches; however, this decision was the first to confront. Soft Contact Lens – Seeing a brighter future 3 EIS – Final Project, Fall 2009 2.1 Eye Glasses Eyeglasses are shaped lenses that are placed inside frames that fit onto your face, a short distance from the eyes, and designed to correct specific vision problems the wearer may have. When eyeglasses were introduced they were made from quarts and beryl, they were then made from glass and currently more than 80% are made from various types of lightweight plastic. Eyeglasses represented a valid vision choice for individuals who cannot afford other options, have biological aversions to contacts or just enjoy the fashion statement. Eyeglass lenses are produced from a piece of material with a prefabricated curve on the front side. The material is shaped like a slightly curved hockey puck and referred to as a “blank”. The blank is then placed into a machine that will gradually shave off material from the back, until the curvature of the blank matches the patient‟s prescription. The thickness and contour of the blank will vary depending on the specific prescription. The degree of the convexity or concavity will determine the overall optical strength. The lens is then ground, polished and coated in order to more accurately match the specific prescription. The lens is then placed into a machine in order to determine where the exact optical center is located. The lens is then beveled and ground around the periphery in order to match the shape and size of the chosen frame. The goal, once the lens has been inserted, is to have the optical center fall directly over the user‟s pupil, if done incorrectly visual distortion can occur. If specific coatings or tints are necessary the lens can be dipped before they are added to the frame. The eyeglass production market is very small, as of 2007 the average annual revenue of eyeglass producers was $6.6mm, with 81% of the market realizing under $1.0mm of revenue a year. The barriers to entry into the eyeglass production market are very low, and there are very little proprietary advantages to be had. For example, the optical manufacturing center at Airway Soft Contact Lens – Seeing a brighter future 4 EIS – Final Project, Fall 2009 Heights Correctional Center produces 300 pairs of eyeglasses per day. This is a heavily saturated market, with very little growth potential. 2.2 Contact Lens The contact lens is similar to the eyeglass lens in that it was designed to correct the vision of the wearer; however, this is where the similarities end. A contact is a thin piece of plastic that floats on a fine layer of tears directly over the wearer‟s cornea. Many people prefer contact lenses over eyeglasses for a number of reasons, eyeglasses provide poor peripheral vision, they could be uncomfortable on your face, and can be difficult to wear during activities. Early contact lenses, produced in the first half of the 1900‟s, were uncomfortable and often involved making a polymer cast of each users own eyeball, which became a large deterrent. However, the production process continued to evolve and today customers can choose between three types of lenses: hard, soft and gas-permeable. The initial forming of contact lenses can be completed using one of two methods, cutting a blank on a lathe, or through a molding process. Injection molding consists of injecting molten plastic into a specific mold under pressure. Then the lens is removed from the mold, cooled and finished on a lathe. Though, it has recently become possible through highly automated, computer controlled mold production, to produce a consumer ready lens without the need of a lathe. The initial forming of the lens can also be done by cutting on a lathe. Similar to eyeglass production, a blank is needed, however, a contact blank is only slightly larger than the size of the finished lens. The blank can be shaved from a plastic rod, or stamped from sheet plastic. The blank is centered on a spinning lathe, and a diamond or a laser cutter, makes concave cuts in the blank to form the inner curves. The blank is then moved to a separate machine where it is ground and polished. The polished lens is then mounted on a steel shaft called an arbor. The arbor is Soft Contact Lens – Seeing a brighter future 5 EIS – Final Project, Fall 2009 installed in a lathe, and the outer cuts of the lens are made, ground, and polished. The final curves to be added to the lens are the peripheral and intermediate anterior and posterior curves, which determine the edge shape of the lens. Quality control is very important for contact lenses, since they are medical devices and they must be custom fit. The lenses are inspected after each stage of the manufacturing process. The lenses are examined under magnification for anomalies. They are also measured by means of a shadow graph. A magnified shadow of the lens is cast on a screen imprinted with a graph for measuring diameter and curvature. Any errors in the lens shape show up in the shadow. This process may be automatically performed by computer. The lenses are inspected for quality after every stage of manufacturing. They are then measured and inspected one last time by computer. Once the lens has passed inspection it is sterilized. The lenses are then packaged along with a saline solution. Soft contacts are packed dry but will soaks up the saline solution, become soft, pliable and ready to wear. 2.2.1 Hard contact lens Modern hard contact lenses, when introduced, represented a huge advantage over the tradition eyeglasses. They are made from a variant of polymethyl methacrylate (PMMA), provide clear vision and have the ability to last up to 10 years. PMMA contact lenses tended to be uncomfortable because they allowed minimal air passage into the eye. Hard contacts were originally designed to move slightly during each blink in order to allow more oxygenation to the eye, however, more blinking was necessary to reach the ideal lubrication. Although there are still people who choose to wear PMMA contact lenses, most eye care physicians consider them to be obsolete. One contributor to the retirement of the PMMA lens is the next generation hard contact lens, the gas permeable lens. Gas Permeable (GP) lenses are a Soft Contact Lens – Seeing a brighter future 6 EIS – Final Project, Fall 2009 newer technology than soft lenses and are made from silicone, which makes them more flexible than standard hard contacts. The silicone also allows oxygen to pass through the lens, resulting in a more comfortable fit, and ultimately healthier eyes. GP lenses fitted precisely to the user‟s cornea and are rigid so have the ability to provide crisper vision because they retain their shape better than soft contacts do. They are also more durable than soft lenses, which can tear easily. Since soft contact lenses are made with a different polymer than PMMA they can more easily soak up liquids, which is great for packaging but may cause eye irritation if they absorb soap, lotion or other harsh chemicals from your hands when inserting them. In addition, GP contact lenses can correct a wider range of problems than can soft contact lenses because they can be individually manufactured. 2.2.2 Soft Contact Lens Soft contact lenses are called soft because they have the ability to absorb liquids. The water content of a soft contact lens at full saturation can vary from 37 to 80 percent. This is important because soft contacts that can attain higher concentration levels can stay in the eye comfortably longer and are usually marketed as “extended wear” lenses. Soft contact lenses are made of hydroxyethyl methacrylate (pHEMA) which allows them to soak up water and still retain shape and optic functions. For many years soft contact lenses were considered a significant innovation in contact lens technology. Soft contacts are smaller and thinner than hard contacts, and provided clear vision to the people who found hard contacts too uncomfortable to wear. Soft contacts don‟t take as long to become comfortable as the new GP lenses, which require an extended period of time for the eyes to adjust to them. Because of this soft contact lenses also allow for more flexible wear. A user can easily switch between contacts and eyeglasses without hindering the adjustment time. Concordantly, a person wearing GP lenses who decides to wear Soft Contact Lens – Seeing a brighter future 7 EIS – Final Project, Fall 2009 prescription eyeglasses for a period of time may lose their acclimatization to the use of the rigid contact lenses. Therefore, in order for GP users to maintain a stable level of comfort they will need to use their contacts for an extended period of time, every day. Similar to daily medication options, some consumers may not appreciate having to take an all or nothing approach to contacts. But, soft contacts come in disposable varieties, which need zero maintenance, cleaning or nightly packaging. They are worn, removed and thrown away. The science of lens material is always being updated by lens manufacturers, and the specific material of any contact lens may differ depending on the maker. 2.3 Contact Lens Timeline 1986 - Acuvue introduced 1802-1948 1802 1948 1961 1980 1999 1999 Today Early Development Corneal Lenses Soft Lenses Disposable Lens Soft Contact Lens – Seeing a brighter future 8 EIS – Final Project, Fall 2009 Early developments of contact lens begun at the 19th century, those lenses were more of a concept than a plausible product. The first corneal lenses appeared in 1948 but only during the 60‟s soft contact lens were used more broadly. The number of people wearing contact lens increased from 1.8 million people in 1966 to 7 million in 1977. During the 80‟s there have been several technological breakthroughs in manufacturing and material technology which improved significantly the quality of soft lenses. With this improvement, 65-75% of the people wearing contact lens were estimated to be using soft lens in 1987, from 45% in 1978. . Soft Contact Lens – Seeing a brighter future 9 EIS – Final Project, Fall 2009 3 Acuvue The development of Acuvue begun at Frontier Contact Lens Company, a small business that begun in the 50‟s. In 1981 the company was sold to J&J and the name of the company was changed to Vistakon. Using Stabilized Soft Molding (SSM) technology Vistakon revamped its production practices, and as a result, Acuvue was launched in 1986. 3.1 Positioning in 1986 The first disposable contact lenses were introduced in 1982 in Denmark by Danalens. However in 1986 there were not many disposable lenses available and the quality of contact lens was not good enough to impose a real threat to more traditional eye vision correction techniques. However due to technological advancement (SSM technology) J&J saw a great opportunity in this market and introduced for the first time the Acuvue brand in 1986 (extended wear – 1 week contact lens). The main forces influencing Acuvue were: Entry barrier - FDA approval needed Suppliers - Porous liquid-absorbing plastic Competition Bausch Lamb Danalens Pilkington Customers - ECPs - Distributers - Consumers needing vision correction Alternatives - Eyeglasses - Hard/soft long term contact lens Soft Contact Lens – Seeing a brighter future 10 EIS – Final Project, Fall 2009 SWOT analysis Strength Opportunity - New Advanced Technology - J&J Brand - New disposable contact lens are attractive substitute for „permanent‟ contact lens and glasses - One of first movers to this market Weakness Threats - Not experienced in this market - New technology, exist for a short time - Bausch & Lomb The launch of the soft contact lens in 1986 was the first shot of J&J at disposable contact lens market. 3.2 Value Creation & Value Capture The convenience of disposability was attracted by patients who experienced heavy deposits on lens or a dry eye condition with conventional soft lenses. Although eye care professionals recommended that conventional lenses be cleaned and replaced in the prescribed schedule, customers often did not comply with the prescription of their eye care professionals. Without the daily cleaning and the more intensive weekly cleaning of conventional lenses, it could result in protein deposits on the lenses, and dry and uncomfortable eye condition. However, disposable lenses ensured comfort, convenience and visual acuity without cleaning. The disable lenses were particularly appealing to patients who had previously worn contact lenses but stopped. According to a study of 117 million households who wore eyeglasses in 1994, 13% (15.5 million) were people who had previously experienced contact lenses related illness and switched from contact lenses to eyeglasses. The benefits generated by disposable lenses would be prominent to patients who had previously become discontented with other type of soft lenses. In additional, J&J‟s “pennies a day” strategy was appealing especially part-time wearers who wore their soft lenses less than five days per week. Although 1-Day Acuvue‟s annual cost to the Soft Contact Lens – Seeing a brighter future 11 EIS – Final Project, Fall 2009 consumer was way more than that of eyeglasses or conventional contacts, the daily cost of using 1 Day Acuvue was approximately $1.67 per day. The inexpensive daily cost to customers was particularly appealing to part-time wearers. According to a study of 21 million households who wore soft lenses, approximately 19% (3.9 million) were part-time wearers. Customer Cost of Vision Correction Products Exam Fitting Product Material Total Annual Modality fee fee Cost cost Expense Eyeglasses $50 $37.50 $110-150 n/a $190.00 n/a Conventional Contacts $50 $37.50 $40 $150 $317.50 9 – 18 mos. Acuvue $50 $37.50 $4.5 n/a $551.50 1 week 1 Day Acuvue $50 $37.50 0.83 n/a $690.50 Daily Lastly, the characteristics of Acuvue were creating a unique value to eye care professionals who would have a significant influence to patients‟ purchasing decision. Disposable lenses encouraged patients to visit eye care professional more frequently. Otherwise, the patients did not return until the lenses were damaged or lost or until there was a health problem. On average, users of disposable lenses purchased a supply every three months and visited eye care professional for eye exams and more lenses. Still, compliance to the prescription remained an issue; however Acuvue, disposal lenses, would promote more frequent patients‟ visit to them. Soft Contact Lens – Seeing a brighter future 12 EIS – Final Project, Fall 2009 3.3 Innovation, Marketing & Supply Chain Strategy 3.3.1 Innovation The strategy of Vistakon and Acuvue as a brand has been based on innovation and quality in both products, and processes. From 1989 to 1993 marketing and distribution costs, which represented 65% to 70% of sales, were halved and Vistakon actively managed costs, however funding for research and development remained constant at 9% to 10% of sales. In 1981 soft contact lenses were developed and in most cases were manufactures by hand. Until 1983 Vistakon was a $13 million producer of specialty contact lenses for people with astigmatism, but with the help of Johnson & Johnson‟s huge human and financial resources, the company secured a method of manufacturing contact lenses inexpensively, from an ophthalmologist in Copenhagen. This new method was very reliable and gave Vistakon the capability to manufacture at a relatively low cost of $0.50 per lens, making a $2.50 price per lens to eye care professionals feasible. With the improvement of this process, Vistakon was allowed to go from 100,000 contact lenses per day to 1 million, facilitating the national launch of Acuvue, the first disposable contact lens in 1987. The company kept its emphasis on innovation, customer research indicated that comfort and convenience were two major drivers of contact lenses purchases, and as people cannot tolerate a single lens in their eye for long periods of time, Acuvue introduced a revolutionary concept, “short is better,” and in 1995 launched the daily disposable lens, and the first disposable prebyopic contact lens. Moreover; in 1998 they began incorporating ultraviolet protection in its contact lenses, now days all Acuvue offer class 1 or class 2 UV blocking. Soft Contact Lens – Seeing a brighter future 13 EIS – Final Project, Fall 2009 Innovation in contact lenses technology, as well as continuity in being a low cost producer, has been a constant in Acuvue‟s strategy. The Oasys sub-brand was introduced fabricated with second generation gel materials that provided users with more comfort. The production process has also evolved very much through time; Vistakon manufactures millions of Acuvue contact lenses daily with a miniaturized and nearly fully automated robotic technology. Tools like Six Sigma, Predictive Indicator and Design Excellence, became important elements of the operating culture and essential to the production of quality products. 3.3.2 Sales & Marketing From the first stages of contact lens development, Vistakon‟s management realized that product innovation and quality in manufacturing would not be enough to achieve success in the market, thus the team determined that innovation was also needed in sales and marketing. During the late 1980‟s and early 1990‟s, Vistakon‟s marketing team designed a strategy in which the first objective was to drive consumers to eye care professionals through a campaign that reached directly to consumers. The second step was to sell doctors on Acuvue‟s superiority, so that they recommended the product to patients, through a sales force of single reps distributed in 137 sales territories. These efforts were complemented by the largest advertisement campaign the industry had ever seen, emphasizing the advantages of disposable lenses. The final step of the marketing strategy was to leverage Vistakon‟s information systems to create a marketing system driven by feedback from customer telephone calls and reply card generated by advertizing and print media respectively. 1 Day Acuvue contact lenses, which had become their most important product was packed in boxes of 30 lenses, thus a customer would need two boxes per month. This type of lenses were Soft Contact Lens – Seeing a brighter future 14 EIS – Final Project, Fall 2009 priced premium because the advantages in convenience and commodity provided a superior product, and customers were willing to pay for it. To support sales, the marketing team decided to implement promotions and in most cases those promotions were targeted to eye care professionals that eventually would recommend Acuvue lenses to patients, in addition Vistakon introduced a shipping method in which lenses were send directly to the customers address, on behalf of their doctor. The purpose of this delivery system was to minimize the opportunity for eye care professionals to substitute another brand, and Vistakon gain access to customer information, which was essential to their customer data and the feedback that drove their R&D and marketing strategies. Eye care professionals played a vital role in converting customers to Acuvue, even though they did not make the final decision of which product the consumer should buy, they provided a technical recommendation that in most cases was followed by the consumer, and in many occasions those professionals were in charge of the fitting process. Doctors were key players in the ecosystem, thus Vistakon put a huge effort in establishing relations with these professionals. Once a customer contacted Vistakon, a local eye care professional was notified, and the patient was provided with a free pair of lenses. The main challenge in the relationship with eye care professionals was that doctors perceived profits on disposable lenses to be lower than that for conventional ones, therefore Acuvue‟s sales fore worked hard to educate doctors on the value of retaining customers over time, versus a single visit. In addition early in its business planning, Vistakon realized that for eye care professionals prompt delivering and accurate ordering taking were very important, thus they established an 800 telephone number and a reliable and speedy delivery service. Finally, Vistakon maintains a worldwide network of held care professionals, Soft Contact Lens – Seeing a brighter future 15 EIS – Final Project, Fall 2009 which help them gain customer feedback that is used to new product development and improving processes. 3.3.3 Manufacturing and Distribution The pad of a contact lens to the final user starts with Vistakon manufacturing soft lenses with a polymer such as poly hydroxyethyl methacrylate (pHEMA) that, as was mentioned in previous sections, has hydrophilic qualities, or in more simple word that can absorb considerable amount of water and does not lose its shape and optic functions. However the technology for lens fabrications is constantly evolving and companies like Vistakon are always researching new materials and processes. Vistakon distributes contact lenses mainly through three different channels, distributors that supply eye care professionals, that did not want to buy directly form Vistakon for different reasons, accounted for around 25% of sales, and retail chain stores like Wal-Mart accounted for around 28% of sales. Usually these types of stores had optometrists to serve customers and recommend the appropriate contact lens. Sales in retail stores varied a lot from store to store because they were influenced by the training and capability of the optometrist available in the store. For this reason sales reps had the responsibility of covering this sales channel, and establishing relationships and training programs with eye care professionals that provided service in this chains. Finally the remaining of sales was done to eye care professionals through direct sales via Vistakon‟s sales force. To get a pair of lenses, a consumer would first visit an eye care professional that would provide them with the prescription describing the vision correction required. The prescription could be filled by the eye care professional or the patient could explore other distribution channels to get Soft Contact Lens – Seeing a brighter future 16 EIS – Final Project, Fall 2009 the product they needed. However eye care professionals would charge patients for checking their eye health and prescribing corrective measures, thus filling prescriptions provided and extra income for physicians. In addition doctors did not have large inventories, therefore established very good relation with suppliers, like Vistakon, that were able to deliver quality products promptly, Acuvue contact lenses had a 2 day delivery system. Finally to secure a strong network of eye care professionals prescribing and providing feedback on Vistakon products, they created The Vision Care Institute LLC, where they offer training for students from different optometry schools and colleges around the country, in contact lens prescribing and fitting for different types of eye conditions, in addition students receive advise from faculty on positive patient relationships and post-examination practices, plus patient feedback on their communication style and effectiveness. With a great structure in their distribution channels, a strong R&D and marketing organizations, as well as access to economies of scale, and presence in over 70 countries, Acuvue remains the number one contact lens brand in the world. 3.4 Positioning in 1995 In 1995 when J&J was planning to launch 1-Day Acuvue disposal contact lenses, approximately 146 million people in the United States required corrective lenses. The number of lens wearers was expected to increase slowly with the aging of the overall U.S population. The total expenditure of corrective lenses was about $15 billion in 1992, consisting of an estimated $3.5 billion in eye examination fees and $11.5 billion for optical supplies, excluding over-the-counter reading glasses and non-prescriptive sunglasses. 80% of the U.S vision corrected population chose eyeglasses. And, the remaining 20% of the population wore contact lenses. Eye glasses wearers purchases new spectacles about every 3-5 years and spent $110 $150 on average. Soft Contact Lens – Seeing a brighter future 17 EIS – Final Project, Fall 2009 According to a study of US households, 70% of those who needed vision correction products had never used contact lenses and 11% were people who had previously used contacts and had discontinued. The remaining 19% were people who used either soft lens or hard/other lens. Penetration of Different Vision Correction Products – 1994 (Million, %) Conventional soft lens Disposable wearers, 16.4, soft lens 11% wearers, 4.6, 3% Spectacles contact lens dropouts, 15.5, 11% Hard/Other lens wearers, 8, 5% Spectacles never-ever wore contacts, 101.5, 70% Forces influencing Acuvue Entry barrier - FDA approved Suppliers - Porous liquid-absorbing plastic - Silicone hydro gel Competition Bausch Lamb CibaVision Customers - ECPs - Distributers - Consumers needing vision correction Alternatives - Eyeglasses - ‘Permanent’ contact lens - Disposable contact lens Soft Contact Lens – Seeing a brighter future 18 EIS – Final Project, Fall 2009 In the early 2000‟s, Vistakon introduced the Acuvue Advance with Hydraclear, which contained a heydrogel material with a moisture-rich agent. In just four months this lens became the leader in the U.S. market and second most prescribed overall. Vistakon knew that continued innovation was necessary to maintain leadership, Acuvue had benefited from first movement advantage, but with only around 14.8% market share, it was not enough to keep competitors from entering the market Soft Contact Lens – Seeing a brighter future 19 EIS – Final Project, Fall 2009 4 Summary By 2003 Johnson & Johnson‟s Vistakon division was the industry leader focusing on the large price sensitive commodity segment. Other companies, like CIBA Vision led the smaller cosmetic lenses market, and Cooper Vision dominated the “toric” market for customers with astigmatism. However there was little confrontation among these players creating a stable balance of power, which in fact was favorable to Vistakon. Despite that CIBA and Vistakon, both offered products in each other core markets, the latter, with the financial backup of Johnson &Johnson, represented a strong threat for CIBA because they were able to held footholds in CIBA‟s core markets, establishing presence with bifocal products in the multifocal market, which was more profitable, while preventing CIBA from attacking Vistakon‟s core market. In 2003 the industry dynamics changed, as another competitor, Bausch & Lomb, entered multifocal and “toric” soft lens market segments. Cooper Vision was in the most vulnerable position and in an attempt to recover sales, moved to the cosmetic and commodity segments of the market by introducing an innovative product that was priced at premium, but offered improvements in night vision, comfort and dry eyes. The introduction of a new player generated disruption in the industry balance, and to recover market share, Vistakon increased its presence in the cosmetic segment. Soft Contact Lens – Seeing a brighter future 20 EIS – Final Project, Fall 2009 The soft contact lens industry has high barriers to entry for small players, but with a huge market companies are always tempted to explore opportunities, thus constant product and process innovation, quality, and marketing with strong relations, based on trust, with eye care professionals have become the foundations of Vistakon‟s leadership. 5 Contact Lens future and potential ECO systems As the contact lens production market grows and more players enter it is becoming increasingly difficult to gain competitive advantage. Recently a few different firms are researching potential relationships in order to introduce lenses with very distinguishable characteristics. Major contact companies are currently producing multifocal lenses designed for an older population, but this is only the beginning. Advances in drug and manufacturing technologies could lead to the availability of drug-dispensing lenses that deliver medication directly into the Soft Contact Lens – Seeing a brighter future 21 EIS – Final Project, Fall 2009 eye itself. This option will be interesting to follow, because it has the potential, if successful, to eliminate the need for prescription eye drops, the competitive response from pharma and lubricant companies should be telling. A Virginia based company has been researching the possibility of combining liquid crystals with contacts to have automatically adjustable distance focusing and range finding abilities. There is also the potential for corporations to partner with contact producers in order to increase advertising with non-prescription lenses that the younger generations, athletes or celebrities could wear. Soft Contact Lens – Seeing a brighter future 22 EIS – Final Project, Fall 2009 Sources Drug-Dispensing Lens - http://www.technologyreview.com/biomedicine/22680/ Contact Lens Technology - http://clearlycontacts.net/contact-lens-technology.html Contact Lens Overview - http://www.eyecaresource.com/contact-lenses/overview/ How is an eyeglass lens made - http://www.answers.com/topic/eyeglass-lens How is an eyeglass lens made http://www.associatedcontent.com/article/230594/production_of_glasses_how_eyeglass_pg2_pg2.html?cat=46 How is a contact lens made - http://www.answers.com/topic/contact-lens How a contact lens is made - http://www.madehow.com/Volume-2/Contact-Lens.html Background Information on Contact Lenses - http://en.wikipedia.org/wiki/Contact_lens Harvard Case Study on Acuvue & Vistakon Hard Vs. Soft Contact Lenses - http://www.docshop.com/education/vision/general-eye/contact-lenses/ Contact Lenses vs. Glasses - http://www.contactlenses.org/clsglasses.htm GP Contacts vs. Soft Contacts - http://www.contactlenses.org/rgpvsoft.htm B&L to Consolidate CL Manufacturing http://www.bausch.com/en_US/corporate/corpcomm/news/consolidate_lens_manufacturing.aspx Eyeglass Metrics - http://www.entrepreneur.com/benchmark/details27.html LASIK Information - http://en.wikipedia.org/wiki/LASIK Future of Contacts - http://www.eyes-and-vision.com/contact-lens-of-the-future.html MIT Sloan Management Review Summer 2004 Vol. 45 No. 4 Innovation, Marketing & Supply Chain Strategy – http://www.jnjvisioncare.com http://www.thevisioncareinstitute.com/Pages/home.aspx http://www.i2.com/assets/pdf/CSS_CPG_ciba_vision_css6842.pdf Soft Contact Lens – Seeing a brighter future 23