REF 541, 543 and 545 Feeder terminal

advertisement

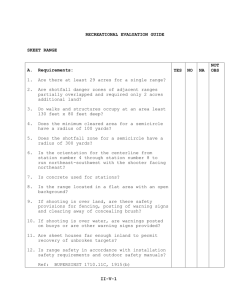

Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 1 Issued: June 1999 Status: New Data subject to change without notice Features • Feeder terminal for protection, control, measurement and supervision of medium voltage networks • Voltage and current measurement via conventional measuring transformers or current and voltage sensors • Local man-machine interface including a large graphic display • Extended functionality through libraries for protection, control, measurement, condition monitoring and communication • Basic protection functions including nondirectional and directional overcurrent and earth-fault protection, residual voltage, overvoltage and undervoltage protection, thermal overload protection, CBFP and auto-reclosing • Control functions including local and remote control of six switching objects, status indication of the switching objects and interlockings on bay and station level • Measurement including phase currents, phase-to-phase and phase-to-neutral voltages, residual current and voltage, frequency, power factor, harmonics, active and reactive power and energy, etc. • Condition monitoring including circuitbreaker condition monitoring, trip circuit supervision and internal self-supervision of the feeder terminal • Communication including two communication interfaces: one for local communication with a PC and the other for remote communication via a substation communication system • Part of the ABB’s Distribution Automation system and ABB’s Panorama concept Application The REF 541, REF 543 and REF 545 feeder terminals are designed to be used for protection, control, measurement and supervision of medium voltage networks. They can be used with different kinds of switchgear configuration including single busbar, double busbar and duplex systems. The protection functions also support different types of earthing systems such as isolated neutral networks, resonant earthed networks and partially earthed networks. In addition to protection, measurement and control functions the feeder terminals are provided with a large amount of PLC functions, which allow all the functions needed for the substation automation to be integrated into one terminal. The data communication properties include SPA bus communication or LON bus communication to higher-level equipment. Further, the LON communication together with the PLC functions minimizes the need for hardwiring between the feeder terminals. ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 2 Design The REF 541, REF 543 and REF 545 feeder terminal incorporates a wide range of relay functions: • Protection functions • Measurement functions • Control functions ers and disconnectors, indication objects for switching device indications, on/off switching objects for control logic purposes, miscellaneous objects for data monitoring, etc. The indication of objects can be configured on the local display. The display is a graphic display and the mimic configuration picture can be designed by the user. • Condition monitoring functions • Communication functions Condition monitoring functions • Standard functions Condition monitoring function blocks like supervision of the energizing current and voltage input circuit, operation time counter, circuit breaker electric wear, scheduled maintenance, trip circuit supervision and breaker travel time are available for the REF 54_ feeder terminals. The function blocks are documented on the CD-ROM “Technical Descriptions of Functions” (1MRS 750889-MCD). Protection functions Protection is one of the most important functions of the REF 54_ feeder terminal. The protection functions are independent of each other and have their own setting groups, data recording, etc. Typical current-based protection functions (e.g. overcurrent) can use either Rogowski coil or conventional current transformer measurement. Correspondingly, voltage-based functions (e.g. overvoltage) use either voltage sensors or voltage transformers. Measurement functions The measurement functions include three phase currents, neutral current, three-phase voltages, residual voltage, frequency, active and reactive power and power factor. In addition, other measurement functions are available. As a standard feature the REF 54_ terminal includes pulse counter inputs. The number of pulse inputs varies from 7 (REF 541) to 10 (REF 545) according to the REF variant. Control functions Control functions are used to read status information of the switching devices, i.e. circuit breakers, disconnectors and earthing switches, and information of alarm channels. The control functions also execute open and close commands for controllable switching devices of the switchgear. The control functions provide control objects for circuit break- Communication functions The Feeder Terminal REF 54_ provides two serial communication protocols: SPA and LON. Standard functions Standard functions are used for logics such as interlocking, alarming and control sequencing. The use of logic functions is not limited and the functions can be interconnected to protection, control, measurement, condition monitoring and other standard functions. In addition, binary inputs, outputs, LON inputs and outputs can be connected to standard functions by using the Relay Configuration Tool. Other functions Low auxiliary voltage indication The REF 54_ terminal includes indication of a low auxiliary voltage. The power supply module issues an internal alarm signal when a drop in the power supply voltage is detected (AC fail, active low). The alarm signal will be activated if the power supply voltage is about 10% below the lowest rated DC input voltage of the power supply module. Indication of a low auxiliary voltage is available in the relay configuration and can be connected to any signal output of the REF 54_. ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 3 Overtemperature indication The REF 54_ terminal includes indication of the internal relay temperature. The power supply module gives an internal alarm signal when overtemperature has been detected inside the relay enclosure. The alarm signal will be activated if the temperature inside the relay enclosure increases to +78°C (+75°C…+83°C). Overtemperature indication is available in the relay configuration and can be connected to any signal output of the relay. Analogue channels The number of channels used depends on the feeder terminal configuration and the kind of matching transformers or sensor inputs used. A REF 54_ feeder terminal can have a maximum of 10 external analogue channels. Furthermore, the feeder terminal has two internal analogue channels, channels 11 and 12, for the residual current and voltage calculated from phase currents and voltages. The feeder terminal measures the analogue signals needed for protection, measuring, etc. via current and voltage sensors developed by ABB or galvanically separated matching transformers. A current sensor (Rogowski coil) or a voltage sensor can be connected to each sensor input. The feeder terminal allows the user to configure each sensor input for the type of sensor to be used. The matching transformers and sensor inputs of the feeder terminal are designed so that either sensors or matching transformers can be used on the measuring channels 2…4 and 7…10. Should a matching transformer be used on a channel, it is not allowed to use a sensor on the same channel or vice versa. On channel 1 only sensors can be used and on channel 5 and 6 only matching transformers can be used. The last letter of the hardware number of the feeder terminal (e.g. 1MRS 090133-AA_/ CA_) specifies whether the feeder terminal is to be equipped with conventional matching transformers or with matching transformers and sensor inputs. Each analogue channel of the feeder terminal is separately configured by using the Relay Configuration Tool. A separate scaling factor can be set for each analogue channel. The factors enable differences between the ratings of the protected unit and those of the measuring device (CTs, VTs etc.). The setting value 1.00 means that the rated value of the protected unit is exactly the same as that of the measuring device. • Feeder terminals with the hardware number 1MRS090xxx-AAA/CAA are configured for matching transformers • Feeder terminals with the hardware number 1MRS090xxx-AAB/CAB are configured for matching transformers and sensor inputs Calculated analogue channels The REF 54_ feeder terminal includes two virtual channels to obtain the residual current and voltage when sensors are used. Current and voltage sensors are connected to the feeder terminal via coaxial cables and therefore residual connection of the phase currents or open-delta connection of the phase voltages cannot be made. Both amplitude and phase angle are calculated for the virtual channels. Channel 11 is used to numerically derive the residual current I0 from the three phase currents (I0 = I 1 + I 2 + I 3 ). Note! When sensitive earth-fault protection is needed, it is not, however, recommended to replace cable current transformers with the numerically derived sum of the phase currents. Normally, an earth-fault setting below 10% of the rated value requires a cable current transformer. Channel 12 is used to derive the residual voltage U0 from the three phase voltages (U0 = U 1 + U 2 + U 3 ). This channel is used instead of the open-delta connection when voltage sensors are used to measure the phase voltages. Binary inputs The binary inputs of the feeder terminals are voltage-controlled and optically isolated. The function of a binary input can be inverted. The programmable filter time removes debounces and short disturbances on a binary input. The filter time is set for each binary input of the feeder terminals. The feeder terminals REF 541, REF 543 and REF 545 differ from each other regarding the number of binary inputs available. Some of ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 4 Design (cont’d) the binary inputs can be programmed to operate as pulse counters. When a binary input is programmed to operate as a pulse counter, the frequency range of the input is 0…100 Hz. Oscillation suppression The feeder terminals have two global parameters for the suppression of binary input oscillation. The settings of these parameters determine the oscillation level and hysteresis for all binary inputs. Oscillation suppression is used to reduce the load from the system when a binary input starts oscillating. A binary input is regarded as oscillating if the number of valid status changes after filtering is more than the set number of changes per 1 s. During oscillation, the binary input is blocked (status is invalid) and an event is generated. Attributes of a binary input for relay configuration For each binary input the status of the input (value), the time tag for the status change (time) and the validity of the binary input (invalidity) can be issued by the attributes. These attributes are available in the relay configuration and can be used for different purposes, e.g. by using PLC logic functions. Outputs The outputs of the feeder terminal are categorized as follows: • HSPO: High speed power output, doublepole contact, for tripping purposes, etc. (e.g. circuit breaker) • PO: Power output, either single-pole or double-pole contact • SO: Signal output, either NO (Normal Open) or NO/NC (Normal Open/Normal Closed) contact. The output contact is a normal-duty contact and cannot be used for controlling a heavy load like a circuit breaker Alarm indication LEDs The feeder terminal has eight alarm indication LEDs to be freely configured using the Relay Mimic Editor. ON and OFF state texts and LED colours (green, yellow, red) can be freely defined. Three basic operation modes are supported: non-latched, latched-steady and latched blinking. Alarms can be acknowledged remotely, locally and by using logic. The alarm channels include time tagging for detected alarms. The time tagging principle used depends on the operation mode. Interlocking indication The interlocking LED has three modes: • Normal state: LED is inactive • Steady lit yellow LED indicates the interlocking disabling operation • Blinking red LED indicates the interlocking by-pass mode and control test mode The interlocking LED text can be defined in the same manner as other alarm channels. The colour of the interlocking LED cannot be changed. The REF 54_ Feeder Terminal has a general control test mode that overrides all interlocking signals. Activation of the interlocking test mode activates the interlocking enable signals of all control objects. Then all control operations are allowed and the enable signals of the objects are not checked during the control of the object. The interlocking LED is blinking red as long as the test mode is active. Trip Circuit Supervision The trip circuit supervision inputs consist of two functional units: • A constant current generator including the necessary hardware elements • A software-based functional unit for signalling Functional units are based on function blocks included in the condition monitoring library. The supervision of the trip circuit is based on the constant current injection principle. By default, the trip circuit supervision function is unconfigured. For more information about the trip circuit supervision function, please refer to the CDROM “Technical Descriptions of Functions” (1MRS 750889-MCD) and the trip circuit supervision function block specific documentation. ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 5 Control panel External serial communications The feeder terminal is provided with a graphical MMI panel. The display consists of 19 rows divided into two windows: a main window (17 rows) and an assisting window (2 rows). The feeder terminal has two serial communication ports, one on the front panel and the other on the rear panel. The graphic MMI panel presents detailed information on objects, events, measurements, control alarms, and parameters. The assisting window is used for device-dependent indications/alarms and help messages. Additionally, the front panel includes the following MMI items: • a button for control position selection (local/remote/logic) • three push-buttons for object control (I, 0, object selection) • eight freely programmable alarm LEDs with different colours according to the configuration • interlocking LED for control and test mode indication • three protection indication LEDs • a push-button section with four arrow-buttons and buttons for Clear and Enter • an optically isolated serial communication port • freely programmable button (F) which can be used in relay configuration The MMI has two main operation levels: the user level and the technical level. The user level is for measurements and monitoring and the technical level for advanced protection relay programming. ABB’s standard RS 232 SPA bus opto-connection on the front panel is for a PC to be used for configuring the feeder terminal, feeder-oriented interlocking and other parameters. The 9-pole RS 485 connection on the rear panel connects the feeder terminal to the distribution automation system via the SPA bus or a LON bus. The fibre-optic interface module type RER 103 is used to connect the feeder terminal to the fibre-optic communication bus. The module RER 103 supports both SPA bus and LON bus communication. Self-supervision The feeder terminals are provided with an extensive self-supervision system. The selfsupervision system handles run-time fault situations and informs the user about existing faults over the MMI and SPA bus or LON bus communication. About one minute after a fault has been detected the green READY indicator starts blinking. At the same time, the relay delivers a fault signal to the self-supervision output relay and blocks protection trip outputs. Additionally, a fault indication text appears on the MMI of the feeder terminal. The fault code is stored in the memory and can be read from the main menu. ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 6 Design (cont’d) Relay configuration Relay parameterization The Relay Configuration Tool is used for configuring the functions of protection, control, condition monitoring, measurement and logics. The parameters of the feeder terminal units can be set either locally over the MMI or externally via serial communication using the Relay Setting Tool. The configuration tool is based on the IEC 1131-3 standard. The programmable system of REF 54_ feeder terminals allows the output contacts to be operated in accordance with the state of the logic inputs and the outputs of protection, control, measurement and condition monitoring functions. The PLC logics (e.g. interlocking and alarm logic) are programmed with Boolean functions, timers, counters, comparators and flip-flops. The program is written in the function block diagram language by using the configuration software. Local parameterization Mimic configuration with Relay Mimic Editor The Relay Mimic Editor is used for configuring the graphic display and the alarm channels of the feeder terminal. The mimic configuration may include circuit breakers, disconnectors, indicators, measurement data objects and user-defined texts and explanations. Any design can be saved for later use. All of the eight alarm function blocks can be configured in the same alarm view of the mimic editor. ON and OFF state texts (only one language version can be supported for the alarm at a time) and LED colours can be defined. Three different colours can be used to define the ON and OFF state. Three basic modes are available: • non-latched • latched-steady • latched blinking Interlocking LED texts can also be defined in the same alarm view but the interlocking LED colours cannot be changed. Lon network configuration The Lon Network Tool is used for binding network variables between the feeder terminal units. Typically, LON is used for transferring status data between units for interlocking sequences running in each feeder terminal. When the parameters are set locally, the setting parameters can be chosen from the hierarchical menu structure. The desired language for parameter description can be selected. External parameterization The Relay Setting Tool is used for parameterizing the feeder terminal units. The parameters can be set off-line in a PC and downloaded to the relay over a communication port. The menu structure of the setting tool, including views for parameterization, are the same as the views on the technical level of the local MMI. Terminal connections All external circuits are connected to the terminal blocks on the rear panel. The terminal block for the measuring transformers consists of fixed screw terminals. ABB sensors (Rogowski coil or voltage sensor) are connected to the feeder terminal with a special type of shielded twin BNC connectors. This type of connectors is used to improve reliability and protection against disturbances. Unused sensor inputs must be short-circuited with a special connector, type 1MRS 1200515. The serial interface RS 485 on the rear panel is used for connecting the feeder terminal to the SPA bus or the LON bus. The SPA bus or LON bus is connected via a connection module type RER 103. The RER 103 is fitted to the 9-pole D-type subminiature connector and screwed to the rear panel. The binary input and output contacts of the feeder terminal are connected to the multipole connectors. Protective earth is connected to the screw marked with the earth symbol. ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 7 Connector description + + L1 Q1 A Q0 N L3 0 n *) + Q9 a da dn X1.1 27 P1 L1 L3 25 24 S1 22 21 S2 19 18 P2 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 S1 S2 + PS1_4_ACFail 100V Mains 1 - 2 Ch 10, VT4 PS1_4_TempAlarm 100V Ch 9, VT3 100V Ch 8, VT2 100V Ch 7, VT1 0,2A 1A Ch 6, CT5 1A 5A Ch 5, CT4 1A 5A Ch 4, CT3 SERIAL BUS X3.3 X4.1 3 4 IRF 5 6 7 8 9 PS1_4_HSPO3 10 1A 5A Ch 2, CT1 PS1_4_HSPO1 PS1_4_TCS1 11 12 13 TCS1 15 DIFF X2.2 DIFF X2.3 DIFF X2.4 DIFF X2.5 DIFF X2.6 DIFF DIFF Ch 9, sensor 16 17 18 PS1_4_HSPO2 PS1_4_TCS2 TCS2 Ch 8, sensor Ch 7, sensor X4.2 8 Ch 4, sensor Ch 3, sensor 9 10 11 12 Ch 2, sensor Ch 1, sensor DIFF 13 14 15 PS1_4_HSPO5 16 17 X4.2 1 2 PS1_4_BI1 4 5 PS1_4_BI2 6 7 PS1_4_BI3 X5.1 1 2 3 BIO1_5_BI1 PS1_4_SO1 18 X5.2 3 4 5 BIO1_5_SO1 BIO1_5_BI2 - 4 5 6 6 BIO1_5_SO2 BIO1_5_BI3 7 9 BIO1_5_BI4 - 7 8 9 8 BIO1_5_SO3 BIO1_5_BI5 10 12 BIO1_5_BI6 - 10 11 12 11 BIO1_5_SO4 BIO1_5_BI7 13 15 BIO1_5_BI8 *) Power flow direction 13 14 15 16 17 18 14 BIO1_5_SO5 16 18 BIO1_5_BI9 BIO1_5_BI10 17 BIO1_5_SO6 BIO1_5_BI11 X5.2 1 2 BIO1_5_BI12 REF 541 (1MRS 090115-AAB/CAB) ef541ext Fig. 1 Sample connection diagram of REF 541 + Ch 10, sensor PS1_4_HSPO4 X2.7 - + Ch 3, CT2 1A 5A X2.1 X2.8 I X4.1 Disconnector Q1 Close Disconnector Q1 Open - ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 8 Design (cont’d) + Q1 + Q2 L1 L3 A + 0 Q0 N + Q3 n *) + a Q9 da I dn X4.1 X1.1 27 P1 L1 L3 25 24 S1 PS1_4_ACFail 100V S2 19 18 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 S1 S2 Ch 10, VT4 PS1_4_TempAlarm 100V Ch 9, VT3 100V Ch 8, VT2 22 21 P2 + Mains 1 2 SERIAL BUS 100V 0,2A 1A IRF Ch 7, VT1 X3.3 X4.1 3 4 Ch 6, CT5 5 6 1A 5A Ch 5, CT4 1A 5A Ch 4, CT3 1A 5A 7 8 9 PS1_4_HSPO3 10 Ch 3, CT2 1A 5A Ch 2, CT1 PS1_4_HSPO1 PS1_4_TCS1 TCS1 15 X2.1 DIFF X2.2 DIFF X2.3 DIFF X2.4 + 11 12 13 + Ch 10, sensor Ch 9, sensor PS1_4_HSPO2 PS1_4_TCS2 TCS2 16 17 18 Ch 8, sensor DIFF Ch 7, sensor DIFF Ch 4, sensor DIFF Ch 3, sensor DIFF Ch 2, sensor X4.2 X2.5 X2.6 8 PS1_4_HSPO4 X2.7 9 Ch 1, sensor X2.8 DIFF PS1_4_HSPO5 Disconnector Q1 Close 10 11 12 13 14 15 Disconnector Q1 Open 16 17 X4.2 1 2 PS1_4_BI1 4 5 PS1_4_BI2 6 7 PS1_4_BI3 PS1_4_SO1 X5.2 3 X5.1 - 1 2 3 18 BIO1_5_BI1 BIO1_5_SO1 4 5 BIO1_5_BI2 - 4 5 6 BIO1_5_BI3 BIO1_5_SO2 6 7 9 BIO1_5_BI4 - 7 8 9 BIO1_5_BI5 BIO1_5_SO3 8 10 12 BIO1_5_BI6 - 10 11 12 BIO1_5_BI7 BIO1_5_SO4 11 13 15 BIO1_5_BI8 13 14 15 16 17 18 BIO1_5_BI9 BIO1_5_SO5 16 18 BIO1_5_SO6 17 BIO1_5_BI11 X7.1 X5.2 1 2 14 BIO1_5_BI10 BIO1_5_BI12 BIO2_7_PO1 17 18 X7.2 X7.1 - 1 2 3 4 5 6 *) Power flow direction 7 8 9 10 11 12 BIO2_7_PO2 1 2 BIO2_7_PO3 4 5 6 BIO2_7_BI1 3 BIO2_7_BI2 BIO2_7_BI3 7 BIO2_7_BI4 BIO2_7_BI5 Disconnector Q2 Close BIO2_7_PO4 BIO2_7_BI6 8 9 10 Disconnector Q2 Open 11 BIO2_7_BI7 BIO2_7_PO5 BIO2_7_BI8 12 13 14 Disconnector Q3 Close 15 13 14 15 16 BIO2_7_BI9 BIO2_7_PO6 BIO2_7_BI10 16 17 18 REF 543 (1MRS 090127-AAB/CAB) ef543ext Fig. 2 Sample connection diagram of REF 543 Disconnector Q3 Open - ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 9 + Q1 + Q2 L1 L3 A + 0 Q0 N + Q3 n *) + a Q9 da dn P1 L1 L3 25 24 S1 + PS2_4_ACFail 100V Ch 10, VT4 100V Ch 9, VT3 S2 19 18 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 S1 S2 100V Ch 8, VT2 100V Ch 7, VT1 0,2A 1A 1A 5A X4.1 5 7 8 9 PS2_4_HSPO3 10 1A 5A + Ch 3, CT2 1A 5A Ch 2, CT1 PS2_4_HSPO1 PS2_4_TCS1 TCS1 11 12 13 TCS2 16 17 18 15 DIFF + Ch 10, sensor Ch 9, sensor DIFF Ch 8, sensor X2.4 DIFF Ch 7, sensor DIFF Ch 4, sensor DIFF Ch 3, sensor DIFF Ch 2, sensor PS2_4_HSPO2 PS2_4_TCS2 X4.2 1 X2.5 X2.6 X2.7 PS2_4_HSPO4 *) PS2_4_HSPO5 DIFF X5.1 1 2 3 BIO1_5_BI1 PS2_4_HSPO6 Disconnector Q1 Close 6 7 8 9 10 11 12 Disconnector Q1 Close Disconnector Q2 Open 13 BIO1_5_BI2 BIO1_5_BI3 2 3 4 5 Ch 1, sensor X2.8 7 8 9 3 4 IRF Ch 6, CT5 Ch 4, CT3 X2.3 - 2 Ch 5, CT4 X2.2 4 5 6 1 X3.3 6 1A 5A DIFF - SERIAL BUS X2.1 - Mains PS2_4_TempAlarm 22 21 P2 I X4.1 X1.1 27 PS2_4_HSPO7 14 15 16 Disconnector Q2 Open BIO1_5_BI4 PS2_4_HSPO BIO1_5_BI5 - 10 11 12 17 18 X5.2 3 BIO1_5_BI6 BIO1_5_BI7 BIO1_5_SO1 4 5 BIO1_5_BI8 13 14 15 16 17 18 BIO1_5_BI9 BIO1_5_SO2 BIO1_5_SO3 BIO1_5_BI11 BIO1_5_SO4 X6.1 1 2 3 BIO1_5_SO6 7 8 9 BIO1_6_BI5 BIO1_6_SO2 4 5 6 7 9 BIO1_6_BI7 BIO1_6_SO3 8 10 12 BIO1_6_BI8 13 14 15 16 17 18 17 3 BIO1_6_SO1 BIO1_6_BI6 10 11 12 16 18 X6.2 BIO1_6_BI3 BIO1_6_BI4 *) Power flow direction 14 BIO1_6_BI1 BIO1_6_BI2 4 5 6 11 13 15 BIO1_5_BI12 BIO1_5_SO5 - 8 10 12 X5.2 1 2 6 7 9 BIO1_5_BI10 BIO1_6_BI9 BIO1_6_SO4 11 BIO1_6_BI10 13 15 BIO1_6_BI11 14 BIO1_6_SO5 16 18 X6.2 1 2 BIO1_6_BI12 BIO1_6_SO6 17 X7.1 X7.1 1 2 3 4 5 6 7 8 9 10 11 12 BIO2_7_BI1 BIO2_7_PO1 BIO2_7_BI3 17 18 X7.2 BIO2_7_BI2 BIO2_7_PO2 1 2 3 BIO2_7_BI4 BIO2_7_BI5 BIO2_7_PO3 BIO2_7_BI6 BIO2_7_BI7 BIO2_7_PO4 BIO2_7_BI8 13 14 BIO2_7_BI9 15 16 BIO2_7_BI10 BIO2_7_PO5 BIO2_7_PO6 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 ef545ext Fig. 3 Sample connection diagram of REF 545 Disconnector Q3 Close Disconnector Q3 Open - ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 10 Auxiliary voltage For its operation the REF 54_ terminal requires a secured auxiliary voltage supply. The feeder terminal’s internal power supply module forms the voltages required by the relay electronics. The power supply module is a galvanically isolated (fly-back type) dc/ dc converter. A green LED indicator “READY” on the front panel is lit when the power supply module is in operation. Technical data Power supply There are two basic versions of power supply modules available for the REF 54_: type PS1 and type PS2. The module PS1 is used in REF 541 and REF 543 terminals. The module PS2 is only used in the REF 545 terminal. The power supply version is specified by a letter combination in the hardware number of the REF 54_ feeder terminal. Table 1: Application function blocks Functions Description MMIWAKE INDRESET SWGRP1…SWGRP20 Activation of MMI backlight Operation indication, relay and register reset Switchgroup SWGRP1…SWGRP20 Table 2: General function blocks (a partial list) Functions Description ABS ADD AND BITGET BOOL_TO_INT BOOL_TO_REAL COMH CTD CTU CTUD EQ F_TRIG GE GT INT2BOOL LE LIMIT LT MAX MIN NE NOT OR R_TRIG TOF TON TP TRUNC_REAL_TO_DINT WORD_TO_BYTE WORD_TO_DWORD XOR Absolute value Adder Bitwise Boolean AND Get one bit Type conversion BOOL to INT Type conversion BOOL to REAL Hysteresis comparator Down-counter Up-counter Up-down counter Equal Falling edge detector Greater than or equal Greater than INT input to BOOL outputs Less than or equal Limiter Less than Maximum Minimum Not equal Bitwise Boolean NOT Bitwise Boolean OR Raising edge detection Time delay OFF Time delay ON Pulse Truncation toward zero Type conversion WORD to BYTE Type conversion WORD to DWORD Bitwise Boolean XOR Please refer to the CD-ROM "Technical Descriptions of Functions" for the complete list. ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 11 Table 3: Condition monitoring function blocks Functions Description CMCU3 CMVO3 CMTIME1 CMTIME2 CMGAS1 CMBWEAR1 CMBWEAR2 CMSCHED CMSPRC1 CMTCS1 CMTCS2 CMTRAV1 Supervision function of the energizing current input circuit Supervision function of the energizing voltage input circuit Operate time counter 1 for the operate time used (motors) Operate time counter 2 for the operate time used (motors) Gas density monitoring CB electric wear 1 CB electric wear 2 Scheduled maintenance Spring charging control 1 Trip Circuit Supervision 1 Trip Circuit Supervision 2 Breaker travel time 1 Table 4: Control function blocks Functions Description COCB1 COCB2 CODC1…COCD5 COIND1…COIND8 COSW1…COSW4 CO3DC1 CO3DC2 COCBDIR COLOCAT MMIDATA1…MMIDATA5 MMIALAR1…MMIALAR8 Circuit breaker 1 (2 state inputs / 2 control outputs) Circuit breaker 2 (2 state inputs / 2 control outputs) Disconnector 1…5 (2 state inputs / 2 control outputs) Object indication 1…8 (2 state inputs) On/off switch 1…4 (1 output) Three state disconnector 1 (3 state inputs / 4 control outputs) Three state disconnector 2 (3 state inputs / 4 control outputs) Direct open for CBs via MMI Logic control position selector MIMIC dynamic data point 1…5 Alarm 1…8 (MMI, remote) Table 5: Measurement function blocks Neutral current measurement, MECU1A and MECU1B Io (A) Io (%) 0.0…20000.0 A 0.0…80.0% of In Three-phase current measurement, MECU3A IL1 (A) IL2 (A) IL3 (A) IL1 (%) IL2 (%) IL3 (%) IL1 demand (A) IL2 demand (A) IL3 demand (A) IL1 demand (%) IL2 demand (%) IL3 demand (%) 0.0…20000.0 A 0.0…20000.0 A 0.0…20000.0 A 0.0…1000.0% of In 0.0…1000.0% of In 0.0…1000.0% of In 0.0…20000.0 A 0.0…20000.0 A 0.0…20000.0 A 0.0…1000.0% of In 0.0…1000.0% of In 0.0…1000.0% of In System frequency measurement, MEFR1 Frequency Average Freq. Voltage U 10.00…75.00 Hz 10.00…75.00 Hz 0.0…2.0 x Un ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 12 Technical data (cont’d) Three-phase power and energy measurement, MEPE7 P3 (kW) Q3 (kvar) Power factor DPF Power factor PF P3 demand (kW) Q3 demand (kvar) Energy kWh Reverse kWh Energy kvarh Reverse kvarh -999999…999999 kW -999999…999999 kvar -1.00…1.00 -1.00…1.00 -999999…999999 kW -999999…999999 kvar 0…999999 kWh 0…999999 kWh 0…999999 kvarh 0…999999 kvarh Residual voltage measurement, MEVO1A Uo (V) Uo (%) 0…150000 V 0.0…120.0% of Un Three-phase voltage measurement, MEVO3A U1_12 (V) U2_23 (V) U3_31 (V) U1_12 (pu) U2_23 (pu) U3_31 (pu) U1_12 Aver (V) U2_23 Aver (V) U3_31 Aver (V) U1_12 Aver (pu) U2_23 Aver (pu) U3_31 Aver (pu) 0.00…999.99 kV 0.00…999.99 kV 0.00…999.99 kV 0.00…2.00 x Un 0.00…2.00 x Un 0.00…2.00 x Un 0.00…999.99 kV 0.00…999.99 kV 0.00…999.99 kV 0.00…2.00 x Un 0.00…2.00 x Un 0.00…2.00 x Un Transient disturbance recorder for 16 analogue channels, MEDREC16 The transient disturbance recorder MEDREC16 is used for monitoring the current and voltage waveforms, and the status data of internal IEC 1131-3 based logic signals and binary inputs connected to the relay terminals. The maximum number of analogue channels and logic signals is 16. One fundamental cycle contains 40 samples. Operation mode Pre-trg time Over limit ILx Over limit Io Over limit Iob Over limit Uo Over limit Ux Over limit Uxy Over limit U12b Over limit ILxb Under limit Ux Under limit Uxy AI filter time Saturation Overwrite Extension 0…100% 0.00…40.00 x In 0.00…40.00 x In 0.00…40.00 x In 0.00…2.00 x Un 0.00…2.00 x Un 0.00…2.00 x Un 0.00…2.00 x Un 0.00…40.00 x In 0.00…2.00 x Un 0.00…2.00 x Un 0.000…60.000 s ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 13 The recording can be triggered by one or several of the alternatives listed below: • triggering by rising or falling edge of any (or several) of the binary inputs • triggering by overcurrent, overvoltage or undervoltage • manual triggering via MMI • triggering via serial communication or a parameter • periodic triggering The recording length depends on the number of records and channels used. For example, the following combination of recording length, number of records and number of channels is available at 50 Hz: # records \ # channels 1 3 10 1 1066 cyc. 21.3 s 399 cyc. 7.9 s 125 cyc. 2.5 s 5 212 cyc. 4.2 s 79 cyc. 1.5 s 25 cyc. 0.5 s 10 106 cyc. 2.1 s 39 cyc. 0.7 s 12 cyc. 0.24 s Table 6: Protection function blocks Three-phase non-directional overcurrent protection, low-set stage, NOC3Low, 3I> Start current Operate time at DT mode Time multiplier at IDMT mode Operation mode Measuring mode Drop-off time of the operate time counter Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode Accuracy class index E at IDMT mode 0.10…5.00 x In 0.05…300.00 s 0.05…1.00 Not in use Definite time Extremely inverse Very inverse Normal inverse Long time inverse RI-type inverse RD-type inverse Peak-to-peak Fundamental frequency 0...1000 ms Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value or ±0.01 x In Injected currents > 2.0 x start current: internal time < 32 ms total time < 40 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 < 45 ms ±2% of set value or ±20 ms Class index E = 5.0 or ±20 ms ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 14 Technical data (cont’d) Three-phase non-directional overcurrent protection, high-set stage, NOC3High, 3I>> and instantaneous stage, NOC3Inst, 3I>>> Start current Operate time Operation mode 0.10…40.00 x In 0.05…300.00 s Not in use Definite time Instantaneous Measuring mode Peak-to-peak Fundamental frequency 0...1000 ms Drop-off time of the operate time counter Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode Note! The values below apply when f/fn = 0.95...1.05 0.1...10 x In: ±2.5% of set value or ±0.01 x In 10...40 x In: ±5.0% of set value Injected currents > 2.0 x start current: internal time < 32 ms total time < 40 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 < 45 ms ±2% of set value or ±20 ms Three-phase directional O/C function, low-set stage I>→, DOC6Low Operation mode Start current Operate time Time multiplier Basic angle ϕb Operation direction Earth-fault protection Measuring mode Drop-off time of the operate time counter Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode Accuracy class index E at IDMT mode Not in use; Definite time Extremely inv.; Very inverse Normal inverse Long-time inv.; RI-type inverse RD-type inverse 0.05…40.00 x In 0.05…300.00 s 0.05…1.00 0…90° Forward Reverse Disabled Enabled Phase-to-phase voltages, peak-to-peak measurement Phase-to-phase voltages, fundamental freq. measurement Phase-to-earth voltages, peak-to-peak measurement Phase-to-earth voltages, fundamental freq. measurement 0...1000 ms Note! The values below apply when f/fn = 0.95...1.05 0.1...10 x In: ±2.5% of set value or ±0.01 x In 10...40 x In: ±5.0% of set value ±2.5% of measured voltage or ±0.01 x Un ±2° Injected currents > 2.0 x start current: internal time < 42 ms total time < 50 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 < 45 ms ±2% of set value or ±20 ms Class index E = 5.0 or ±20 ms ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 15 Three-phase directional O/C function, high-set stage I>>→, DOC6High and instantaneous stage I>>>→, DOC6Inst Operation mode Start current Operate time Basic angle ϕb Operation direction Earth-fault protection Non-directional operation (when the direction cannot be determined) Measuring mode Drop-off time of the operate time counter Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode Not in use Definite time Instantaneous 0.05…40.00 x In 0.05…300.00 s 0…90° Forward Reverse Disabled Enabled Disabled Enabled Phase-to-phase voltages, peak-to-peak measurement Phase-to-phase voltages, fundamental freq. measurement Phase-to-earth voltages, peak-to-peak measurement Phase-to-earth voltages, fundamental freq. measurement 0...1000 ms Note! The values below apply when f/fn = 0.95...1.05 0.1...10 x In: ±2.5% of set value or ±0.01 x In 10...40 x In: ±5.0% of set value ±2.5% of measured voltage or ±0.01 x Un ±2° Injected currents > 2.0 x start current: internal time < 42 ms total time < 50 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 < 45 ms ±2% of set value or ±20 ms Three-phase transformer inrush and motor start-up current detector Inrush3, 3I2f/I1f Ratio I2f/I1f> Start current Operation mode Operation accuracy Start time 5…50 % 0.10…5.00 x In Not in use Inrush mode Start-up mode Note! The values below apply when f/fn = 0.95...1.05 Current meas.: ±2.5% of set value or ±0.01 x In Ratio I2f/I1f measurement: ±5.0% of set value Internal time < 32 ms Total time < 40 ms ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 16 Technical data (cont’d) Non-directional earth-fault protection, low-set stage, NEF1Low, Io> Start current Operate time at DT mode Time multiplier at IDMT mode Operation mode Measuring mode Drop-off time of the operate time counter Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode Accuracy class index E at IDMT mode 1.0…100.0 % of In 0.05…300.00 s 0.05…1.00 Not in use Definite time Extremely inverse Very inverse Normal inverse Long time inverse RI-type inverse RD-type inverse Peak-to-peak Fundamental frequency 0...1000 ms Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value + 0.0005 x In Injected currents > 2.0 x start current: internal time < 32 ms total time < 40 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 < 45 ms ±2% of set value or ±20 ms Class index E = 5.0 or ±20 ms Non-directional earth-fault protection, high-set stage, NEF1High, Io>> and instantaneous stage, NEF1Inst, Io>>> Start current Operate time Operation mode Measuring mode Drop-off time of the operate time counter Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode 0.10…12.00 x In 0.05…300.00 s Not in use Definite time Instantaneous Peak-to-peak Fundamental frequency 0...1000 ms Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value or + 0.01 x In Injected currents > 2.0 x start current: internal time < 32 ms total time < 40 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 < 45 ms ±2% of set value or ±20 ms ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 17 Directional earth-fault protection, low-set stage, DEF2Low, Io>→ Start current Start voltage Operate time at DT mode Time multiplier at IDMT mode Operation mode Operation criteria Operation direction Basic angle ϕb Operation characteristic Intermittent E/F Measuring mode Drop-off time of the operate time counter Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode Accuracy class index E at IDMT mode 1.0…25.0% of In 2.0…100.0% of Un 0.1…300.0 s 0.05…1.00 Not in use Definite time Extremely inverse Very inverse Normal inverse Long time inverse Basic angle & Uo Basic angle IoSin/Cos & Uo IoSin/Cos Non-directional Io Non-directional Uo Forward Reverse -90° -60° -30° 0° IoSin(ϕ) IoCos(ϕ)(0) Not active Active Peak-to-peak Fundamental frequency 0...1000 ms Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value + 0.0005 x In ±2.5% of set value or + 0.01 x Un Phase angle ±2° Injected neutral current > 2.0 x start current and residual voltage > 2.0 x start voltage: internal time < 72 ms total time < 80 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 < 50 ms ±2% of set value or ±20 ms Class index E = 5.0 or ±20 ms ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 18 Technical data (cont’d) Directional earth-fault protection, high-set stage, DEF2High, Io>>→ and instantaneous stage, DEF2Inst, Io>>>→ Start current Start voltage Operate time Operation mode Operation criteria Operation direction Basic angle ϕb Operation characteristic Intermittent E/F Measuring mode Drop-off time of the operate time counter Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode 1.0…200.0% of In 2.0…100.0% of Un 0.1…300.0 s Not in use Definite time Instantaneous Basic angle & Uo Basic angle IoSin/Cos & Uo IoSin/Cos Non-directional Io Non-directional Uo Forward Reverse -90° -60° -30° 0° IoSin(ϕ) IoCos(ϕ)(0) Not active Active Peak-to-peak Fundamental frequency 0...1000 ms Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value + 0.0005 x In ±2.5% of set value or + 0.01 x Un Phase angle ±2° Injected neutral current > 2.0 x start current and residual voltage > 2.0 x start voltage: internal time < 72 ms total time < 80 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 < 50 ms ±2% of set value or ±20 ms Phase discontinuity protection, CUB3Low, 3∆I> Start unbalance Operate time Operation mode Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode 10.0…95.0% 1.0…300.0 s Not in use Definite time Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value or ±1 % unit internal time < 95 ms total time < 100 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 Total time for blocking: < 25 ms Total time when current drops below start value: < 50 ms ±2% of set value or ±50 ms ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 19 Three-phase overvoltage protection, low-set stage, OV3Low, 3U> Start voltage Operate time Time multiplier Operation mode Measuring mode Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode Accuracy class index E at IDMT mode, typically 0.80…1.60 x Un 0.05…10.00 s 0.05…1.00 Not in use Definite time A curve B curve Phase-to-phase voltages; peak-to-peak measurement Phase-to-phase voltages; fundamental freq. measurement Phase-to-earth voltages; fundamental freq. measurement Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value Injected voltages = 1.1 x start voltage: internal time < 42 ms total time < 50 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 < 50 ms ±2% of set value or ±20 ms ±20 ms Three-phase overvoltage protection, high-set stage, OV3High, 3U>> Start voltage Operate time Operation mode Measuring mode Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode 0.80…1.60 x Un 0.05…10.00 s Not in use Definite time Phase-to-phase voltages; peak-to-peak measurement Phase-to-phase voltages; fundamental freq. measurement Phase-to-earth voltages; fundamental freq. measurement Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value Injected voltages = 1.1 x start voltage: internal time < 42 ms total time < 50 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 < 50 ms ±2% of set value or ±20 ms ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 20 Technical data (cont’d) Three-phase undervoltage protection, low-set stage, UV3Low, 3U< Start voltage Operate time Time multiplier Operation mode Measuring mode Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode Accuracy class index E at IDMT mode, typically 0.30…1.20 x Un 0.1…120.0 s 0.1…1.0 Not in use Definite time C curve Phase-to-phase voltages; peak-to-peak measurement Phase-to-phase voltages; fundamental freq. measurement Phase-to-earth voltages; fundamental freq. measurement Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value or ±0.01 x Un Injected voltages = 0.9 x start voltage: internal time < 42 ms total time < 50 ms Injected voltages < 0.5 x start voltage: internal time < 32 ms total time < 40 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 < 60 ms ±2.5% of set value ±35 ms Three-phase undervoltage protection, high-set stage, UV3High, 3U<< Start voltage Operate time Operation mode Measuring mode Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode 0.30…1.20 x Un 0.1…120.0 s Not in use Definite time Phase-to-phase voltages; peak-to-peak measurement Phase-to-phase voltages; fundamental freq. measurement Phase-to-earth voltages; fundamental freq. measurement Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value or ±0.01 x Un Injected voltages = 0.9 x start voltage: internal time < 42 ms total time < 50 ms Injected voltages < 0.5 x start voltage: internal time < 32 ms total time < 40 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 < 60 ms ±2.5% of set value ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 21 Residual overvoltage protection, low-set stage, ROV1Low, Uo> Start voltage Operate time Operation mode Measuring mode Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode 2.0…20.0% of Un 0.05…300.00 s Not in use Definite time Peak-to-peak Fundamental frequency Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value or ±0.01 x Un Injected voltages >2 x start voltage: internal time < 32 ms total time < 40 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 Total time for blocking: < 25 ms Total time when voltage drops below start value: < 50 ms ±2% of set value or ±20 ms Residual overvoltage protection, high-set stage, ROV1High, Uo>> and instantaneous stage, ROV1Inst, Uo>>> Start voltage Operate time Operation mode Measuring mode Operation accuracy Start time Reset time Reset ratio, typically Retardation time Operate time accuracy at DT mode 2.0…80.0% of Un 0.05…300.00 s Not in use Definite time Peak-to-peak Fundamental frequency Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value or ±0.01 x Un Injected voltages >2 x start voltage: internal time < 32 ms total time < 40 ms 40...1000 ms (depends on the minimum pulse width set for the trip output) 0.95 Total time for blocking: < 25 ms Total time when voltage drops below start value: < 50 ms ±2% of set value or ±20 ms Three-phase thermal overload protection for cables TOL3Cab 3 Time constant for the cable Maximum load current for the cable Maximum temperature of conductor Reference temperature Trip temperature Prior alarm temperature Reclosure temperature Ambient temperature Operation mode (principle of ambient temperature compensation) Operation accuracy Reset ratio 1…999 min 1.0…5000.0 A 40.0…150.0°C -50.0…100.0°C 80.0…120.0% 40.0…100.0% 40.0…100.0% -50.0…100.0°C Not in use No sensors; the set ambient temperature 1 sensor used 2 sensors used Note! The values below apply when f/fn = 0.95...1.05 ±1.0%, I = 0.1...10.0 x In Trip: (Calculated temp. rise - 0.1) / Trip temperature Start: (Calculated temp. rise - 0.1) / Prior alarm temperature ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 22 Technical data (cont’d) Underfrequency or overfrequency protection, 5 stages, Freq1St1… Freq1St5 Operation mode Undervoltage limit for blocking Start value for under-/overfrequency prot. Operate time for under-/overfrequency prot. Start value for df/dt protection Operate time for df/dt protection Operation accuracy Start time Reset time Operate time accuracy Not in use f</f> 1 timer f</f> 2 timers f</f> OR df/dt> f</f> AND df/dt> f</f> OR df/dt< f</f> AND df/dt< 0.30…0.90 x Un 25.00…75.00 Hz 0.10…120.00 s 0.2…10.0 Hz/s 0.12…120.00 s Under-/overfrequency (f</f>): ±10 mHz Frequency rate of change (df/dt); real df/dt < ±5 Hz/s: ±100 mHz/s real df/dt < ±15 Hz/s: ±2.0% of real df/dt Undervoltage blocking: ±1.0% of set value Total start times at fn = 50 Hz: Frequency measurement < 100 ms Df/dt measurement < 120 ms 140...1000 ms (depends on the minimum pulse width set for the trip output) ±2% of set value or ±30 ms Auto-reclosure function, AR5Func Number of reclosures Initiation mode AR1 AR2, AR3, AR4 start delay Dead time Synchro-check Discriminating time td 0…5 Trip Start No operation AR shot initiated Initiation of AR shot blocked 0…10.00 s 0.20…300.00 s Not in use; ARSYNC in use 0…30.00 s Operation accuracy ±1% of setting value or ±30 ms AR1, AR2, AR3, AR4 starting line operation mode Synchro-check/voltage check function stage 1 and stage 2, SCVCSt1 and SCVCSt2 Upper threshold voltage Umax Lower threshold voltage Umin Voltage difference ∆U Phase angle difference ∆phase Frequency difference ∆f 0.50…1.00 x Un 0.10…0.80 x Un 0.02…0.50 x Un 5…60° 0.02…0.50 Hz Operation accuracy Note! The values below apply when f/fn = 0.95...1.05 ±2.5% of set value or ±0.01 x Un ±10 mHz ±2° < 50 ms 0.975 x Un ±2% of set value or ±20 ms Reset time Reset ratio Operate time accuracy ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 23 Table 7: Energizing inputs Rated frequency Current inputs 50.0/60.0 Hz rated current Thermal withstand capability Voltage inputs Sensor inputs, max 8 0.2 A/1 A/5 A continuously 1.5 A/4 A/20 A for 1 s 20 A/100 A/500 A dynamic current withstand, half-wave value 50 A/250 A/1250 A input impedance <750 mΩ/<100mΩ/ <20 mΩ rated voltage 100 V/110 V/115 V/120 V (parameterization) voltage withstand, continuous 2 x Un (240 V) burden at rated voltage <0.5 VA voltage range RMS ±9.4 V voltage range peak ±12 V input impedance >4.7 MΩ input capacitance < 1 nF Table 8: Auxiliary power supplies Type PS1/240V (REF 541, REF 543) Input voltage, ac 110/120/220/240 V - Input voltage, dc 110/125/220 V 24/48/60 V Operating range ac 85…110%, dc 80…120% of rated value dc 80…120% of rated value PS2/240V (REF 545 only) Burden quiescent/operating ~20/~40 W Ripple in dc auxiliary voltage max. 12% of the dc value Interruption time in auxiliary dc voltage without resetting <50 ms, 110 V and <100 ms, 200 V Internal overtemperature indication +78°C (+75…+83°C) PS1/48V (REF 541, REF 543) Table 9: Binary inputs Operating range 18…265 V dc (24/48/60/110/220 V dc) Current drain ~2…25 mA Power consumption/input <0.8 W Pulse counting (specific binary inputs), frequency range 0…100 Hz Table 10: Signal outputs Rated voltage 250 V ac/dc Continuous carry 5A Make and carry for 0.5 s 10 A Make and carry for 3 s 8A Breaking capacity when control circuit time-constant 1 A/0.25 A/0.15 A L/R <40 ms, at 48/110/220 V dc PS2/48V (REF 545 only) ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 24 Technical data (cont’d) Table 11: Power outputs Rated voltage 250 V ac/dc Continuous carry 5A Make and carry for 0.5 s 30 A Make and carry for 3 s 15 A Breaking capacity when control circuit time-constant 5 A/3 A/1 A L/R <40 ms, at 48/110/220 V dc Minimum contact load 100 mA, 24 V ac/dc (2.4 VA) HSPO (High-Speed Power Output) 5 ms faster than a power output (PO) TCS (Trip Circuit Supervision) 20…265 V ac/dc Control voltage range Current drain through the approx. 1.5 mA (0.99…1.72 mA) supervision circuit Minimum voltage (threshold) over a contact 20 V ac/dc (15…20 V) Table 12: Environmental conditions Specified service temperature range -10…+55°C Transport and storage temperature range -40…+70°C Enclosure class Front side, flush-mounted IP 54 Rear side, connection terminals IP 20 Note! A rear protective cover (accessory) can be used to protect and shield the rear of the case Dry heat test according to IEC 68-2-2 (BS 2011: Part 2.1 B) Dry cold test according to IEC 68-2-1 (BS 2011: Part 2.1 A) Damp heat test cyclic according to IEC 68-2-30 (BS 2011: Part 2.1 Db), r.h. = 95%, T = 20°…55°C Storage temperature tests according to IEC 68-2-48 Table 13: Standard tests Insulation tests Mechanical tests Dielectric test (IEC 60-2; BS 932: Part 2 and IEC 255-5; BS 5992: Part 3) Test voltage 2 kV, 50 Hz, 1 min. Impulse voltage test (IEC 255-5) Test voltage 5 kV, unipolar impulses, waveform 1,2/50 µs, source energy 0.5 J Insulation resistance measurements (IEC 255-5) Insulation resistance > 100 MΩ, 500 V dc Vibration tests (sinusoidal) IEC 255-21-1, class I Shock and bump test IEC 255-21-2, class I ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 25 Table 14: Electromagnetic compatibility tests The EMC immunity test level fulfills the requirements specified in the generic standard EN 50082-2 1 MHz burst disturbance test, class III (IEC 255-22-1) common mode 2.5 kV differential mode 1.0 kV Electrostatic discharge test, class III (IEC 61000-4-2) for contact discharge 6 kV for air discharge 8 kV Radio frequency interference test conducted, common mode (IEC 61000-4-6) 10 V (rms), f = 150 kHz…80 MHz radiated, amplitude-modulated (IEC 61000-4-3) 10 V/m (rms), f = 80…1000 MHz radiated, pulse-modulated (ENV 50204) 10 V/m, f = 900 MHz radiated, test with a portable transmitter (IEC 255-22-3, method C) f = 77.2 MHz, P = 6 W; f = 172.25 MHz, P = 5 W Fast transient disturbance test (IEC 255-22-4 and IEC 61000-44) ac/dc ports 4 kV signal contacts 2 kV Surge immunity test (IEC 61000-4-5) power supply, ac/dc ports 4 kV, common mode 2 kV, differential mode I/O ports 2 kV, common mode 1 kV, differential mode conducted RF emission (mains terminal) EN 55011, class A radiated RF emission EN 55011, class A Electromagnetic emission tests (EN 55011 and EN 50081-2) CE approval Complies with the EMC directive 89/336/EEC and the LV directive 73/ 23/EEC Table 15: Data communication Rear interface, connector X3.3 RS485 connection LON bus or SPA bus, selectable the fibre-optic interface module RER 103 is needed for galvanic isolation data transfer rates Rear interface, connector X3.2 Front panel not used, reserved for future purposes optical RS 232 connection data code ASCII data transfer rates 4.8, 9.6 or 19.2 kbps, selectable serial communication cable Serial communication parameters number of data bits Communication protocols SPA bus: 4.8/9.6/19.2 kbps LON bus: 78 kbps/1.2 Mbps 1MKC 9500011 7 number of stop bits 1 parity even baud rate 9.6 kbps (default) SPA-bus protocol LON bus ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 26 Table 16: General Ordering Toolboxes CAP 501 CAP 505 Event recording all events are recorded in higher level syntax: reason, time, date are in clear text format in the selected language. The last 100 events are recorded Data recording records operate values Protection functions see Technical Descriptions of Functions, CD-ROM (1MRS 750889-MCD) Control functions see Technical Descriptions of Functions, CD-ROM (1MRS 750889-MCD) Condition monitoring functions see Technical Descriptions of Functions, CD-ROM (1MRS 750889-MCD) Measurement functions see Technical Descriptions of Functions, CD-ROM (1MRS 750889-MCD) Self-supervision RAMs ROMs EEPROMs all analogue reference voltages automatic test sequences for I/Os and MMI output contact wide condition monitoring (all contacts) Mechanical dimensions Width: 223.7 mm (1/2 of a 19” rack) Height, frame: 265.9 mm (6U) Height, box: 255.8 mm Depth: 235 mm (245.1 mm with a protective rear cover, available as an option) Weight of the unit ~8 kg Order data for the REF 54_ feeder terminals includes an order number that identifies the feeder terminal type as well as the hardware and the software as described below. The order number is labelled on the marking strip on the front panel of the feeder terminal delivered. REF543E 127AAA Analogue interface type A: Only matching transformers included (MIM) B: Sensor inputs and transformers included (MIM and SIM) Digital input voltage range A: Ur = 24/48/60/110/220 V dc Auxiliary voltage range of a power supply module A: Ur = 110/120/220/240 V ac; 110/125/220 V dc (PS1/240 V or PS2/240 V) C: Ur = 24/48/60 V dc (PS1/48 V or PS2/48 V) Hardware number Software revision Feeder terminal type When ordering, please specify: Ordering information Ordering example 1. Order number REF543E 127-AAA 2. Language(s) to be used on the MMI English/German 3. Quantity 5 pieces Typedesf Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 27 Overview of REF hardware configurations 1MRS090115-AAB/CAB 1MRS090126-AAA/CAA 1MRS090126-AAB/CAB Transformers 4 4 4 4 Current transformer 0.2/1 A 1 1 1 1 1 1 1 1 1 1 Voltage transformer 100 V 1 1 4 4 1 1 4 4 4 4 Current transformer 1/5 A 4 8 8 8 4 4 8 1MRS090133-AAB/CAB 1MRS090115-AAA/CAA 4 4 Sensor channels (current or voltage) 1MRS090133-AAA/CAA 1MRS090114-AAB/CAB 4 1MRS090113-AAB/CAB Analogue interface REF 545 1MRS090114-AAA/CAA Order numbers REF543 1MRS090127-AAB/CAB REF541 1MRS090127-AAA/CAA Hardware modules 1MRS090113-AAA/CAA ABB Substation Automation Products and Systems 4 4 8 8 Main processor boards CPU module 1 1 1 1 1 1 1 1 1 1 1 1 Power supply boards Power supply 48 V or 240 V 1 1 1 1 1 1 1 1 1 1 1 1 I/O module, type 1 1 1 1 1 1 1 I/O boards I/O module, type 2 1 1 1 1 2 2 1 1 1 1 1 1 Display boards Graphic MMI display 1 1 1 1 1 1 1 1 1 1 1 1 Mechanical design 1/2 enclosure 1 1 1 1 1 1 1 1 1 1 1 1 Digital inputs 15 25 Power outputs, single-pole 0 2 34 3 Power outputs, double-pole 5 9 11 Signal outputs (NO) 2 2 4 Signal outputs (NO/NC) 5 5 8 Trip circuit supervision 2 2 2 IRF outputs 1 1 1 ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 28 Ordering (cont’d) Hardware configurations of the REF 541 All the REF 541 hardware versions include the same number of binary inputs and outputs. The number of matching transformers and sensor inputs and the auxiliary voltage range vary between the different REF 541 hardware versions. The hardware configuration alternatives for the feeder terminal REF 541 are as follows: Hardware no. Matching transformers Sensor inputs Auxiliary voltage 1MRS090113-AAA In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) - 110…240 V ac/dc 1MRS090113-CAA In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) - 24…60 V dc 1MRS090113-AAB In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) 8 inputs for Rogowski coil or voltage sensor 110…240 V ac/dc 1MRS090113-CAB In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) 8 inputs for Rogowski coil or voltage sensor 24…60 V dc 1MRS090114-AAA In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) - 110…240 V ac/dc 1MRS090114-CAA In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) - 24…60 V dc 1MRS090114-AAB In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) 8 inputs for Rogowski coil or voltage sensor 110…240 V ac/dc 1MRS090114-CAB In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) 8 inputs for Rogowski coil or voltage sensor 24…60 V dc 1MRS090115-AAA In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) Un=100/110/115/120 V (VT2, VT3, VT4) - 110…240 V ac/dc 1MRS090115-CAA In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) Un=100/110/115/120 V (VT2, VT3, VT4) - 24…60 V dc 1MRS090115-AAB In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) Un=100/110/115/120 V (VT2, VT3, VT4) 8 inputs for Rogowski coil or voltage sensor 110…240 V ac/dc 1MRS090115-CAB In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) Un=100/110/115/120 V (VT2, VT3, VT4) 8 inputs for Rogowski coil or voltage sensor 24…60 V dc ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 29 Hardware configurations of the REF 543 All the REF 543 hardware versions include the same number of binary inputs and outputs. The number of matching transformers and sensor inputs and the auxiliary voltage range vary between the different REF 543 hardware versions. The hardware configuration alternatives for the feeder terminal REF 543 are as follows: Hardware no. Matching transformers Sensor inputs Auxiliary voltage 1MRS090126-AAA In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) - 110…240 V ac/dc 1MRS090126-CAA In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) - 24…60 V dc 1MRS090126-AAB In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) 8 inputs for Rogowski coil or voltage sensor 110…240 V ac/dc 1MRS090126-CAB In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) 8 inputs for Rogowski coil or voltage sensor 24…60 V dc 1MRS090127-AAA In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) Un=100/110/115/120 V (VT2, VT3, VT4) - 110…240 V ac/dc 1MRS090127-CAA In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) Un=100/110/115/120 V (VT2, VT3, VT4) - 24…60 V dc 1MRS090127-AAB In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) Un=100/110/115/120 V (VT2, VT3, VT4) 8 inputs for Rogowski coil or voltage sensor 110…240 V ac/dc 1MRS090127-CAB In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) Un=100/110/115/120 V (VT2, VT3, VT4) 8 inputs for Rogowski coil or voltage sensor 24…60 V dc ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 30 Ordering (cont’d) Hardware configurations of the REF 545 All the REF 545 hardware versions include the same number of binary inputs and outputs. The number of matching transformers and sensor inputs and the auxiliary voltage range vary between the different REF 541 hardware versions. The hardware configuration alternatives for the feeder terminal REF 545 are as follows: Hardware no. Matching transformers Sensor inputs Auxiliary voltage 1MRS090-133AAA In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) Un=100/110/115/120 V (VT2, VT3, VT4) - 110…240 V ac/dc 1MRS090-133CAA In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) Un=100/110/115/120 V (VT2, VT3, VT4) - 24…60 V dc 1MRS090-133AAB In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) Un=100/110/115/120 V (VT2, VT3, VT4) 8 inputs for Rogowski coil or voltage sensor 110…240 V ac/dc 1MRS090-133CAB In=1A/5 A (CT1, CT2, CT3) In=1 A/5 A (CT4) In=0.2 A/1 A (CT5) Un=100/110/115/120 V (VT1) Un=100/110/115/120 V (VT2, VT3, VT4) 8 inputs for Rogowski coil or voltage sensor 24…60 V dc Software configuration The desired functionality can be freely activated from comprehensive libraries within the scope of the processing capacity and the I/O connections and analogue channels available in the selected hardware variant. Parts and assembly descriptions To achieve the best possible operation accuracy, all parts of a REF 54_ product have been calibrated together. Thus, each product forms a whole for which no separate spare parts can be supplied. In the event of malfunction, please consult your relay supplier. ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 31 Application examples MF 3I > 50/51 MCS I0> 50N/51N TCS * /62 CBCM CBFP 000 0 I R U 90V U R 000 R 000 q q p> 3DI > 50/51 CBFP * /62 3I > 50/51 MCS 51B TCS 3U > 59 CBCM CBFP * /62 000 0 3I > & I R P 3I Q 3U MF E M Fig. 4 M EXINFDR1 Protection, control, measurement and supervision functions of a utility infeeder, implemented with REF feeder terminals, an REA arc monitoring system and SPACOM differential relay and voltage regulator (main single-line diagram presentation). The neutral point of the MV network supplied by the infeeder is isolated. ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 32 Application examples (cont’d) 3I > 50/51 MCS I0> 50N/51N TCS * /62 CBCM MF CBFP 000 0 I R U 3D I > q q p> 90V U R 000 R 000 87T CBFP * /62 3I > 50/51 MCS 51B TCS U0> 59N CBCM 3U > 59 CBFP * /62 q 0 3I > & I R P Q MF 000 3I 3U U0 M M I0 E EXINFDR3 Fig. 5 Protection, control, measurement and supervision functions of a utility infeeder, implemented with REF feeder terminals, an REA arc monitoring system and SPACOM differential relay and voltage regulator (main single-line diagram presentation). The neutral point of the MV network supplied by the infeeder is earthed via the Petersen coil. ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 33 M M 50/51 MCS 67N TCS I0-0> 51N CBCM 3I2f > 68 DI> 46 f< 81U 3I > 000 MF I0> 0 I CBFP 0 I R P 3I I0 3U 79 * /62 E EXFDR1 Fig. 6 An REF feeder terminal used for the protection, control, measurement and supervision functions of a utility feeder (main single-line diagram presentation). The neutral point of the supplying network is isolated. The scheme is also fully applicable in high-impedance earthed networks, where the neutral point is earthed via a high resistance or a Petersen coil. ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 34 Application examples (cont’d) 3U > 59 MCS 3U < 27 TCS U0> 59N f< 81U 000 R U0 3U f 3U > 59 MCS 3U < 27 TCS U0> 59N f< 81U 000 R U0 3U f EXMEAS1 Fig. 7 REF feeder terminals used for the protection, control, measurement and supervision functions of a utility/industrial measurement cubicle (main single-line diagram presentation). The neutral point of the supplying network is isolated. The scheme is also fully applicable in high-impedance earthed networks, where the neutral point is earthed via a high resistance or a Petersen coil. ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 35 MF 3I > 50/51 MCS I 0> 50N/51N TCS U0> 59N CBCM CBFP * /62 000 0 I R U 3D I > q q p> MF U R 000 R 000 87T CBFP * /62 3I > 50/51 MCS 51B TCS 67 CBCM 3I> MF 90V I0> 50N/51N SYNC 25 3U > 59 CBFP * /62 000 0 3I > & I R P 3I Q 3U I0 E EXINFDR4 Fig. 8 Protection, control, measurement and supervision functions of a utility/industrial infeeder, implemented with REF feeder terminals, an REA arc monitoring system and SPACOM differential relay and voltage regulator (main single-line diagram presentation). The neutral point of the MV network supplied by the infeeder is earthed via a high resistance. ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 36 Application examples (cont’d) MF 3I> 67 MCS I0> 67N TCS 3 49F CBCM SYNC 25 f< 81U 3U > 59 3U < 27 CBFP * /62 000 0 I R P 3I Q 3U pf f E EXFDR3 3I > & Fig. 9 An REF feeder terminal and an REA arc monitoring system (main single-line diagram presentation) used for the protection, control, measurement and supervision functions of a utility/industrial ring/meshed network cable feeder. The earthing of the supplying network can be of low or high impedance type. ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 37 50/51 MCS 50N/51N TCS 3I2f> 68 CBCM DI> 46 CBFP * /62 3I > 000 MF I0> 0 I R P 3I E 3U EXFDR4 Fig. 10 An REF feeder terminal used for the protection, control, measurement and supervision functions of a utility/light industrial cable feeder (main single line diagram presentation). The earthing of the supplying network can be of low or high impedance type. ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 38 Application examples (cont’d) MF 3I > 50/51 MCS I0> 50N/51N TCS I02f> 68 CBCM CBFP * /62 000 0 I R U 90V U q q R 000 R 000 p> 87T DI0> 87N DI0> 87N CBFP * /62 67 MCS I0> 50N/51N TCS SEF 51N CBCM 3U > 59 3U < 27 f< 50N/51N CBFP * /62 3I> MF 3D I > 000 0 3I > & I R P 3I pf 3U f E EXINFDR2 Fig. 11 Protection, control, measurement and supervision functions of a utility infeeder, implemented with REF feeder terminals, an REA arc monitoring system and SPACOM differential relay and voltage regulator (main single-line diagram presentation). The neutral point of the MV network supplied by the infeeder is earthed via a low resistance. The scheme is also fully applicable to other types of low-impedance earthed networks, where the neutral point is earthed effectively or via a low reactance. ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 39 3I > 50/51 MCS I0> 50N/51N TCS SEF 51N CBCM 3I2f> 68 DI> 46 f< 81U 000 MF 0 I CBFP 0 I R P 3I E 3U 79 * /62 EXFDR2 Fig. 12 An REF feeder terminal used for the protection, control, measurement and supervision functions of a utility feeder (main single-line diagram presentation). The neutral point of the supplying network is earthed via a low resistance. The scheme is also fully applicable to other types of low-impedance earthed networks, where the neutral point is earthed effectively or via a low reactance. ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 40 Application examples (cont’d) 3I > 50/51 = multiple-stage three-phase overcurrent protection, low-set, high-set and instantaneous stage available 3I> 67 = multiple-stage three-phase directional overcurrent protection, low-set, high-set and instantaneous stage available I0> 67N = multiple-stage directional earth-fault protection, low-set, high-set and instantaneous stage available I0-0> 51N = instantaneous stage for earth-fault protection, to operate in the event of a double earth fault in isolated or impedance earthed networks I0> 50N/51N SEF 51N 3I > 50/51 = multiple-stage earth-fault protection, low-set, high-set and instantaneous stage available = low-set stage for sensitive earth-fault protection, to operate in the event of a high resistive earth fault in effectively or low-impedance earthed networks = multiple-stage three-phase overcurrent protection, one stage dedicated for blockable busbar overcurrent protection 51B 3U > 59 = three-phase overvoltage protection, low-set and high-set stage available 3U < 27 = three-phase undervoltage protection, low-set and high-set stage available U0> 59N = multiple-stage residual overvoltage protection, low-set, high-set and instantaneous stage available 3I2f > 68 = inrush detection based on the 2nd harmonic content of phase currents, applied for preventing possible unnecessary operation of overcurrent or earth-fault protection during transformer switching-in or to start cold load pick-up logic DI> 46 = phase discontinuity protection f< 81U = underfrequency protection/load shedding scheme 3 49F = thermal overload protection for feeders I 79 = multiple-shot auto-recloser SYNC 25 = circuit breaker synchro-check/direction of energizing check function 0 3D I > 87T = differential protection for transformers DI0> 87N = restricted earth-fault protection, low- or high-impedance type I02f> CBFP Fig. 13 68 = inrush detection based on the 2nd harmonic content of neutral current, applied to prevent possible unnecessary operation of the earth-fault protection during transformer switching-in * /62 = circuit-breaker failure protection Symbol notations, part I SYMNOT1 ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 41 3I > & = arc protection MCS = measuring circuit supervision TCS = trip circuit supervision CBCM = circuit-breaker condition monitoring 90V U = automatic voltage regulation = manual voltage regulation U = active power measurement, indication and supervision P = reactive power measurement, indication and supervision Q = 3-phase current measurement, indication and supervision 3I = 3-phase voltage or phase-to-phase voltage measurement, indication and supervision 3U = frequency measurement, indication and supervision f = power factor measurement, indication and supervision pf = residual current measurement, indication and supervision I0 = residual voltage measurement, indication and supervision U0 = energy counter, forward or reverse active / reactive energy E = annunciating, event generating and value recording functions R = disturbance recorder 000 = digital value indication 000 0 = MMI/MIMIC display I = local and remote control interface = bay-oriented interlocking logic Fig. 14 Symbol notations, part II SYMNOT2 ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 42 Application examples (cont’d) Application selection tables for REF 541, REF 543 and REF 545 functions Table 17: Protection functions Types of fault IEEE Device No. IEC Symbol Protection function Function block code Short circuits 51 3I > Non-directional overcurrent, low-set stage NOC3Low 50 / 51 3I >> Non-directional overcurrent, high-set stage NOC3High 50 / 51B 3I >>>/ Non-directional overcurrent, instantaneous stage NOC3Inst 67 3I> → Three-phase directional o/c, low-set stage DOC6Low 67 3I>> → Three-phase directional o/c, high-set stage DOC6High 67 3I>>> → Three-phase directional o/c, high-set stage DOC6Inst 51N Io > / SEF Non-directional earthfault, low-set stage NEF1Low 50N / 51N Io >> Non-directional earthfault, high-set stage NEF1High 50N Io>>> / Io-o > Non-directional earthNEF1Inst fault, instantaneous stage 67N / 51N Io> → / SEF Directional earth-fault, low-set stage DEF2Low 67N Io>> → Directional earth-fault, high-set stage DEF2High 67N Io>>> → Directional earth-fault, instantaneous stage DEF2Inst 59N Uo> Residual overvoltage, low-set stage ROV1Low 59N Uo>> Residual overvoltage, high-set stage ROV1High 59N Uo>>> Residual overvoltage, instantaneous stage ROV1Inst Overload 49F 3 Three-phase thermal overload (feeders & cables) TOL3Cab Overvoltage/ undervoltage 59 3U > Three-phase overvoltage, low-set stage OV3Low 59 3U >> Three-phase overvoltage, high-set stage OV3High 27 3U< Three-phase undervoltage, low-set stage UV3Low 27 3U<< Three-phase undervoltage, high-set stage UV3High Earth faults ABB Substation Automation Products and Systems Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 43 Table 17: Protection functions Load shedding and restoration 81 f<, f> Underfrequency or overfrequency, stage 1 Freq1St1 81 f<, f> Underfrequency or overfrequency, stage 2 Freq1St2 81 f<, f> Underfrequency or overfrequency, stage 3 Freq1St3 81 f<, f> Underfrequency or overfrequency, stage 4 Freq1St4 81 f<, f> Underfrequency or overfrequency, stage 5 Freq1St5 Additional functions 79 O→I Auto-reclosure AR5Func 25 SYNC Synchro-check/voltage check, stage 1 SCVCSt1 25 SYNC Synchro-check/voltage check, stage 2 SCVCSt2 68 3I2f > Three-phase inrush detector Inrush3 46 ∆I> Phase discontinuity CUB3Low Table 18: Measurement functions Types of measurement IEC Symbol Measurement function Function block code Current 3I Three-phase current MECU3A Io Neutral current MECU1A Io Neutral current (LV side) MECU1B 3U Three-phase voltage MEVO3A Voltage Uo Residual voltage MEVO1A Energy / Power E / P / Q / pf Three-phase power and energy (incl. cos ϕ) MEPE7 Frequency f System frequency MEFR1 Transient disturbance recorder MEDREC16 Recording Table 19: Condition monitoring functions Types of condition monitoring Cicuit breaker Trip circuit Measuring circuit Symbol Condition monitoring function Function block code CBCM CB electric wear 1 CMBWEAR1 CBCM CB electric wear 2 CMBWEAR2 CBCM Operation Time Counter 1 (e.g. motors) CMTIME1 CBCM Operation Time Counter 2 (e.g. motors) CMTIME2 CBCM Gas density CMGAS1 CBCM Spring charging control 1 CMSPRC1 CBCM Breaker travel time 1 CMTRAV1 CBCM Scheduled maintenance CMSCHED TCS Trip Circuit Supervision 1 CMTCS1 TCS Trip Circuit Supervision 2 CMTCS2 MCS Supervision of the energizing current input circuit CMCU3 MCS Supervision of the energizing voltage input circuit CMVO3 ABB Network Partner Feeder terminal REF 541, 543 and 545 1MRS 750443-MBG Page 44 Table 20: Control functions Types of control Cicuit breaker Symbol 0↔ 1 0↔ 1 0↔ 1 Disconnector 0↔ 1 0↔ 1 0↔ 1 Other control functions Types of control References Symbol Control function Function block code Circuit breaker 1 (2 state COCB1 inputs / 2 control outputs) Circuit breaker 2 (2 state COCB2 inputs / 2 control outputs) Direct open for CBs via MMI COCBDIR Disconnector 1...5 (2 state inputs / 2 control outputs) CODC1...CODC5 Three-state disconnector CO3DC1 (1) with indication Three-state disconnector CO3DC2 (2) with indication Object indication 1...8 (2 state inputs) COIND1...COIND8 On/off switch 1...4 (1 output) COSW1...COSW4 Logic control position selector COLOCAT MIMIC dynamic data point 1...5 MMIDATA1...MMIDATA5 Alarm 1...8 (MMI, remote) MMIALAR1...MMIALAR8 Control function Function block code Additional information Technical Reference Manual 1MRS 750527-MUM Technical Descriptions of Functions 1MRS 750889-MCD (CD-ROM only) Installation Manual 1MRS 750526-MUM Operator’s Manual 1MRS 750500-MUM Technical Reference Manual RER 103 1MRS 750532-MUM Configuration Guideline 1MRS 750745-MUM Echelon, LON and LonTalk are registered trademarks of Echelon Corporation. All other product names or brands are trademarks, registered trademarks, or service marks of their respective owners. ABB Substation Automation Oy P.O. Box 699 FIN-65101 Vaasa Finland Telephone: +358 10 224 000 Fax: +358 10 224 1094 Internet: http://www.abb.fi