Development of a Beam Deflection Apparatus from Locally

advertisement

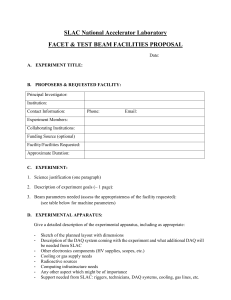

ISSN: 2277-3754 ISO 9001:2008 Certified International Journal of Engineering and Innovative Technology (IJEIT) Volume 2, Issue 6, December 2012 Development of a Beam Deflection Apparatus from Locally Sourced Material Buliaminu Kareem Department of Mechanical Engineering, Federal University of Technology, Akure, Nigeria Abstract— Continued hike in cost of laboratory equipment calls for seeking an alternative way of manufacturing such equipment using indigenously sourced material. The most critical laboratory equipment useful in material testing is Beam Deflection Apparatus (BDA) which is useful in the determination of elastic modulus of engineering materials and among others. It was designed to comprise a spring, dial gauge, beam support and measuring scale. The spring permitted the horizontal movement, while the deflection of beam was measured by the dial gauge with the scale measuring the length of the expansion. The assembled apparatus comprised leaf spring, bolts, load hanger, T-leg and spring support with one side fixed. Test experiments were carried out on the apparatus, in the areas of young’s modulus of material determination under a given loading system. The results from the test showed that the apparatus performance is adequate. This has supported the efficacy of the apparatus as a replacement to the imported ones in the institutional laboratories. Index Terms—Mechanical Test, Beam Deflector, Elastic Modulus, Laboratory. I. INTRODUCTION The beam theory is one of the basic knowledge to be acquired for all industrial engineers. The beam deflection is capable of measuring support reaction, shearing force, bending moment, deflection, deflection angle, young modulus of various materials [1-2]. In the same way, the apparatus allow deeper understanding of the significance of the beam theory through comparative examination between obtained experimental values and the theoretical values. The production of beam deflection apparatus, is to enable one especially students, study beam deflection under various load and fixing conditions. There are different sizes and product codes of this apparatus from different countries (such as United States of America, Canada, England etc.). There were product codes such as beam deflection apparatus SAN 313, Benkelmen Beam Deflection Apparatus, deflection of beam apparatus, Norwood Instruments, HSM1 Beam Deflection Apparatus, SM104 Beam Apparatus, etc.[3-8]. A. Beam Deflection Apparatus San 313 This apparatus is of dimension (420 X 420 X 1200) mm and net weight 26kg. It consists of a rigid main support on which the hardened knife edge and cantilever supports for the test beams can be easily positioned. The standard equipment includes three test beam of the same material having suitable cross sectional dimensions. This apparatus is produced by both Delta Analytical Instruments (U.S.A) and society Delta Lab. (France) [9,10]. B. Benkelmen Beam Deflection Apparatus The beam theory is one of the basic knowledge to be acquired for all industrial engineers. The beam deflection apparatus is a newly developed epoch making small model experimentation apparatus This apparatus consists of a Benkelman beam (B.B) which measures static pavement deflection. The BB consists of a slender beam 3.6m long pivoted at a distance of 2.44m from the tip. By suitable planning the prove between the dual wheels of a loaded truck, it is possible to measure the rebound and residual deflections of the pavement structure. The over long thickness required for strengthening of a given road stretch is derived from the BB deflection record and other necessary design parameters [11,12}. C. Deflection of Beam Apparatus (Norwood Instrument The apparatus consist of a twin beam support fitted with a scale to which the various supports are attached. The beam is loaded by a double ended hook and stirrup passing through the support beams [11]. D. HSM1 Beam Deflection Apparatus This apparatus has features such as rigid base and supports, choice of end conditions. It can be used for verification of beam deflection formula, deflection and slope of beams and cantilevers, verification of both area moment theories [12]. E. SM104 Beam Apparatus The SM104 beam apparatus was tested to industrial standards and can be used for class demonstrations, student experiments, projects and research. Its dimensions 1870 X 320 X 580mm and Net weight 43kg. It is very simple to design and fabricate [8,11]. The modification of this design will be adopted in this study because of its simplicity and availability of local material substitution. F. Beam Column Much research has been done on metal beams and their behavior under Compressive loads. In many cases, members are subjected to both a bending moment and a compressive or tensile load. When the magnitude of one is relatively small, its effect is neglected and the section is designed as a beam, an axially loaded column, or a tensile member. However in some cases magnitudes are relatively large and cannot be easily neglected. Therefore combined loads have to be accounted for in design. In the case where members are subjected to compressive loads and bending moments, they are referred to as beam-columns. They therefore provide a link between columns under pure axial loads, and a beam under pure bending loads. Since axial load is involved, stability related factors such as buckling have to be considered. When a 343 ISSN: 2277-3754 ISO 9001:2008 Certified International Journal of Engineering and Innovative Technology (IJEIT) Volume 2, Issue 6, December 2012 member is subjected to small loads, its shape remains the operate the apparatus at a convenient working height. The same, but as the load increases the deflection of the member size of the individual components, sub-system and the entire increases as well, the member could suddenly become apparatus were designed to ensure portability, easy unstable. Such a phenomenon is called the buckling accessibility for maintenance and operation. phenomenon. Usually the buckling of a column can lead to B. Design Specification and Analysis The main frame of the apparatus consist of an upper cross catastrophic failures in many structures. Therefore special attention has to be taken in order to make sure that such member carrying graduated scale and two lower members members can safely support combined loads without bolted tee-legs to form a rigid assembly. becoming unstable. Though many high precision systems Spring: It slides freely on the main support beam when [13,14] had been developed in literature but the beam load is applied. Springs based on the principle of long slander deflection apparatus is important in allowing deeper beams of rectangular section subjected to bending. They are understanding of the significance of beam theory and practice used as cantilever springs (fixed at one end), or as simple in developing economy [15-17]. beams (fixed at both ends). The leaf springs can be used either independently or in sets (laminated leaf springs). Single II. MATERIAL AND METHODS springs are used for the following reasons: suitable for low To satisfy operational requirement and design purposed and medium load forces; linear working characteristics; standard values were used in developing the design relatively low spring constant; considerable length consideration, specification analysis and drawing. The design requirements; and minimum space needed with low was then used in the fabrication of the apparatus. The production costs. The maximum bending moment occurs designed and fabrication of parts included the dial gauge support, load hanger, spring support, Tee-legs, etc. with all at the centre and is resisted by all N plates equally. these in place, the beam deflection apparatus was assembled by bolting and welding. WL A. Design Consideration /4 This is concerned with the detailed design of the beam deflection apparatus. This includes design specification and choice of material used in the constructing of the apparatus. In W W /2 /2 the production of apparatus, cost, maintenance, portability, efficiency and other characteristics were considered. The beam deflection apparatus is laboratory equipment widely W used in construction industry and tertiary institutions. Some of the design consideration includes: Reliability: This is the acceptability of the apparatus over a period of time. It is the possibility of the apparatus to t perform without failure under a given condition for a specific period. Thus, from the design stage, the possibility of operating the apparatus for a long period of time without W /2 L excessive failure of component parts or breakdown of operation was considered. Ergonomics: This can be defined as the study of working R condition. It is important in the design of equipment to enable C people work more efficiently. It is the study of objects, systems and the environment for their safe and efficient use by people concerned and those within the operational environment. It deals with human comfort obtained in the use of a given product. The apparatus was designed in such a way o that the operator can operate it safely, easily and effectively by putting the following factors into consideration; personnel Fig. 1 Design Configuration of Beam Deflector protection, and stability. Personnel protection entails Resisting moment of each plate, designing for consideration for safety of the personnel such as minimizing excessive noise, guarding moving parts that can (1) course injury and ensuring the comfort of the operator. Stability involves designing to ensure rigidity and stability of Now, the apparatus. The height of the beam deflection apparatus Or was carefully chosen and considered during the design and construction of the apparatus. This allows the operator to 344 ISSN: 2277-3754 ISO 9001:2008 Certified International Journal of Engineering and Innovative Technology (IJEIT) Volume 2, Issue 6, December 2012 Maximum bending moment = = =100N/m Let E = 200GN/ Or (2) Strain energy = U = Where, b = width of each plate t= thickness of each plate a = overlap at each end N = Number of plates in the spring L = the spring span length = δ= E = Young’s modulus of elasticity Refer to the Fig. 1 = (3) δ= , .δ= 2 Also Or, = = (4) .:δ= Or. δ = (5) Strain energy, U = = X total length of leaves X total length of leaves = X total length of leaves = total length of leaves = total length of leaves = U= x volume of spring =25N/m Deflection of the spring =Bending stress Neglecting X total length of leaves spring volume of spring (6) From the design; Number of leave spring used = 1 Length of spring = 1000mm Width of spring = 50mm Thickness of spring = 9.5mm The apparatus was designed to carry a maximum load of 1000N = 43.7mm Dial Gauge: The dial gauge is mounted on magnetic carrier which slide across the upper cross member. It is used to measure all beam deflection. The dial gauge is 0.25mm in 0.1mm division. Since the deflection of the spring is 43.7mm, the dial gauge for the apparatus is above 43.7mm because of safety reasons. Scale: This is suitably marked or graduated scale that is secured to the main support beams so that test beam supports the load and the dial gauge may be quickly and accurately located. It is IM to B54372. Dial Gauge Support: It is mounted in the main support beam and can be readily moved to the selected point where the deflection is to be measured. It holds the dial gauge firmly in position. Slope Indication: This is used for measuring slopes. It is used in fixing moments for a built-in beam experiment and it is placed so that it is symmetrical. Slope Indicator Clamp: It is used to hold the slope indicator to the test beam. It is placed over the outer support bar of the slope indicator. Build in Support: It is a rigid pillar at one end of the heavy steel base of the bench mounted (Beam deflection apparatus) it is positioned on the rigid main support beam; it is used for test beams. Test Beam: They are made of different materials like wood, aluminum, mild steel and brass. The test beams are usually straight steel beams that must be free of corrosion or major blemishes. Load Hanger: They are fitted with cursor, which register on the scale thus ensuring easy accurate positioning, loads weights are applied to the load hangers during experiment. The load on each hanger is identical. Load Rail: It is a heavy steel base on which all weights of most of the component of the apparatus hang on. Load Link: This holds the load hangers on which loads are placed. Spring Support: Mounted on the main frame to permit horizontal movement of the spring. 345 ISSN: 2277-3754 ISO 9001:2008 Certified International Journal of Engineering and Innovative Technology (IJEIT) Volume 2, Issue 6, December 2012 Tee-Legs: The two members of the main frame of the D. Construction Process Some of the processes used during construction are beam deflection apparatus are bolted to the T-legs to form marking out, welding, turning etc. Drilling machine, lathe rigid assembly and balance. Stirrup: The stirrup is used to hold and suspend the load machine, welding machine, hack saw blade etc. were used during the construction. The member bolted to the T-legs is of link. Beam Clamp: It is used to hold the beam in position. It is length 1,501mm (after being cut to size). The T-legs were cut to the size of the base length 304mm and height 390mm. A made up of mild steel iron. 40mm diameter round pipe of length 1240mm was welded to C. Material Selection Generally engineering materials includes, metal and the side of the T-legs for rigidity. Holes were drilled at the non-metals which differ in their chemical, physical and base of the T-legs with a pillar drill to allow the two stands to mechanical properties and therefore determine their usage. be bolted and welded to the base of the T-legs. Other Before any material can be selected for use in the construction assembling works were done in the workshop like the fixing of this apparatus. The following factors have to be of the dial gauge and the spring support. E. Maintenance considered: material analysis; material sourcing; and material For effective condition of the beam deflection apparatus, costing Material Analysis: This is the process of assessing the the following steps need to be taken: the steel beam should be materials to determine the inherent properties posed by that straight and kept free from corrosion or other defect. But in particular material so as to meet or perform the desired the case of a wood beam they are slightly soiled and oil and function without difficulty. The material selected for use in should not be saturated by oil or grease; the dial spindle the manufacturing of beam deflection apparatus must be should not be oiled, but wipe with a clean dry cloth or wiper suitable for the prevailing condition of service. For the which should be lint free. The spindle should be gently pushed purpose of this project, analysis was based on the strength, through the instrument and other side wiped. The dial gauge toughness and hardness of the materials selected. The should be free to move; the clamping screws and nuts should material used for the construction of this apparatus be free to move, clean the threads with suitable tap or die. The component includes: mild steel; and plastics. The mild steel general sizes used are M6 and M8 to B.S and ISO standards; contains 0.05-0.30 percent of carbon and some percentage of and the bright parts and the under sides of base should be free iron. The mild steel because of its desirable properties such as from corrosion and kept lightly oiled. F. Installation ductility was used for the construction of the build in support, The apparatus was designed for bench mounting. Every Tee-legs, spring support, etc. A plastic was chosen for the construction of the meter rule at the side of the cross-bar item of the apparatus was wiped with a soft cloth to remove because of the dominant role it plays both for industrial and any dust. The apparatus was placed on a firm level bench with domestic application. Hence, their high specific strength and legs about 150mm to 200mm away from the front of the stiffness (as a result of low relative density), corrosion bench. A spirit level is placed on the parallel beam and the resistance, good electrical and thermal insulating properties, leveling screws were adjusted to set the apparatus level in two low coefficient of friction, toughness and resilience with good places with the main scale facing the test piece. Every safety vibration damping capacities, ease of fabrication and regulations were observed, such as none flooding the apparatus with solvent, using a wiper that has been dampened inexpensiveness compared to other metals on volume basis. Material Sourcing: The material selected for use should with solvent to clean, allowing the parts to dry and cover with perform satisfactory under loading conditions. Also, the a thin film of oil. In every warm climate, light or less viscous material selected for used are those readily available locally. grease is preferentially used in order to retain a protective film. This making the project cost effective. G. Operational Safety Material Costing: This is one of the factors guiding the The apparatus is safe and possesses no health hazard when selection of material which must be relatively cheap in order to meet up in the competitive market of the product. Any mounted correctly and used properly under adequate industrial set up has to produce at a minimum cost and at the supervision. The operator should be encouraged to adopt safe same time improves the quality of the product. The cost of an working practices by wearing protective boots or shoes. In engineering product can be considered in two ways namely, addition, safety glasses and laboratory coats should be worn at direct cost and indirect cost. Indirect cost is the cost of the all times in the laboratory. It is advisable that all mounted overheads such as land, maintenance cost and repair cost apparatus is guarded to prevent persons from walking into it while direct cost refers to the cost of raw materials, salaries (obstruction) and to prevent a fall of weight onto the feet of and wages etc. The direct costs are mostly considered because person close to the apparatus. When the apparatus is bench they are the costs directly related to the price of a specific mounted and requires a weight on a cord to overhang the product. This type of cost was employed in determining which bench through a pulley, this should not be sited on a main process is feasible for the manufacturing of the beam access or emergency gangway. When performing experiments ensure those load hangers are properly engaged with load deflection apparatus cords, beams hook etc. as appropriate. 346 ISSN: 2277-3754 ISO 9001:2008 Certified International Journal of Engineering and Innovative Technology (IJEIT) Volume 2, Issue 6, December 2012 The Apparatus: consisted of a twin beam support fitted H. Servicing Safety During servicing it is desirable that all personnel should with a scale to which the various support were attached. The wear eye shields and a filter mask with an organic protection beam was loaded by a double hook and stirrup passing filter. If the service involves moving weights no matter how through the support beam, the arrangement of this apparatus small, protective foot wear must be worn. After contact with was described by Fig. 2. A number of different support loads oil and solvents, hands should be washed with a hand cleanser were used at predetermined points in the experiment. to remove all traces. All electrical equipments must be Young’s Modulus Determination: The experimental disconnected from the supply before servicing. Table I shows set-up comprised 3 triangular stirrup, 2 double ended hooks, 1 bill of materials for the apparatus. load hanger, weight, steel beam (normal 25 x 6), 1 dial gauge Table I Engineering Bill of Measurement and Evaluation and a tall dial gauge support, and position gauge. The Material Size Qua Rat Amount arrangement is shown in Fig. 2 similar to Fig. 1, where, for description ntity e the leaf spring, b, width of each plate; T, thickness of each plate; A, distance of each plate; N, number of plate in the spring; L, the spring span length; δ, bending stress; and Mild steel 100mm 1 11, 11, 500 U- channel x75mm 500 young’s modulus of elasticity (Eqns. 1-6). The results 650mm x 650mm 1 75mm x 25mm 2 1,300 x 10mm 1 Bolts and nuts Mild steel Pipe Dial gauge Electrode 14mm Cutting disc m Grinding disc m Miscellan eous Locally made Imported 5 2 2 4,000 1,3 1,300 250 100 60 2pc s W W 410 1 18, 500 30 1 25 750 250 250 10, 300 20 10,300 Ø230m 1 cups 1 2, 000 1,5 00 500 500 10 Ø230m 1 500 500 5 7, 200 α Fig. 2 Experimental Set up 18,500 750 Pkt 1 L/2 L/2 α 2, 600 1,300 Set Mild steel Rod Paint 2,0 obtined using the following parameters: L, 500mm; a, 250mm; W, 40N on each end in step of 10N, is presented as Fig. 3 from which young’s modulus E is 271kN/m2. 00 Ø50m Hack saw blade Leaf Spring 3,500 00 17 19 22 m x 100mm 0.1mm Division Gauge 10 3,5 00 Load (N) 10mm mild steel plate Mild steel rectangular bar Plastic scale 2,000 15 1,500 7, 200 0 0 N 64,710 $ 431.40 N 500,000 $3333.3 3 10 20 30 40 50 Deflection (mm) Fig. 3 Relationship between loads and deflections I. Performance Evaluation The beam deflection apparatus was used to conduct an experiment to determine young’s modulus for a metal bar. III. RESULTS AND DISCUSSION Fig. 3 shows that results are dependent upon the average material properties of the beam rather than being influenced by any localized variation. Four points loading was used in this test because it gave constant bending moment over a 347 ISSN: 2277-3754 ISO 9001:2008 Certified International Journal of Engineering and Innovative Technology (IJEIT) Volume 2, Issue 6, December 2012 relatively long length of the beam under test in the [7] J.A Gilbert, C.L. Carmen, "Chapter 11 – Beam Deflection Test."MAE/CE 370 – Mechanics of Materials Laboratory experiment. The young’s modulus elasticity of the iron bar 2 Manual, 2000. tested was found to be 271kN/m , which indicated that the material is relatively ductile. It was also clear that as the [8] P.A. Hilton, “H.SM1 Beam Deflection Apparatus” United Kingdom, H1– tech Education, P. A Hilton Limited Article modulus of elasticity decreased from material to material, the Published at http://www.intech.com/products/hsm.htm.,2003. deflection increased for the same applied load. This was true for both the theoretical and the experimental data. It will be [9] K. Bramble, “Strength of Materials Engineers” Edge USA: Engineer Edge Inc., 2005. economically justifiable if the beam deflection apparatus could be manufactured and sold locally, in Nigeria (Table I) [10] M.R. Islam, M.A. Mansur, M. Maalej, “Shear strengthening of as compared to the high cost of the imported item (Table I). N, RC deep beams using externally bonded FRP system,” Elsevier Ltd., pp 413-420, 2004. is the symbol for Nigerian currency. Besides, delay in importation, high import duty, and high cost of foreign [11] Norwood, “Deflection of Beam Apparatus”, Great Britain: exchange would lead to high cost of imported item. Norwood Instrument Limited. New Mill Road, Honley Huddershield, 1990. IV. CONCLUSION The beam material size, support spacing and loading can all be adjusted to give a wide range of experimental conditions. The beam deflection apparatus is one apparatus that can be used to understand beam theory which is one of the functional knowledge highly significant to the industrial engineer. The cost of materials required for large-scale production is not too high and can be easily sourced locally. The technical manpower required can be found locally by training and re-training of existing technical artisans, technologists and engineers. The market is large locally and can also be exported to other African countries. More research should be embarked on in the process of production of beam deflection apparatus. The apparatus should be mass-produced to ensure its availability in the laboratories for students’ experimental demonstration. ACKNOWLEDGMENT The effort of Ibraimoh, a Mechanical Engineering Postgraduate Diploma Student, is appreciated in the areas of fabrication and testing of the apparatus. REFERENCES [1] A. S. Mohamad, “Thesis on Flexural strengthening of RC beams using CFRP strips,” UTP Library, Malaysia, 2004. [2] A. Spencer, P.A. Hiltion, “Material Testing and Properties”, U.S.A. Techquipment Inc. Article Published at www.techquip.com. 2003a. [3] A. Spencer, and P.A. Hiltion, “SM 104 Beam Apparatus”, USA Techquiipment Inc. Article Published at www.techquip.com, 2003b [4] C. Riley, K. Muoio, “Beam Deflection Apparatus SAN313”, USA: Delta Analytical Instrument Inc. France: Societe DELTA LAB pared activities de centr’ Alp Moiran Articles Published www.deltalab.com.http://www.deltalab.fr/uk/product.php?pro did579. 2004. [5] L. Chilver, C.T.F. Ross, “Strength of Materials and Structures”, 4th Edition USA and Canada: Elsevier Knouel Corporation, 1999. [6] H. C. Luebkenman, D. Petting”Structures Strength of Materials”, Development in Structural Form, England: Allen Lame/Penguin Books, 1996. [12] R.Ehsani, “Shear and flexural strengthening of R/C beams with carbon fiber sheets, “Journal of structural Engineering, Vol. 123, No.7 pp. 903-911, 1997. [13] R.G. Wight, M.A. Erki, C.T, Shyu, R. Tanovic, P. J. Heffernan, “Development of FRP Short-Span Deployable Bridge-Experimental Results” Journal of Bridge Engineering, pp. 489-498, ASCE / Jul/Aug, 2006 . [14] B. Kareem, “Development of a changeable die forging machine for small scale forging industries”, J. Eng. Applied Sci., Vol 2, No. 1, pp 77-80, 2007. [15] P. Russell, “ Historical evolution of fib instrumentation and technology”, in Nanofabrication using focused ion and electron beams (principles and applications), I. Utke, et al. eds. (Oxford series on Nano manufacturing, pp. 36-42, 2012 [16] R.G. Wight, C.T. Shyu, R. Tanovic, M.A. Erki, P. J. Heffernan, “Short-span deployable GFRP tapered box Beam Bridge” Proc., 4th Int. Conf. on Advanced Composite Materials in Bridges and Structures (CD-ROM), pp. 20–23, 2004a. [17] R.G. Wight, C.T. Shyu, R. Tanovic, M.A. Erki, and P.J. Heffernan, “Deployable Tapered Box Beam Bridge: Advanced Polymer Composites for Structural Applications in Construction”, L.C. Hollaway, M. K. Chrysanthopoulos, and S.S.J. Moy, eds., Wood head Publishing, Cambridge, England, pp. 428-433, 2004b. AUTHOR BIOGRAPHY B. Kareem was trained in Nigeria at the Federal University of Technology, Akure, where he obtained his B.Eng. (Mechanical Engineering), M.Eng. (Production Engineering), and Ph.D (Industrial Engineering) degrees. He served as the Acting Head of the Department of Mechanical Engineering at the Federal University of Technology Akure, Nigeria. He has been the head of the industrial development research group at the University. His areas of research included industrial systems’ design and development. He has supervised to completion several M.Eng. and Ph.D candidates. He has published several research articles in reputable journals and books of conference proceedings. He was given several academic honors and awards including the best researcher of the year by his University. He is a member of many professional bodies including World Academy of Science, Engineering and Technology (WASET). He is a reviewer/editor to many reputable academic journals. 348