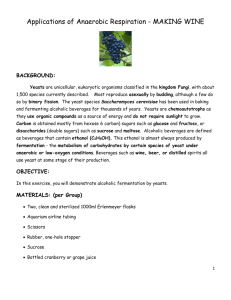

here - Scott Laboratories

advertisement