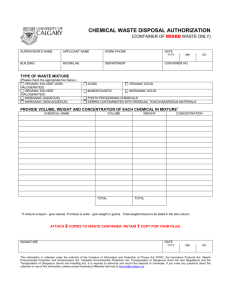

CHEM 202 LAB

advertisement