Evaluation of ethyl formate and nitrogen for disinfestation of eucalyptus weevil on export apples Stewart Learmonth Department of Agriculture & Food Western Australia Project Number: AP09045 AP09045 This report is published by Horticulture Australia Ltd to pass on information concerning horticultural research and development undertaken for the apple and pear industry. The research contained in this report was funded by Horticulture Australia Ltd with the financial support of Fruit West and Forest and Wood Products Australia. All expressions of opinion are not to be regarded as expressing the opinion of Horticulture Australia Ltd or any authority of the Australian Government. The Company and the Australian Government accept no responsibility for any of the opinions or the accuracy of the information contained in this report and readers should rely upon their own enquiries in making decisions concerning their own interests. ISBN 0 7341 2860 6 Published and distributed by: Horticulture Australia Ltd Level 7 179 Elizabeth Street Sydney NSW 2000 Telephone: (02) 8295 2300 Fax: (02) 8295 2399 © Copyright 2012 Final Report HAL AP09045 (31 March 2012) Evaluation of ethyl formate and nitrogen for disinfestation of eucalyptus weevil on export apples Stewart Learmonth YongLin Ren Department of Agriculture and Food, Western Australia Murdoch University i HAL Project: AP09045 Project leader: Mr Stewart Learmonth Entomologist Department of Agriculture and Food, Western Australia Locked Bag 7 MANJIMUP WA 6258 Tel (08) 9777 0000 (Ext 167) Mob 0417 959 319 Email stewart.learmonth@agric.wa.gov.au Research leader: Dr YongLin Ren Principal Research Scientist, DAFWA Associate Professor School of Biological Science and Biotechnology Murdoch University South Street MURDOCH WA 6150 Tel: (08) 9360 1397 Email: y.ren@murdoch.edu.au Research team: Dr Manjree Agarwal Mr James Newman Mr Hui Cheng Mr John Sutton This report describes laboratory and commercial scale trials and contains bioassay, phytotoxicity and residue data, research methodology and chemical application methods. The technology developed from this project can potentially be used for disinfestation treatment of harvested fruit and pre-shipment treatment to ensure market access. Therefore, this report could be very useful and beneficial to orchardists, researchers, regulators, plant biosecurity officers, chemical companies and government agencies. 23 April 2012 Any recommendations contained in this publication do not necessarily represent current HAL policy. No person should act on the basis of the contents of this publication, whether as to matters of fact or opinion or other content, without first obtaining specific, independent professional advice in respect of the matters set out in this publication. ii Contents Media Summary ......................................................................................................................... 2 Technical Summary .................................................................................................................... 3 Introduction ................................................................................................................................ 4 Materials and Methods ............................................................................................................... 5 Fruit and insect samples .......................................................................................................... 5 Commercial scale cool room fumigation trials ....................................................................... 8 Fumigation with nitrogen ........................................................................................................ 9 Bioassays ............................................................................................................................... 11 Measuring temperature and relative humidity of cool rooms ............................................... 12 Results and Discussion ............................................................................................................. 13 Laboratory bioassay of ethyl formate and nitrogen .............................................................. 13 Large scale bioassay of ethyl formate against eucalyptus weevils ....................................... 16 Technology Transfer................................................................................................................. 17 Recommendations .................................................................................................................... 17 Acknowledgments .................................................................................................................... 17 Bibliography of literature cited................................................................................................. 18 Appendix - Media reports ......................................................................................................... 20 Road block for hitch-hiking weevils removed ...................................................................... 20 HAL Apple & Pear Industry Annual Report contribution for 2012 ..................................... 25 1 Media Summary Eucalyptus weevil is considered native to Tasmania and accidentally introduced to Western Australia. Increased commercial cultivation of its main plant host, blue gums in WA, especially during the 1990s, increased abundance dramatically. This increase has occurred in plantations near commercial apple orchards in the south west. The eucalyptus weevil is not a direct pest of apples but uses them as an overwintering site. The weevil adults cling tightly to stalks of apples remaining there from harvest through cool storage to export. Such contamination would lead to automatic rejection of consignments for export. Because the weevil invades orchards at any time, protection of the export trade in apples was considered best approached by disinfesting harvested fruit, rather than attempt to control the weevils in orchards. Two fumigants – ethyl formate and nitrogen - were tested. Ethyl formate is already registered for disinfestation of dried fruit. Vaporised gas was delivered into cool rooms at 50-55 grams per cubic metre (g/m3) at 4-8°C for 24 hours to give 100 per cent mortality of adult weevils without affecting quality and shelf-life of the apples. This treatment was very effective and left negligible residues after apples were aerated. It has great potential for pre-shipment treatment of export apples. Following commercial trials on 2000 tonnes of Pink Lady™ apples in Manjimup in 2010, about 300 tonnes apples were exported to the United Kingdom – a market that lists eucalyptus weevil as a quarantine pest. Consignments of infested export apples for 2011 were all successfully fumigated with ethyl formate. The initial rudimentary system of fumigant delivery was replaced by a commercially robust method. Application is being made for registration of the fumigant for ongoing commercial use. In small scale trials it was very hard to maintain nitrogen above the required level of 99% for more than three days, the duration considered essential for successful fumigation. Therefore, assessment of nitrogen as a fumigant during this study was discontinued. Ensuring that export apples are free from a native weevil should become easier and cheaper thanks to this research. 2 Technical Summary Export of Pink Lady™ apples from Australia has been significantly affected by infestations of adult eucalyptus weevil (eucalyptus snout beetle or gum tree weevil). These weevils do not damage trees or fruit, but cling tenaciously to the stalks of apple fruit when selecting overwintering sites. As a result, apples infested with live eucalyptus weevils lead to rejection for export. The Montreal Protocol restricted use of methyl bromide as post-harvest treatment, therefore it was necessary to consider alternative safer fumigants for disinfestation of eucalyptus weevil on export apples. Laboratory experiments were conducted with ethyl formate, a naturally occurring volatile chemical present in many plant commodities such as grapes, apples, wheat, rice, essential oils of grasses, beer, beef and cheese. Ethyl formate has been registered and used as a fumigant on dried fruits in Australia. Experiments were conducted in the laboratory using concentrations of 5, 10, 15, 20, 25, 30, 40 and 80 mg/L of ethyl formate. Adult mortality was observed after 24 hours exposure. The concentration was measured continuously by gas chromatography (GC-FID). The bioassay data showed that complete control (100% mortality) was achieved at 25-30 mg/L of ethyl formate at 22-24ºC for 24 hours exposure without apples. However, with the area 90-95% full of apples, due to some ethyl formate absorbed by fruit, complete control was achieved at 40 mg/L of ethyl formate at 22-24ºC for 24 hours exposure. Residue analysis conducted after one day of aeration showed ethyl formate residue to have declined to background levels. In comparison with untreated apples, the colour and texture of fruit had no change and no effect on morphology or taste even after one, two and three weeks of treatment. Laboratory bioassays were conducted also using nitrogen as a potential fumigant. These showed all adult weevils were controlled at 99% nitrogen at 22-24ºC for three days. However, only 10-15% mortality was achieved at 97-98% nitrogen at 22-24ºC for 7-10 days. Apples just harvested and fumigated with ethyl formate immediately after Smart Fresh treatment showed signs of skin damage. Whether this occurred because fruit was recently harvested or was the results of an interaction with the Smart Fresh treatment or some other factor remains unresolved. Meanwhile, it is recommended that fumigation with ethyl formate be undertaken when apples are removed from cool store just before being shipped. Ethyl formate has great potential for pre-shipment treatment of export apples. Its use is considerably cheaper than other fumigants used commercially, some of which cause phytotoxic reactions and reduce fruit shelf-life. Five ethyl formate field trials were conducted in cool storages (capacity from 250-900 tonnes) at Newton Brothers’ Orchard, Manjimup. Vaporised ethyl formate was applied at 50-55 mg/L at low temperatures (4-8ºC) for 24 hours. All eucalyptus weevils were killed and after one day of aeration, residue declined to natural levels (0.05-0.2 mg/kg). Two nitrogen trials lacked success in small scale trials from difficulties in maintaining nitrogen level above 99%. 3 Introduction Australia conducts a small but important export trade in Pink Lady™ apples, but recent exports have been significantly affected by infestation of adult eucalyptus weevil (Gonipterus planensis, Marelli 1926). This is native to Tasmania where it feeds on leaves of eucalypts (Mapondera et al. 2012). The insect was accidentally introduced to WA where it inhabits blue gum (Eucalyptus globulus) plantations, but in autumn, like bears and bogong moths, some adult weevils seek shelter in apple orchards for the harsher weather. Weevil legs carry a multitude of tiny hooks which allow the adults to grip very tightly to the stalk of the fruit and are not dislodged when picked. They even remain attached throughout being water-flumed into a grading shed, blow-dried, packed and cool stored until late winter. They can be removed from fruit stalks only after concerted effort. The weevils do not damage apple trees or fruit, but rest at the stalk when selecting overwintering sites. As a result, apples infested in autumn remain infested in late winter when removed from storage. When subjected to quarantine inspection in Australia prior to overseas export, such fruit would be rejected, especially for the lucrative British and European markets. Increasing the export market for Pink Lady apples in Europe is vital in maintaining profitability for the variety. The possibility of exporting fruit in bulk bins has been examined for economies of scale associated with less intensive handling. But a hitchhiking insect such as eucalyptus weevil threatens both this developing market and the more usual trade in cartons. Until successful management programs for the weevil can be developed, the issue of bulk picking, packing and transporting is uncertain and even shipment in cartons is at risk. It is considered that the only practical method for shipping apples free of live weevils is to develop a disinfestation process. Due to restrictions governing use of methyl bromide as mandated by the Montreal Protocol, use of naturally occurring plant volatiles as potential fumigants for post-harvest treatment of insect pests was considered a priority for investigation. One such compound is ethyl formate which has long history as a fumigant for stored products (Cotton and Roark 1928; Roark and Cotton 1929) and for dried fruit in particular (Simmons and Fisher 1945; Vincent and Lindgren 1972; Banks and Hilton 1996). For the past few years, ethyl formate has been re-evaluated as an alternative fumigant for grain stored in unsealed farm bins (Annis 2002; Ren et al. 2003; Ren and Mahon 2006). It is currently registered as a fumigant for dried fruit in Australia and has a history of safe use as a food additive. Ethyl formate occurs naturally in soil, water, vegetation and a range of raw and processed foods including vegetables, fruit, grain, beer, grapes, wine and animal products like milk and cheese (Hiroyasu et al. 1972; Desmarchelier 1999). Unlike other fumigants, ethyl formate kills insects rapidly and its residue breaks down to naturally occurring products, formic acid and ethanol (Desmarchelier et al. 1998). It is a colourless liquid with a low boiling point (54.1oC) and has a pleasant aromatic odour. Its flammable limit is 85 mg/L. The US Food and Drug Administration (FDA 1984) reviewed its use as a flavouring agent and characterised it as safe. Experiments have been conducted using ethyl formate as a post-harvest fumigant for some pests of table grapes (Simpson et al. 2007) and thrips in onion (Van Epenhuijsen et al. 2007). Here we report the effectiveness of various concentrations of ethyl formate in controlling eucalyptus weevil both at laboratory scale and commercial scale. 4 Materials and Methods Fruit and insect samples For both laboratory study and field trials, Cripps Pink apples harvested in April/May 2009, were supplied by Harvey Gilbert from Newton Brothers’ Orchard. The fruit samples were stored at 5ºC in a cool room. Adult eucalyptus weevils collected from blue gum plantations in Manjimup were used for bioassay. Reagents and apparatus Ethyl formate used for laboratory study (standard preparation and laboratory bioassays) was supplied by Sigma Aldrich, reagent grade, 97% purity. For commercial scale fumigation, food grade ethyl formate, Eranol, was supplied by Orica Australia and SRL India. One litre Erlenmeyer flasks (Bibby Sterilin, Staffordshire, Cat. No. FE 1 L/3) were used for preparation of standards; 250 mL Erlenmeyer flasks (Crown Scientific, Code FE1L3) equipped with cone/screw-thread adapter (Crown Scientific, Code ST 5313) with 7/16” blue septa (Grace Davison Discovery Sciences, catalog: 6518 ) were used for fumigation; 120 mL glass bottles (Plasdene Glass Pak, Perth) were used to monitor weevils after fumigation; and 4 litre glass jars (Plasdene Glass Pak, Perth) with screw tight lids were used for phytotoxicity and residue studies; 4 L glass jars were used for the fumigation of the apple samples plus insects. The measured volume of each Erlenmeyer flask and inlet system was calculated from the weight of water required to fill the container and used for calculations. A 100 µL syringe (SGE, Melbourne, Cat. no. 005250) and 5 uL syringe (SGE, Melbourne, Australia; Cat. no. 001000 5F) were used for injection of gas samples into the gas chromatographs (GC) and transfer of liquid ethyl formate to make gas standards; 50 mL air tight syringes (SGE, Melbourne; Cat. no. 008900) were used to withdraw air from empty flasks to make the standard. Analysis of ethyl formate Ethyl formate was determined using DPS portable GC companion 600 equipped with a flame ionisation detector (FID) after isothermal separation on a 30 m × 0.53 mm (i.d.) 3 um, metallic column, Restek 800-356-1688 phase MXTr-S, (Catalogue no. 70285, serial no. 702152) at oven temperature 90ºC, detector temperature 150ºC and carrier flow Helium regulator 55 KPa and Air regulator 100 Kpa (see Figure 1). All the samples and standards were injected in duplicate. The concentrations of ethyl formate were calculated on the basis of peak areas which were calibrated periodically using the external gas standards or fortified standards and recorded in Microsoft Excel. 5 Figure 1. DPS GC-600 equipped with a flame ionisation detector (FID) for analysis of ethyl formate in the laboratory and field Preparation of gas standard Gas standards were prepared by taking out a calculated amount of air from the Stoppard Erlenmeyer flask (1 L) and then injecting calculated amount of ethyl formate liquid into the flask. Formulas used for calculations are: Dose of ethyl formate to be added (uL) = Volume of flask/1000 × concentration of standards required (mg/L)/0.97 × 1/0.0914 Volume of air withdrawn (mL) = Dose added × 0.914/MW of EF × 22.414. Preparation of fortified standard samples For analysis of residues in fruit, fortified standards in duplicate were prepared using sodium chloride solution with untreated finely cut apples in 100 mL of Erlenmeyer flask and then adding known amounts of ethyl formate into the two flasks. The untreated controls were prepared by using untreated apples without adding ethyl formate. The samples and standards were kept at room temperature for three hours after exposure to ethyl formate was completed and before analyses for residues were undertaken. Laboratory bioassays Fumigation was carried out in 250 mL Erlenmeyer flasks without apples at 5, 10, 15, 20, 25, 30, 40 and 80 mg/L of ethyl formate. Four replications of each concentration with 25 adult weevils in each were taken. The experiment was repeated four times. For bioassays with apples, seven 4 litre glass jars were loaded 90-95% full with apples and 100 adult weevils in each. The jars were sealed with airtight lids equipped with septa as an injection port and a cone-shaped filter paper inside for carrying the liquid ethyl formate to avoid liquid ethyl formate directly contacting the fruit. Three jars were treated with 40 mg/L, three with 80 mg/L of ethyl formate and one served as an untreated control. The concentration of ethyl formate was measured by gas chromatography (GC-FID) at intervals over the exposure period of 24 hours. After 24 hours fumigation, flasks or jars were 6 opened to assess insect mortality and the insects were transferred to new 120 mL bottles containing fresh blue gum leaves at 25ºC to check for their recovery. The end point for assessment was two days after removal to account for any possible recovery of insects. Laboratory bioassays with 99% nitrogen or low oxygen were conducted on adult weevils. A 2.5 litre jar containing three apples and 100 weevils was used as a fumigation chamber. High purity food grade nitrogen was delivered from a cylinder through a manifold system to each chamber. The concentrations of nitrogen, oxygen and carbon dioxide were measured at intervals with Oxbaby gas monitor (Garman), shown in Figure 2. Figure 2. Laboratory nitrogen fumigation system and Oxbaby for measurement of nitrogen, oxygen and carbon dioxide Laboratory phytotoxicity and residual studies For phytotoxicity and residual studies eight apples were placed in each of seven 4 litre glass jars. The jars were sealed with lids with septa as injection ports and a cone-shaped filter paper inside to absorb the liquid ethyl formate. Three jars were treated with 40 mg/L, another three with 80 mg/L of ethyl formate and one served as an untreated control. After 24, 48 and 96 hours fumigation, one jar each of 40 and 80 mg/L were opened and the apples were checked for morphological and physiological changes compared with unfumigated fruit. For analysis of ethyl formate residues, one apple each from 24, 48 and 96 hours exposure with no aeration, one day, two days and four days’ aeration and the untreated control were taken out and kept in a freezer prior to determination of levels of ethyl formate. If unable to be analysed immediately they were stored in a -20oC freezer and thawed to room temperature for analysis. 7 Commercial scale cool room fumigation trials Fumigation with ethyl formate Two different methods for application of ethyl formate were tested at Newton Brothers’ Orchard (Manager, Harvey Gilbert), Manjimup, Western Australia (Figure 3). In the first three trials, 10 electric frying pans placed on the top of fruit stacks were used for vaporizing ethyl formate (see Figure 4). The circulation fans on the wall of the cool room were run to disperse vapour throughout the storage area during the vaporising. A Logitech WilLife Outdoor Camera with Master System USB connected to computer was used for monitoring vaporisation of ethyl formate from electric frying pans during fumigation. In the second two trials, a new outdoor ethyl formate nitrogen purging unit was tested (see Figure 5). The new unit used high temperature nitrogen as a carrier to vaporize and deliver ethyl formate vapour into the storage area. Dosages of 50-55 g/m3 were applied for all five large scale fumigation trials. Figure 3. The ethyl formate trials were conducted at Newton Brothers’ Orchard, Manjimup, Western Australia. This cool room was 900 m3 capacity fully loaded with Pink Lady apples for export. Team members from left to right are James Newman (Laboratory Manager, Murdoch University), Harvey Gilbert (Newton Brothers’ Orchard, Manjimup), Hui Cheng (Research Officer, Murdoch University) and Stewart Learmonth (Entomologist, DAFWA). 8 Figure 4. Ethyl formate vaporising in the powered up frying pan – captured by Logitech Wilife Surveillance outdoor camera Figure 5. Pilot scale outdoor ethyl formate nitrogen purging unit Fumigation with nitrogen Two small scale nitrogen fumigation trials were conducted at DAFWA’s Manjimup Horticultural Research Institute. The first trial was conducted in a modified 5 cubic metre cool room (Figure 6). A pressure swing adsorption (PSA) nitrogen generator with a capacity of 30 m3 of 99.5% nitrogen per hour (Figure 7) was used to supply high purity nitrogen into the cool room. The second trial was conducted in a PVC-covered stack of volume 2 cubic metres containing two bins of apples (1200 kg). Nitrogen was food grade gas supplied by BOC. 9 Difficulties in maintaining nitrogen above the required level of 99% for more than three days resulted in poor results with these small scale fumigation trials.. Figure 6. A cool room was modified for the nitrogen fumigation trial Figure 7. A pressure swing adsorption (PSA) nitrogen generator with a capacity of 30 m3 of 99.5% nitrogen per hour 10 Bioassays Eucalyptus weevils were collected from blue gum plantations at Manjimup. When preparing the fumigation bioassays, five eucalyptus weevils were transferred to plastic vials (100 mL) with screen lids and perforated bottoms. The vials were placed in different locations throughout the cool room including some being suspended down the sides of stacks on the end of string lines. The treated and unexposed insect numbers used were 800-1200 and 200-300 adults respectively for each trial (Figure 8). Figure 8. Perforated vials containing live eucalyptus weevil adults and a gas sampling line for large scale assessment of ethyl formate fumigation After 24 hours fumigation, the cool room was opened and aired for 2-4 hours and then all vials were retrieved. To assess insect mortality, vials were transferred to a laboratory at 25ºC to check for recovery (Figure 9). End point was delayed for two days to account for possible recovery of insects. Figure 9: Vials with weevils were assessed in a laboratory at 25ºC until two days after collection from fumigation trials 11 Measuring temperature and relative humidity of cool rooms During the fumigation, headspace air temperature and relative humidity were automatically recorded in the cool room with a HOBO data logger unit (Model H08-00402, Onset Computer Corporation, MA 02532, USA, www.onsetcomp.com). To measure fruit temperature, the HOBO probe sensor was inserted 1 m below the fruit at the top of bin stacks in the centre of the cool room. To measure the headspace air temperature and relative humidity, the HOBO was hung 0.5 m above the fruit at the top of the bin stacks. The recorded data were read with BoxCar Version 3.6+ for Windows (Onset Computer Corporation) software. The HOBO units had previously been calibrated in the laboratory against each other and an alcohol-filled glass thermometer as well as a range of glycerol/water solutions for relative humidity. Determination of concentration × time products (Ct) The concentrations of fumigants were monitored by GC at intervals over the exposure period and were used to calculate the product Ct = Concentration × time. The Ct products were calculated from Equation 1. Ct = ∑ (Ci+Ci+1) (ti-ti-1)/2 Equation 1. Where: C is ethyl formate concentration (g/m3) t is time of exposure (hours, h) i is the order of measurement Ct is concentration × time products (g h/m3) Gas sampling and monitoring To monitor the concentration of ethyl formate in cool rooms during the exposure and ventilation periods, 8-10 nylon gas sampling lines (3 mm i.d.) were installed at various positions inside the cool room before the application of ethyl formate. Gas samples were drawn from the storage through these lines using an electric pump to a position 5 m from the storage, which was outside the fumigation area. The gas samples were stored in Tedlar sample bags (1 L) until analysis (usually within one hour) using the gaschromatographic conditions previously described. 12 Results and Discussion Laboratory bioassay of ethyl formate and nitrogen All bioassay results were compared with untreated controls which were kept under the same temperature and relative humidity, with the same number of weevils. For bioassays without apples, adult mortality was observed after 24 hours exposure. Complete control (100% mortality) was achieved at 30, 40 and 80 mg/L of ethyl formate at 22-24ºC. However, mortality of 81, 72, 13 and 0% were observed at 25, 20, 15 and 5 mg/L of ethyl formate (see Figure 10). End point mortality readings taken at two and four days after the end of fumigation did not show any revival of weevils. Figure 10. Mortality of eucalyptus weevils at different levels of ethyl formate and 22-24ºC for 24 hours exposure Due to some ethyl formate being absorbed by the fruit at a loading of 90-95% apples, complete control was achieved at 40 mg/L of ethyl formate at 22-24ºC for 24 hours. The loss of fumigant in the chamber during fumigation showed that about 50% of applied ethyl formate was absorbed (Figure 11). The concentration of the formulation declined rapidly within the first 10 hours, particularly within the first four hours. These are typical results, and the loss of fumigant from the gas phase followed the expected pattern with an initial rapid sorption giving way to a long-term trend about 10 hours after dosing. This result is consistent with previous trials of ethyl formate on wheat, barley, oats and peas (Desmarchelier et al. 1998; Ren et al. 2003 and 2006). The laboratory bioassays of nitrogen or low oxygen showed all adults were controlled at 99% nitrogen at 22-24ºC for three days. However, only 10-15% mortality was achieved at 97-98% nitrogen for 7-10 days. Compared with other insects, the tested eucalyptus weevils had more tolerance of low oxygen. 13 Figure 11. Sorption of ethyl formate by apples, from measurement of loss of concentration in the headspace of fumigation chamber at 25°C for two rates and three exposure times with ethyl formate after removal from fumigation chamber Phytotoxicity and residue studies of ethyl formate for apples Studies on residue levels in fruit and phytotoxicity were carried out. Residue was analysed and after one day aeration showed that ethyl formate residue in apple to have declined to background levels (0.05-0.2 mg/kg) shown in Table 1. During the holding period, ethyl formate declined in fruit without the need for fan-forced aeration. After one day, residues were above those in the untreated control sample, but below the level of 1 mg/kg which is the current Australian maximum residue level (MRL) for ethyl formate in dried fruit. These results are consistent with previous commercial-scale trials with ethyl formate on wheat, barley, oats and peas (Desmarchelier et al. 1998; Ren et al. 2003 and 2006). Table 1. Ethyl formate residues in treated apples at 40 and 80 mg/L at different exposure durations and untreated control samples just after exposure and aeration for one day Dosage Exposure time After exposure One day of (mg/L) (days) (no aeration) aeration 1 10.4 0.09 40 80 Untreated control 2 12.5 0.05 4 13.2 0.10 1 18.5 0.07 2 16.2 0.11 4 16.3 0.08 1 0.05 0.08 2 0.10 0.06 4 0.08 0.09 14 In comparison with untreated apples, the colour and texture of fruit subjected to fumigation with ethyl formate showed no change and had no effect on morphology or taste even after 1, 2 and 3 weeks of treatment (Figure 12). Figure 12. The colour and texture of fruit fumigated with ethyl formate showed no change or effect on morphology after three weeks of treatment 15 Large scale bioassay of ethyl formate against eucalyptus weevils Ethyl formate application methods The electric frying pans used to vaporise ethyl formate were a simple yet highly efficient method for conducting the trials. It was hard to confirm complete vaporisation of ethyl formate inside the cool rooms without use of an outdoor camera. While this method was suitable for assessment of ethyl formate to disinfest apples of the weevils, it could be a worker safety issue because large amount of liquid ethyl formate have to be carried by hand to the top of fruit stacks. The new outdoor ethyl formate nitrogen purging unit was highly efficient in vaporising and delivering ethyl formate into the commercial-sized cool storage areas. For example, 50 litres of ethyl formate can be vaporised and delivered to a 900 m3 cool room in less than 45 minutes. The unit works reliably and has no OH&S issue. The cost of the treatment was $0.35-0.40/t of fruit. This technology has great potential to offer application of ethyl formate for pre-shipment treatment of other insect pests of fruit and vegetables. Phytotoxicity Large scale fumigation trials with ethyl formate were primarily conducted at the end of the cool storage period, just before export. In one case, recently harvested fruit that had been subjected to Smart Fresh treatment (Smart Fresh Quality System, AgroFresh Inc.) before an ethyl formate fumigation test. While this resulted in 100% kill of weevils, some damage to the apple skin at the calyx end was observed on around 30-40% of fruit (Figure 13). Figure 13. Skin and flesh damage to Pink Lady apple at calyx end where recently harvested fruit was subject to Smart Fresh treatment, followed by ethyl formate fumigation The actual cause of this apparent phytotoxicity is not known. Until this matter is resolved and to avoid a recurrence of such adverse effects, it is recommended that fumigations with ethyl formate be undertaken just after fruit is removed from cool stage as it is being readied for export. Bioassays The total of more than 5000 and 1000 adult weevils were included in fumigated areas and as untreated controls respectively during five commercial-scale trials. All the bioassay results were compared with controls in triplicate, which were kept outside the cool rooms with the same number of weevils. Total mortality was achieved in all the treated plastic vials compared to no mortality in the untreated controls. No revival of weevils was observed even after two days culture at 25ºC in the laboratory. This number of test insects with no survivors could be considered an acceptable result for the purpose of substantiating this use of ethyl formate as a commercial phytosanitary treatment for required quarantine inspections for export fruit. 16 Technology Transfer Presentations on the progress of the project have been made to various meetings of the Pink Lady Australia Group and Fruit West by Dr YongLin Ren, Stewart Learmonth and John Sutton on 6 September 2009, 25 November 2009, 9 November 2010 and 7 November 2011. A progress report in the form of a poster was presented at the Australian Entomological Society Annual Conference in 2010 (Agarwal et al. 2010). A demonstration of the application technology will be held at Newton Brothers’ Orchard in Manjimup, Western Australia in the afternoon of 1st May 2012, to discuss the project and the development of the application equipment. The new outdoor ethyl formate nitrogen purging unit will be available commercially in the near future. The Post-harvest Biosecurity Laboratory, Murdoch University, will collaborate with DAFWA extension officers and work with chemical company representatives to register ethyl formate for biosecurity treatment of fruit. The technology developed from this project could transfer to end users through extension and plant biosecurity officers, horticultural industry networks, media reports and horticultural open day demonstrations. Recommendations The success of these trials with ethyl formate suggest that the processes developed could have wider applications for the benefit of other Australian horticultural industries. We recommend that the technology should be evaluated for other insect pests such as scale, thrips, Fuller’s rose weevil and mealybug on fruit and vegetables. It should also be evaluated as an alternative to methyl bromide for pre-shipment treatment of fruit and vegetables, both interstate and overseas. The cause of the fruit damage that was associated with exposure to Smart Fresh treatment and subsequent ethyl formate fumigation also needs to be investigated to enable clearer recommendations to be made to industry if using this treatment. Acknowledgments This research would not have been possible without funding by the Forest Industries Federation (Western Australia) Inc, Fruit West and Horticulture Australia Limited. The financial support from the Cooperative Research Centre for National Plant Biosecurity (CRCNPB) and Murdoch University was greatly appreciated. We thank Harvey Giblett of Newton Brothers’ Orchard, Manjimup, and his staff for supplying Pink Lady apples and support during fumigation activities. 17 Bibliography of literature cited Agarwal M, Learmonth S, Ren Y, Jansen M, Cheng H and Newman J. 2010. Control of eucalyptus weevil, G. scutellatus (Gyllenhal) (Gonipterus platensis (Marelli 1926)) in apples by ethyl formate. Poster presented at the Australian Entomological Conference, The Vines Resort, Swan Valley, Western Australia, 26-30 September 2010. Annis PC. 2002. Ethyl formate – where are we up to? In Proceedings of the Australian Postharvest Technical Conference, EJ Wright, HJ Banks and E Highley (eds), CSIRO Entomology, Canberra, ACT, Australia, pp. 74–77. Banks HJ and Hilton SJ. 1996. Ethyl formate as a fumigant of sultanas: sorption and efficacy against six pest species. In Proceedings of an International Conference on Controlled Atmosphere and Fumigation in Grain Storage, EJ Donahaye, S Navarro, A Varnava (eds), Nicosia, Cyprus, 21–26 April 1996. Printco Ltd, Cyprus, pp. 409–422. Cotton RT and Roark RC. 1928. Fumigation of stored product insects with certain alkyl and alkylene formates. Industrial and Engineering Chemistry 20, 380. Desmarchelier JM. 1999. Ethyl formate and formic acid: occurrence and environmental fate. Postharvest News and Information 10 (1), 7N–12N. Desmarchelier JM, Allen SE, Ren YL, Moss R and Vu LT. 1998. Commercial scale trials on the application of ethyl formate, carbonyl sulphide and carbon disulphide to wheat. Technical Report No. 75, CSIRO Entomology, Canberra, ACT, Australia. [FDA] US Food and Drug Administration. 1984. Title 21, subchapter B - food for human consumption. CFR Part 184. Title 21, Vol, Sec. 184.1295. Hiroyasu T, Shibanuma C, Ishii H, Yamada R and Nakamura C. 1972. Studies on the sugars, organic acids and volatile components in grape-berries. Technical Bulletin of Faculty of Horticulture, Chiba University 20: 51-60. Mapondera TS, Burgess T, Matsuki M and Oberprieler . 2012. Identification and molecular phylogenetics of the cryptic species of the Gonipterus scutellatus complex (Coleoptera: Curculionidae: Gonipterini). Australian Journal of Entomology. DOI: 10.1111/j.1440-6055.2011.00853.x. Ren YL, Desmarchelier JM, Allen SE and Weller GL. 2003. Commercial scale trials on application of ethyl formate to barley,oats and canola. Technical report No. 93, CSIRO Entomology, Canberra, ACT, Australia. Ren YL and Mahon D. 2006. Fumigation trials on the application of ethyl formate to wheat, split faba bean and sorghum in small metal bins. Journal of Stored Product Research 42: 277–289. Ren YL and Mahon D. 2003. Field trials on ethyl formate for fumigation of on-farm storage, In Proceedings of the Australian Postharvest Technical Conference, EJ Wright, MC Webb and E Highley (eds), CSIRO Entomology, pp 210-216. Roark RC and Cotton RT. 1929. Tests of various aliphatic compounds as fumigants. United States Department of Agriculture Technical Bulletin No. 162, 52. Simmons P and Fisher CK. 1945. Ethyl formate and isopropyl formate as fumigants for packages of dry fruits. Journal of Economic Entomology 38: 715–716. 18 Simpson T, Bikoba V, Tipping C and Mitcham EJ. 2007. Ethyl formate as a postharvest fumigant for selected pests of table grapes. Journal of Economic Entomology 100(4): 1084-1090. Van Epenhuijsen CW, Hedderley DI, Somerfield KG and Brash DW. 2007. Efficacy of ethyl formate and ethyl acetate for the control of onion thrips (Thrips tabaci). New Zealand Journal of Crop Protection and Horticultural Science 35: 267-274. Vincent LE and Lindgren DL. 1972. Fumigation of dried fruit insects with hydrogen phosphide and ethyl formate. Date Growers’ Institute Report 48: 4-5. 19 Appendix - Media reports A media release about progress on the project was generated by the Department of Agriculture and Food and released on 30 August 2011. The release is shown below followed by some media monitoring reports. Road block for hitch-hiking weevils removed Ensuring that export apples are free from a native weevil should become easier and cheaper thanks to new research being undertaken by the Department of Agriculture and Food. Researchers led by YongLin Ren, based at Murdoch University, are using ethyl formate to disinfest fruit and make sure that hitch-hiking eucalyptus weevils cannot survive – a current barrier to export apple sales. “Vaporised ethyl formate was delivered into cool rooms,” Dr Ren said. “We are finding the right concentration and duration at a temperature range of 5-13°C to give 100 per cent mortality of adult weevils without affecting the shelf-life and quality of the apples.” Following commercial trials of ethyl formate on 2000 tonnes of Pink Lady™ apples in Manjimup cool rooms in 2010, about 300 tonnes of Pink Lady™ apples were exported to the United Kingdom – a market that lists eucalyptus weevil as a quarantine pest. The eucalyptus weevil is not a direct pest of apples but uses them as an overwintering site, making it a quarantine pest only, Dr Ren said. The eucalyptus weevil is found in blue gum plantations, but it is not a major economic problem in Australia, due in part to its natural enemies. However, the weevil has become a serious pest in some overseas plantations, which has led to the blocking of apple exports to those countries free of the insect. Dr Ren said while the research was not yet complete, fumigation had been very effective and left negligible residues when the apples were aerated. He believes that ethyl formate has great potential for pre-shipment treatment of export apples. Ethyl formate is already registered as a disinfestation control for some horticultural commodities, but not in the exact way used in the recent trials. This use is considerably cheaper than other fumigants used commercially, some of which cause phytotoxic reactions and reduce fruit shelf-life. The research is supported by Horticulture Australia Limited, with additional contributions from Forest and Wood Products Australia, Fruit West and the CRC Plant Biosecurity. It will be completed in 2012 after further trials. Media contact Dr YongLin Ren, Principal Research Scientist, on 9360 1397 20 21 22 Fruit West Magazine, Spring 2011 23 ABC Midwest Wheatbelt (Geraldton) 07:30 News - 31/08/2011 - 07:33 AM Newsreader News Journalist Mr Grant Wynne 08 9923 4111 The Department of Agriculture and Food has discovered a new method of combating an invasive weevil which affects WA's apple exports. YongLin Ren, Department of Agriculture and Food, says he found spraying vapourised ethyl formate on apples whilst in cool rooms kills the weevils. Orchard, Newton Brothers conducted the trials last year, and Lucinda Gibbet, says the substance is much better than the alternatives previously available. © Media Monitors 2011 ABC Goldfields WA (Perth) 06:30 News - 31/08/2011 - 06:34 AM Newsreader Journalist Ms Jade McMillan 08 9093 7011 The Department of Agriculture and Food has discovered a new method of combating an invasive weevil which affects WA's apple exports. YongLin Ren, Department of Agriculture and Food, says he found spraying vapourised ethyl formate on apples whilst in cool rooms kills the weevils. © Media Monitors 2011 ABC Midwest Wheatbelt (Geraldton) 06:30 News - 31/08/2011 - 06:33 AM Newsreader News Journalist Mr Grant Wynne 08 9923 4111 The Department of Agriculture and Food has discovered a new method of combating an invasive weevil which affects WA's apple exports. YongLin Ren, Department of Agriculture and Food, says he found spraying vapourised ethyl formate on apples whilst in cool rooms kills the weevils. Orchard, Newton Brothers conducted the trials last year, and Lucinda Gibblet, says the substance is much better than the alternatives previously available. © Media Monitors 2011 ABC South Coast WA (Albany) 07:30 News - 31/08/2011 - 07:32 AM Newsreader State Editor News Mr Kim Jordan 08 9842 4031 WA apple producers have a new plan to combat an invasive Weevil. The Eucalyptus Weevil infects apple plantations during the winter by boring into the fruit as a barrier to the cold. The insect is a declared pest in some overseas countries, leading to a ban on infected apples from WA. The Department of Agriculture and Food conducted a study which found spraying the apples with Ethyl Formate, kills the insect, without affecting quality. YongLin Ren, Department of Agriculture and Food, says the chemical is already used to disinfect other foods. The research was done at Newton Brothers Orchards last year, Lucinda Giblett, Orchard, says the naturally derived substance is safe and will give local growers some certainty. © Media Monitors 2011 Interviewees: YongLin Ren, Department of Agriculture and Food, Duration: 1:48 Summary ID: W00045257414 24 HAL Apple & Pear Industry Annual Report contribution for 2012 Ethyl formate protection for export apples Eucalyptus weevil originated in Tasmania, but this keen little traveller has also become established in Western Australia, especially in blue gum plantations. This has created problems for nearby apple producers when weevils seek cosy overwintering sites and infest orchards from March onwards. Weevil adults cling tightly to apple stalks, withstanding washing and other treatments which can lead to automatic rejection of consignments for export. Because the weevil invades orchards at many different times, protecting the export trade by disinfesting harvested fruit was considered a better approach than orchard control. Two fumigants were assessed – ethyl formate and nitrogen – both offering safety to operators and little need for any withholding period compared with alternatives. Small scale tests with nitrogen proved difficult to maintain at high levels in sealed cool stores for more than three days so assessment was discontinued. Ethyl formate is a natural product already registered for disinfestation of dried fruit. Disinfestation for 24 hours provided 100 per cent mortality of adult weevils without adverse effects on either apple quality or shelf life. Following commercial trials in 2010 about 300 tonnes of Pink Lady™ apples were exported to the United Kingdom – a market that lists eucalyptus weevil as a quarantine pest. Consignments of infested export apples from Manjimup during winter 2011 were all fumigated successfully using ethyl formate. Application is being made for registration of the fumigant for ongoing commercial use successfully which should lead to advantages for the wider apple industry. Project: AP09045 For more information contact: YongLin Ren, Department of Agriculture and Food, Western Australia T (08) 9360 1397 E YongLin.ren@agric.wa.gov.au Article forwarded to HAL 20 April 2012. 25

advertisement

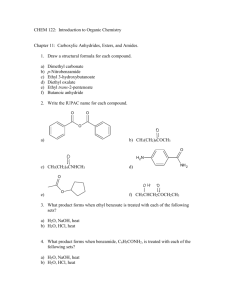

Related documents

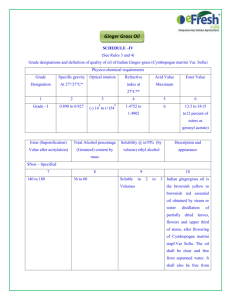

Download

advertisement

Add this document to collection(s)

You can add this document to your study collection(s)

Sign in Available only to authorized usersAdd this document to saved

You can add this document to your saved list

Sign in Available only to authorized users