middle east technical university department of aerospace

advertisement

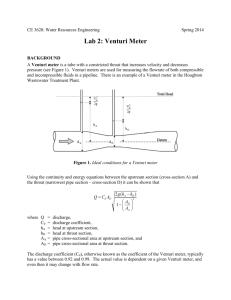

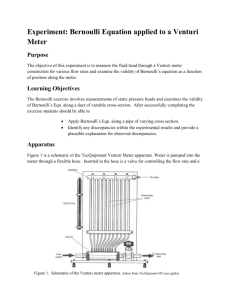

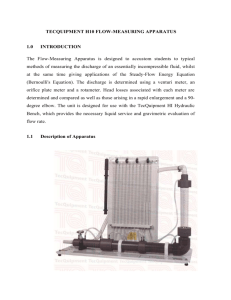

MIDDLE EAST TECHNICAL UNIVERSITY DEPARTMENT OF AEROSPACE ENGINEERING AE 547 EXPERIMENTAL AERODYNAMICS LABORATORY PROCEDURE VENTURI METER (H5) ANIL GÜÇLÜ TABLE OF CONTENT 1. INTRODUCTION ...................................................................................................................... 3 2. VENTURI METER TEST SETUP INFORMATION ......................................................... 3 a. Venturi Meter Apparatus..................................................................................................... 3 b. Volumetric Hydraulic Bench .............................................................................................. 4 3. INSTALLATION AND ASSEMBLY...................................................................................... 6 4. THEORETICAL INFORMATION ......................................................................................... 7 5. EXPERIMENTS ......................................................................................................................... 9 a. Discharge Rate Calculations ............................................................................................... 9 b. Pressure Calculations ........................................................................................................ 11 2 1. INTRODUCTION Venturi meters have been used to measure the volume flow along a pipe for many years. The fluid flowing in the pipe passes through a section which is called as “throat”. The throat has a smaller cross sectional area than other parts of the pipe. Assuming that the volume flow speed is constant, the velocity of the fluid through the throat is higher than the other sides of the pipe. There is a relation of the velocity of the flow and the pressure at the walls. As the velocity increases, the pressure falls proportional to the velocity. So, the flow rate can be calculated with the measured pressure and pipe parameters. 2. VENTURI METER TEST SETUP INFORMATION Venturi meter test setup composed of two main parts, which are Venturi meter apparatus and volumetric hydraulic bench. Detailed information about these components is given in this chapter. a. Venturi Meter Apparatus With using venture meter, which is procured from TecQuipment Company, it is possible to see and measure the complete static head distribution along a horizontal venture tube, Figure 1. Figure 1 – Venturi Meter (H5) The Venturi meter has three main holes. These holes can be named as fluid inlet, outlet, and air valve. As seen from Figure 1, fluid is supplied from the inlet (from 3 supply) and goes out to the measurement tank from the outlet. Flow velocity is adjusted with a control valve. The order of measured pressure can be changed with changing the air pressure in the manometer. Air valve hole is used to change and set the air pressure of the manometers. Technical details of the Venturi meter can be seen in Table 1. Table 1 – Technical Detail of Venturi Meter Item Details Dimensions and Weight 720 mm high x 650 mm wide x 300 mm front to back, 15 kg Nominal Venturi Dimensions Inlet pipe diameter 26 mm Throat diameter 16 mm Water Manometers 11 off 0 to 40 mm water The Venturi tube has two heads. One of them is placed at the cross-sectional area at the upstream section; another one is at the throat section. With the help of eleven manometers, pressure distribution along the meter can be observed. The ideal pressure distribution and the measured pressure distribution can be compared. Coefficients of the discharge for the meter parameter can be identified with using the outcomes of the experiments. b. Volumetric Hydraulic Bench The Volumetric Hydraulic Bench has a mobile water source and a water level indicator. There is a water pool inside the bench. The water is generally is colored as blue. With the water pump, which is placed inside of the bench, the water is pumped from the reservoir, to another test apparatus. It is important that the pump should not be worked when there is not enough water on the reservoir. The water, which goes out of the test apparatus, which is placed, on the bench, goes to the pool again. There are some test apparatus, which is recommended, however the bench can be used for any other suitable test apparatus. The volumetric hydraulic bench can be seen in Figure 2. 4 Figure 2 – H1D Volumetric Hydraulic Bench There is a valve, which controls the flow of water to an outlet pipe that passes through a hole and connects to another test apparatus. Inside of the volumetric hydraulic test bench can be seen in Figure 3. Figure 3 – The Drain Valve There are also some holes on the volumetric tank to prevent forgetting the drain the tank. Inside of the bench can be seen in Figure 4. Figure 4 – Inside of the Hydraulic Bench There is an On/Off switch, a fill level indicator, the stack pipe and a flow control valve mounted to the bench, which is shown in Figure 5. 5 Figure 5 – Tools of the Bench Technical details of the hydraulic test bench are shown in Table 2. Table 2 – Technical Details of the Hydraulic Test Bench Item Details Dimensions and weight Net: 1200 mm long x 760 mm wide x 1100 mm high and 80 kg Sump tank capacity Approximately 160 Liters Volumetric tank capacity 35 Liters Maximum accurate measuring rate 2 L/sec Pump 60L/min Electrical supply 220 to 240 VAC 50Hz 1A or 110 to 120 VAC 60Hz 2A or 220 VAC 60Hz 2.5A Circuit protection Thermal overload and under voltage sensor built into on/off switch. 3. INSTALLATION AND ASSEMBLY For measuring the flow rate with Venturi meter test bench, it has to be mounted on the hydraulic test bench. After the Venturi meter is placed on the hydraulic test bench, test can be operated after the below steps are followed. Steps 1-5 are related with the hydraulic test bench and 6-14 is related with the Venturi meter apparatus. 6 1. 2. 3. 4. Lift the Drain Valve from its hole in the Volumetric Tank. Pour clean water into Volumetric Tank. Connect the electrical supply. Press the ON button of the on/off switch to start the pump and check the leaks. 5. Switch off the pumps. 6. Put the apparatus on the top of the Hydraulic Bench. 7. Connect the bench supply hose to the inlet of the Venturi meter. 8. Connect the outlet of the Venturi meter to the plastic tube. 9. Set both apparatus flow control and bench supply valve to approximately one third fully open positions. 10. Check that the air valve on the other manifold is tightly closed. 11. Switch on the bench supply and allow water to flow. To clear air from the manometer tubes, you may tilt the apparatus. 12. Shut the apparatus flow control valve. Air now will be trapped in the upper parts of the manometer tubing and manifold. 13. Open air valve just enough to allow water to rise approximately halfway up the manometer scale. 14. Watch the values on the manometers and note it down. 15. You will record 3 data sets while turning the valve. 4. THEORETICAL INFORMATION There are some notations which are used during the theoretical calculations. Table 3 – Notation Symbol Meaning Units u, u1, u2 and un Velocity of flow m.s-1 D Diameter of the pipe m h, h1, h2 and hn Head m of water Δh Head Differential (h1-h2) m of water Q Volume flow or discharge m3.s-1 a, a1 and a2 Cross-sectional areas m2 C Flow Coefficient - G Acceleration due to gravity 9.81m.s-2 The relation among the velocity at the throat (u2), the volume flow, and the cross sectional area is the given in equation 1. 𝑄 𝑢2 = 𝑎 2 (1) 7 Figure 6 – Ideal Conditions in a Venturimeter For an ideal venturimeter, Bernoulli’s theorem states that; 𝑢12 𝑢2 𝑢2 + ℎ1 = 2𝑔2 + ℎ2 = 2𝑔𝑛 + ℎ𝑛 2𝑔 (2) Constant flow along the pipe can be found as; 𝑄 = 𝑢1 𝑎1 = 𝑢2 𝑎2 = 𝑢𝑛 𝑎𝑛 (3) Substituting the equation 2 from equation 3 yields; 𝑢22 𝑎 2 𝑢2 ( 2 ) + ℎ1 = 2𝑔2 + ℎ2 2𝑔 𝑎 1 (4) After solving the equations for u2 leads; 2𝑔(ℎ1 −ℎ2 ) 𝑢2 = √ 𝑎 2 1−( 2 ) (5) 𝑎1 Lastly, the discharge rate (volume flow) can be found as; 2𝑔(ℎ1 −ℎ2 ) 𝑄 = 𝑎2 √ 𝑎 2 1−( 2 ) (6) 𝑎1 Ideal dimensionless pressure can be obtained from; 𝑎 2 𝑎 2 (𝑎2 ) − (𝑎2 ) 1 𝑛 (7) 8 5. EXPERIMENTS After the experiment setup is prepared for test, the pressure tap values on the venturi meter manometers are observed and recorded with rotating the valve. Then, you must have ten different data sets at different flow rates. According to the data set, you will do some calculations about discharge rate and the pressure. a. Discharge Rate Calculations During the experiment, write down the heights of the manometer bars in the cells in Table 4. Note: Q1 flow rate is zero which means there is no flow (valve is closed), Q 3 is the fastest flow rate among Q1-Q3. Table 4 – Experimental Data Sets Tapping Heads (h) (mm) Q1 Q2 Q3 A (Upstream) (h1) B C D (Throat) (h2) E F G H J K L 9 Draw the heights of the manometers in the following plot at different discharge rates (Q1-Q3). 60 Manometer Heights (mm) 50 40 Q1 30 Q2 Q3 20 10 0 A B C D E F G Venturi Meter Sections H Figure 7 –Measured Data vs. Venturi Meter Sections J K L According to the heights data at 3 different discharge rates, calculate the each discharge rate Q1-Q3 and write down in Error! Reference source not found.. Table 5 – Discharge Rate Values ( x 10-4 m3/s) Q1 Q2 Q3 b. Pressure Calculations In pressure calculations, you will calculate and compare the ideal and actual dimensionless pressure values. For ideal case, the venturi shape parameters will be used (Figure 8). Figure 8 – Venturi Meter Parameters 11 Fill the Table 6 with your calculations. Table 6 – Ideal Pressure Distribution Throat Area (a2) / Upstream Area (a1) = (a2/a1)2 = Tapping Distance along Venturi (mm) A (Upstream)(a1) Diameter (m) Area (m2) Throat Area/Area (a2/an) 0 (a2/an)2 Ideal Dimensionless Pressure 𝒂𝟐 𝟐 𝒂𝟐 𝟐 ( ) −( ) 𝒂𝟏 𝒂𝒏 0 B(a3) C(a4) D(Throat)(a2) 1 E(a5) F(a6) G(a7) H(a8) J(a9) K(a10) L(a11) 12 The actual pressures will be calculated in Table 7. As stated before, there are ten measurement data sets. Fill the actual pressure distribution table, Table 7, according to the flow rate, Q3 which you calculated before. Table 7 – Actual Pressure Distribution Flow Q3 = 𝒖𝟐𝟐 = 𝟐𝒈 Tapping Distance along Venturi (mm) A (Upstream)(h1) 0 hn (m) hn-h1 (m) Actual Dimensionless Pressure 0 0 𝒉𝒏 − 𝒉𝟏 (𝒖𝟐𝟐 /𝟐𝒈) B(h3) C(h4) D(Throat)(h2) E(h5) F(h6) G(h7) H(h8) J(h9) K(h10) L(h11) 13 Calculate the pressure values at each section of flow discharge rates Q1-3 (x 10-4 m3/s) are given in Table 8. Table 8 – Actual Pressure Distribution for all Qs Tapping Q1 Q2 Q3 A(Upstream)(h1) B(h3) C(h4) D(Throat)(h2) E(h5) F(h6) G(h7) H(h8) J(h9) K(h10) L(h11) 14 After calculating the actual pressure values, compare with the ideal pressure values. The data graph of the pressure values are given in Figure 9. 1.2 Dimensionless Pressure 1 0.8 Ideal 0.6 Q1 Q2 Q3 0.4 0.2 0 A B C D E F G Distance along venturi (mm) H J K L Figure 9 – Pressure Distribution Results 15