Medtronic Xomed: Change at "People Speed"

advertisement

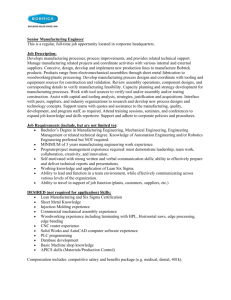

FUNDAMENTALS Medtronic Xomed: Change at "People Speed" Robert W. Hall Background on Vigorous Companies Medtronic Xomed is the fourth in a series of top performing companies called "vigorous," a term coined to describe a business unit that in total seems to be thriving in tough global competition. As many companies have found, sustained lean manufacturing, while essential, is not all that is required. Customers must be impressed enough to pay for fair treatment of all other stakeholders, and environmental responsibilities should not be neglected. To endure in this status, the leadership must build a culture that is always pushing the envelope in many directions, never satisfied with the status quo, and never complacent. Postulated is that a vigorous company must do well in three performance categories: process improvement ("lean everything"), innovation, and external responsibility. Trying to think about all this at once hurts the head, but it is achievable. To do it, the capability has to build up over time by developing the total workforce and its working culture, reducing the seemingly impossible and conflicting demands to rules for work, and a way of life that integrates many best practices into something relatively simple. Real people can actually do it. One reason for this series is to find vigorous operating companies that embody striving for a "B rating," or better, on the cultural scale shown below. The Medtronic Xomed story is best interpreted in that context. Class Process Improvement Innovation External Responsibility A Process improvement routine; eliminates waste from all-new processes very early. Capable of transforming its industry; can adapt business model to innovate. Unified by social mission; serves all stakeholders well; resilient to change/surprise. B Autonomous improvement; embedded in the culture. Innovate by collaborating; part of everyone's job. "Outside in;" much more customer focused. C Integrated core operations; directed improvement; still coaching the tools. Structured new product/ service development; some collaboration. Serves customers well; great quality, efficiency, and delivery. In Brief Medtronic Xomed has won both a Shingo Prize and an IndustryWeek Best Plant's Award. By regarding it as a cultural change, conversion to lean manufacturing has been a change "from the heart as well as the head." Also proficient bringing new products to market, Xomed works with physicians to improve medical practice while carefully developing its field force to avoid blurring the line between science and commerce. 7 First Issue 2004 M edtronic Xomed specializes in medical devices for the ear, nose, and throat (ENT), as well as niche ophthalmic (eye) products; many are for surgery; some are for diagnosis or treatment. Well known for trying to experience the needs of doctors and surgeons first hand, Xomed gives them what they want, and helps them devise something better — sometimes building custom orders for those with a little different technique in mind. Consequently, the ENT product line has greatly expanded over the past ten years. Xomed's strategic objective is market leadership in devices used "above the torso," relying on three core competencies: • Direct sales and distribution in the United States. • Speed and quality in manufacturing to "out-service competitors." • Research and development of new products and variations. On the way to market, new medical devices must jump many hurdles. Someone, somewhere — often a surgeon — must develop a new device, or at least be a partner in development. If experimental use shows promise, device modification may be necessary before other physicians and surgeons can learn to use it. Before offering it for general use, a new device must have FDA approval in the United States, and approval by comparable agencies in other countries. Xomed tries to work closely with approval agencies, plus ECRI, an independent health services research agency that tracks the performance of medical devices in use, and which is very influential in the field. External Responsibility Medtronic Xomed's field, medical and surgical devices, is tightly regulated, and in addition, filled with ethical minefields. To negotiate this terrain, Xomed complies with Medtronic's strict Code of Conduct and Business Conduct Standards, thoroughly training its field representatives to conduct their activities according to it. What can and cannot be done for customer enticement and interpreting clinical trial results is carefully proscribed. Everyone who deals with customers and other external parties is annually retrained using scenarios depicting situations in which what you should do is not obvious. Much more than merely reading a code, scenarios engrain ethical judgment in how people behave. To develop or discover new devices, Xomed is active at the forefront of treatment. For example, they invested in a focus group of doctors and patients to review sleep apnea, a condition that has no known cure or effective alleviation, trying to About Medtronic Xomed The Medtronic mission statement well captures why its Xomed Division exists: "To contribute to human welfare by application of biomedical engineering to alleviate pain, restore health, and extend life." Headquartered in Jacksonville, FL, the Xomed Division's devices primarily work on peoples' heads: ear, nose, and throat (ENT), and ophthalmology (eyes). The Jacksonville operation produces about 3200 end items and distributes 6000 more — 900 orders a day to about 30,000 customers in 120 countries. Most sales, promotion, and R&D are in Jacksonville, but there are two other operational locations; Mystic, CT for surgical sponges and MicroFrance in St. Aubin le Moniel, France for specialized micro-surgical handheld instruments. By expanding its offerings, Xomed now believes that it is the only full service ear, nose, and throat (ENT) company in the medical device business. Some of the more innovative products in Xomed's lineup are: 8 Target Volume 20, Number 1 Nerve Monitoring Equipment: The NIM-Response™ Nerve Integrity Monitor™ System, along with its associated line of disposable electrodes and nerve stimulators, allows surgeons to monitor nerves during surgery, dramatically improving patient safety and recovery by reducing the chance of unnecessarily compromising or severing nerves. Powered Systems for Sinus Surgery: The XPS® 2000 Microresector System, and recently introduced XPS 3000 System, (flexible, powered systems) improves the precision of least-invasive surgery, decreases surgical time, and improves post-operative recovery. Most of these units, including control boxes and the disposable micro-shaver blades, are produced in Jacksonville. Fluid Control: The Merocel® surgical sponge is used for surgical packing and for various applications in ophthalmology. sponges originate in the Mystic, CT plant and are finished and packaged in Jacksonville. Image Guided Surgery, or IGS: Surgeons have many applications for the LANDMARX EVOLUTION™ ENT Image Guidance System. Obviously, performance improves when a surgeon can guide from a screen an internal procedure that cannot be seen directly. Otology: Ventilation tubes and middle ear prostheses for the treatment of chronic ear infection and disease continue to see improvements. Notably, Xomed now offers the Meniett® 20 Pressure Pulse Generator for treatment of Ménière's Disease, a particularly debilitating disease of the inner ear. Ophthalmology: The primary line is equipment for tonometry, measurement of the inter-ocular pressure of the eye, but also includes several devices for cauterization, corneal transplant surgery, management of ocular hypertension caused by glaucoma, and LASIK surgery. Timeline history of the Medtronic Xomed Division: 1970 1978 1982 1989 1994 1996 1997 1998 1998 1999 2000 2001 2002 Company is founded in Cincinnati as "Xomox," making ear ventilation tubes, the bread and butter of the business for many years. Bristol-Myers Squibb buys Xomox, intent on broadening the product line into medical instruments as well as expendables. Operation moves to Jacksonville. Move into the present plant location. In the 1980s, Xomed attempted, with limited success, to implement elements of Total Quality Management and lean manufacturing. Bristol-Myers merges Xomed with Treace Medical and moves production of ear ventilation tubes into the Jacksonville facility. Warburg Pincus buys Xomed from Bristol-Myers Squibb. Xomed is merged with Merocel® (surgical sponges). Warburg takes Xomed public. The Treace brothers assume management and begin an aggressive program to develop and introduce new products. Introduce the XPS 2000 powered surgical system line (micro-shavers), which revolutionizes ENT surgery. Enter the Image Guided Surgery (IGS) and the biomaterial markets. These too take off, and Xomed starts to become what it is today. Acquire MicroFrance (better entrée to European markets). Acquired by Medtronic; becomes Medtronic Xomed. The Mentor ophthalmic line is merged with Xomed and moved to Jacksonville. Development of lean manufacturing begins to accelerate. Purchase the Meniett™ portable pressure-pulse generator for Ménière's Disease symptoms from Pascal Medical AB. The Medtronic Xomed plant wins both a Shingo Prize and one of IndustryWeek's 10 Best Plants Awards. Today the Xomed Division expects to grow revenue at a rate of about 15 percent annually. It serves nearly 50,000 physicians and 22,000 hospitals, and is clearly the market share leader in a market dominated by a large number of small companies. Some of them create innovative products, but lack resources to take them to a global market, so there is opportunity to grow by acquisition as well as through internal development. As a division of Medtronic, Xomed is relatively low-to-medium in volume and high mix in product. Most other Medtronic divisions are higher volume and lower mix. The core of operations is the Jacksonville headquarters, with 150,000 square feet and 550 employees. Jacksonville production occupies only 50,000 square feet of the facility and 300 of the employees, but accounts for about 80 percent of all Xomed revenue. Organization of complex production operations is based on 48 different value streams; non-production operations are organized more functionally. Simplification of the burgeoning complexity of offerings is critical to Xomed sustaining itself as a full service provider in the ENT field. 9 First Issue 2004 understand sufferers' true needs. They concluded that present technology cannot do much better alleviating the condition, but that Xomed might be able to field a device to improve its diagnosis. Culture Building Inside Xomed, the component of Xomed's working culture with the greatest longevity is the operating people at Jacksonville and elsewhere, often called the "money earners" because they create the billable shipments. Among senior managers, ten years is a long tenure; ownership changes and several acquisitions took a toll. But some of the "money earners" can remember moving into the Jacksonville facility in 1982 — and earlier. Despite all the changes, no managerial regime ever subjected Xomed workers to broken promises, pay reductions, or layoffs. Consequently, their reservoir of trust in management was never drained. "Money earners" are pleasant, open, eager to talk, and very serious assuming responsibility. Any of them will say that peoples' health and sometimes their lives depend on the quality of their processes. They seldom rush; doing everything just right is more important than speed — quality before output, always. However, as can be seen from the timeline in the box copy, change is a way of life for Xomed's money earners. Everything — products, managers, ownership — changed for them more than once in the past decade. No one is "hung up in the past," longing for bygones. In the 1980s, under Bristol-Myers Squibb, Xomed attempted to install various techniques for process improvement: Teams, Total Quality Management (TQM), JIT, and other buzzwords of that time. These were pushed, not from the top, but by middle managers without long tenure, so disjoint programs appeared and disappeared. TQM, for example, lasted about a year. Although the operative workforce learned to doubt the staying power of these programs, each of them stimulated teamwork, so that over time the working culture 10 Target Volume 20, Number 1 became more collaborative. In contrast with the more cosmopolitan managers, this "stable" workforce shared a long cultural apprenticeship prior to managers beginning a push toward integrated, sustained lean manufacturing. When Jerry Bussell, now vice-president, global operations, arrived in 1992, he immediately began work to build a culture of trust. His first confab with upper management stressed culture change — no swift transformation, but a gradual increase in empowerment to those doing the work, making change fun, not a threat. Jerry's first themes were derived from Stephen Covey's Seven Habits, followed by stimulating people to create skits and open up. But the most important ingredient solidifying trust was making sure that management commitments to the workforce were upheld. As this cultural migration proceeded, more and more managers began to see the value of lean manufacturing. One objective was to achieve market dominance by having customer service unmatched by the competition. Another was to offset the complexity of product line proliferation with process simplification. Xomed frequently refers to two plants, one for product, and one for paperwork. The paperwork satisfies QSRs (FDA Quality System Requirements), and allows any field problems to be traced, but the paper factory need not be inefficient. By 2000 a critical mass of lean thinking managers had formed, ready to aggressively implement an integrated version of lean manufacturing. They started in classic fashion, mapping value streams. Process changes came rapidly: cells, pull systems, 5S visibility, failsafe methods, and of course, grassroots problem solving methods. Soon Jacksonville operations were organized into value streams, and by 2003 there were 48 of them. Each value stream had a manager responsible for processes supplier-to-customer. Previously many of them were called business unit managers. Team leaders for each value stream handle most of the daily work, freeing the value stream managers to interact with cus- tomers and suppliers — and lead process improvement for a total enterprise. But this rapid transformation was made possible by the history of trust building in the culture. They were ready for the big paradigm change -— from taking direction to taking initiative. Managers no longer "tell them what to do;" they say, "It's your area; show me the best way to perform the work." For managers as well as money earners, that was a profound cultural change. This change was promoted by having people see and feel it, making it fun, not threatening, stimulating them to openly identify with the change. A typical bit of exhibitionism was a 5S dance. Symbolically repeated, the dance and other insider rites say, "I'm with it (the changed method of work), and you're with it, so we're with it." People opened up, got a little silly together, and bonded as a team to make changes stick. (Almost everywhere, active teams adopt "cool" monikers and use internal terms that outsiders might consider quirky. Xomed went a little beyond that.) By reaching people emotionally, outward displays of enthusiasm change collective behavior. Pure intellectual acceptance of lean tools and principles may not touch people enough to actually change their behavior. Bussell refers to this as the heart of change.1 That heart is the cultural hook on which the lean tools are hung. Transformation is not fully complete, but in three years they have come a long way, as shown in Figure 1. The improvement in line fill rate has been particularly important to Xomed's drive to best all competitors in customer service. From training to IT, Xomed's leadership and staff supports lean operations. Exactly what to do has not always been anticipated, so for instance, major IT changes friendly to fast flow operations were still pending in 2003. Tooling, maintenance, and manufacturing engineering assign people to support particular value stream lines. Cost accounting reports are by value stream. Rotating these assignments occasionally has proved to be a stimulus to problem solving by putting fresh eyes on old problems. Production and distribution of the devices has been relatively "leaned out," but more remains to be done. For example, in 2003 Jacksonville began to aggressively remove waste from the "paper factory." Jacksonville, the biggest operations center, is the core of lean transformation, but advance is not limited to that location. Culture change at other locations is roughly A Few of Medtronic Xomed's Lean Manufacturing Accomplishments 1998 2003 Line fill rate (percent orders complete shipped on time) 80% 96% Average manufacturing cycle time, start to finish 23 days 6 hours Work in process inventory turns 16 230 Rework as a percentage of revenue 0.14% 0.06% Sales per square foot* $1818 $2800 *Not shown in these numbers, an external warehouse was also eliminated. Figure 1. 11 First Issue 2004 comparable. For example, MicroFrance experienced a 58 percent productivity improvement in five years, while order leadtimes dropped from 16 weeks to two days. Xomed's objective is not fast lean conversion, but sustained — and sustainable — lean conversion. tioner a penny. And songs like, "Hit the road Muda; don't come back no more, no more …." Executives take the same training, learning to participate in the funky customs that socialize learning. Nothing builds confidence like a senior manager acting as goofy as you feel when trying to learn how to work in a whole new way. Training and Development Executives at Xomed credit Rick Kundert and Lea Carter for developing training to establish a sustained, cheerful "search for excellence." They made the change fun and introduced new ideas at a rate that made it possible for people to actually use them. The first round of training for lean manufacturing was mostly big picture "edutainment," using simulations to demystify it — removing the fear of specific techniques to implement, like 5S and cell building. Round two goes into more depth on established tools, like value stream mapping and problem solving methods. Quality training starts with simple statistics. People learn to use tools they know before learning more. Few people within Xomed are trained on advanced methods such as Design of Experiments. Previously, ambitious programs at Xomed failed by trying to change too much, too fast. Now the objective is to project from a solid understanding of what Xomed actually is toward what it must become. Training is personalized; everyone has a training record. So do departments. Knowledge gaps moving forward are addressed by more training. The key to success of the recent approach is eliminating various fears: looking stupid, being out of step with the group, making mistakes, and so on. There's little need for separate "touchy-feely" development because Xomed teaches techniques as behavior modification. People learn to "actually work and think the language of new methods." Training sessions initiate socializing customs that carry on long after the training, for example, the lean handshake and Penny Five: If someone cannot recite the steps of 5S, they owe their ques12 Target Volume 20, Number 1 Non-Operational Process Improvement Beyond the factories and laboratories, Xomed's lean revolution has begun to cascade into other functions, anxious to catch up. The time for new product introduction is being trimmed; Xomed has had numerous doctors touring their facilities express a sincere interest in running a "leaner practice." The field agents were one of the first to benefit from the push to eliminate waste. To give the reps more time with customers, and less paperwork and drive time, Xomed developed a sales support system using Palm technology. Using it, reps have at their fingertips the complete pricing structure, rosters of phone numbers, doctors' billing codes, extended warranty information, brush-up instructions on anatomy and surgical techniques, and more. The system's database of cross-references with competitive products is particularly useful. Previously, if a rep wanted to substitute a Xomed product for a competitors' — as when it failed or broke — she often had to plow through manuals for hours to be sure that a Xomed product could substitute for it. Now a rep can usually seize any such opportunity by quoting a substitute within five minutes or less. More systems like the Palm sales support are contemplated, but for them to be effective, professionals need to understand lean tools and principles in a personal context. As with the money earners, a "socializing version" of training for professionals in IT, R&D, sales, and accounting is being developed — very carefully. More issues must be addressed than for operations personnel moving product. Xomed wants to build a base, not a backlash. Suppliers and Distribution Today Xomed manages about 500 suppliers and 10,000 item numbers in their total system, end-to-end. Besides shipping items produced in their own factories, Xomed purchases items from suppliers for redistribution. Few of Xomed's suppliers are strong in lean manufacturing, although there are exceptions. For example, Dannaher, which supplies small motors, is a well-known lean company from whom Xomed has taken some operational cues, for example emulating Dannaher's policy deployment process. However, most suppliers are small shops with specialized products, so working with them to smooth out operations is a sizeable challenge. Xomed is just beginning to make substantive progress in supplier development. About 30 suppliers are currently on ship-on-demand status. Only packaging is now handled dock-to-stock (straight to the point of use with no stops and no inspections), but many other items are candidates, and the goal is to have 95 percent of all supplied items go straight to production. Certifying supplier process quality is slow work. Two supplier quality engineers are educating suppliers and working this issue, but before Xomed can dramatically shorten the inbound pipeline of material, many more suppliers must be able to ship defect-free materials. Without this, dockto-stock cannot happen. Relations with many suppliers are quite good. For example, if Xomed needs a modified material for new product development, they are responsive — nimble and imaginative, if not quick. And Xomed provides suppliers computer visibility of their stock on hand, and uses min-max stock levels to trigger re-shipments. This greatly reduced stockouts and diminished on-hand inventory by 25 percent. But dock-to-stock is a big step beyond, involving much more than visibility and logistical procedures. For this step, culture change is again the key ingredient. Supplier capabilities are not expected to improve with the snap of a finger, and Xomed is start- ing with internal reorganization, shifting responsibility for ordering and shipment from a central purchasing department to the value stream organizations. This move will shorten the "communication distance" between Xomed's "money earners" and the operating personnel of suppliers. On the outbound side — distribution — the "communication distance" to customers has already been shortened. The Jacksonville distribution center uses a heijunka box to initiate rounds of order picking on a 15-minute takt time. Just as if circulating around a production cell, order pickers fill each order by walking past sequenced locations of the 500 highest volume items, working from pick lists autogenerated by each order. Using this "flow system”, 99.9 percent of all incoming orders ship at least partial the same day, and 96 percent of them ship complete. Distribution is tied to production by a pull system that signals manufacturing value streams to replenish stock that has been shipped. This innovative system was a major step in Xomed being able to "out-service" competitors while reducing space and investment consumed by finished goods by half. As great as that improvement is, total inventory turns are only about four, so much opportunity remains. Xomed is challenged to dramatically reduce this further because many items are low volume with irregular demand. Research and Innovation Xomed's R&D department, headed by Craig Drager, concentrates on keeping Xomed in the technical lead in ENT and related devices. Most of them work on product concept and development. Although Xomed does not do basic research on fundamental science, they do search the world for promising technology. One person spends nearly full time tracking down interesting phenomena, and Xomed could create a new product right from scratch. However, this is not a highly productive approach. Most new product ideas come from outside Xomed. R&D seeks 13 First Issue 2004 technical solutions to promising problem opportunities, selecting projects that advance Xomed's market and technical leadership. Xomed does not want to be surprised, and forced into defensive, reactive product development. Projects are prioritized based on: • • • • Strategic fit in the product/service offerings Leadtime to develop Anticipated financial return Resources required. To assure that engineers pay close attention to projects, Drager limits them to no more than two projects concurrently. Xomed can't afford to have time conflicts delay moving a hot new product to market. To avoid compromising either quality or time-to-market with not-invented-here (NIH) issues, Xomed contracts expertise when needed. For example, they will contract an expert in high speed micro-motor design if that is not a specialty of anyone on staff. Since being purchased by Medtronic, Xomed has also found advantages in working with corporate R&D or other Medtronic divisions' R&D, tapping their experience and talent in areas new to Xomed, as for example in implantable devices, in which other Medtronic divisions are technical leaders. No product development project has totally bombed — been dropped or recalled. Few have missed their expected market target. The combined judgment of senior management has worked well picking winners. The same is true of adding new products through acquisition. "Due diligence" includes an assessment of how to integrate different operations and work cultures into Xomed. Today, Xomed integrates new products into their operational system much better. They carefully develop process standards for products developed in-house; for those acquired, they validate standard procedures from elsewhere and translate them into the formats used within Xomed. This practice simplifies life inside Xomed, and leaves much less complexity to explain during audits by standards or regulatory groups. 14 Target Volume 20, Number 1 Development or conversion of standards is done by cross-functional teams that include "money earners." To pass regulatory approval, development projects always had to be well documented. Now, in order to "take the air out" of project completion times, Xomed works harder validating processes at each stage of a project, which forces them to ask the right questions earlier and earlier, and wastes less overall project time by reducing the number of bad assumptions made to compensate for incomplete information. This begins before project inception, by validating user specifications (what the customer really needs). Further along, but well before launch, both the design specs and the process specs must be validated — including such considerations as whether suppliers have the capacity to provide new parts. However, project information flows remain a bit "convoluted." IT is working to remove waste from the project information system. The Cultural Foundation Inside Xomed there is little doubt that conversion to lean manufacturing, which is still in progress, accelerated around 1999 because it was preceded by a lengthy ramp up of cultural development among the operations personnel — the "money earners." Intense conversion was not an intense shock because changing work habits had become fun, and therefore nonthreatening. No "money earners" had to be dismissed because they could not adapt. In most cases, their work became easier, and after adjusting to it, much less confusing. Xomed's lean conversion tools and the sequence in which they were introduced are similar to those used by many other organizations. But Xomed is more successful than most because of the patient development of the culture for it. Within Xomed, change goes at "people speed." Jerry Bussell says that culture is the foundation on which all lean progress has been built. The cultural shift has proceeded the furthest with the "money earners," while the cultural shift among the staff, Organizational Vigor Ratings by the A-B-C Framework 15 First Issue 2004 Medtronic Xomed's A-B-C Rating: 16 Target Volume 20, Number 1 thus far, primarily supports the "money earners." Lean conversion has only begun to progress in non-operational processes, where the opportunities are at least as great as those in operations. Xomed has the challenge of making changes in "work think" as non-threatening to professionals as it was for the money earners. Robert W. Hall is editor-in-chief of Target and a founding member of AME. Footnote 1. Bussell's expression is from the title of a book by John P. Kotter and Dan S. Cohen, The Heart of Change, Harvard Business School Press, Boston, MA, 2002. However, his earliest efforts were based on Stephen Covey, The Seven Habits of Highly Successful People, Simon & Shuster, New York, 1998; followed by skits and role playing to draw people out and decrease their fear. © 2004 AME® For information on reprints, contact: Association for Manufacturing Excellence www.ame.org 17 First Issue 2004