ME 443 Engineering Economy and Production Management

advertisement

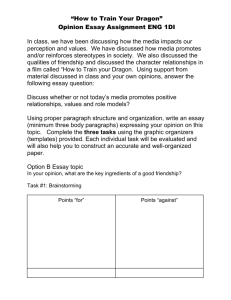

ME 443 Engineering Economy and Production Management Prof. Dr. S. Engin KILIÇ Middle East Technical University Department of Mechanical Engineering Office: B-305 Tel: 210 25 70 Engineering Economy and Production Management METU, Mech. Eng. Dept. Title Page ME 443 i 2009 Fall Content Chapter 1 : Chapter 2 : Chapter 3 : Chapter 4 : Chapter 5 : Chapter 6 : Chapter 8 : Chapter 7 : Class Notes : Engineering Economy and Production Management METU, Mech. Eng. Dept. Introduction Cost Concepts Time Value of Money Measures of Worth Comparison of Alternatives Replacement Analysis Depreciation Sensitivity Analyses Public Projects Linear Programming Large-Scale Project Planning Course Content ME 443 2009 Fall 2h 4h 10 h 3h 5h 3h 3h 3h 3h 4h 2h ii Content •What is Engineering and Engineering Economy? •Principles for Decision-Making •Decision-Making Process •Present Economic Studies Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 1 2009 Fall What is Engineering and Engineering Economy? •Engineering is the profession in which a knowledge of mathematical and natural sciences gained by study, experience and practice is applied with judgement to develop ways to utilise, economically, the materials and forces of nature for the benefit of mankind •Engineering economy evaluates the monetary consequences of the products, projects and processes that engineers design Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 2 2009 Fall Engineering Economy and Production Management METU, Mech. Eng. Dept. ME 443 2009 Fall What is Engineering and Engineering Economy? •It is the collection of mathematical techniques which simplify economic comparisons •It is a decision assistance tool to find the most economical solution •It uses mathematical formulas to account for the time value of money and to balance current and future revenues and costs Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 3 2009 Fall Principles for Decision Making •Common measure : all savings and losses must be expressed in the same monetary units. •Only differences matter : only the pertinent differences between alternatives must be included in the cash flow diagrams. Sunk costs should be ignored. •Separable decisions should be made separately •Adopt a systems viewpoint •Use a common planning horizon Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 4 2009 Fall Decision - Making Process •Define problem •Choose objective(s) •Identify alternatives •Evaluate consequences •Select •Implement •Audit Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 5 2009 Fall Present Economy Studies • Time value of money does not have to be considered: study period is shorter than a year • Applicable conditions : 1. – – – 2. Revenues and other economic benefits are not present or are constant among all alternatives: select alternative that minimizes total cost per defect-free unit of output no investment of capital, only out-of pocket costs are involved long-term costs are the same for all alternatives or they are proportional to first costs alternatives have identical results regardless of capital investment Revenues and other economic benefits are present and vary among alternatives: select alternative that maximizes overall profitability based on the number of defect-free units of output Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 6 2009 Fall Problems 1.1. In a certain manufacturing activity, 40 employees are engaged in identical activities. The average output of the group as a whole is 46.4 units/hour. The average output of the less productive half is 40.2 satisfactory and 1.4 unsatisfactory units per hour and the average of the more productive half is 52.6 satisfactory and 0.8 unsatisfactory units per hour. The employees work on a straight piecework plan and receive $3.30 per hundred satisfactory units. The firm sustains a loss of $0.07 for each unsatisfactory unit. One machine is required for each employee. Each machine has an annual fixed cost of $320 and a variable cost of $0.18 per hour. Supervision and Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 7 2009 Fall Problems 1.1. Cont.’d other overhead costs are estimated at $720 per employee per year. The average employee works 1900 hours per year. How much could be paid annually for a selection, training and transfer program which would result in raising the average productivity of the entire group to 52.6 satisfactory and 0.8 unsatisfactory units per hour? Solution: FC=(320+720)x20=$20,800/year VC=0.18x1900x20= $6,840/year Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 8 2009 Fall Problems 1.1. Cont.’d Solution: Before training: Cost of succ. parts: 1900x20x(40.2x3.3)/100 = $50,410.80/year Cost of unsucc. parts: 1900x20x1.4x0.07 = $3,724/year Cost/part: (20,800+6,840+50,410.80+3,724)/(1900x40.2x20) = 5.35 cents Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 9 2009 Fall Problems 1.1. Cont.’d Solution: After training: Cost of succ. parts: 1900x20x(52.6x3.3)/100 = $65,960.40/year Cost of unsucc. parts: 1900x20x0.8x0.07 = $2,128/year Cost/part: (20,800+6840+65,960.40+2,128)/(1900x52.6x20) = 4.79 cents Money which can be spent yearly for increased productivity: (5.35-4.79)x1900x20x52.60/100 = $ 11,193 Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 10 2009 Fall Problems 1.2. Either aluminium alloy or stainless steel will serve equally well in a certain corrosive environment. Aluminium alloy has a yield strength of 155MPa and stainless steel has a yield strength of 256MPa. The aluminium alloy will cost $1.50/kg and the stainless steel will cost $2/kg. The specific gravities of aluminium alloy and stainless steel are respectively 2.8kg/dm3 and 7.8kg/ dm3. If selection is based upon yield strength, which material will be more economical? Solution: In order that both materials carry the same amount of load: 155AAl = 256ASt Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 11 2009 Fall Problems 1.2. Cont. solution: If AAl = 1 WAl = 2.8 Cost of Al / length: 1.5x2.8 = $4.20 ASt = 155/256 WSt= (155/256)x7.8 Cost of Steel/length: (155/256)x7.8x2 = $9.44 Hence, Al is more economical. Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 12 2009 Fall Problems 1.3. In connection with surfacing a new highway, the contractor has a choice of two sites on which to set up his asphalt-treating equipment. He will pay a subcontractor $0.10 per cubic meter per kilometre for hauling the mixed material from the mixing plant to the job site. Factors relating to the two sites are as follows: Site A Site B Average hauling distance 6km 4km Monthly rental $100 $500 Cost to set up and remove equipment $1,500 $2,500 If site B is selected, there will be an added charge of $36/day for a flagman. Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 13 2009 Fall Problems 1.3. Cont. The job involves 50,000 cubic meters of mixed material. It is estimated that 4 months (17 weeks of 5 working days per week) will be required for the job. Solution: The relevant costs for the two sites can be tabulated as follows: Site A 4x$100 = $ 400 1,500 Rental Set-up cost Flagman Hauling 50,000x$0.10x6 = 30,000 TOTAL $31,900 Hence, Site B is more economical Engineering Economy and Production Management METU, Mech. Eng. Dept. Site B 4x$500 = $ 2,000 2,500 5x17x$36 = 3,060 50,000x$0.10x4 = 20,000 $27,560 Chapter 1: Introduction ME 443 1. 14 2009 Fall Problems 1.4. A manufacturing plant consists of three departments: A, B, and C. Department A occupies 100m2 in one corner of the plant. Product X is one of several products being produced in Department A. The daily production of X is 576 pieces. The cost accounting records show the following average daily production costs for X: Direct labor (1 operator working 4 hours per day at $22.5/hr, including fringe benefits, plus a part-time foreman at $30 per day) $120.00 Direct material 86.40 Overhead (at $0.82 per m2 of floor area) 82.00 Total cost per day $288.40 Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 15 2009 Fall Problems 1.4. Continued There is an outside company that sells X at $0.35 per piece. Hence the daily cost would be $0.35(576) = $201.60, resulting a daily savings of $288.40-$201.60 = $86.80. Buy alternative therefore seems to be more atractive than producing X in the plant. Engineering Economy and Production Management METU, Mech. Eng. Dept. Chapter 1: Introduction ME 443 1. 16 2009 Fall