BANK SOAL – BMFP 4542 (TEST -1)

advertisement

Haeryip Sihombing BANK SOAL – BMFP 4542 (TEST -1)

1. Identify and briefly describe the five commonly traded organizational currencies.

•

Task-related; the ability to contribute to others accomplishing their work,

•

Position-related; the ability to enhance others' positions within their organization,

•

Inspiration-related; the ability to enhance people's desire to make a difference and

add meaning to their lives,

•

Relationship-related; the ability to form relationships that transcend normal

professional boundaries and extend into friendship,

•

Personal-related; the extent to which one can help others feel a sense of importance

and personal worth.

2. Identify and compare the old-fashioned view of managing projects and the new

perspective of managing projects.

The old-fashioned view of managing projects emphasized directing and controlling

subordinates; the new perspective emphasizes managing project stakeholders and

anticipating change as the most important jobs.

3. Under what conditions would the top-down approach to estimating project times

and costs be the best choice?

In the early stages of a project to help develop the initial plan, in making strategic decisions,

in projects of high uncertainty, in small internal projects, or in projects with an unstable

scope.

4. Under what conditions would the bottom-up approach to estimating project times

and costs be the best choice?

When low cost, efficient estimates are needed, when time and cost are important, when

working on a fixed price contract, or when the customer wants details.

5. In the network computation process what is a forward pass and what three things

does it determine?

Starting with the first activity, each path is traced forward through the network, adding times

until the end of the project. This determines 1. how soon each activity can start, 2. how soon

each activity can finish, and 3. how soon the entire project can be completed.

6. What is a risk profile and what benefits does it provide to risk management?

A risk profile is a list of questions that address traditional areas of uncertainty on a project.

The questions have been developed and refined from previous, similar projects. These

profiles are generated and maintained by the project office and are updated and refined

during the life of the project. This historical file assists in identifying risks for future projects.

1

Haeryip Sihombing 7. What is Change Control Management and what function does it perform?

Change Control Management is the formal process for making and tracking changes once a

project has started. Any changes must be detailed and accepted by the project team. Risks

associated with making changes are thus assessed and documented.

8. Why would a project manager use heuristics rather than a mathematical solution

to level resources?

Mathematical models work on small networks and a small number of resources. Larger

projects have massive data requirements. Heuristics tend to yield a good solution without the

heavy burden imposed by math models.

9. Identify and briefly describe five reasons for attempting to reduce the duration of a

project.

1. imposed durations made by top management, 2. market demands created by competition

and rapid technology advances, 3. incentive contracts that pay for early project completion,

4. recovery of unforeseen project delays, 5. to reduce project costs by reducing charges

created by high overhead costs, 6. to reassign key resources to other projects.

10. Why is the project duration with the lowest direct costs seldom the optimum

duration for a project?

Indirect costs, those accumulating each day, will at some point outweigh the reduction in

direct costs leading to an increase in total costs. The Project Cost-Duration graph is a model

that demonstrates this.

2

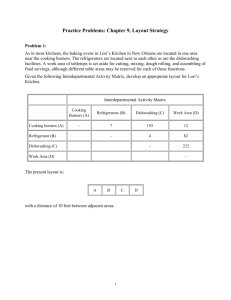

Haeryip Sihombing Problem Statement 1

Prem Binny Appliances wants to establish an assembly line to manufacture its new

product, the Mini-Me Microwave Oven. The goal is to produce five Mini-Me

Microwave Ovens per hour. The tasks, task-times, and immediate predecessors for

producing one Mini-Me Microwave Oven are as follows:

Task

A

B

C

D

E

F

Time (min)

10

12

8

6

6

6

Immediate Predecessors

A

A, B

B, C

C

D, E

a. What is the theoretical minimum for the smallest number of workstations

that Binny can achieve in this assembly line?

Output rate:

Prem Binny Appliances need to produce 5 Mini-Me Microwave Ovens per hour

The amount of time each workstation is allowed to complete its tasks:

Limited by the bottleneck task (the longest task in a process):

Theoretical Minimum (TM) = number of station needed to achieve 100%

efficiency

Therefore, the theoretical minimum for the smallest number of workstations that

Binny can achieve in this assembly line is 4 stations.

3

Haeryip Sihombing b. Graph the assembly line and assign workers to workstations. Can you

assign them with theoretical minimum?

Workstation

1

2

3

4

5

Eligible Task

A,B

A

C

D

E

F

Task Selected

B

A

C

D

E

F

Task Time

12

10

8

6

6

6

Idle Time

0

2

4

6

0

6

As conclusion, the workers are failed to assign with theoretical minimum.

c. What is the efficiency of your assignment?

Hence, there is left a balance delay of:

100% - 80% = 20%

Problem Statement 2

Paul Silver, owner of Sculptures International, just initiated a new art project. The

following data are available for the project.

Activity

Activity Time (days)

Immediate Predecessor(s)

A

B

4

1

4

Haeryip Sihombing C

D

E

3

2

3

A

B

C, D

a. Draw the network diagram for the project.

b. Determine the project’s critical path and duration.

The critical path is the longest path through the project, defining the minimum

completion time for the overall project. The critical path in this project is A-C-E,

determining that the project can be completed in 10 days.

Critical path duration, A-C-E

= 4 days + 3 days + 3 days

= 10 days

c. What is the total slack for each activity?

Calculation for slack time of each activity

Activity

Early Start

Early Finish

Late Start

Late Finish

Slack

A

B

C

D

E

Day 0

Day 0

Day 4

Day 1

Day 7

Day 4

Day 1

Day 7

Day 3

Day 10

Day 0

Day 4

Day 4

Day 5

Day 7

Day 4

Day 5

Day 7

Day 7

Day 10

0

4

0

4

0

Slack for the individual activities is calculated by taking the difference between the

late-start and early-start times (or, alternatively, between the late-finish and earlyfinish times) for each activity. If the difference is zero, then there is no slack; the

activity is totally defined as to its time-position in the project and must therefore be

5

Haeryip Sihombing a critical path activity. For other activities, the slack defines the flexibility in start

times, but only assuming that no other activity on the path is delayed.

Problem Statement 3

Given the activities whose sequence is described by the following table, draw the

appropriate activity-on-arrow (AOA) network diagram.

Activity

A

B

C

D

E

F

G

H

I

Immediate Predecessor(s)

A

A

B

B

C

E, F

D

G, H

Time (days)

5

2

4

5

5

5

2

3

5

a. Which activities are on the critical path?

The critical path is A-C-F-G-I

Activity

Duration

ES

EF

LS LF

Slack

Critical Path

A

5

0

5

0

5

0

*

B

2

5

7

6

8

1

C

4

5

9

5

9

0

D

5

7

12

8

13

1

E

5

7

12

9

14

2

F

5

9

14

9

14

0

*

G

2

14

16

14

16

0

*

H

3

12

15

13

16

1

I

5

16

21

16

21

0

6

*

*

Haeryip Sihombing b. What is the length of the critical path?

Length of critical path, A-C-F-G-I

= [5 + 4 + 5 + 2 + 5] days = 21 days

Problem Statement 4

Dr. Lori Baker, operations manager at Nesa Electronics, prides herself on excellent

assembly-line balancing. She has been told that the firm needs to complete 96

instruments per 24-hour day. The assembly-line activities are:

Task

Time (min)

Predecessors

A

3

-

B

6

-

C

7

A

D

5

A, B

E

2

B

F

4

C

G

5

F

H

7

D, E

I

1

H

J

6

E

K

4

G, I, J

Total

50

a. Draw the precedence diagram.

A

7

4

5

C

F

G

5

B

D

7

1

2

H

I

E

6

J

7

K

Haeryip Sihombing b. If the daily (24-hour) production rate is 96 units, what is the highest

allowable cycle time?

The highest allowable cycle time is

Therefore, the highest allowable cycle time is 15 min/unit.

c. If the cycle time after allowances is given as 10 minutes, what is the daily

(24-hour) production rate?

Therefore, the daily production rate is 57 units per day.

d. With a 10-minute cycle time, what is the theoretical minimum number of

stations with which the line can be balanced?

Cycle time = 10 minutes

Theoretical Minimum (TM) = number of station needed to achieve 100%

efficiency

Therefore, the theoretical minimum number of workstations which the line can

be balanced is 5 stations.

e. With a 10-minute cycle time and six workstations, what is the efficiency?

Number of workstation = 6 workstations

f. What is the total idle time per cycle with a 10-minute cycle time and six

workstation?

Cycle time = 10 minutes

Number of workstation = 6 workstations

8

Haeryip Sihombing Therefore, total idle time per cycle with a cycle time of 10 minutes and 6

workstations is 16.67%.

g. What is the best work station assignment you can make without exceeding a

10-minute cycle time and what is the efficiency?

Workstation

Eligible Task

Task Selected

Task Time

Idle Time

1

A, B, C, D, E

2

B, D, E, F

3

D, E, G

4

E, H, I, J

5

J, K

A

C

B

F

D

G

E

H

I

J

K

3

7

6

4

5

5

2

7

1

6

4

7

0

4

0

5

0

8

1

0

4

0

Therefore, the best workstations assignment is with the theoretical minimum number

of workstation which is 5 stations without exceeding the 10 minutes cycle time and

reached an efficiency of 100%. The assignment is shown in table above.

Problem Statement 5

Registration at Delhi University has always been a time of emotion, commotion, and

lines. Students must move among four stations to complete the trying semiannual

process. Last semester’s registration, held in the north campus, is described in

Figure below. You can see, for example, that 450 students moved from the

paperwork station (A) to advising (B), and 550 went directly from A to picking up

their class cards (C). Graduate students, who for the most part had preregistered,

proceeded directly from A to the station where registration is verified and payment

collected (D). The layout used last semester is also shown in Figure below. The

registrar is preparing to set up this semester’s stations and is anticipating similar

numbers.

9

Haeryip Sihombing Advising

station

(B)

Pick up

paperwork

and forms

(A)

--350

0

0

Paperwork/forms (A)

Advising (B)

Class cards (C)

Verification/payment

(D)

Pick up

class

cards

(C)

550

200

--0

450

--0

0

Verification of

status and

payment (D)

50

0

750

---

Existing Layout

A

B

C

30’

30’

D

30’

Figure. Registration flow of students

a)

What is the “load x distance,” or “movement cost,” of the layout shown?

From (A) to (B) = 450 x 30’ = 13 500

From (A) to (C) = 550 x 60’ = 33 000

From (A) to (D) = 50 x 90’ = 4 500

From (B) to (A) = 350 x 30’ = 10 500

From (B) to (C) = 200 x 30’ = 6 000

From (C) to (D) = 750 x 30’ = 22 500

b)

Provide an improved layout and compute its movement cost.

B

A

30’

C

30’

D

30’

From (A) to (B) = 450 x 30’ = 13 500

From (A) to (C) = 550 x 30’ = 16 500

From (A) to (D) = 50 x 60’ = 3 000

From (B) to (A) = 350 x 30’ = 10 500

From (B) to (C) = 200 x 60’ = 12 000

From (C) to (D) = 750 x 30’ = 22 500

10

Haeryip Sihombing Problem Statement 6

Recently, you were assigned to manage a project for your company. You have

constructed a network diagram depicting the various activities in the project (Figure

3.15). In addition, you have asked your team to estimate the amount of time that

they would expect each of the activities to take. Their responses are shown in the

following table.

Activity

A

Time estimates (days)

Optimistic

Most likely

5

8

Pessimistic

11

B

4

8

11

C

5

6

7

D

2

4

6

E

4

7

10

C

A

Start

D

Start

E

B

Figure. Network diagram for your project

Answer

teA

=

(a + 4m + b) / 6 = (5 + 4(8) + 11) / 6 = 8

teB

=

(4 + 4(8) + 11) / 6 = 7.8

teC

=

(5 + 4(6) + 7) / 6 = 6

teD

=

(2 + 4(4) + 6) / 6 = 4

teE

=

(4 + 4(7) + 10) / 6 = 7

σteA2

=

[(b – a) / 6]2 = [(11 – 5) / 6]2 = 1

σteB2

=

[(11 – 4) / 6]2 = 1.36

σteC2

=

[(7 – 5) / 6]2 = 0.11

σteD2

=

[(6 – 2) / 6]2 = 0.44

σteE2

=

[(10 – 4) / 6]2 = 1

11

Haeryip Sihombing Activity Predecessor Optimistic

A

B

C

D

E

A

A

B, D

0

5

4

5

2

4

8

0

A

0

8

3.8

Most

likely

8

8

6

4

7

8

0

0

Expected

time

8

7.8

6

4

7

11

11

7

6

10

Variance

1

1.36

0.11

0.44

1

14

0.8

C

8.8

6

8

0

Pessimistic

14.8

12

0

D

3.8

4

7.8

7.8

B

7.8 7.8

7.8

14.8

0

E

7.8

7

14.8

a) What is the expected completion time of the project?

Critical path = A – D – E

Duration

= 8 + 4 + 7 = 19 days

b) What is the probability of completing the project in 21 days?

Z=

= 1.280

p = 0.89973

The probability is 89.973%

c) What is the probability of completing the project in 17 days?

Z=

= -1.280

p = 0.10027

(by using Calculator fx 570, is: MODE – MODE – 1 – SHIFT -3 -1, -1.280 ENTER)

The probability is 10.027%

12

Haeryip Sihombing Problem Statement 7

Consider a project with the following information. Construct the project activity

network using AOA methodology and label each node and arrow appropriate.

Identify all dummy activities required to complete the network.

Activity

Duration

Predecessors

A

B

C

D

E

F

G

H

3

5

7

3

5

4

2

5

A

A

B, C

B

D

C

E, F, G

Activity

Duration

ES

EF

LS

LF

Slack

A

B

C

D

E

F

G

H

3

5

7

3

5

4

2

5

0

3

3

10

8

13

10

17

3

8

10

13

13

17

12

22

0

5

3

10

12

13

15

17

3

10

10

13

17

17

17

22

2

4

5

-

a. What is the critical path of the project?

A–C–D–F–H

b. Draw the graphic of the project

13

Haeryip Sihombing Problem Statement 8

Subsidiary Manufacturing produces custom-built pollution control devices for

medium-size steel mills. The most recent project undertaken by Subsidiary

Manufacturing requires 14 different activities.

a. The managers would like to determine the total project completion time (in

days) and those activities that lie along the critical path. The appropriate data

are shown in the following table.

b. What is the probability of being done in 53 days?

c. What date results in a 99% probability of completion?

Activity

Immediate

Predecessor(s)

Optimistic

Time

Most

Likely

Time

Pessimistic

Time

A

B

C

D

E

F

G

H

I

J

K

L

M

N

A

A

B, C

D

D

E, F

G, H

I

I

J

K

L, M

4

1

6

5

1

2

1

4

1

2

8

2

1

6

6

2

6

8

9

3

7

4

6

5

9

4

2

8

7

3

6

11

18

6

8

6

8

7

11

6

3

10

14

Haeryip Sihombing Answer:

a. The total project completion time (in days) and those activities that lie along the

critical path.

TE = (O + 4M + P) ÷ 6

Variance = [(P – O)/6]2

Where

O - Optimistic time ; M - Most likely time ; P - Pessimistic time ; TE Expected time

`Activity

Immediate

Optimistic Most Likely

Predecessor(s)

Time

Time

A

A

B, C

D

D

E, F

G, H

I

I

J

K

L, M

A

B

C

D

E

F

G

H

I

J

K

L

M

N

4

1

6

5

1

2

1

4

1

2

8

2

1

6

Pessimistic Expected

Variance

Time

Time

6

2

6

8

9

3

7

4

6

5

9

4

2

8

7

3

6

11

18

6

8

6

8

7

11

6

3

10

Critical path = A – C – E – H – I – K – M – N (55.92 days)

b. What is the probability of being done in 53 days?

Where

= critical path duration

= scheduled project duration

Z = probability (of meeting scheduled duration)

15

8.75

3

9

8

9.17

3.33

6.17

4.33

5.5

4.83

9.17

4

2

8

0.25

0.11

0

1

8.03

0.44

1.36

0.11

1.36

0.69

0.25

0.44

0.11

0.44

Haeryip Sihombing = 10.55

= 3.248

c. What date results in a 99% probability of completion?

When P = 0.9901, Z = 2.33

Problem Statement 9

Tailwind, Inc., produces high quality but expensive training shoes for runners. The

Tailwind shoes, which sells for $210, contains both gas and liquid-filled

compartments to provide more stability and better protection against knee, foot, and

back injuries. Manufacturing the shoes requires 10 separate tasks. There are 400

minutes available for manufacturing the shoes in the plant each day. Daily demand

is 60. The information for the task is as follows:

Task

Performance

Time(min)

Task Must Follow Task Listed

Below

A

1

-

B

3

A

C

2

B

D

4

B

E

1

C, D

F

3

A

G

2

F

H

5

G

I

1

E,H

J

3

I

16

Haeryip Sihombing a) Draw a precedence diagram.

C

120

A

B

60

180

E

D

60

240

F

J

60

180

H

G

180

I

300

120

b) Assign tasks to the minimum feasible number of workstations according to the

“ranked positioned weight” decision rule.

Cycle time =

= 400 sec per unit

Task

A

Position weight

1080

Rank

1

Performance time

60

B

840

2

180

C

420

5

120

D

540

4

240

E

300

6

60

F

840

2

180

G

660

3

120

H

540

4

300

I

240

7

60

J

180

8

180

Total standard time

Workstation =

1500

≈ 4 workstations

Cycle time = 400 second per unit

Stations

1

2

3

4

Time remaining

400, 340, 160,40

400, 220 160, 0

400, 280, 40

400, 100, 40

17

Tasks

A, B, C

F, I, J

G, D

H, E

Haeryip Sihombing c) What is the efficiency of the process?

Efficiency of the process = Ratio of productive time to total time

= [1500/4(400)] x 100%

= 93.7%

d) What is the idle time per cycle?

Stations

1

Time remaining

400, 340, 160,40

Tasks

A, B, C

Idle time per cycle

40 seconds

2

400, 220 160, 0

F, I, J

0 second

3

400, 280, 40

G, D

40 seconds

4

400, 100, 40

H, E

40 seconds

Problem Statement 10

The project manager of Good Public Relations gathered the data shown in table

shown for a new advertising campaign.

Time Estimates (days)

Optimistic

Most likely

Pessimistic

Activity

A

8

10

12

Immediate

Predecessor(s)

-

B

5

8

17

-

C

7

8

9

-

D

1

2

3

B

E

8

10

12

A, C

F

5

6

7

D, E

G

1

3

5

D, E

H

2

5

8

F,G

I

2

4

6

G

J

4

5

8

H

K

2

2

2

H

a. How long is the project likely to take?

Expected time,

Activity

=

2

, Variance,

Optimistic

A

Immediate

predecessor(s)

-

B

-

2

=

Pessimistic

8

Most

Likely

10

5

8

18

Variance

12

Expected

time(Days)

10

17

10

4

0.44

Haeryip Sihombing C

-

7

8

9

8

0.11

D

B

1

2

3

2

0.11

E

A, C

8

10

12

10

0.44

F

D, E

5

6

7

6

0.11

G

D, E

1

3

5

3

0.44

H

F, G

2

5

8

5

1

I

G

2

4

6

4

0.44

J

H

4

5

8

5

0.44

K

H

2

2

2

2

0

36

2.43

Total

Critical path is A-E-F-H-J

The project is has to take 36 days to be done.

b. What is the probability that project will take more than 38 days?

Z=

-

P( X > 38 )

/

= 1 - P( X < 38 )

= 1= 1- 0.8997 = 0.1003

The probability of the project will more than 38 days is 10.03%

c. Consider the path A-E-G-H-J what is the probability that this path will

exceed the expected project duration?

19

Haeryip Sihombing Expected time for A-E-G-H-J = 33days

Variance for A-E-G-H-J = 2.76

P( X > 33 ) = 1 - P( X < 33 )

= 1= 1- 0.0351 = 0.9649

The probability A-E-G-H-J path will exceed the expected project duration is

96.5%

Problem Statement 11

The optical disk project team has started gathering the information necessary to

develop the project network-predecessor activities and activity times in weeks. The

results of their meeting are found in the following table:

Activity

Description

Duration

Predecessor

1

Define scope

6

None

2

Define customer problems

3

1

3

Define data records and relationship

5

1

4

Mass storage requirements

5

2,3

5

Consultant needs analysis

10

2,3

6

Prepare installation network

3

4,5

7

Estimate costs and budget

2

4,5

8

Design section “point” system

1

4,5

9

Write request proposal

5

4,5

10

Compile vendor list

3

4,5

11

Prepare management control system

5

6,7

12

Prepare comparison report

5

9,10

13

Compare system “philosophies”

3

8,12

14

Compare total installation

2

8,12

15

Compare cost of support

3

8,12

16

Compare customer satisfaction level

10

8,12

17

Assign philosophies points

1

13

18

Assign installation cost

1

14

19

Assign support cost

1

15

20

Assign customer satisfaction points

1

16

21

Select best system

1

11,17,18,19,20

22

Order system

1

21

20

Haeryip Sihombing The project team has requested that you create a network for the project, and

determine if the project can be completed in 45 weeks.

The project can complete within 45 weeks. This is because the project can complete

in 44 weeks according to the network below

Problem Statement 12

Boiling Electronics manufactures DVD players for commercial use. W. Blaker

Boiling, president of Boiling Electronics, is contemplating producing DVD players

for home use. The activity necessary to built an experimental model and related data

given in the following table:

Activity Normal Time

(weeks)

A

3

Crash Time

(weeks)

2

Normal Cost

($)

1,000

Crash Cost

($)

1,600

Immediate

Predecessor (s)

-

B

2

1

2,000

2,700

-

C

1

1

300

300

-

D

7

3

1,300

1,600

A

E

6

3

850

1,000

B

F

2

1

4,000

5,000

C

G

4

2

1,500

2,000

D,E

21

Haeryip Sihombing a) What is the project completion date?

The project completion date is in 14 weeks.

b) Crash this project to 10 weeks at the least cost.

Crash

Time

(weeks)

2

Crash –

Normal

(weeks)

1

Normal

Cost ($)

Crash

Cost ($)

Crash – Normal($)

Time (weeks)

A

Normal

Time

(weeks)

3

1,000

1,600

600

B

2

1

1

2,000

2,700

700

C

1

1

0

300

300

0

D

7

3

4

1,300

1,600

75

E

6

3

3

850

1,000

50

F

2

1

1

4,000

5,000

1000

G

4

2

2

1,500

2,000

250

Activity

10,950

So, the project completion date is 10

weeks. The cost as below:

4 X D = 4 X 75 = $300

2 X E = 2 X 50 = $100

TOTAL = $300 + $100 + $10950 =

$11350

22

Haeryip Sihombing c) Crash this project to 7 weeks (which is the maximum it can be crash) at

the least cost.

So, the project completion date is 7

weeks. The cost as below:

7 X D = 7 X 75 = $525

5 X E = 5 X 50 = $250

TOTAL = $525 + $250 + $10950 =

$11725

Problem Statement 13

A firm with four departments has the following closeness matrix and the current

block plan shown in Figure below

1

2

3

A

B

4

5

6

C

D

Conway Consulting’s Block

Plan

Department

A

B

C

D

Current Block Plan

Closeness Matrix

Trips Between Departments

A

B

C

12

10

20

-

D

8

6

0

-

a) What is the weighted-distance score for the current layout (assuming

rectilinear distance)?

The weighted-distance score for the current layout is

84.

Department Pair

Number of trips

Distance

A, B

A, C

A, D

12

10

8

1

1

2

23

Current weighteddistance score

12

10

16

Haeryip Sihombing B, C

B, D

C, D

20

6

0

2

1

1

Total:

40

6

0

84

b) Develop a better layout. What is its weighted-distance score? After proposed

a better layout, the total weighted-distance score is 72.

Department

Pair

A, B

A, C

A, D

B, C

B, D

C, D

B

C

A

D

Number of

trips

12

10

8

20

6

0

Distance

1

2

1

1

2

1

Total:

proposed weighted-distance

score

12

20

8

20

12

0

72

Problem Statement 14

A small renovation of a Hard Rock Café gift shop has six activities (in hours). For

the following estimates of a, m, and b, calculates the expected time and the standard

deviation for each activity:

Activity

A

B

C

D

E

F

a

11

27

18

8

17

16

m

15

31

18

13

18

19

b

19

41

18

19

20

22

Weighted average activity time, te =

Where

a = optimistic activity time (1 chance in 100 of completing the activity earlier under

normal conditions)

b = pessimistic activity time (1 chance in 100 of completing the activity later under

normal conditions)

m = most likely activity time

24

Haeryip Sihombing Standard deviation for the activity,

Activity

A

B

C

D

E

F

a

11

27

18

8

17

16

m

15

31

18

13

18

19

b

19

41

18

19

20

22

te

15

32

18

13.17

18.17

19

1.33

2.33

0

1.83

0.50

1.00

Problem Statement 15

Rezin Enterprises, a machine shop, is planning to move to a new, larger location.

The new building will be 60 feet long by 40 feet wide. Rezin envisions the building

as having six distinct production areas, roughly equal in size. He feels strongly about

safety and intends to have marked pathways throughout the building to facilitate the

movement of people and materials. See the following building schematic.

1

2

3

4

5

6

His foreman has completed a month-long study of the number of loads of material

that have moved from one process to another in the current building. This

information is contained in the following matrix.

To

Materials

(M)

Welding

(W)

Drills

(D)

Lathes

(L)

Materials (M)

0

100

50

0

0

50

Welding (W)

25

0

0

50

0

0

Drills (D)

25

0

0

0

50

0

Lathes (L)

0

25

0

0

20

0

Grinders (G)

50

0

100

0

0

0

Benders (B)

10

0

20

0

0

0

From

Grinders Benders

(G)

(B)

Finally, Rezin has developed the following matrix to indicate distances between the

work areas shown in the building schematic.

25

Haeryip Sihombing 1

2

3

4

5

6

1

-

Distance between Work Areas

2

3

4

5

20

40

20

40

20

40

20

60

40

20

6

60

40

20

40

20

What is the appropriate layout of the new building?

Current building schematic (Current Layout):

M

W

D

L

G

B

Proposed Layout

wd Score

wd Score

Distance (2)

Distance (3)

(1) x (2)

(1) x (3)

20

2000

20

2000

40

2000

20

1000

60

3000

40

2000

20

500

20

500

40

2000

40

2000

40

1000

20

500

40

2000

20

1000

40

1000

40

1000

20

400

20

400

40

2000

40

2000

40

4000

20

2000

60

600

40

400

20

400

20

400

wd = 20900

wd

Current Layout

Department

Pair

M,W

M,D

M,B

W,M

W,L

D,M

D,G

L,W

L,G

G,M

G,D

B,M

B,D

Number of

Trips (1)

100

50

50

25

50

25

50

25

20

50

100

10

20

= 15200

New building schematic (Proposed Layout):

M

D

B

W

G

L

26

Haeryip Sihombing Problem Statement 16

Barbara Gordon, the project manager for Web Ventures, Inc., compiled a table

showing time estimates for each of the company’s manufacturing activities of a

project, including optimistic, most likely, and pessimistic.

a. Calculate the expected time, te, for each activity.

b. Calculate the variance, σ², for each activity.

Activity

A

B

C

D

E

Optimistic

(a)

3

12

2

4

1

Most

Likely (m)

8

15

6

9

4

Pessimistic

(b)

19

18

16

20

7

9

15

7

10

4

7.11

1

5.44

7.11

1

Problem Statement 17

You are the manager of a project to improve a billing process at your firm. Table

below contains the data you will need to conduct a cost analysis of the project.

Indirect costs are $1,600 per week, and penalty costs are $1,200 per week after week

12,

a. What is the minimum-cost schedule for this project?

b. What is the difference in total project costs between the earliest completion

time of the project using “normal” times and the minimum-cost schedule

you derived in part (a)?

Immediate

Normal Crash Normal

Crash

Activity predecessor(s)

time

time

cost

cost

A

4

1

5,000

8,000

B

-

5

3

8,000

10,000

C

A

1

1

4,000

4,000

D

B

6

3

6,000

12,000

E

B, C

7

6

4,000

7,000

F

D

7

6

4,000

7,000

a.

B

A

D

C

F

E

B + D + F = (8,000+10,000) + (6,000+12,000) + (4,000+7,000) = 47,000

A + C + E = (5,000+8,000) + (4,000+4,000) + (4,000+7,000) = 32,000

27

Haeryip Sihombing B + E = (8,000+10,000) + (4,000+7,000) = 29,000

So, from the calculation above, the minimum-cost schedule for this project is for B +

E that is only 29,000.

b. The total project costs between the earliest completion time of the project using

“normal” times is the total cost of Normal cost only without adding the Crash cost.

So, the total cost of Normal Cost for this project is 31,000. While for the minimumcost schedule for this project is the Normal Cost adding with the Crash Cost. But

after we have calculated all, we have to only take the minimum value only. The total

minimum-cost schedule for this project is 29,000.

Problem Statement 18

After an extensive product analysis using group technology, Bob Buerlein has

identified a product he believes should be pulled out of his process facility and

handled in a work cell. Bob has identified the following operations as necessary for

the work cell. The customer expects delivery of 250 units per day, and the work day

is 420 minutes.

a. What is the Takt Time?

b. How many employees should be cross-trained for the cell?

c. Which operations may warrant special consideration?

Operation

Shear

Bend

Weld

Clean

Paint

Standard Time (min)

1.1

1.1

1.7

3.1

1.0

a. 250 units per day

420 minutes

= 0.5952 unit per minute

The takt time is 0.5952 unit per minute

b. 2 employees should be cross-trained for the cell that is for Shear and Bend

operation. This is because the operations are quite same and the standard time

also same for both of the operations that is 1.1 min.

c. The operation that may warrant special consideration is Clean operation. This

due to the standard time that is larger than the others operation. The standard

time is 3.1 min while others are only 1.0, 1.1, and 1.7. So, it means that this

operation are harder than the others operation.

28

Haeryip Sihombing Problem Statement 19

Development of a new deluxe version of a particular software product is being

considered by Ravi Bedara’s software house. The activities necessary for the

completion of this project are listed in the following table:

Maximum

Crash

Direct cost

Normal

Time

(weeks)

Cost

4

$2,000

Crash

Time

(weeks)

3

Cost

$2,600

2200

1

2800

3

500

3

500

4

8

2300

4

2600

100

3

6

900

3

1200

F

1200

1

3

3000

2

4200

G

300

2

4

1400

2

2000

Activity

A

Slope

600

Time

1

B

600

1

2

C

0

0

D

75

E

a) What is the project completion date?

=

Duration

of

A+D+G

=4+8+

4 weeks

= 16

weeks

In normal cost

b) What is the total cost required for completing this project on normal time?

= Cost A + B + C + D + E + F + G

= $ 2,000 + 2,200 + 500 + 2,300 + 900 + 3,000 + 1,400 = $ 12,300

c) If you wish to reduce the time required completing this project by 1 week,

which activity should be crashed, and how much will this increase the total

cost?

29

Haeryip Sihombing Activity C is the lowest cost, activity c is being chosen.

Increase the total cost: $12,300 - $75 = $12,225

Activity C should be crashed and $12,225 will increase the total cost.

d) What is the maximum time that can be crashed? How much would costs

increase?

In crash cost

Maximum time can be crashed:

= project completion date – ( Crash time of A + D + G )

= 16 weeks – ( 3 + 4 + 2 weeks) = 7 weeks

Costs increase:

= (slope * maximum crash time) of D + A + G

= (4*75) + ( 1*600) + (2*300) = $1500

The maximum time can be crashed in 7 weeks by increase $1,500.

Problem Statement 20

The associate administrator at Getwell Hospital wants to evaluate the layout of the

outpatient clinic. Table below shows the interdepartmental flows (patients/day)

between departments; Figure below shows the current layout.

Table: Closeness Matrix

Trips between Departments

Department

1. Reception

2. Business Office

3. Examining room

1

2

3

4

5

6

-

25

35

5

10

15

-

5

10

15

-

20

30

30

7

8

20

15

20

10

Haeryip Sihombing 4. X-ray

-

5. Laboratory

25

15

25

-

20

25

6. Surgery

-

40

7. Postsurgery

15

8. Doctor’s office

-

4

6

5

7

2

8

3

1

Figure Current Layout

a) Determine the effectiveness of the current layout, as measured by the total

wd score, using rectilinear distances. = 790

Department

pair

1,2

1,3

1,4

1,5

1,6

1,8

2,3

2,4

2,5

2,8

3,4

3,5

3,6

3,8

4,5

4,6

4,7

5,6

5,8

6,7

7,8

Number of

tips (1)

25

35

5

10

15

20

5

10

15

15

20

30

20

10

25

15

25

20

25

40

15

Current layout

Proposed layout

Distance Wd score

(2)

(1) * (2)

3

75

1

35

4

20

2

20

3

45

2

40

2

10

1

10

3

45

1

15

3

60

1

30

2

40

1

10

2

50

1

15

3

45

1

20

2

50

2

80

3

45

Current layout, wd =

790

Distance

Wd score

(3)

(1) * (3)

3

75

1

35

4

20

3

30

2

30

2

40

2

10

1

10

2

30

1

15

3

60

2

60

1

20

1

10

1

25

2

30

3

75

1

20

1

25

1

40

3

45

Proposed layout, wd =

705

4

5

6

7

2

8

3

1

Proposed Layout

Current layout, total wd score is 790.

31

Haeryip Sihombing b) Try to find the best possible layout based on the same effectiveness measure.

4

5

6

7

2

8

3

1

Proposed Layout

Proposed layout, total wd score is 705.

c) What is the impact on your new solution if it must be revised to keep

department 1 at its present location?

There is no impact on the new solution for the proposed layout, the total wd

still remain same which is 705.

d) How should the layout developed in part (c) be revised if the

interdepartmental flow between the examining room and the X-ray

department is increased by 50 percent? Decreased by 50 percent?

The proposed layout did not change the location of examining room and Xray department, so will not affect the new proposed layout. For the increased

by 50% of the interdepartmental flow between the examining room and the

X-ray department, the total wd is 735 which is increase 30

from the

previous proposed layout. For the decrease 50%, the total wd is 675 which is

decrease 30 from the previous proposed layout.

Problem Statement 21

From the following information, draw the project network. Compute the early, late,

and slack times for each activity. Identify the critical path. (Hint: Draw the finish-tostart relationship first.)

5

10

15

5

Finish-to-start

Predecessor

NONE

A

A

B

Finish-to-Start

Lag

0

0

0

5

20

15

10

20

B

D

C

F

0

0

10

0

ID

Duration

A

B

C

D

E

F

G

H

32

Additional lag

Lag

Relationship

None

0

None

0

Start-finish C to D

20

Start-start D to E

5

Finish-finish D to E

Finish-finish E to F 25

None

0

Finish-finish G to F 0

None

10

Haeryip Sihombing Problem Statement 22

The Maser is a new custom-designed sports car. An analysis of the task of building

the Maser reveals the following list of relevant activities, their immediate

predecessors, and their duration:

Job

Description

Letter

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

Immediate

predecessor(s)

Start

design

order special accessories

Build frame

Build doors

Attach axles, wheels gas tank

Build body shell

Build transmission and drive train

Fit door to body shell

Build engine

Bench-test engine

Assemble chassis

Road-test Chassis

Paint body

Install wiring

Install interior

Accept delivery of special accessories

Mount body and accessories on chassis

Road test car

Attach exterior trim

Finish

Normal

time (days)

A

B

B

B

D

B

B

G,E

B

J

F,H,K

L

I

N

N

C

M,O,P,Q

R

S

T

a) Draw a network diagram for the project.

b) Mark the critical path and state its length.

c) If the Maser had to be completed 2 days earlier, would it help to:

i) Buy preassembled transmissions and drive train?

ii)Install robots to halve engine-building time?

iii)Speed delivery of special accessories by 3 days

d) How might resources be borrowed from activities on the non-critical

path to speed activities on the critical pa

33

0

8

0.1

1

1

1

2

3

1

4

2

1

0.5

2

1

1.5

5

1

0.5

1

0

Lag exercise 18 (QUESTION 39):

Lag 5

Lag 20 Lag 5 Lag 25 Lag 10 Lag 10 The critical paths of the network are shown by dashed-lines in the diagram, or

as below:

i.

ii.

iii.

A, C, G, F, and H.

A, C, D, E, F, and H

A, B, D, E, F, and H

b) Critical path is marked as black arrow along the flow of the process, as shown at

the network diagram above. Total length of critical path (A, B, J, K, L, M, R, S,

T, and U) is 18 weeks without slack time.

c) I) No. Since the process H (build transmission and drive train) is not a process

within the critical path, hence it wouldn’t help to complete the project 2 days

earlier with preassembled transmission and drive train.

II) No. It is not helpful to install robots to halved engine-building time. This is

because of other process path would prevent the project to be finished 2 weeks

earlier. The installation of robot would only make the complete time of project

earlier by 1 week.

III) No. Process Q is not within the critical path. Even the special accessories

are accepted 3 days earlier, the project complete time is still restricted by the

process time of critical path as stated above.

d) In order to speed up the activities on the critical path, some recourses from the

non-critical path, especially those activities with many slack time, can be

borrowed to facilitate the activities on the critical path. The activities with many

slack time here might be process d, f, and h, can be holden for awhile and the

resources used such as the assembly material, tools and manpower can be

borrowed to perform the activities on the critical path. As long as the time of the

resources stated are not borrowed to critical path more than the slack time as

indicated in the box of network diagram above, the activities on the critical path,

and hence the whole system, will be speeded up.

Haeryip Sihombing Problem Statement 23

Summit Arora is developing a program in leadership training for middle-level managers.

Sumit has listed a number of activities that must be completed before a training program of

this nature could be conducted. The activities, immediate predecessors and times appear in

the accompanying table:

Activity

A

B

C

D

E

F

G

Immediate

Predecessor(s)

B

A,D

C

E,F

Time (days)

2

5

1

10

3

6

8

a) AON network:

E

A

(3)

(2)

START

0

B

D

G

(5)

(10)

(8)

C

F

(1)

(6)

2

13

A

13

2

0

0

B

0

5

0

11

C

11

1

15

18

0

E

15

15

3

5

5

15

0

D

5

5

6

1

1

12

18

15

7

11

F

12

6

18

b) Critical Path: B,D,E,G

37

18

26

0

G

18

8

26

END

Haeryip Sihombing c) Total project completion time= 5+10+3+8 = 26 days

d) Slack time for activity A = 15-2 = 13 days

B,D,E,G = No Slack Time = 0

C&F

= 18-7 = 11 days

Problem Statement 24

Suppose production requirements in solved Problem 9.2 increase and require a reduction in

cycle time from 8 minutes to 7 minutes. Balance the line once again, using the new cycle

time. Note that it is not possible to combine task times so as to group task into the minimum

number of workstation. This condition occurs in the actual balancing problems fairly often.

Task

A

B

C

D

E

F

G

H

Performance

Time (mins)

5

3

4

3

6

1

4

2

28

Task Must Follow This

Task

A

B

B

C

C

D,E,F

G

New line balancing

4

6

C

E

4

2

G

H

5

3

1

A

B

F

WS5

3

WS1

WS2

D

WS4

WS3

The theoretical minimum number of workstation (WS) is:

=

= 4 workstation.

By theory minimum number of 4 workstations can be group together but after trial and error

for the new line balancing to group into necessary workstation for 7 minutes cycle time, it is

proven that 4 workstation can’t be achieve as theory indicated but instead it only can be

group into 5 workstations.

38

Haeryip Sihombing Problem Statement 25

Chunmum Furniture Inc., produces all types of office furniture. The “Executive Secretary” is

a chair that has been designed using ergonomics to provide comfort during long work hours.

The chair sells for $130. There are 480 minutes available during the day and the average

daily demand has been 50 chairs. There are 8 tasks:Task

Performance

Time (minutes)

Task Must Follow Task

Listed Below

A

B

C

D

E

F

G

H

4

7

6

5

6

7

8

6

A, B

C

D

E

E

F, G

a. Draw a precedence diagram of this operation

A

C

D

E

F

H

B

G

b. What is the cycle time for this operation?

Cycle time,

The desired output rate is 50 Chairs 480 minutes per day.

C = 1/r

C= 480/50

= 9.6 minutes/units

c. What is the theoretical minimum number of work station?

Theoretical minimum ( TM )

TM = ∑ t / C

TM = 49 / 9.6

= 5.1 @ 5 stations.

d. Assign tasks to work stations

39

Haeryip Sihombing How much total idle time is present each day?

Idle time = nc - ∑t

= 8(9.6) – 49 = 27.8 seconds

Percentage of idle time = idle time per cycle X 100

Nactual X Cycle Time

= 27.8 X 100

8X9.6

= 36.2 %

f. What is the overall efficiency of the assembly line?

Efficiency

= 100 % - 36.2 % = 63.8 %

Problem Statement 26

The diagram in Figure below was developed for a project that you are managing. Suppose

that you are interested in finding ways to speed up the project at minimal additional cost.

Determine the schedule for the completing the project in 25 days at minimum cost. Penalty

and project overhead costs are negligible. Time and cost data for each activity are shown in

Table below.

Activity

A

B

C

D

E

F

G

H

I

Normal

Time (days)

12

13

18

9

12

8

8

2

4

Crash

Cost ($)

1, 300

1, 050

3, 000

2, 000

650

700

1, 550

600

2, 200

Time (days)

11

9

16

5

10

7

6

1

2

40

Cost ($)

1, 900

1, 500

4, 500

3, 000

1, 100

1, 050

1, 950

800

4, 000

Haeryip Sihombing D

Start

A

E

B

F

G

C

Activity

A

B

C

D

E

F

G

H

I

Slope

600

112.5

750

250

225

350

200

200

450

I

Maximum

Crash

Time

1

4

2

4

2

1

2

1

2

Day 25

Initial total direct cost $13050

A

12

Start

Finish

H

Direct Cost

Normal

Time

Cost

12

1,300

13

1,050

18

3,000

9

2,000

12

650

8

700

8

1,550

2

600

4

2,200

Crash

Time

11

9

16

5

10

7

6

1

2

Cost

1,900

1,500

4,500

3,000

1,100

1,050

1,950

800

4,000

D

AC

9

DU

E

G

12

8

B

F

H

13

8

2

C

I

18

4

41

Finish

Haeryip Sihombing Day 24

Initial total direct cost $13800

Activity Change

C

D

750

9

A

12

Start

E

G

12

8

B

F

H

13

8

2

C

I

17

4

Finish

Day 23

Initial total direct cost $12450

Activity Change

D

I

9

450

A

12

Start

Project duration

25

24

23

E

G

12

8

B

F

H

13

8

2

C

I

17

4

Direct Cost +

13050

13800

14250

42

Indirect Cost

10050

7050

4050

=

Total Cost

23,100

20,850

18,300

Finis

Haeryip Sihombing The project will actually materialize as planned any movement away from this tie option

duration will increase projects cost. The optimum cost-time duration is 24 time units and

$20,850. The movement from 25 time units occurs, in this range the absolute slopes of the

indirect costs are greater than the direct cost slopes.

Problem Statement 27

The following is a table of activities associated with a project at Bill Figg Enterprise, their

durations and what activities each must precede:

Activity

A (start)

B

C

E

F (end)

Duration (weeks)

1

1

4

2

2

Precedes

B, C

E

F

F

-

a) Draw an AON diagram of the project, including activity durations

1

0

0

A

0

1

2

2

1

B

1

2

1

1

1

0

C

1

4

4

1

E

3

3

2

5

5

5

5

7

0

F

5

2

7

b) Define the critical path, listing all critical activities in chronological order

Critical path are A, C, F

c) What is the project duration (in weeks)?

Project duration (in week) is 7 weeks

d) What is the slack (in weeks) associated with any and all noncritical paths through

the project?

Activity

Early start

A

B

C

E

F

0

1

1

2

5

Early

finish

1

2

5

4

7

Late start

Late finish

Slack

0

2

1

3

5

1

3

5

5

7

0

1

0

1

0

The slack (in weeks) happen for activity B and E.

43

Haeryip Sihombing Problem Statement 28

Use trial and error to balance the assembly line described in the following table and Figure

8.19 so that it will produce 40 units per hour.

a.

b.

c.

d.

What is the cycle time?

What is the theoretical minimum number of workstations?

Which work elements are assigned to each workstation?

What are the resulting efficiency and balance delay percentages?

Work

element

A

B

C

D

E

F

G

H

I

J

K

Time (sec)

40

80

30

25

20

15

60

45

10

75

15

Total

Immediate Predecessor

(s)

None

A

A

B

C

B

B

D

E,G

F

H, I, J

415

D

25

B

F

80

15

H

45

A

G

40

J

60

75

E

I

20

10

C

30

a. Cycle time = available

output rate

= 60 x 60 = 90

40

b. Theoretical minimum number of workstations

= 415 = 4.611 @ 5 = 5 stations

90

44

K

15

Haeryip Sihombing D

25

B

F

45

H

15

80

A

G

40

J

60

K

75

15

C

30

E

I

20

10

c. Workstation 1: A, C, E

Workstation 2: B

Workstation 3: F, J

Workstation 4: D, H

Workstation 5: G, I, K

d. Efficiency = ratio of productive time to total time

= 415 / 5 (90) x 100

= 92.2 %

Balance Delay = amount by which efficiency falls short of 100%

= 100% – 92.2 % = 7.8 %

Problem Statement 29

McGee Carpet and Trim installs carpet in commercial offices. Andrea McGee has been very

concerned with the amount of time it took to complete several recent jobs. Some of her

workers are very unreliable. A list of activities and their optimistic completion time, the most

likely completion time, and their pessimistic completion time (all in days) for a new contract

are given in the following table:

Activity

A

B

C

D

Time (days)

a

3

2

1

6

m

6

4

2

7

45

b

8

4

3

8

Immediate

predecessor (s)

C

Haeryip Sihombing E

F

G

H

I

J

K

a)

b)

c)

d)

2

6

1

3

10

14

2

4

10

2

6

11

16

8

6

14

4

9

12

20

10

B,D

A,E

A,E

F

G

C

H,I

Determine the expected completion time and variance for each activity

Determine the total project completion time and the critical path for the project

Determine ES, EF, LS, LF and slack for each activity

What is the probability that McGee carpet and Trim will finish the project in 40

days or less?

a)

Activity

A

B

C

D

E

F

G

H

I

J

K

Time (days)

a

m

b

Immediate

predecessor (s)

3

2

1

6

2

6

1

3

10

14

2

6

4

2

7

4

10

2

6

11

16

8

8

4

3

8

6

14

4

9

12

20

10

C

B,D

A,E

A,E

F

G

C

H,I

te =

a + 4m + b

6

5.833

3.667

2.000

7.000

4.000

10.000

2.167

6.000

11.000

16.333

7.333

variance

{(b − a ) / 6}2

b) Total completion time

= 5.883 + 3.667 + 2 + 7 + 4 + 10 + 2.167 + 6 + 11 + 16.333 + 7.333 = 75.333

= 75 day

c) Critical path of the project

= C, D, E, F, H, K = 2 + 7 + 4 + 10+6+7.33 = 36.33 ≈ 37 day

∑σ Te = √ (0.111 + 0.111 + 0.444 + 1.778 + 1.000 + 1.778) = √ 5.222 = 2.28517

Activity

A

B

C

D

E

F

G

H

I

ES

0

0

0

2

9

13

13

23

15

EF

6

4

2

9

13

23

15

29

36

LS

-9

-5

-10

-8

-1

3

6

13

8

46

LF

3

4

-8

-1

3

13

2

19

19

Slack

9

5

10

10

10

10

7

10

7

0.694

0.111

0.111

0.111

0.444

1.778

0.250

1.000

0.111

1.000

1.778

Haeryip Sihombing J

K

0

6

9

A

-9

6

0

5

B

-5

4

9

18

10

2

29

13

G

3

6

2

4

13

10

F

3

10

-1

2

19

15

7

13

18

37

2

15

I

8

8

11

23

23

13

10

D

d)

-1 Probability

4 3

-8

7

-1

0

10

26

7

9

E

18

37

19

29

10

H

13

6

0

10

C

-10

2

29

37

10

K

19

19

8

2

2

-8

37

18

0

J

2

16

18

Ts = 40 day

Te = 37 day

Z = (40 – 37)/ 2.28517 = 1.312813

0.90538

[by using CASIO fx 570 : mode-mode-1-shift-3-1-1.312813]

Problem Statement 30

The department of engineering at a university in New Jersey must assign six faculty members

to their new offices. The closeness matrix shown indicates the expected number of contact

per day between professors. The available office spaces (1-6) for the six faculty members are

show in figure 8.18. Assume equal-sized offices. The distance between office 1 and 2 (and

between offices 1 and 3) is 1 unit.

Professor

A

B

C

D

E

F

Closeness matrix

Contact between professor

A

B

C

D

4

12

2

-

E

F

10

7

4

-

a) Because of their academic positions, professor A must be assigned to office 1, professor C

must be assigned to office 2 and professor D must be assigned to office 6. Which faculty

47

Haeryip Sihombing members should be assigned to office 3, 4 and 5 respectively to minimize the total weighted

distance score (assuming rectilinear distance)?

1

2

3

4

5

6

b) What is the weighted distance score of your solution?

Professor

pair

AC

BD

BF

CD

CE

DF

Current plan

Number Distance

of trip (1)

(2)

4

1

12

1

10

2

2

1

7

1

4

1

A

B

C

D

E

F

wd score

(1) X (2)

4

12

20

2

7

4

Total wd = 49

Current layout

a) To minimize the total weighted distance score, I was choosing to arrange the position of

the professor. That is professor F must be assigned to office 3, professor E must be assigned

to office 4 and professor B must be assigned to office 5.

A

C

F

E

B

D

New layout

Professor

pair

AC

BD

BF

CD

Solution plan

Number of

Distance

trip (1)

(2)

4

1

12

1

10

1

2

2

48

wd score

(1) X (2)

4

12

10

4

Haeryip Sihombing CE

DF

7

4

1

2

7

8

Total wd = 45

b) The solution of the layout shows that the weighted distance score are 45. The old layouts

of the weighted distance score are 49. The differences of the weighted distance score are 4.

That is show that the new layouts are more effective and less weighted distance score.

Problem Statement 31

A. Mach 10 is a none-person sailboat designed to be used in the ocean. Manufactured by

Creative Leisure, Mach 10 can handle 40-mph winds and seas over 10 feet. The final

assembly plant is in Cupertino, California. At this time, 200 minutes are available each day to

manufacture Mach 10. The daily demand is 60 boats. Given the following information:i) Draw precedence diagram and assign task to the fewest workstations possible

ii) What is the efficiency of the assembly line?

iii) What is the theoretical minimum number of workstation?

iv) What is the idle time?

Task

A

B

C

D

E

F

G

H

I

Performance

time (min)

1

1

2

1

3

1

1

2

1

Task must follow

task listed below

A

A

C

C

C

D, E, F

B

G, H

i)

A

B

H

C

D

E

F

iii)

Desired output rate, r = 60 units /day

49

I

G

Haeryip Sihombing Time available = 200 minutes/day

r = 60 units/200 minutes

= 0.3 units/minute

Cycle time, C = 1/r = 1/0.3 = 3.33 minutes/unit

TM

iv)

ii)

= ∑t / C

= 13 / 3.33

= 3.9 ≈ 4 stations

Idle time

= nc - ∑t

= 4 (3.33) – 13

= 0.32 minutes

Percentage idle time = ((idle time / (TM x C)) x100

= ((0.32 / (4x3.33)) x100

= 2.40 %

Efficiency

= 100% - percentage idle time

= 100% - 2.40 %

= 97.6%

Problem Statement 32

A. Because of the expected high demand for Mach 10, Creative Leisure has decided to

increase manufacturing time available to produce the Mach 10:i) If demand remained the same and 300 minutes were available each day, how

many work stations would be needed?

ii) What would be the efficiency of the new system?

iii) What would be the impact or the system if 400 minutes were available?

i) Desired output rate, r = 60 units /day

Time available = 300 minutes/day

r = 60 units/300 minutes

= 0.2 units/minute

Cycle time, C = 1/r

= 1/0.2 = 5 minutes/unit

TM

= ∑t / C

= 13 / 5 = 2.6 ≈ 3 stations

ii)

Idle time

= nc - ∑t

= 3 (5) – 13 = 2 minutes

Percentage idle time = ((idle time / (TM x C)) x100

= ((2 / (3x5)) x100 = 13.33 %

Efficiency

= 100% - percentage idle time

= 100% - 13.33 % = 86.67%

iii) Desired output rate, r = 60 units /day

Time available = 400 minutes/day

r = 60 units/400 minutes

= 0.15 units/minute

50

Haeryip Sihombing Cycle time, C = 1/r

= 1/0.15 = 6.67 minutes/unit

TM

Idle time

= ∑t / C

= 13 / 6.67 = 1.95 ≈ 2 stations

= nc - ∑t

= 2 (6.67) – 13 = 0.34 minutes

Percentage idle time = ((idle time / (TM x C)) x100

= ((0.34 / (2x6.67)) x100 = 2.55 %

Efficiency

= 100% - percentage idle time

= 100% - 2.55 % = 97.45%

B. Draw the activity on node (AON) project network associated with the following activities

for Dave Carhart’s Consulting Company project. How long should it take Dave and his team

to complete this project? What are the critical path activities?

Activity

A

B

C

D

E

F

G

H

0

3

0

A

0

3

3

3

Immediate

Predecessor

A

A

B

B

C

D

E, F

7

0

B

3

4

3

0

C

3

6

Time

(days)

3

4

6

6

4

4

6

8

7

13

0

D

7

7

6

9

7

9

11

2

E

9

4

9

Critical Path = A-B-E-H

21 Days.

51

13

13

13

0

F

9

4

13

13

19

0

G

13

6

13

19

21

0

H

13

8

21

Haeryip Sihombing Problem Statement 33

Xinshang Electronics wants to establish an assembly line for producing a new product, the

Personal Little Assistant (PLA). The tasks, task times, and immediate predecessors for the

tasks are as follows:

Task

Time

(sec)

12

15

8

5

20

A

B

C

D

E

Immediate

Predecessors

A

A

B, C

D

Xinshang’s goal is to produce 180 PLAs per hour.

a) What is the cycle time

Given r = desired output rate = 180 / hour

1 hour = 180 unit

c = 1 / r = (1 / 180)*3600sec =20 sec/unit

b) What is the theoretical minimum for the number of workstations that Xinshang can

achieve in this assembly line?

TM = ∑ of all work element

Cycle time

= 12+15+8+5+20

60 sec

=

20 sec/unit

=

= 3 workstation

20 sec/unit

15

B

12

5

20

A

D

E

C

8

c) Can the theoretical minimum actually be reached when workstations are assigned?

Yes, the theoretical minimum actually can be reached when workstations are assigned.

Problem Statement 34

Jason Ritz, district manager for Gumfull Food Inc., is in charge of opening a new fast-food

outlet in the college town of Clarity. His major concern is the hiring of a manager and a cadre

52

Haeryip Sihombing of hamburger cooks, assemblers, and dispensers. He also has to coordinate the renovation of

a building that was previously owned by a pet supplies retailer. He has gathered the data

shown in Table 3.8.

Activity

Description

A

B

C

Interview at college for new manager

Renovate building

Place ad for employees and interview

applicants

Have new manager prospects visit

Purchase equipment for new outlet and

install

Check employee applicant references and

make final selection

Check reference for new manager and

make final selection

Hold orientation meetings and do payroll

paperwork

D

E

F

G

H

Immediate

Predecessor(s)

-

Time (wk)

a

m

b

2

5

7

4

8

9

6

11

17

A

B

1

2

2

4

3

12

C

4

4

4

D

1

1

1

E,F,G

2

2

2

Top management told Ritz that the new outlet is to be opened as soon as possible. Every

week that the project can be shortened will save the firm $1,200 in lease costs. Ritz thought

about how to save during the project and came up with two possibilities. One was to employ

Artic, Inc., a local employment agency to locate some good prospects for the manager’s job.

This approach would save three weeks in activity A and cost Gumfull foods $2,500. The

other was to add a few workers to shorten the time for activity B by two weeks at an

additional cost of $2,700. Help Jason Ritz by answering the following questions.

a) How long is the project expected to take?

Activity times and variances table

Activity

A

B

C

D

E

F

G

H

a

2

5

7

1

2

4

1

2

m

4

8

9

2

4

4

1

2

b

6

11

17

3

12

4

1

2

53

te

4

8

10

2

5

4

1

2

[{b-a}/6]2

0.44

1

2.78

0.11

2.78

0

0

0

Haeryip Sihombing 0

4

4

7

A

7

4

0

1

B

1

8

0

0

C

0

10

6

7

D

11

11

2

8

8

13

1

E

9

9

4

10

10

10

13

14

6

7

0

G

13

1

14

14

16

0

H

14

2

16

14

0

F

10

4

14

Critical path is= C + F + H = 10 + 4 + 2 = 16week