MFG 316 Chapter 5 //Jig Design

advertisement

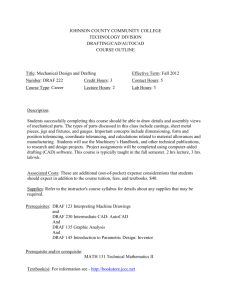

MFG 316 Chapter 5 //Jig Design A Jig is a workholder designed to locate, hold, and support a workpiece while guiding the cutting tool throughout its cutting cycle. Types of Jigs ⌧Drill Jigs-most common used for drilling, tapping, reaming… ⌧Boring Jigs-used for boring holes to a precise size, bushing used on both ends General Considerations Cost of tool vs. benefit; should save more than cost ⌧complexity, location, number of holes, accuracy, number of parts to be made all must be considered MFG 316 Chapter 5 //Jig Design Process Considerations Type of jig, number needed, processing steps First-operation jigs ⌧Used to put first holes into rough part to act as locators for subsequent operations. Adjustable locators and/or supports are generally used MFG 316 Chapter 5 //Jig Design Developing the preliminary jig design Product analysis considerations Operation considerations Machine considerations Operator considerations Production considerations Economic evaluation MFG 316 Chapter 5 //Jig Design Machine Considerations Process usually dictates the machine used, but general requirements stay the same regardless of machine size Machine requirements ⌧Must be large and rigid enough to perform required operation ⌧suitable production capabilities and accuracy ⌧Safely accommodate workholding device ⌧Close to machines used for subsequent operations ⌧Specified cutting tools compatible with machine ⌧Standard size cutting tools used whenever possible Specification sheet for each machine in shop Specification sheets for all standard cutting tools MFG 316 Chapter 5 //Jig Design Other process considerations ⌧Repeatability between jigs ⌧Multiple jigs- same location point used in each of the jigs ⌧Stack or align parts to allow multiple part processes ⌧Consider step drilling large holes ⌧Chip control MFG 316 Chapter 5 //Jig Design Drill Jigs Correctly locate part wrt tool Securely clamp and rigidly support part during operation Guide the tool Position and/or fasten the jig on a machine Open and Closed Advantages Minimize tool breakage Minimize possibility of human error Permit use of less skilled labor Reduce manufacturing time Eliminate retooling for repeat orders 1 MFG 316 Chapter 5 //Jig Design MFG 316 Chapter 5 //Jig Design Template Drill Jigs Advantages Simplest, easiest to build, least expensive Disadvantages Not as foolproof, may not be as accurate, not good when used with RFS MFG 316 Chapter 5 //Jig Design MFG 316 Chapter 5 //Jig Design Universal Jigs Plastic Drill Jig Channel/tumble Jigs MFG 316 Chapter 5 //Jig Design Plate Jigs MFG 316 Chapter 5 //Jig Design Leaf Jigs 2 MFG 316 Chapter 5 //Jig Design MFG 316 Chapter 5 //Jig Design Indexing Jig MFG 316 Chapter 5 //Jig Design Drill Jig Bushings Headless press fit Head press fit Slip renewable, slip-fixed renewable Oil groove bushings Specials (consult vendor) Bushings for plastic & etc. Template Bushings Rotary Bushings Tips and accessories MFG 316 Chapter 5 //Jig Design Chip clearance Modified Vises Collet Fixtures Self centering Vises MFG 316 Chapter 5 //Jig Design Mounting of Bushings Installation of Drill Bushings Hole size and location MFG 316 Chapter 5 //Jig Design Chip control to ensure correct operation ⌧use different length bushings ⌧burr clearance ⌧length 1 to 2 times the cutting tool 3 MFG 316 Chapter 5 Jig Design Bushing must conform to irregular shaped pieces MFG 316 Chapter 5 //Jig Design Add locators and supports ⌧must appear in all views as req’d MFG 316 Chapter 5 //Jig Design Designing a Jig Sketch part ⌧all views required; scale, draw in red MFG 316 Chapter 5 //Jig Design Add clamping devices ⌧show in all views; check for interference Add tool body ⌧check for interference, redundant locators MFG 316 Chapter 5 //Jig Design Add drill bushings ⌧check tolerances (50% of req’d tolerance); check clearances MFG 316 Chapter 5 //Jig Design Check machine clearances ⌧final check 4 MFG 316 Chapter 5 //Jig Design Reaming General jig rules apply Closer tolerances required Provide support for reamer Enter bushing before part Remain piloted throughout Carbide for production runs Boring Jigs General jig rules apply Closer tolerances required Enter bushing before part Support on far end of jig Support on both ends of operation 5